Take Cover! Phase 3: Competition Document

Updated 20 January 2021

1 Introduction

This Defence and Security Accelerator (DASA) competition is seeking proposals for innovative technologies that provide improved methods to protect small groups (1-10 personnel) of dismounted troops in the field.

Within defence and security, protection of personnel is a priority area and deployment of rapid protection solutions for dismounted troops on the front-line is of high importance. This competition seeks to access recent developments in materials science and/or novel design technologies to provide advanced and readily deployable protection solutions for our troops.

In this phase of the competition, DASA is seeking proposals that can be developed into a deployable battlefield solution.

Up to £480k is available to fund at least two proposals in this phase, which must start at Technology Readiness Level (TRL) 5 (or closely approaching), in order to achieve TRL 6 by the end of Phase 3.

Applications for Phase 3 of this competition close on Thursday 11 February 2021 at midday (GMT).

Please note this is the third phase of funding for a multi-phase competition. It is not compulsory to have been involved in the previous phases to apply. You should however make yourself aware of the previous competitions and the bids that were funded to achieve preceding TRLs (Phase 1 and Phase 2).

2 Competition scope

2.1 Background

The current force protection measures at the tactical level, referred to as in-field fortifications, are temporary fortifications for dismounted soldiers that are resource intensive. This competition provides an opportunity to apply modern materials and/or structural design to achieve improved performance of in-field fortifications by developing lightweight, rapidly deployable protection for troops and other small military assets such as ammunition caches.

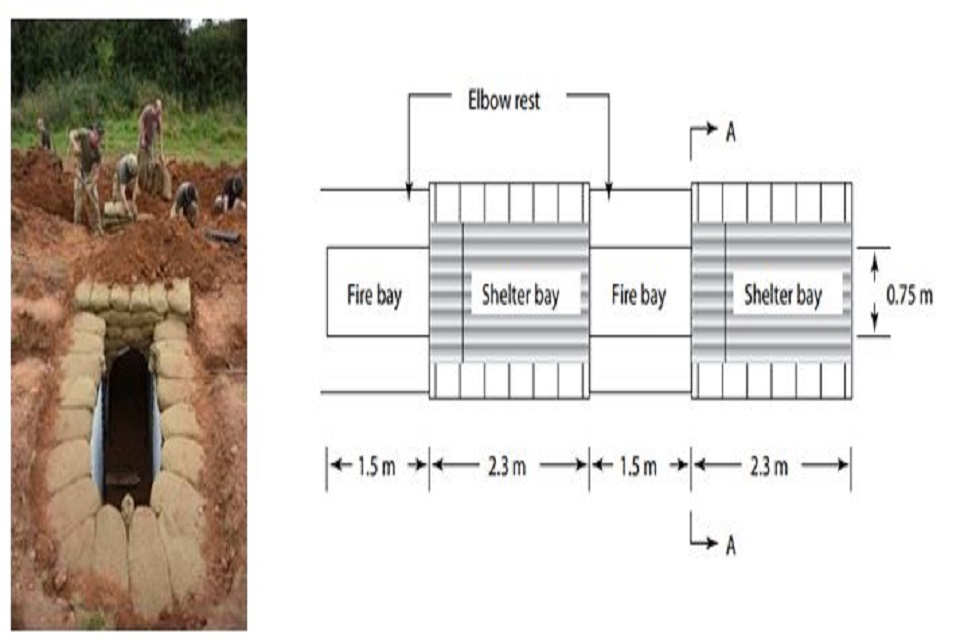

Traditionally, such in-field fortifications have consisted of corrugated iron, concrete bollards and sandbags, as depicted in Figure 1, to provide structural support and overhead protection in the 4-Man Battle Trench. Current dimensions for the 4-Man Battle Trench are 0.75 m wide x 1.5 m deep x 7.75 m long but given the additional equipment soldiers now carry, a 25% increase on width would be beneficial . Pictures and a video demonstrating the battle trench are available at the following link.

Figure 1: A 4-man battle trench

In addition to the 4-Man Battle Trench, another scenario for field fortifications currently includes a hastily deployed, short duration Vehicle Check Point (VCP) where soldiers will likely only have personal protective equipment (PPE), such as body armour and helmets for protection (Figure 2).

Figure 2: A Hastily Deployed VCP

2.2 Scope

This competition focuses on novel materials, designs and deployment technologies for in-field fortifications that are easily stored, transported and rapidly deployed, using in-service ‘prime movers’, such as logistic vehicles and rotary/fixed-wing aircraft. It should be noted that this competition is not looking for PPE, such as is already provided by body armour, helmets, and ballistic resistant body armour and shields.

Deployed fortifications should be able to protect troops from ballistic threats, blast/fragmentation and ground shock, however additional protection against directed energy threats is also of interest. Directed energy can include hand-held anti-tank grenade launchers (more commonly referred to as rocket propelled grenades or RPGs), high-energy lasers or other novel weapons.

Observability (in multiple environments) across the optical, infra-red (IR), ultra-violet (UV) and radio-frequency (RF) spectra will need to be considered, for this competition. Whilst this is not a call for camouflage technologies, innovative camouflage, concealment and deception (CCD) innovations that could form part of an overall solution are welcomed. The solution may also be utilised for discreet protection of cached equipment in addition to protection of troops.

Chemical, biological, radiation and nuclear (CBRN) threats are not the focus of this competition, but it is worth noting that in an operational situation, the solution may be deployed in a CBRN threat environment.

3 Competition challenges

Phase 3 is intended to fund different approaches that address the Battle Trench and VCP challenge areas described in Phase 2 to work towards an integrated solution that can be developed through to a higher maturity level (TRL 6 - technology system demonstration in a relevant environment). As such, the competition challenges for Phase 3 are scenario based as per Phase 2. Collaboration between new and existing suppliers is welcomed, where appropriate, to integrate promising solutions from previous phases. Successful companies from Phase 1 and Phase 2 of this competition can be found on gov.uk pages (Phase 1 funded proposals, Phase 2 funded proposals).

For further information please contact your local DASA Innovation Partner.

The overarching requirement here is for innovative structures that can be easily stored, transported and rapidly deployed by troops in forward operating environments with minimal burden, including the burden of tools required for construction. Examples could include novel self-erecting, inflatable or folding structures. Any solution should be simple to emplace and not require specialist training or high levels of qualifications (for example: can only be deployed by an engineer).

Future modularity, flexibility and scalability of the technology are also important aspects, which should be considered. For example can multiple systems be linked together to protect a larger number of soldiers.

Size and mass of the protective materials is a consideration. Protection measures packaged for transport must be able to fit on a standard NATO pallet(s), which has dimensions 1 m x 1.2 m and a loading limit of 1 tonne. Individual elements, once removed from the NATO pallet should be portable by a single soldier.

Proposals at Phase 3 may address one or more of the following 2 challenges/scenarios.

3.1 Challenge 1: Battle Trench

The protection solution proposed should be designed for 4 to 10 personnel (and their equipment). The proposed shelter should also be designed to allow personnel to operate for a number of days. The number of days will depend upon the nature of the operation. The current solution for this scenario, Figure 1, is labour intensive and is required to be emplaced within 36 hours, but may take longer depending on ground conditions.

In this phase, suppliers need to demonstrate, with evidence of performance, either of the following two protective measures from their proposed solution if not done already:

Above ground protective measures that protect against:

- blast and fragmentation effects of an artillery shell detonating nearby

- ballistic penetration by up to 14,5 mm Armour Piercing Incendiary (API) round fired at point blank range

Below ground protective measures that protect against:

- ground shock produced by an artillery shell detonating nearby, without collapse or deformation large enough to endanger occupants

- retaining walls able to withstand collapse as a result from inclement weather conditions

It would be desirable for the capability to withstand a single vehicle run-over. For the purposes of this call we would be looking at an armoured military vehicle up to Main Battle Tank (MBT) mass. For reference, the mass of a UK Challenger 2 MBT is approximately 75 tonnes. Understanding of lower mass run-over would also be of benefit.

3.2 Challenge 2: Vehicle Check Point (VCP)

VCPs are required at entrances to facilities and area access control. There are currently no systems that have a low logistic burden that will allow the emplacement of a rapid VCP if required. Soldiers in these instances have little to no protection and generally it is only afforded by any vehicles they are in. If a hasty VCP is required they only have PPE for protection. For this scenario we are interested in demonstration of above ground protective measures that protect against:

- blast and fragmentation effects of an fragmenting munition detonating nearby

- ballistic penetration by at least a 7.62 mm ball round fired from a stand off < 30m between weapon and target

Solutions to this challenge should be man portable and easily fit through a standard doorway to facilitate use in urban environments.

3.3 Test requirement

Further details of the standards required for ballistic and blast testing are detailed in Annex A.

Your proposal should contain a costed and credible test plan(s) for intended ballistic and fragmentation testing, if not already demonstrated. Blast testing is addressed in section 3.3.2. Feedback and guidance will be provided to successful bidders regarding their test plans and classification of the effects of weapons on structures.

3.3.1 User trials

It is anticipated that user-trials will be organised during autumn 2021.These trials will be organised centrally by Dstl. Bidders must cost for provision of prototype, attendance at and retrieval of prototype in their proposal, Dstl will cover other costs This will provide an opportunity to test ease of build and use and allow successful proposals to receive feedback from end user communities. Trials will be held at a military establishment with further details supplied at kick off meetings. One structure and deployment instructions should be provided by successful suppliers for this testing. The structure will be returned to the bidder after the trials. It is not intended to damage the structure during these trials but Dstl take no responsibility for any damage that may occur.

End user feedback will be provided to the bidder after the trials. An interim project report of how the bidder intends to follow up on this feedback will be required.

3.3.2 Blast testing

It is intended that blast testing of Phase 3 technologies will be organised by MOD at a commercial facility as Government Furnished Facilities (GFF). Trials will likely be scheduled for around the end of 2021, to allow time for development prior to the testing and an opportunity to address any highlighted issues following the tests. A minimum of three structures from successful suppliers are required for the blast testing. Structures may be damaged and will be returned to the supplier for failure analysis allowing refinement of designs by end of contract.

Bidders must cost for provision of prototype, attendance at and retrieval of prototype in their proposal, Dstl will cover other costs.

End user feedback will be provided to the bidder after the blast trials. A report of how the bidder intends to follow up following the results of the trials will be required.

3.3.3 General

At the end of Phase 3, all structural and deployment aspects of proposed field fortifications should be demonstrated through rigorous testing in representative environments. This should be at full scale as a technology demonstrator prototype. Where proposed field fortifications employ structure placed above ground, ballistic testing should have been performed against representative ballistic and fragment simulating projectiles (FSP).

Vehicle run over should be supported by design calculations but will not be tested.

3.4 Clarification of what we want

Solutions should be re-deployable and should only be considered for single use if costs and use-case enable it.

It is recognised that there may not be a ‘one-size-fits-all’ solution to the challenges and so suites of technologies are viable. Potential for future modularity, flexibility and scalability should also be borne in mind, as well as operation in different environments (for example, mountain, desert, jungle, urban) and climates (for example, temperate, tropical, arid, polar). DEFSTAN 00-35 Environmental Handbook for Defence Material Part 4 Natural Environments may provide useful guidance regarding the effects of climate and weather on materials. It is accessible at this link.

Your proposal should include:

- innovation or a creative approach

- a materials and structures focused approach to the problem (such as making use of a range of material characteristics to provide a holistic protection solution)

- clear demonstration of how the proposed work builds on Phases 1 and 2, existing published or open knowledge

- clarity on how the proposed solution offers an improvement on existing technologies

- a clear understanding of the pathway to future commercialisation/exploitation

3.5 Clarification of what we don’t want

For this competition we are not interested in proposals that:

- constitute consultancy, paper-based studies or literature reviews which just summarise the existing literature without any view of future innovation (which therefore cannot be extended into further phases)

- do not offer significant benefit to defence and security capability

- are an identical resubmission of a previous bid to DASA or MOD without modification

- offer demonstrations of off-the-shelf products requiring no experimental development (unless applied in a novel way to the challenge)

- offer no real long-term prospect of integration into defence and security capabilities

- offer no real prospect of out-competing existing technological solutions

- cannot demonstrate that the solution is feasible within the Phase 3 timescale

- minor improvements on existing high TRL technologies (unless it is being applied in a novel way to the challenge)

4 Exploitation

It is important that over the lifetime of DASA competitions and phases, ideas are matured and accelerated towards appropriate end-users to enhance capability. How long this takes will be dependent on the nature and starting point of the innovation. Early identification and appropriate engagement with potential end-users during the competition and subsequent phases are essential in order to develop and implement an exploitation plan.

All proposals to DASA should articulate the expected development in technology maturity of the potential solution over the lifetime of the contract and how this relates to improved operational capability against the current known (or presumed) baseline. The intended output from your proposal should be designed to evidence these aspects with the aim of making it as easy as possible for possible collaborators/stakeholders to identify the innovative elements of your proposal in order to consider routes for exploitation. DASA Innovation Partners are available to support you with defence and security context. You can contact your Regional Innovation Partner using this link.

The following points will all be considered as part of the assessment process:

- the intended defence or security users of your final product and whether you have previously engaged with them, their procurement arm or their research and development arm

- awareness of, and alignment to, any existing end-user procurement programmes

- the anticipated benefits (for example, in cost, time, improved capability) that your solution will provide to the user

- whether it is likely to be a standalone product or integrated with other technologies or platforms

- expected additional work required beyond the end of the contract to develop an operationally deployable commercial product (for example, ‘scaling up’ for manufacture, cyber security, integration with existing technologies, environmental operating conditions)

- additional future applications and wider markets for exploitation

- wider collaborations and networks you have already developed or any additional relationships you see as a requirement to support exploitation

- how your product could be tested in a representative environment in later phases

- any specific legal, ethical, commercial or regulatory considerations for exploitation

5 How to apply

Proposals for funding to meet these challenges must be submitted by Thursday 11 February 2021 at midday (GMT) via the DASA submission service for which you will be required to register. Funding for this phase of the competition is up to £480k. It is expected to support at least two proposals. Individual proposals cannot exceed £240k (ex VAT). If successful, contracts will be awarded to run until the End of February 2022.

Further guidance on submitting a proposal is available on the DASA website.

5.1 What your proposal must include

When submitting a proposal, you must complete all sections of the online form, including an appropriate level of technical information to allow assessment of the bid and a completed finances section. Completed proposals must comply with the financial rules set for this competition. The upper-limit for this competition is £240k (ex VAT) per proposal. Proposals will be rejected if the financial cost exceeds this capped level. You must include a list of other current or recent government funding you may have received in this area if appropriate, making it clear how this proposal differs from this work.

Your proposal must demonstrate how you will complete all research and development activities/services and provide all deliverables within the competition timescales (completion by end of February 2022). A project plan with clear milestones and deliverables must be provided. Deliverables must be well defined and designed to provide evidence of progress against the project plan and the end-point for this phase; they must include a final report. You should also plan for attendance at a kick-off meeting at the start of Phase 3, a mid-project event and an end of project event at the end of Phase 3, as well as monthly reviews with the appointed Technical Partner and Project Manager; all meetings will be in the UK and organised in accordance with any COVID related restrictions in place at the time. Tele meetings may also be arranged, if required. The proposal should focus on the Phase 3 requirements but must also include a brief (uncosted) outline of the next stages of work required for exploitation.

Proposals with any deliverables (including final report) outside the competition timeline will be rejected as non-compliant.

A resourcing plan must also be provided that identifies, where possible, the nationalities of those proposed Research Workers that you intend working on this phase. In the event of proposals being recommended for funding, the DASA reserves the right to undertake due diligence checks including the clearance of proposed Research Workers. Please note that this process will take as long as necessary and could take up to 6 weeks in some cases for non-UK nationals.

You must identify any ethical / legal / regulatory factors within your proposal and how the associated risks will be managed, including break points in the project if approvals are not received. MODREC approvals can take up to 5 months therefore you should plan your work programme accordingly. Further details are available in the DASA guidance. If you are unsure if your proposal will need to apply for MODREC approval, then please contact DASA for further guidance.

It should be clearly indicated in your proposal if you require access to Government Furnished Assets (GFA) and Government Furnished Information (GFI). If no access to GFA or GFI will be required then please clearly state this. DASA cannot guarantee that GFA and GFI will be available. Failure to provide any of the above listed will automatically render your proposal non-compliant.

5.2 Public facing information

When submitting your proposal, you will be required to include a proposal title and a short abstract. If your proposal is funded, the title and abstract you provide will be used by DASA, and other government departments as appropriate, to describe the project and its intended outcomes and benefits. It will be used for inclusion at DASA events in relation to this competition and included in documentation such as brochures for the event. Your proposal title will also be published in the DASA transparency data on gov.uk, along with your company name, the amount of funding, and the start and end dates of your contract.

5.3 How your proposal will be assessed

At Stage 1 all proposals will be checked for compliance with the competition document and may be rejected before full assessment if they do not comply. Only those proposals who demonstrate their compliance against the competition scope and DASA criteria will be taken forward to full assessment. Failure to achieve full compliance against Stage 1 will render your proposal non-compliant and will not be considered any further.

| Mandatory Criteria | |

| The proposal outlines how it meets the scope of the competition. | Within scope (Pass) / Out of scope (Fail) |

| The proposal fully explains in all three sections of the DASA submission service how it meets the DASA criteria. | Pass / Fail |

| The proposal clearly details a financial plan, a project plan and a resourcing plan to complete the work proposed in Phase 3. | Pass / Fail |

| The proposal contains a credible test plan including blast, ballistic and fragmentation testing where appropriate. | Pass / Fail |

| The proposal identifies the need (or not) for MODREC approval. | Pass / Fail |

| The proposal clearly identifies the requirement, or not, of GFA and GFI for Phase 3. | Pass / Fail |

| Maximum value of proposal is £240k (ex VAT). | Pass / Fail |

| The proposal demonstrates how all research and development activities/services (including delivery of the final report) will be completed by the end of February 2022 (Contracts expected to commence Mid April 2021). | Pass / Fail |

| The proposal includes provision of an interim report following User trials. | Pass / Fail |

| The proposal includes provision of an interim report following Blast trials. | Pass / Fail |

| The bidder provides unqualified acceptance of the terms and conditions of the Contract. | Pass / Fail |

| The bidder has submitted a Supplier Assessment Questionnaire (SAQ) - See Section 5.4 below. | Pass / Fail |

Proposals that pass Stage 1 will then be assessed against the standard DASA assessment criteria (Desirability, Feasibility and Viability) by subject matter experts from the MOD (including Dstl), other government departments and front-line military commands. You will not have the opportunity to comment on assessors comments.

DASA reserves the right to disclose on a confidential basis any information it receives from bidders during the procurement process (including information identified by the bidder as Commercially Sensitive Information in accordance with the provisions of this competition) to any third party engaged by DASA for the specific purpose of evaluating or assisting DASA in the evaluation of the bidder’s proposal. In providing such information the bidder consents to such disclosure. Appropriate confidentiality agreements will be put in place.

Further guidance on how your proposal is assessed is available on the DASA website.

After assessment, proposals will be discussed internally at a Decision Conference where, based on the assessments, budget and wider strategic considerations, a decision will be made on the proposals that are recommended for funding.

Proposals that are unsuccessful will receive brief feedback after the Decision Conference.

5.4 Things you should know about DASA contracts

Please read the DASA terms and conditions which contain important information for suppliers. For this competition we will be using the Innovation Standard Contract (ISC), links to the contract here: Terms and Schedules. We will require unqualified acceptance of the terms and conditions. For the avoidance of any doubt, for this Themed Competition we are NOT using the DASA Short Form Contract (SFC).

This competition has a cyber risk level of ‘very low’ and as such, suppliers must submit a Supplier Assessment Questionnaire (SAQ) on the Supplier Cyber Protection Portal. The SAQ allows suppliers to demonstrate compliance with the specified risk level and the corresponding profile in Def Stan 05-138, the levels of controls required will depend on this risk level. Suppliers should create an account in the Supplier Cyber Protection Portal if they do not already have one, and will be able to find the corresponding SAQ to the requirement by searching the Risk Assessment Reference (RAR) for this competition: RAR-Q5K53XH7. Further guidance can be found at: DCPP: Cyber Security Model industry buyer and supplier guide.

Suppliers must complete the SAQ prior to competition close at midday GMT on Thursday 11 February 2021. You will be prompted to enter the SAQ reference number within the submission service portal when you submit your proposal.

Funded projects will be allocated a Project Manager (to run the project) and a Technical Partner (as a technical point of contact). In addition, the DASA team will work with you to support delivery and exploitation. We will use deliverables from DASA contracts in accordance with our rights detailed in the contract terms and conditions. For this phase, £480k is currently available to fund proposals. There may be occasions where additional funding from other funding lines may subsequently become available to allow us to revisit those proposals deemed suitable for funding but where limitations on funding at the time prevented DASA from awarding a subsequent Contract. In such situations, DASA reserves the right to keep such proposals in reserve. In the event that additional funding subsequently becomes available, DASA may ask whether you would still be prepared to undertake the work outlined in your proposal under the same terms.

6 Phase 3 dates

| Pre bookable 1-1 telecom sessions | Tuesday 15 December 2020 |

| Pre bookable 1-1 telecom sessions | Wednesday 13 January 2021 |

| Completion of Supplier Assessment Questionnaire | Thursday 11 February 2021 at midday GMT |

| Competition closes | Thursday 11 February 2021 at midday GMT |

| Contracting | Aim to start April 2021 and complete by 31 March 2022. Contracts must be completed within the financial year 21/22 |

6.1 Supporting events

- Tuesday 15 December 2020 (afternoon) – A series of 15 minute one-to-one teleconference sessions, giving you the opportunity to ask specific questions. If you would like to participate, please register on the Eventbrite page.

- Wednesday 13 January 2021 (afternoon) – A further series of 15 minute one-to-one teleconference sessions, giving you the opportunity to ask specific questions. If you would like to participate, please register on the Eventbrite page. Subject to demand.

7 Help

Competition queries including on process, application, technical, commercial and intellectual property aspects should be sent to accelerator@dstl.gov.uk, quoting the competition title. While all reasonable efforts will be made to answer queries, DASA reserves the right to impose management controls if volumes of queries restrict fair access of information to all potential suppliers.

8 Additional Information

8.1 Previously supplied information from Phase 2

Some common questions raised during the Take Cover! Phase 2 Dial in and 1-2-1 sessions are answered here.

9 Annex A: Phase 3 Technical Clarification on Test Requirements

9.1 What and how should we test performance against ballistic and fragmentation threats if this has not already been demonstrated?

The competition document asks for protection measures against ballistic threats of up to 14.5 mm armour piercing incendiary (API). It is recognised that 14.5 mm is a stretch target based on requirement documents for current systems and may not be achievable with systems that are man-portable and rapidly deployable.

Therefore, from this testing we want to understand the actual performance of your system against either/both small arms and fragments rather than setting possibly unachievable targets. We require actual performance (V50 or residual velocity) rather than achieving a particular Vproof.

Test categories: For small arms pick one or more test category based on anticipated performance of your system:

- 7.62x51 mm NATO ball (STANAG 4569 Level 1), or

- 7.62x54R mm B32 API (STANAG 4569 Level 3), or

- 12.7x99 mm B32 API (Not in STANAG 4569).

For fragments we will use 20 mm Fragment Simulating Projectiles (FSP) at up to 1250 metres per second. Please note, velocities above ~1150 metres per second, probably need to use a 30 mm barrel with saboted 20 mm FSP, so may be more difficult to test.

Test requirements:

- All testing should use the damage codes from Defence Standard 08-42 to describe the result.

- Pass/fail criteria should be as per AEP-55 Volume 1 (i.e. can light be seen through a witness plate of 0.5 mm thick 2024 T4 aluminium placed 150 mm behind the target rear face?).

- FAIR/UNFAIR impact criteria, particularly for yaw/pitch (<5º).

- There is no multi-hit requirement at this stage, but this may be required for a future phase.

- All testing will be conducted at ambient and NATO normal obliquity (perpendicular to target surface) in the first instance.

- V50, if provided, should be calculated as per Mil-Std 662F.

Test reports should include:

- Details of the threat used, including head stamp, etc., for bullets.

- Shot spacing and firing sequence.

- Results of every shot, including damage code, velocity and yaw.

- Labelled photos of the front and back of the system post-firing, with a scale.

- Record and explanation of any UNFAIR impacts (yaw too high, too close to another impact, etc.).

- Description of overmatch (use of overmatch plate or high speed video of rear face).

- Description of instrumentation calibration.

- Range setup, including muzzle-to-target distance and location of the projectile velocity system and photograph of setup.

Most reputable European ballistic test houses should be able to provide advice on how to test your systems based on this information. Standards will be provided as necessary to successful bidders.

9.2 What and how should we test against blast and ground shock?

The blast testing requirements will be different for each of the challenges. This is due to the differing natures of the protection measures and what is a realistic, achievable level of protection for each within those scenarios.

Blast testing shall be organised by Dstl at an appropriate test facility and supplied to successful bidders as Government Furnished Facilities (GFF). Scenario 1 –Battle Trench From Annex F in Reference 3, which lists the performance specification for battle trenches, the protection system will be tested using a 155 mm artillery shell, in the following configurations:

- A set distance above the trench

- A set distance from the walls of the trench at ground level and the same distance but buried down to a specified depth

The distances/depth cannot be included here but will instead be confirmed at a later point.

The trench shoring system must be capable of withstanding the effects of the shell detonating at a particular standoff without collapse of the trench or sustaining a deformation large enough to endanger its occupants. Raised Overhead Protection (OHP) structures must resist lateral movement due to blast and any penetration of protective measures by the fragmentation. Protective surfaces or OHP structure should resist penetration by a 14.5 mm API (armour piercing incendiary) round.

Scenario 2 – Vehicle Check Point (VCP)

The VCP is a relatively lightweight protection technology, which favours a rapid deployment/dismantling compromise over outright protection levels. Therefore, it is unlikely to have the same level of inherent resilience against significant blast threats as that of the battle trench. The terrain in which the VCP is likely to be used is also very different to that of the battle trench i.e. at roadsides or possibly in urban areas.

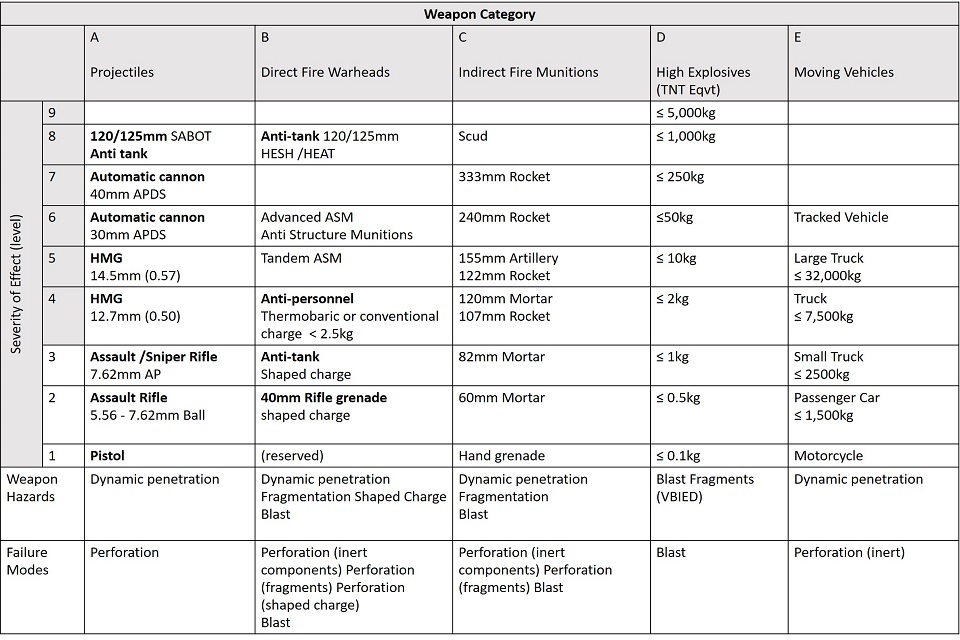

Table 1 shows a selection of weapon categories and a range of severity levels, depending upon the specific threat considered, which has been taken from Reference 4. It is proposed that the indirect fire munition threat corresponding to the same ballistic severity level is used for testing. This will allow an assessment of protection performance against blast loading and fragmentation effects. For example, if the VCP is expected to provide protection against the 7.62 mm AP threat (Severity Level 3), the corresponding blast test should use the 82 mm mortar threat at a specified stand-off distance.

The structure must resist significant lateral movement, which would be likely to cause injury to personnel behind, the formation of secondary fragments/debris and penetration by the weapon fragments.

Table 1: Weapon Categories and Severity of Effect

References:

Standards used for ballistic testing:

1) NATO (2014) STANAG 4569 Protection Levels for Occupants of Armoured Vehicles, dated 23 May 2014.

2) NATO (2016) STANAG 2280: Test Procedures and Classification of the Effects of Weapons on Structures Edition 2, dated 10 Jun 2016.

Standards used for blast/fragmentation testing:

3) MOD (2007) Military Engineering Volume IX Force Protection Engineering Part 1 Fundamentals, Army Code 71838, dated Jan 2007.

4) NATO (2016) STANAG 2280: Test Procedures and Classification of the Effects of Weapons on Structures Edition 2, dated 10 Jun 2016.

9.3 What and how should we test against vehicle run over?

Vehicle run over is only applicable to Challenge 1: Battle Trench. In Phase 3 we are not looking for you to undertake any vehicle run over tests; it is recognised that this is not possible within the funding and time constraints. Instead, we would like to see an engineering calculation and simulation to show/predict how your system will behave under such conditions.

A system designed to protect dismounted soldiers at a VCP is there only to protect against ballistic and fragmentation threats, not vehicle run over / vehicle stopping.

9.4 What and how should we test deployment mechanisms?

The deployment of your system should be demonstrated within environments and conditions described within the competition document and above, commensurate with the funding and time constraints of the competition. Testing may be at full system, sub-component or sub-scale but must allow for an understanding of how and in what timescale the system could be deployed by the dismounted soldier under operational conditions.

10 Annex B: Phase 3 Clarification Questions

Common questions raised during the Take Cover! Phase 3 1-to-1 sessions are answered here

10.1 General

1) What is the weight limit that can be carried by a soldier?

It is recommended that individual components do not exceed 20 kg and the maximum weight of the component is dependent on a number of characteristics such as single person lift, size of the load, handles, end position of the lift, number of lifts per hour and would need to consider the anthropometric and physical characteristics of the user population. For more information please refer to Defence Standard 00-251: Human Factors Integration for Defence Systems (2015) and the associated Human Factors Integration Management System (HuFIMS). Any solution must be compliant with Manual Handling Operations Regulations 1992.

2) Are there any criteria related to vehicle deployment?

No. Proposed solutions should fit on standard NATO pallet (dimensions are in the call document).

3) Is there a target time to erect and deconstruct the system?

No target time is specified as this will depend on deployment scenario. For example the 4-man trench on soil type; digging in soft sand is easier and quicker than in heavy clay. In all cases, deployment time should be as fast as possible.

4) The reference for Military Engineering is not in the public domain, can this be supplied?

The relevant section and any other essential standards will be supplied to successful bidders, if required, when placed on contract.

5) Is there any particular advantage for coming in under the £240k cost cap?

No. It is the output of the research and how this meets the objectives of the call. Please see the DASA site for evaluation criteria, including value for money.

6) Is the pre-testing requirement all the environmental tests in the relevant DEFSTAN?

No, a representative set of tests can be made. In the proposal it is important for Dstl/MOD to understand the limitations or challenges environments such as those given in DEFSTAN 00-35 Environmental Handbook for Defence Material may pose to the storage and deployment of proposed systems.

7) Can I send more than one prototype to the user trials?

Bringing two systems would be permitted to evaluate the difference in design variations.

8) Are suppliers expected to attend blast and user trials?

It is expected that the supplier will be present at these trials in order to guide the users.

9) Is there a need to perform our own blast testing or can this be modelled?

It is not expected that supplier perform their own blast testing. Suppliers may use numerical modelling to simulate the effects of blast on their structures if they wish, but it is not a specific requirement of the call.

10) For FSP testing is it best to use 20 mm or smaller fragment?

20 mm diameter was the standard FSP type defined in the call.

11) Does signing a DASA contract restrict my other commercial activities?

No but suppliers have to manage resources to ensure that they can fulfil all obligations under the contract.

12) Do sub-contractors also need a DASA contract?

No. The contract is between the proposer / main supplier and the MOD. The supplier is responsible for sub-contractor payment and to protect IP. IP rights in the contract must flow down to any sub-contractors. Research worker forms will need to be completed for sub-contractors.

13) Do ballistic tests from Phase 2 need to be repeated?

No, only if there are significant changes to the design. Suppliers who did not take part in Phase 2 will be expected to provide evidence of ballistic testing in Phase 3. In this case, evidence to suggest viability of meeting the required ballistic performance should be provided in the proposal.

14) Will Dstl/ DASA broker Phase 3 collaborations or marry up proposals?

No, any collaborative working arrangements are the responsibility of the potential suppliers. In the interests of fairness, submitted proposals are not married up by Dstl/DASA.

10.2 Challenge 1 – Battle Trench

1) Is there any preference for digger or manual construction?

Manual or mechanical digging may be used to construct the trench for blast testing dependant on range time available and soil condition. The proposal should indicate the volume of soil required to be removed for their solution and if there is any time saving benefits through emplacement of their solution relative to the current split hairpin shelter. Where possible this should be supported through calculation and based on both manual and mechanical digging.

2) Which type of ground will be used for the trials?-

A soil type for blast trials has not been specified. System designs should however consider worst-case soil types e.g. wet clay.

3) Is there a need to consider different size trenches?

The standard trench is a 4-man trench with dimensions shown in the call document. This competition is looking at modularity to permit larger and smaller sizes.

4) Does the end of the trench have to be rounded?

No. In the split hairpin shelter this allows pieces to be used as overhead protection or at the end of the trench. It should be noted that angular structures will experience different loadings.

5) Are there any specific deflection criteria?

Deflection should not endanger or injure soldiers occupying the trench.

6) What is the maximum depth that can be dug without trench face support?

When deploying the split hair pin shelter the trench is dug to full depth before the trench supports are emplaced. This may require a sloped or benched excavation to prevent collapse or spoil falling into the trench.

7) Do sandbags also require supporting?

Vehicle overrun may dislodge sandbags compromising the trench so support should be applied to sandbags.

10.3 Challenge 2- Vehicle Check Point (VCP)

1) Is camouflaging of interest for the VCP challenge?

Due to the nature of a VCP i.e. it requires to be seen by the approaching traffic, camouflage is not of primary concern in this phase of the competition. However, its integration should still be considered to provide flexibility and adaptability for scenarios where less visibility may be required.

2) Is there any guidance on the total size/height of the VCP?

The VCP should be of sufficient size to protect at least two people (standing or kneeling) and provide a point from which a firing position can be adopted.

3) For blast testing trials what ground surface will it be on and can the VCP be anchored in any way?

The likely surface will be a concrete base. The base may be uneven. Solutions can be anchored or tethered but consideration needs to be given to speed/ease of deployment.

4) What is the relative importance of blast vs. ballistic protection?

For the VCP challenge, this is more weighted towards ballistic as that is the more likely threat but it should be able to provide some blast protection or at least have no negative effect upon personnel. Blast testing is to see what structures can survive rather than set a minimum requirement.

5) What will be used for the blast test, mortar, explosive or both?

A mortar or surrogate will be used. Stand-off distance will be provided to successful bidders upon award of contract. It is expected that blast will be ground burst.

6). A minimum of three structures from successful suppliers are required for MOD testing – does this apply to VCP? If yes, can one of the three be from the user-trials?

This applies to both challenges. Structures employed for user trials may also be used for blast testing but it cannot be guaranteed that structures will not be damaged in user trials.

7) The VCP structure must resist significant lateral movement,- what is definition of significant lateral movement?

Lateral movement or deflection of the protection solution should not be so large or occur at such a velocity that it would endanger or injure soldiers sheltering behind the structure.

8) Ballistic protection has dropped to 7.62 mm ball, why is that and what is the threat they want addressing?

We want the solution to have the maximum ballistic protection possible, within the significant constraints of weight and cost. The 7.62 mm ball represents the very minimum baseline protection that the system must achieve.

9) Table does not state velocity for 20 mm fragment for the different threat levels. For 7.62 mm AP threat (Severity Level 3), the corresponding blast test should use the 82 mm mortar, so what is the 20 mm FSP velocity?

This document will be updated to address this question week commencing 25th January.

10) What the 20 mm FSP velocity for 7.62 mm ball with 60 mm mortar?

This document will be updated to address this question week commencing 25th January.