D. Requirements for authorisation

Who is eligible to become an authorised examiner, their responsibilities, how to apply, what happens when DVSA receives an application, site requirements, mandatory roles, required training, testing requirements for all vehicle classes.

An authorised examiner (AE) is the organisation that operates and manages one or more vehicle testing stations (VTSs) and is responsible for controlling the quality of testing carried out. Except in the case of a sole trader the AE is not a person but a legal entity, for example a company, partnership or a local authority.

A designated council (DC) is a local authority authorised to carry out MOT tests.

Unless stated DCs are treated the same as AEs within this document.

This document sets out the requirements to be met when applying to become an AE or DC. It’s intended to assist with the application process by providing the information required on how to start a new application or to apply for a variation to an existing authorisation.

Normally an application to become an AE is made in conjunction with an application for a VTS. However, DVSA will accept an application to become an AE without a link to a tester or an approved VTS.

In all cases applicants should be conversant with their responsibilities. Before final authorisation to test is granted an AE must demonstrate compliance with all requirements.

All applicants should be fully aware of the requirements before completing and returning an Application for MOT Authorisation Form (VT01).

The application must be made by the legal entity that holds full control and responsibility for MOT testing functions. Authorisations are granted in accordance with the conditions applicable to the authorisation.

These conditions include compliance with the requirements set out in the MOT testing guide and appropriate inspection manuals (as amended) together with any additional specific conditions contained within the written authorisation notice.

AEs are in law fully responsible for ensuring that statutory MOT testing at all their VTSs is carried out to the required standard and in the manner instructed by DVSA. Failure to comply with the authorisation requirements for the MOT service may lead to your application being rejected.

An AE entity may be authorised without access to approved facilities however, before authorisation to test is granted an AE must have an approved testing facility. Authorisation of an AE and approval of a vehicle test station (VTS) may be done using a single application form; the specific requirements for a VTSs’ approval are set out in common to all classes.

Who is eligible to become an authorised examiner

Authorisation to carry out MOT testing will be granted only to applicants who can satisfy DVSA that they are of good repute, as defined in Appendix 7: Convictions and repute, and where applicable that their premises, equipment and personnel meet the required standards.

An application for appointment as an AE can be made by a:

- sole trader

- partnership

- company

- designated council

Any authorisation by DVSA allows only the legal entity authorised to provide the testing service. If a company is reconstituted in a way that leads to a new company registration and number being issued, then it will be regarded as a new entity and a new authorisation is needed. If, in a partnership, a partner leaves or joins the partnership this becomes a new entity and a new authorisation is needed. The same is true in the case of a sole trader who either takes on a partner or forms a company.

Sole trader

If the application is made by a sole trader, the AE would be the person making the application, and who must sign it.

Partnership

If the application is made by a partnership, the AE would be the partnership itself (for example, the partnership of F Bloggs and A N Other) and the application is to be signed by a person ‘duly authorised’ by the partnership to do so. Confirmation that the person is ‘duly authorised’ in a form of a statement to that effect signed by each of the partners will normally be required together with a copy of the current partnership agreement

Company

If the application is made by a company, the AE would be the company itself, not the directors or company management staff regardless of who owns the company and who the directors are. The application is to be signed by any person ‘duly authorised’ by the company to do so. Written confirmation that the person is ‘duly authorised’ signed by an ‘officer of the company’ is required. The directors must be recorded on the company’s register at Companies House.

Designated council

A designated council is:

- the council of a county, district or London borough

- a unitary authority or island council of a region or Islands area (in Scotland)

- the City of London

Authorised examiners (AEs) responsibilities

It’s important that you understand all that is required to be an AE before signing the application.

General

AEs are held fully responsible for the actions of their staff and others acting on their behalf or with their agreement, all such staff must be adequately supervised and fully conversant with their testing duties. For a partnership or company, all partners or directors and officers of the company are equally responsible. Each authorised entity is required to have an authorised examiner designated manager (AEDM) (see Mandatory roles). The responsibilities of testers are set out in Section E. Tester.

Every new AE is required to have at least one person, who is an AEP, plus the AEDM, who has attended a DVSA approved MOT Managers Course.

AEs must notify DVSA immediately in writing of any conviction of an individual involved in the MOT scheme under their authorisation. This includes:

- AE principals (AEPs)

- AEDMs

- AE delegates (AEDs)

- site managers

- site admin

- testers

For conviction definitions see Appendix 7:Convictions and repute.

The extent of an AE’s liability for vehicle damage is set out in Regulation 14 (1) of the Motor Vehicles (Tests) Regulations 1981 (SI 1981 No 1694) as amended. AEs must not display disclaimers against liability for loss, damage or injury caused while vehicles are in their custody for MOT tests and must ensure that no vehicle presenter is asked to sign any such disclaimer. Appendix 4: Liability for loss or damage describes fully the scope of AE’s liabilities.

AEs are advised to be members, or become members, of a Chartered Trading Standards Institute (CTSI) approved code of practice. Details of approved codes can be found on the TSI website.

Premises and equipment

After approval of the site, every AE must, at all times, properly maintain the premises, facilities and testing equipment at all the VTSs for which they are responsible. This includes:

-

all facilities and equipment that were present at the time of the VTS’s approval and any additions or alternatives that were agreed with DVSA by prior notification

-

all facilities and equipment required by any mandatory upgrade introduced by DVSA

All testing equipment must be kept in good working order and measuring apparatus must be kept calibrated in accordance with DVSA’s requirements.

Testing must stop on any class or type of vehicle, if any mandatory item of equipment falls out of calibration, is missing a mandatory upgrade or inspection, is unable to connect to the MOT testing service when required or malfunctions in a way that could prevent a test being properly conducted on that class or type of vehicle. Refer to B4. General responsibilities - premises and equipment for information on what to do in the event of equipment failure.

An AE must apply to DVSA for approval prior to the changes being made if they want to:

- add test classes

- replace or modify any fixed test equipment that will alter the approved dimensions or layout

- alter the building or the layout of equipment

The AE can apply using the VT01 application form. Supporting drawings should be enclosed with the application.

No proposed change will be acceptable if it reduces clearances or dimensions (including those for access) below the limits specified in the requirements for authorisation or, for features approved only as `acceptable variations’, below their existing values.

DVSA must be notified of any changes to fixed equipment and/or equipment that needs to be connected (transfer results to the MOT testing service) using the ‘Change testing equipment’ link on the VTS page on the MOT testing service.

The changes will be checked by DVSA at the next visit. If the changes do not meet the requirements for authorisation approval may not be given.

The renewal of mobile testing equipment does not have to be notified to DVSA provided that the replacement is on the current DVSA approved list and will not affect the range of vehicles that can be tested.

Access by DVSA staff

AEs must allow the inspection of their testing arrangements, equipment, facilities, records, and the checking of their tester’s competence, re-examinations of recently tested vehicles by DVSA staff at any time during normal working hours or when the VTS is open. AEs should always ask to see the official warrant that DVSA enforcement staff carry. If you have doubts about anyone asking to see official documents, refuse access and call the DVSA customer service centre.

AEs must allow their VTSs to be used by DVSA for examining vehicles subject to an appeal or complaint about a test result provided that 3 days’ notice has been given. The notice period may be reduced by mutual agreement. DVSA will pay one half of the relevant test fee for the use of the premises and equipment, unless the arrangement is cancelled at least 24 hours ahead.

Contact DVSA

DVSA Customer Service Centre

enquiries@dvsa.gov.uk

Telephone: 0300 123 9000

Monday to Friday, 8am to 5pm

Find out about call charges

Security

AEs are responsible for ensuring that blank MOT contingency testing (CT) certificates are not accessible at any time to unauthorised persons.

The AE shall take reasonable precautions to ensure that all MOT security code users which they are responsible for safeguard their MTS passwords and access to their security cards or authentication app and unique email address recorded on the users MTS profile.

Outside working hours, the security of the MOT security code generator and email is the responsibility of the service user.

Testing responsibilities

AEs must ensure that the MOT tests are carried out without avoidable distraction or interruption and strictly in accordance with the conditions of their authorisation, which includes compliance with the MOT testing guide, the appropriate inspection manual and any other instructions issued by DVSA.

They must ensure that, for each test, all assessments of pass/fail criteria are made, all appropriate documents are signed, and all database input details are confirmed by the tester who carried out the test. AEs must ensure that assistance is always available to testers for those parts of the test that require it.

AEs must offer an appointment to test any vehicle of a class within their authorisation at the earliest practicable date and time, with consideration for their existing MOT workload and customer requirements.

All appointments made for vehicles without a current MOT certificate must be recorded in writing. The record must include the vehicle’s registration mark (VRM), the date and time of the appointment and the name of the person making it. This record must be kept for at least 3 months after the date of the appointment.

An AE must not carry out an MOT test on a vehicle if it’s of a class or type of vehicle which they are not authorised to test, or a type of test they are not authorised to carry out, or the vehicle cannot be accommodated within the test facilities. They must tell the vehicle presenter immediately of any such circumstances, pointing out that consequently the test cannot be carried out.

Full details of reasons for refusal to test are contained in the respective MOT inspection manuals.

Any individual presenting a vehicle for an MOT test has the right to observe the test in safety from the approved viewing area(s).

Cessation for disciplinary reasons

DVSA, on behalf of the Secretary of State, has the discretionary power to take disciplinary action against an AE, including cessation of the authorisation. Failure to adhere to the requirements of authorisation may result in disciplinary action against the AE and/or the tester.

When the AE is a sole trader the responsibility for taking action to ensure that the authorisation is operated in accordance with the Secretary of State’s requirements and the penalties for failure to do so falls on that person. With partnerships and companies, however, individuals must ensure correct operation of testing. The responsibility therefore falls not only on the company or partnership but also on the following individuals:

- in the case of a company, all the officers of the company and any other person ‘duly authorised’ by the company to sign applications and other similar documents relating to the authorisation

- in the case of a partnership, each partner and any other person ‘duly authorised’ by the partnership to sign applications and other similar documents relating to the authorisation

Where the authorisation of the AE operating at a particular site has been ceased, for disciplinary reasons as above, anyone wishing to apply for authorisation at that site must be able to show that they are sufficiently independent from the former AE, partners or officers of the company. The maximum acceptable involvement of the former AE is as a landlord.

The former AE, including the AEDM and any individuals who were directly accountable in the cessation of the previous authorisation shall not be involved in any way with the management or responsibility of any authorisation. The spouse, partner, family members of the former AE, including the AEDM and any individuals who were directly accountable in the cessation of the previous authorisation, would not be considered sufficiently independent.

If an AE has received a 2 or 5 year disciplinary cessation of all their sites, none of the associated AEPs will be able to hold any role within another AE and/or Vehicle Testing Station during the cessation period.

Changes to businesses

DVSA must be told within 28 calendar days about any significant changes to the control or operation of the business. Failure to notify such changes within this period may be treated as a shortcoming under Section I. Discipline. For further information on changes to business, see Section B3. Cessation of authorisation and other changes to businesses.

A company that continues to operate under the same registration and company number may continue testing provided that any changes to the officers of the company or change in the relationship to any parent company have been notified to DVSA in writing.

Any directors added to a currently Approved AE will need to meet the current requirements, including a DBS check. An exception to this is for directors who are permanently based abroad; however, the AE must still inform DVSA of their inclusion as directors to the business.

An AE that makes a change (addition or removal) to the members (AE principals) of the business will need to meet the current requirements. For example, each AE principal will need to have an account in the MOT testing service.

It’s possible for the AEDM, or other appropriate roles, to update some authorisation details directly, such as telephone numbers, email and correspondence addresses, via the MOT testing service. Any other details must be notified to DVSA in writing.

The AE can cease the nomination of a tester. In the case of a multi-site AE, this cessation may be from all sites, a selection of sites, or a single site. A cessation by one AE or DC does not affect any current or future nominations by other AEs. DVSA must be notified by recording the change of details on the MOT testing service.

How to apply to become an AE

Application

An AE (DC) is the legal business entity that operates and manages one or more VTSs and is responsible for controlling the quality of testing carried out.

With the exception of a sole trader the AE (DC) is not a person but the legal entity, for example a partnership, a company or local authority.

All applications must be made on an Application for MOT Authorisation Form (VT01). All relevant sections should be completed, and the form returned to DVSA along with the relevant enclosures.

Those applying should not submit their application until confident that they will fully meet all the requirements as set out, further detail of the requirements are contained within the Motor Vehicle (Tests) Regulations as amended, the MOT testing guide and other sections of the applications pack (as appropriate).

Your failure to supply the required documents applicable to your application may lead to your application being delayed or refused.

Third Parties submitting an application on behalf of an AE

If a consultant or third party is dealing with an application on behalf of the AE. A letter of authority must accompany the application.

The letter of authority must be:

- on the AE applicants headed paper

- signed by an AE principal or the AE designated manager if you are already an approved AE

A scanned copy of letter of authority can be sent by email if it’s sent from the AE applicant’s email address.

Personal verification checks

You must provide a declaration of non-conviction supported by a basic Disclosure and Barring (DBS) certificate for each person proposed to be involved within the authorisation. This includes all company directors, partners, or sole traders and the AEDM.

The declaration of non-conviction must be signed along with the DBS check details sections completed or copy of certificate attached.

The basic DBS check must be dated within 3 months of DVSA’s receipt of any application.

A basic DBS check verifies an applicant’s identity based on the evidence provided and can confirm they are free from any unspent convictions.

A basic DBS check can be requested from a number of source, including directly from the Disclosure and Barring Service.

A criminal conviction is a judgement made by a court that a person or company is guilty of any offence. The penalty imposed may range from an absolute discharge through to imprisonment. This does not include fixed penalty offences. You must inform DVSA, in writing immediately of any convictions, as defined in Appendix 7: Convictions and repute, that occur between the date of application and authorisation of that application, and there on after.

If following approval, it’s brought to DVSA’s attention there are any unspent convictions that have not been disclosed, this may result in the cessation of authorisation to carry out statutory testing. Cessation may occur even though the conviction would no longer be considered but would have led to refusal on the initial VT01 application.

Declaration of non-conviction

In the case of a company you must provide a declaration of non-conviction for the company. A criminal conviction is a judgement made by a court that a person or company is guilty of any offence. The penalty imposed may range from an absolute discharge through to imprisonment. You must inform DVSA, in writing immediately of any convictions, as defined in Appendix 7: Convictions and repute, that occur between the date of application and authorisation of that application, and there on after.

If following approval, it’s brought to DVSA’s attention there are any unspent convictions that have not been disclosed, this may result in the cessation of authorisation to carry out statutory testing. Cessation may occur even though the conviction would no longer be considered but would have led to refusal on the initial VT01 application.

Partnership agreement

A copy of the partnership agreement signed by all partners must be provided.

Companies Act 2006

If the applicant is subject to the Companies Act 2006 you’ll need to demonstrate either:

- the corporate name

- the name of each partner

- the individual person’s name

For each person named, you’ll need to give an address at which documents can be served.

You’ll need to include this in all:

- the places where you carry on your business and where you deal with customers or suppliers

- business letters

- written orders for the supply of goods or services

- invoices and receipts

- written demands for the payment of business debts

For more information on the requirements of the Act, please visit Companies House.

The company number of the business to provide access to the Companies House record of appointments that confirms that all the listed applicants are known to Companies House.

Trained AEDM

Every new AE is required to have a trained AEDM.

Bankrupt or sequestrated

A person that is adjudged bankrupt or, in Scotland, has his estate sequestrated is not eligible to apply whilst this status remains. For applicants that have been subject to this order, within five years of the application date, DVSA require either a copy of the Certificate of Discharge or an independent declaration to confirm that you are no longer under these restrictions.

Receipt of application by DVSA

If the information supplied in the application form and enclosures is satisfactory, DVSA will progress the application. Where the application form or enclosures are incomplete, they will be returned to the applicant with details of the additional information required.

After reviewing the application and following appropriate enquiries and possible inspections the applicant will be informed in writing of the outcome of DVSA’s considerations, which will be either:

- approval in principle (AIP) given

- authorisation/designation granted

- intention to refuse notified

Approval in principle given

Where the requirements for authorisation/designation are not met but with reasonable changes they can be met, the applicant will be given written AIP. This will list items to be complied with before authorisation/designation is granted and will include a time limit after which the AIP will expire. Final approval will only be given when all the required changes (or agreed alternatives) have been made.

Where the applicant is not prepared to comply with an item, or items, listed they must notify DVSA as soon as is possible, and before the expiry date of the AIP. The application will then be issued with an intent to refuse.

Delays to authorisation

To reduce the number of dormant applications, all applications will be reviewed periodically. A request will be sent to the applicant either by email or letter by recorded delivery, seeking evidence of good intent (which could be a letter confirming the application is proceeding). This review will be carried out during the 6th month after receipt of the application and 14 calendar days given for the reply. If no reply is received or the reply is such that the terms of the initial AIP are no longer valid, then the original application will be terminated without further notice.

Authorisation granted

Authorisation will be granted when DVSA is satisfied that:

- the requirements for authorisation have been met

- an AE Principal has attended the MOT Managers Course

- an AE Designated Manager has attended the MOT Managers course;

- a quality management system (if applicable) has been agreed

In the case of a council’s application, designation will be recommended. This will always have a standard set of conditions but may be subject to additional conditions specified in the authorisation/designation letter.

It’s emphasised that responsibility for ensuring that premises and equipment comply with other relevant acts, regulations, bylaws, health and safety at work requirements, and all other applicable instructions, rests with the applicant.

DVSA publishes information about authorised VTSs. This includes your trading name, address and phone number to assist the public in finding a VTS in their area.

DVSA will provide information when requested under the Freedom of Information Act. Personal information will not be included in these requests.

Information regarding an authorised examiner, VTS or its staff may also be supplied in response to a request from other enforcement agencies, for example the Police and HM Revenue and Customs.

Intent to refuse the authorisation or the designation

Where the Secretary of State is minded to refuse the application for authorisation, DVSA will notify the applicant in writing, detailing the reason(s) why the application may be refused.

The intention to refuse may be sent to the applicant at any stage during the application process when it becomes apparent that the application does not or is unlikely in the foreseeable future to meet the criteria.

The applicant may appeal against the intention to refuse to authorise or designate. Any appeal must be made in writing to the DVSA Office that issued the notice and be received within 14 calendar days from the date of the notification of the intention. An informal hearing may be requested in accordance with the Informal Hearing Notes for Guidance and Code of Practice issued with the notice.

If at the end of this appeal period no such appeal has been received DVSA will write to the applicant confirming the refusal to authorise.

If an application is from an entity or involves individuals that have been subject to cessation for disciplinary reasons, that application will not normally be considered until shortly before the cessation period expires. As such there can be no ‘intent to refuse’ until the cessation period has expired.

If at any time in the application process the applicant considers they cannot, or refuses to, meet the conditions they may give written notice to this effect to DVSA. On receipt of the applicant’s letter DVSA will confirm intent to refuse authorisation.

Additional requirements before a site is authorised to test

DVSA will accept an application to become an AE without a link to an approved VTS, however before final authorisation to test is granted an AE must demonstrate compliance with this requirement. The following additional requirements are required to be in place at each site to be approved.

MOT testing guide and inspection manuals

Online access to the MOT testing guide and the relevant inspection manuals for all the classes of vehicle for which authorisation to test is available.

Evidence of exclusive use

Evidence that the applicant has the sole use of the proposed MOT facility, including the test bay and reception area/office.

This evidence should be provided as a solicitor’s letter, supplied on headed paper, which specifically confirms ownership of the premises or lease or rental agreement.

The statement must confirm:

- the applicant has the legal right to operate within the premises

- that planning permission is in place

- that the applicant is the owner of the land or that an enforceable lease or rental agreement is in place between the applicant and the owner of the land

- the applicant has exclusive use of the premises and MOT testing facilities

This letter must be signed by a solicitor of the firm you appoint.

If the applicant is the site owner, DVSA may request they supply copies of documents from the land registry confirming that the applicant is the registered owner of the land. If a land registry entry is not available alternative proof of ownership must be accompanied by a written explanation from a solicitor.

If the applicant is not the site owner, DVSA may request evidence that the applicant has the right of exclusive use of the premises, in the form of a lease or rental agreement. The document needs to include:

- the rent to be paid for the premises

- specific mention that the prospective AE has exclusive use of the premises and facilities necessary for MOT testing

- evidence that the person or body granting the lease (the lessor) owns the site, or that the lessor’s lease for the premises allows sub-letting or assignment of all or part of the lease to someone else

- written confirmation from a solicitor that the lease is a proper and enforceable legal document

Irrespective of whether the applicant is the site owner or not, an applicant may provide written confirmation from a solicitor that a proper and enforceable lease is in place, in lieu of the document. This may, at DVSA discretion, allow a time limited approval of authorisation until suitable documents are provided. Failure to provide these documents by the time specified by DVSA will result in a suspension of authorisation until the requirements have been fulfilled.

Test appointments

Arrangements for making MOT test appointments by telephone and by personal visit.

AEs must offer an appointment to test any vehicle of a class within their authorisation and that can be safely accommodated on their MOT equipment at the earliest practicable date and time bearing in mind their existing MOT workload.

Testers

The AE will not be able to test until they appoint a DVSA approved tester. The AE must appoint a tester and conduct MOT tests within 12 months of approval to retain their authorisation.

Quality management

AEs are responsible for the quality of testing within their garage or garages.

Others, most notably testers, also have a responsibility upon them associated with this, but it’s for AEs to ensure there are adequate systems for the management of the quality of testing at their garage or garages.

To that end AEs must ensure an adequate system of quality management at each of their VTSs.

Such systems are defined further within Section B6. Quality management.

MOT testing service IT and associated equipment

Authorised examiners are responsible for the supply and maintenance of all IT equipment and internet connection used for MOT testing purposes. The requirements for this equipment are defined within Appendix 2: Facilities and security

Mandatory roles and training

For an AE to be authorised and a site to start testing, MOT specific roles must be appointed to individuals. These identify the individuals’ responsibilities with regard to the MOT service and where applicable, allow them appropriate access to the MOT testing service.

The following mandatory roles are required for the authorisation of a site to test:

- authorised examiner principal (AEP)

- authorised examiner designated manager (AEDM)

- tester

- site manager (SM)

Depending on the size and make up of a business an individual can hold one or multiple roles. The roles of AE principal and AEDM will be appointed by DVSA from the information supplied in the AE’s application, the remaining roles must be appointed by the AEDM.

There are additional non mandatory roles, giving varying levels of access to the MOT testing service, which AEs may find useful to aid with the running of their business.

Authorised examiner principal (AEP)

Authorised examiner principals (AEPs) are legally responsible for the entity. Every partner in a partnership; every director in a company or the sole trader in person must complete and submit separate AEP personal details using a VT01.

Authorised examiner designated manager (AEDM)

Every AE is required to have an AEDM who, on behalf of the AE, is responsible for ensuring testing is carried out in compliance with the Requirements of Authorisation.

Typically, the AEDM would be a person from within the AE, however it may also be a senior manager who has responsibility for testing across the entire AE.

Training requirements

Trained AE principal (AEP)

Each AE must have one AEP or more who has attained a Level 3 Award in MOT Test Centre Management or have attended the previously named MOT Managers course or Authorised Examiners course.

This course covers testing responsibilities, administrative arrangements, disciplinary and appeal processes. The course is designed to help the AE to fully understand their responsibilities within the MOT Service and the function that is carried out by the AEDM.

If the application to become an AE is from an individual they must attend the course.

If the application is from a partnership, the partner who will exercise the most direct control over all MOT testing operations must attend the course.

If the application is from a company, the director or an officer of the company having the most direct responsibility for all MOT testing operations at all sites, must attend the course.

If the application is from a designated council, then a senior council officer having direct responsibility for all MOT testing operations must be the one to attend the course.

Trained AE designated manager (AEDM)

Each AEDM must attain a Level 3 Award in MOT Test Centre Management or have attended the previously named MOT Managers course or Authorised Examiners course.

Timing of training

Normally, training must be completed before the authorisation can be granted.

In cases where a new authorisation becomes necessary only because a business undergoes one of the changes indicated below, the authorisation can be granted before training has taken place, provided that a suitable person is trained within 35 working days of the change. Failure to complete the necessary training within the specified period will result in cessation. These changes are:

- a sole trader takes on a partner or forms a company of which he or she is a director

- a partnership splits up, but an untrained partner continues the business as a sole trader

- a partnership splits up, but one untrained partner continues in a new partnership or as a director of a company; the same would apply if more than one of the untrained partners stayed with the new partnership or company

- a partnership that had originally applied for authorisation before 1 April 1995, and therefore did not need to have a trained person, is reconstituted by the addition or departure of one partner or more and therefore is now required to have a trained person in the partnership

- a receiver or manager ‘of the body’s undertaking’ is appointed for a company

Validity of training

The training is valid indefinitely unless an AE has been subject to cessation for disciplinary reasons. The AEDM for that AE may be required to attend a further course before again being acceptable as a trained person. If the AEDM is judged to have been directly involved in the incident leading to cessation then retraining will be mandatory. In such cases retraining will normally be permitted only when the AE is eligible for re-authorisation

The training will also not be valid if an AE is given a formal warning under DVSA’s disciplinary procedures - the AEDM for that AE may be required to achieved a Level 3 Award in MOT Test Centre Management within 35 working days of the date that the AE is notified of the disciplinary action

Applications for training

A Level 3 Award in MOT Test Centre Management course is booked with a training provider. There is a charge for the course, which varies and is set by the individual course provider.

Tester

Every new AE is required to have at least one person, the tester, who has achieved a Level 2 Award in MOT Testing or previous equivalent DVSA MOT Testers course, before testing can begin. If a tester isn’t present authorisation to test can be is granted but the test station will have deemed to have surrendered it approval if testing doesn’t begin within 12 months of the approval date.

Site manager (SM)

This is the role responsible for the day to day running of one or more VTSs. The SM can carry out VTS management, and non-testing functions for example assign users within a VTS. Normally there will be only one SM per VTS, however, in some cases there may be a requirement to have more than one SM listed against a VTS.

Many smaller single site AEs may well choose to assign the SM role to the AEDM, larger single site businesses may allocate it to another manager or supervisor. The decision on how many SM roles are needed and to whom they are given is left to the AEDM based on how the business is run.

The Driver and Vehicle Standards Agency (DVSA), on behalf of the Secretary of State appoints authorised examiners and designated councils to carry out inspections known generally as MOT tests. The following sections set out the application procedure and requirements that must be met.

This section should be read in conjunction with the requirements for authorisation for authorised examiners

This section details the requirements for those applying to have a site approved as a VTS or seeking approval for changes to an existing VTS. It covers:

- how to apply

- application enclosures

- requirements for premises

- equipment requirements

- MOT testing signs and notices

- acceptable variations to layout and equipment

Applicants are advised not to proceed with alterations to buildings or purchase of equipment, etc, before receiving written approval in principle from DVSA.

How to apply

Applications must be made on the current Application for MOT Authorisation Form (VT01). All relevant sections should be completed, and the signed form returned to DVSA along with any requested enclosures as outlined in this section.

Where possible application enclosures, for example plans and drawings, should be supplied in a digital format. Those applying should not submit their application until confident that it will fully meet all the requirements, approval to test will only be granted to applicants who also meet the requirements to be an authorised examiner or are already authorised.

The requirements in this section should be read in conjunction with the class specific requirements for class(es) approval is sought and the list of acceptable equipment.

If the applicant proposes to carry out building alterations or obtain new equipment, it’s recommended that this is not done before DVSA has given approval in principle to the application.

Solicitors that submit evidence on behalf of the applicant must be governed by the Solicitors Regulator Authority (England and Wales) or the Law Society of Scotland (Scotland).

Application enclosures

Applications for a new site to be approved for testing or alterations to existing sites will need to be supported by the following evidence:

- site plan showing the buildings, the location of the testing bay, the access from and to the public highway and the location of the MOT notice board

- a fully dimensioned drawing of the proposed testing bay, or bays, showing adjacent equipment and parts of the building, the location of the test equipment, the position and dimensions of the entrances and exits, and the area from which the test may be observed

- planning permission or an exemption, such as a Certificate of Lawful Existing Use or Development (CLEUD), or written confirmation from the local authority. A letter from a solicitor confirming that the existing approval covers MOT testing or garage services and vehicle repair may be accepted.

The plan and drawings must show that the site will meet the requirements outlined in this section and the requirements for the class(es) approval to test is sought.

Requirements for premises

For a site to be considered for approval it must provide the following.

Premises

The premises must have:

- test facilities housed in a weatherproof building capable of being totally enclosed and provide a satisfactory working area – this is not mandatory for roller brake test or headlamp aim standing area on class 3, 4, 5 and 7 authorisations

- equipment laid out so that testing can be performed effectively – the equipment should be laid out and located so that other garage activities will not affect the proper conduct of the test

- unobstructed, safe and easy access via a metalled road from the site entrance to the building entrance

- adequate off-road parking

- a clearly defined weatherproof viewing area from which all stages of the MOT test in progress can be observed safely without interruption, except for road testing (room for 2 seated people is considered sufficient)

- a sign installed in the customer reception area to alert presenters of vehicles for MOT tests of the presence of the MOT viewing area

- safe access from the customer reception to the designated viewing area if the viewing area is to be located in the workshop

Alternatively, you may opt to install a fixed display monitor in the customer reception or waiting area to display camera relayed ‘live feed’ images of the whole of the test bay area. The image displayed on the monitor must be in colour and of good quality but must not be recorded.

If monitors are used:

- the monitor must be identified as the MOT viewing facility/area

- the monitor must be available to view the test when requested by the vehicle presenter

- the relayed images cannot be interrupted or used for other purposes during that period, for example displaying advertisements

Supplementary monitors (such as portable handheld devices) are acceptable only when a fixed viewing monitor is also available and functional.

Test bay

The test bay must have:

- clear unobstructed access and egress from the entrance of the building

- vehicle entrances and exits that conform to the dimensions applicable to the class(es) for which authorisation is sought

- a width which conforms to the dimensions applicable to the class(es) which authorisation is sought. Minor intrusions such as wall piers may encroach on these dimensions provided vehicle testing is not impeded. Minor intrusion means any part of the building structure or other fixtures which come within the minimum bay outline.

- they must be so positioned that vehicle movement and the recommended method of inspection are not impeded

- items of equipment other than the brake tester console and a desk surface for MOT purposes are not normally permitted

- headroom which conforms to the dimensions applicable to the class(es) for which authorisation is sought

- adequate general illumination. There must be sufficient artificial lighting to enable testing to be carried out without difficulty

Layout

The layout must:

- conform to the requirements of the class(es) for which authorisation is sought

- have at least 600mm clearance between the outer edges of equipment in adjacent bays on side by side layouts

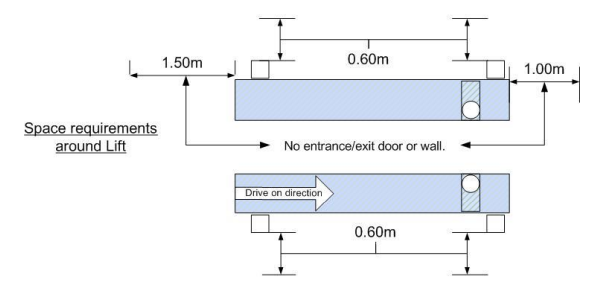

- have at least 600mm clearance around all parts of a lift, including control boxes

- have a clearance of at least 1.0m forwards of the non drive on end and 1.5m to the rear of the drive on end of a lift or pit to any entrance/exit door or wall

MOT testing distraction or disruption

Where there is an increased likelihood of distraction and disruption to MOT tests when bays are not separated by walls, for example from other activities on the premises.

New applicants should be aware that where DVSA considers there may be a risk of testing distraction or disruption, they may be asked to clearly paint the outline of the boundaries of the test bays in open plan workshops/premises.

Test bays must then be kept clear of all non-MOT testing activities and equipment when testing is in progress

Existing testing stations that make alterations increasing the likelihood of testing distraction or disruption may be required to comply with the above paragraphs

Equipment requirements

Major equipment

A testing station needs a means of allowing the underside of vehicles to be properly examined without obstruction or hindrance. This will need to be fitted with steering and suspension play detectors on the DVSA list of acceptable equipment if it’s an Automated Test Lane (ATL) or One Person Test Lanes (OPTL).

A testing station may be permitted to have more than one underside inspection facility which share the same brake tester, headlamp testing area and emissions equipment providing:

- the underside facilities are located so that testing can be carried out effectively

- the additional underside facility meets the requirements for the class(es) tested and does not adversely affect the standard of the test

- if the additional underside facility is used as a headlamp standing area then it must have a dedicated headlamp aim tester unless the rails are continuous across all bays. The facility must also meet all the requirements associated with headlamp testing, including level and calibration certificates

- the viewing area has an unrestricted view of all the testing facilities - if this cannot be achieved from one viewing area then additional viewing areas must be provided

A testing station also needs:

- a headlamp aim testing facility

- brake testing equipment

- emissions testing equipment (excluding motor bicycles)

All testing equipment must be kept in good working order. Measuring apparatus must be calibrated in accordance with DVSA’s requirements. If an item of mandatory test equipment is not recalibrated by its due date, then testing which uses that item will be prevented until the item is recalibrated.

Miscellaneous equipment

A testing station also needs:

- a tyre tread depth gauge selected from DVSA’s latest list of acceptable equipment

- a corrosion assessment tool

- suitable pinch bars, long and short (not applicable to class 1 and 2)

- a steel tape measure (minimum extended length 1.0m)

- suitable wheel chocks for the class(es) of vehicle to be tested (not applicable class 1 and 2)

- brake pedal application device from the DVSA list of acceptable equipment (only mandatory for ATL and OPTL installations)

- suitably positioned mirrors or colour camera system for lighting checks (only mandatory for ATL and OPTL installations)

- a suitable handheld low voltage inspection lamp

- a 13 Pin Trailer Socket Test Tool from the DVSA approved equipment list (not applicable to class 1 and 2)

- a proprietary leak detection spray which meets BS EN 14291:2004 (not applicable to class 1 and 2)

MOT testing signs and notices

The three triangles MOT sign detailed in The Traffic Signs Regulations and General Directions 2016, Schedule 11, diagram 864 must be displayed in a prominent position, no part higher than 4.5m from the ground and no more than one sign on each road frontage.

The business trading name as described within either the Companies or the Business Names Acts is displayed conspicuous and legibly.

A notice board with a protective transparent covering must be positioned inside the vehicle testing station so that DVSA notices can be easily read by any persons intending to or submitting vehicles for test.

The MOT notice board must not be obscured or be inaccessible and must be of sufficient size to accommodate at least one A3 fees poster (landscape) and one Certificate of Authorisation (A4 portrait). It must not be used for any other purpose other than official DVSA MOT notices and company public liability insurance and certificates of incorporation.

If the notice board displays both MOT and business documents, there must be clear and distinct separation between the MOT documents and any documents not related to MOT testing.

All authorised examiners (AEs) must display:

- the certificate of authorisation (VT9) issued by DVSA

- the current fees and appeals poster (form VT9A) showing vehicle classes, test fees and appeals procedure and the details of how to contact DVSA

The current fees and appeals poster may be displayed adjacent to the ‘official’ notice board if it will not fit on the notice board proper. Additional copies of this poster can be obtained online.

Acceptable variations to layout and equipment

Provided there is no change in the class of vehicles tested, particular variations will be allowed for authorised examiners and applicants as shown below.

For existing authorised examiners

For existing authorised examiners moving their test bay or equipment within their present building(s), the test bay and equipment layout of these existing authorised examiners will be considered suitable if they meet the requirements as laid down above, except where it would be impossible to do so without major structural alteration, such as significant work to the roof, floor or loadbearing walls.

Test equipment requirements will be considered met if the existing authorised examiner retains their current equipment. If new equipment is obtained, it must meet the current relevant requirements.

For new applicants or existing authorised examiners moving into previously authorised premises using an existing test bay

For new applicants or existing authorised examiners moving into previously authorised premises using an existing test bay, provided a full test has been carried out and recorded on the MOT testing service by a tester at the site within the previous 12 months, the test bay and equipment layout of new applicants moving into previously authorised premises will be considered suitable if they meet the requirements for authorisation (previously Conditions of Appointment) that were current when the site was last accepted. Occasionally, certain updates will have to be complied with for example test equipment, tools. Advice should be sought from DVSA at the initial inspection.

Test equipment requirements will be considered met if the equipment last used for MOT testing is retained, provided that it’s still in full working order. However, any changes to required equipment that would have been necessary had the premises been in continuous testing must also be complied with.

MOT connected equipment as specified on DVSA’s latest list of acceptable equipment must be fitted and used when:

- applying to open a new MOT centre

- reopen a closed MOT centre (this applies regardless of how long it’s been closed)

- a MOT centre changes from one authorised examiner to another

- replacing previously authorised equipment

- adding an extra test lane (where changes include the installation of equipment that needs to be connected)

The Salter type brake meter (pull along brake tester) is not acceptable for new or reauthorisations.

Authorised examiners and new applicants in remote rural areas

The premises, equipment layout and equipment of authorised examiners and new applicants in remote rural areas will be considered suitable if the requirements are met in DVSA’s view as far as is reasonably possible.

To be considered for remote rural area status:

- the premises must be 15 miles or more by road from a testing station that meets the specification as laid down or as varied above.

- not more than 350 tests per year are likely to be carried out

Equipment awaiting approval

Brake and headlamp test equipment will normally be selected from DVSA’s latest list of acceptable equipment.

All applicants that wish to use any equipment not on DVSA’s list of acceptable equipment will be referred to DVSA

Exceptionally, where a manufacturer has sought acceptance of their equipment but DVSA has not assessed its suitability, applicants may use equipment not on the list of acceptable equipment, provided the application is supported by:

- a certificate signed by the manufacturer, or recognised agent in the case of imported equipment, that it meets the performance specification and is correctly installed

- an undertaking signed by the applicant that they will cease testing until the equipment is replaced or modified if subsequently DVSA decides that it does not meet its specification, or it’s not correctly installed (this would normally be three months)

Installation and equipment requirements

November 2009

DVSA, on behalf of the Secretary of State, appoints authorised examiners and designated councils to carry out inspections known generally as MOT tests. The following section sets out the additional requirements that must be met for testing Class 1 and 2 vehicles.

This section should be read in conjunction with the requirements for authorisation for a vehicle test station (common to all classes) and requirements for authorisation for authorised examiners

The dimensions in this section are the minimum requirements for authorisation as a vehicle test station for class 1 and 2 vehicles.

The dimensions of your test bay should take into account the requirements of your business.

When considering the contents of this document you should be aware that the equipment and/or layout selected may affect the type of vehicle able to be tested.

Applicants are advised not to proceed with alterations to buildings or purchase of equipment, etc, before receiving written approval in principle from DVSA.

Premises and test bay

Premises, test bays and equipment will be considered suitable if they meet the requirements laid out in Requirements for Authorisation for Vehicle Testing Station (Common to all Classes).

Test bay

A test bay with:

- an inspection area at least 3.2m wide by 3.7m long by 2.1m high, which must be substantially level and may include the brake test and/or headlamp aim standing area(s)

- vehicle entrances and exits at least 2.3m wide and 2.0m high

General inspection area equipment

Inspection area equipment will be considered suitable if the following are provided:

- wheel alignment checking apparatus comprising two straight bars of at least 2.0m long or two strong cords of at least 2.5m long

- sufficient jacks or stands so that motorcycles without centre stands can have each of their wheels raised clear of the floor independently

The following optional equipment may also be provided:

- a wheel supporting stand or bench capable of lifting the motorcycle to a comfortable working height

- a positively located turning plate which allows the steering to be turned freely from lock to lock

Headlamp aim testing

A headlamp aim testing facility will be considered suitable if it has a rail mounted headlamp tester on DVSA’s latest list of acceptable equipment.

Headlamp aiming screens are no longer acceptable for new authorisations.

Headlamp tester installation

A headlamp tester installation must have:

- a designated clearly marked vehicle standing area at least 2.5m long, 2.0m wide, certified as flat and level to within +/- 6mm - the forward edge of the standing area should be positioned so that it’s in line with the headlamp tester lens

- rails certified as being flat and level to within +/- 2mm and parallel to the forward edge of the standing area - the rails must be straight and the headlamp tester must not have excessive rock

- equipment positioned to take account of the vertical and horizontal location of headlamps tested, the standing area and datum line(s)

- clearance at the rear of the tester optical head to be at least 600mm

The standing area must be durably and clearly marked with a datum line (or lines) at the headlamp tester manufactures operational tolerance limits for positioning the vehicle headlamp in relation to the headlamp tester. A centre line on the standing area at right angles to the datum line is required.

The certificate for the above must show height measurements from a level plane at all intersecting points on a 300mm (max) square grid covering the standing area and at points 300mm apart on the rails, which must be within the limits stated. It must be signed by a competent person, such as; a surveyor, manufacturer’s representative or agent and include date, status, address of firm and VTS address. A copy must be provided to DVSA for placing on the garage file

Headlamp aim operating instructions

Headlamp aim equipment operating instructions must be available.

Checking the equipment alignment

Suitable arrangements for checking the alignment of the equipment with the standing area must be in place. These may consist of evidence provided by a competent outside agency or by the VTS using the manufacturer’s acceptable equipment. Provision must be made for checks to be carried out at no more than 6 monthly intervals and for records to be kept. It’s acceptable if an alignment check is within the 6th calendar month in which the alignment was last checked.

Brake testing

A brake testing facility will be considered suitable if it has:

- a calibrated decelerometer on DVSA’s latest list of acceptable equipment as approved for Class 1 and 2 testing (mandatory for garages authorised after November 2009)

- either a calibrated roller or plate brake tester that is on DVSA’s latest list of acceptable equipment

Roller brake tester

A roller brake tester (RBT) must be installed so that:

- it is centrally positioned in an area of substantially level floor (which in good building practice is within +/- 12mm of a level plane) at least 4.6m long and 1.2m wide

- the console is positioned so that it can easily be read by the tester performing the test on the machine

Plate brake tester

A plate brake tester (PBT) must be installed so that:

- it is centrally located in a substantially level area, at least 1.5m wide

- there is an unobstructed area of substantially level floor at least 4m long in front of the measuring plate and a similar area at least 2m long behind it. The width of each area must not be less than that in bullet point 1 above and all of these areas must lie within the test bay

- the measuring plate high friction surface to be flush with the floor

Weighing equipment

Suitable calibrated weighing equipment must be available, which may be incorporated into the roller or plate brake tester (weight charts are not acceptable).

Separate weighing equipment will be considered suitable provided:

- it is accurate to +/- 3%

- if weighing one wheel at a time, it must have a minimum capacity of 125kg for Class 1 testing or 250kg for Class 2 testing

- if weighing the whole machine, it must have a minimum capacity of 250kg for Class 1 testing or 500kg for Class 2 testing

Additional brake testing requirements

Operating instructions must be available for the decelerometer and the roller/plate brake tester.

Suitable arrangements for re-calibration of the decelerometer, weighing equipment and either the roller brake or the plate brake tester (whichever is installed). Arrangements for checking calibration may consist of evidence provided either by a competent outside agency or by the VTS using the manufacturer’s acceptable equipment

Installation and equipment requirements

November 2009

DVSA, on behalf of the Secretary of State, appoints authorised examiners and designated councils to carry out inspections known generally as MOT tests. The following section sets out the additional requirements that must be met for testing Class 3 and 4 vehicles.

This section should be read in conjunction with the requirements for authorisation for a vehicle test station (common to all classes) and requirements for authorisation for authorised examiners

The dimensions in this section are the minimum requirements for authorisation as a vehicle test station for class 3 and 4 vehicles.

The dimensions of your test bay should take into account the requirements of your business.

When considering the contents of this document you should be aware that the equipment and/or layout selected may affect the type of vehicle able to be tested.

Applicants are advised not to proceed with alterations to buildings or purchase of equipment, etc, before receiving written approval in principle from DVSA.

Premises, test bay and equipment layout

The test bay and layout dimensions stated are the minimum requirements measured from the inside of walls and doors, as appropriate. If there is a capability to test longer wheel based vehicles, such as if the lift will accommodate more than 3.35m wheelbase and the headlamp standing area is at the minimum requirements then the headlamp standing area dimensions will take precedence and a 3.35m wheelbase would be the longest which could be tested. If a longer dimension is required then all other dimensions must be proportional to this.

Premises, test bays and equipment will be considered suitable if they meet the requirements laid out in Requirements for Authorisation for Vehicle Testing Station (Common to all Classes).

Test bay

A test bay needs:

- vehicle entrances and exits at least 2.4m high by 2.4m wide (for plate brake testers see brake testing section below)

- a width of at least 3.6m. On a side by side layout bay size may overlap providing a 600mm clearance/working space is provided between equipment

- headroom of at least 2.4m (except over a lift - see below)

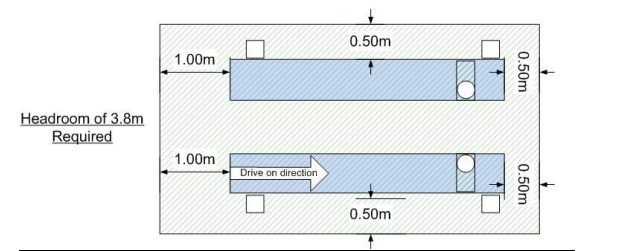

It must have headroom over a lift of at least 3.8m measured from the platform surfaces when fully lowered.

The headroom must extend:

- 500mm further than the outer edges of the lift platforms

- 500mm to the front of the platforms non drive on end

- 1m to the rear of the drive on end of the lift platforms

Equipment layout

Class 4 - Critical lift dimensions

Underside inspection

The designated means of inspecting the underside of vehicles will be considered suitable if either a lift or a pit meeting the following is provided:

Lift

If a wheel supporting platform lift is provided, it must have:

- platforms without upstands or guard rails at least 3.9m long - the platform length does not include access ramps

- rolled edges or vertical rails for jacking equipment that are not more than 25mm higher than the platform.

- platform surfaces capable of being raised at least 1.5m from the floor - this is measured from the floor on which the lift is mounted

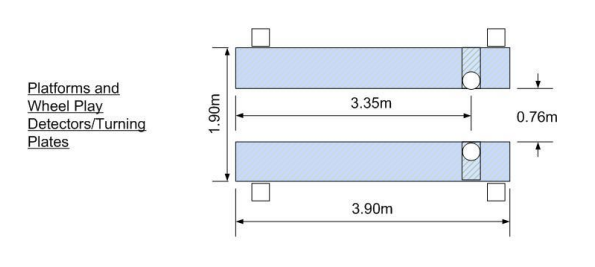

- a minimum of at least 760mm (may be reduced to 600mm if testing narrow track vehicles) between the inner edges of the platforms and at least 1.9m between the outer edges

- a safe working load (SWL) of at least 3 tonnes clearly marked on the lift

- jacking equipment clearly marked with a minimum SWL of 1.5 tonnes, capable of simultaneously raising both front or both rear wheels using the recommended test procedures and jacking points - it must also be capable of lifting vehicles fitted with independent suspension (duplicated jacking equipment is acceptable)

- captive bearing based turning plates, positively secured to the platforms, which permit the steered wheels to be turned freely from lock to lock - the turning plates must move laterally across the full platform width - when installed there must be a minimum distance of 3.35m from the centre of the turning plates to the drive on end of lift platform

- chocks that operate automatically when the lift is raised - the 3.35m dimension for turning plates must not interfere with operation of the chocks - on non drive through layouts permanent chocks may be fitted to the non drive on end

Changes to jacking equipment specifications from 1 April 2026

If you apply to open a new MOT centre or make changes to an existing centre from 1 April 2026, your jacking equipment must have a:

- minimum safe working load of 2 tonnes

- distance of at least 1,700mm between the centre of the lifting pads

You can find the full details in MOT special notice on changes to jacking equipment specifications.

You should have confirmation in writing by the lift installer that the installation of the lift complies with BS 7980:2024. A current LOLER thorough examination certificate. Vehicle lifts should be CE and or UKCA marked. Any modifications to existing vehicle lifts should conform to BS 7980:2024 and BS EN 1493:2022 regarding safety distances for toe protection.

If a scissor lift is used, the scissors must be located underneath the platforms, allowing unobstructed access between them.

An automated test lane (ATL) or one person test lane (OPTL) needs:

- wheel play detectors from the DVSA list of acceptable equipment, securely fixed to the lift

- at least 3.35m from the drive on end of the lift platforms to the centre line of the wheel play detectors. The 3.35m dimension for wheel play detectors must not interfere with operation of the chocks

- written declaration from the hoist manufacturer (not installer) that the hoist is suitable to be fitted with wheel play detectors

Pit

If a pit is provided, it must have:

- an uninterrupted working length of at least 3.9m

- a width of at least 760mm and not more than 920mm over the working length measured across both pit walls (this may be extended up to 1300mm if used in combination with Class 7)

- a depth of at least 1.5m and not more than 1.8m, over the working length. Staging may be used to meet this requirement

- adequate access for personnel which does not intrude on the working dimensions. Access steps may encroach on the required dimensions to an entrance/exit door or wall provided there is a minimum clearance width of not less than 600mm

- been sealed to prevent the ingress of water

- jacking equipment as required for a lift. Rolled edges and vertical rails for jacking equipment must not exceed 25mm height

- captive bearing based turning plates, positively secured to the floor which permits the steered wheels to be turned freely from lock to lock

If it has an ATL or OPTL, it must have combined steering and wheel play detectors on DVSA’s list of acceptable equipment. No part of the installation should be within 1.5m of the pit working length drive on end.

The location of turning plates and play detectors must be that the tester has adequate space to safely inspect all the items required when stood in the pit.

Headlamp aim testing

A headlamp aim testing facility will be considered suitable if it has a calibrated rail mounted 2005 specification headlamp tester on DVSA’s latest list of acceptable equipment.

Headlamp tester installation

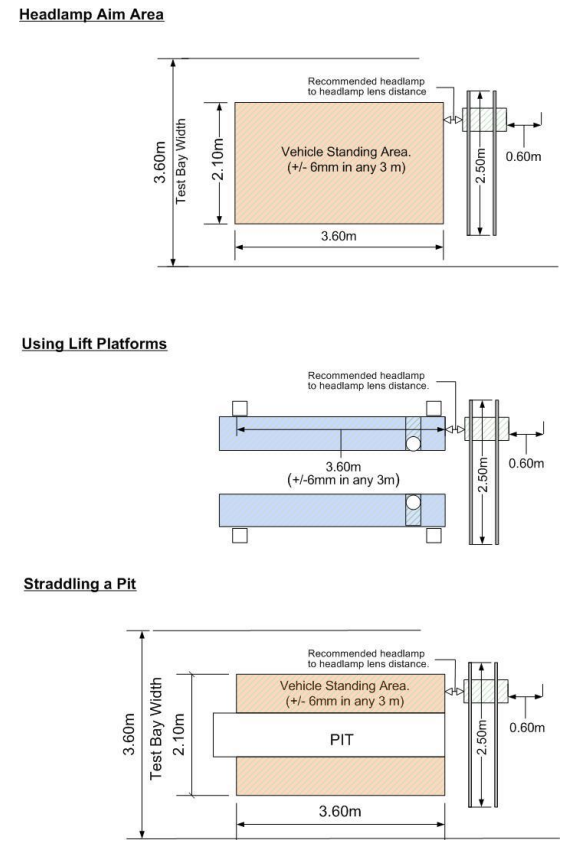

A headlamp tester installation must have a designated vehicle standing area which is certified as flat and level to within +/- 6mm in any 3m.

It must have a clearly outlined area of floor 3.6m long measured from the datum line by 2.1m wide, which may:

- be the lift platforms (lift platforms must rest on positive stops when lowered)

- straddle a pit or roller brake tester

- be the plates of a plate brake tester

If during headlamp testing vehicle wheels rest on turning plates which are not longitudinally adjustable by at least 600mm, they must be within the +/- 6mm limits.

Additional equipment fitted in the standing area must comply with the +/- 6mm level requirements.

The headlamp tester installation must have rails certified as level to within +/- 2mm and parallel to the standing area. The rails must be straight and the headlamp tester must not have significant rock or twist at any point along the rails.

The certificate for the above must show height measurement from a level plane at all intersecting points on a 300mm (max) square grid covering the standing area and at points 300mm (max) apart on the rails. It must be signed by a competent person, such as a surveyor, manufacturer’s representative or agent and include date, status, address of firm and VTS address. A copy must be provided to DVSA for the garage file.

The headlamp aim tester must have 600mm clearance behind the headlamp aim tester optical head. Floor mounted equipment must not be installed in this area.

The standing area must be durably and clearly marked with a datum line (or lines) at the headlamp tester manufactures operational tolerance limits for positioning the vehicle headlamp in relation to the headlamp tester.

Headlamp aim equipment operating instructions must be available .

Headlamp aim tester drawings

Class 4 - Headlamp aim dimensions

Brake testing

Brake testing equipment will be considered suitable if the following are provided:

- a calibrated decelerometer on DVSA’s latest list of acceptable equipment

- a calibrated roller brake tester or a calibrated plate brake tester that is on DVSA’s latest list of acceptable equipment - if it’s being used on an ATL lane, it needs to be approved for ATL use on DVSA’s latest list of acceptable equipment

- roller/plate brake tester user/operator instructions

Roller brake tester

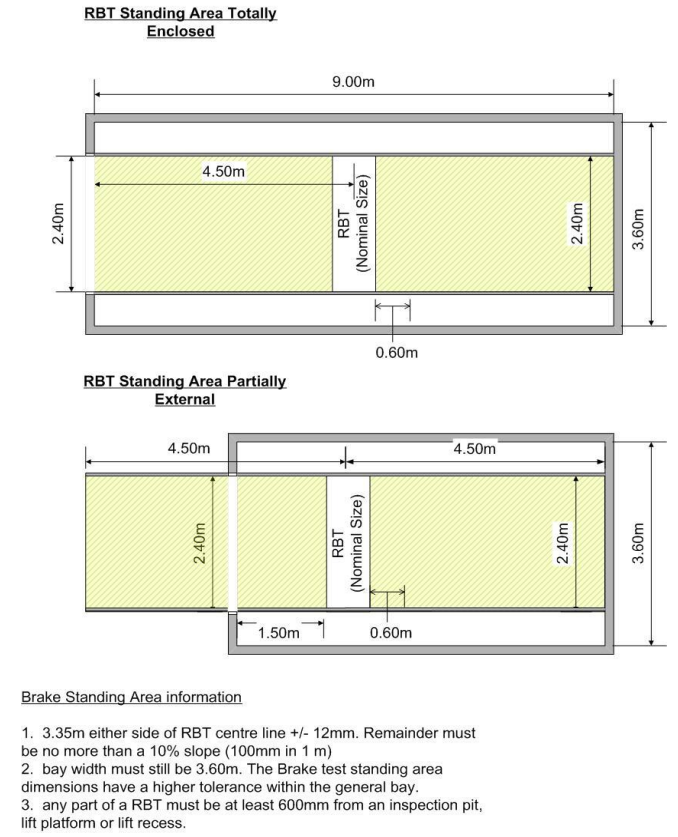

A roller brake tester (RBT) must be installed so that it is centrally located in an unobstructed working area at least 9.0m long and at least 2.4m wide. At least 3.35m to the front and rear of the RBT centre line should be substantially level (which in good building practice is within +/- 12mm of a level plane). The remainder of the area must not exceed a 10% slope (100mm in 1m).

Part of the brake testing standing area can be outside the building, providing the first part of the RBT floor plate is at least 1.5m inside the building (where a doorway meets the class 7 width requirement then the 1.5m can be measured from the RBT centre line).

Where part of the roller brake test vehicle standing area is located outside of the building, the standing area must not encroach any public thoroughfare.

In the case of a ‘drive-through’ layout where the roller brake tester is fitted after the lift or pit there shall be a clear distance of at least 3.35m between lift platforms and the RBT centre line. Lead-off ramps from floor mounted lifts shall not encroach on this area.

You must also make sure that the RBT is installed so that:

- any part of a roller brake tester is at least 600mm from an inspection pit, lift platform or lift recess (except cross pit rollers)

- it is in accordance with the manufacturer’s instructions

- the console is positioned to be easily read whilst performing the test

- when a cross-pit RBT is installed there must be an isolator that prevents operation of the RBT when a person is in the pit - it must be positioned so other equipment will not interfere with brake testing. i.e. turning plates

Plate brake tester

A plate brake tester (PBT) must be installed so that:

- it is certified as installed in accordance with the manufacturer’s instructions

- the plates are centrally located in a substantially level test area which (including approach and run-off area) is at least 3.0m wide

- a clear area of 4.5m shall be provided in advance of the plate brake tester. This area must be substantially level and any gradient must not exceed 5% (50mm in 1m) nor the equipment positioned within it. All or part of the 4.5m can be outside the building. Where it is perceived that there may be a safety risk, barriers and/or warning signs may be required along the approach area and/or the run off area

- doorways positioned within the 4.5m approach area must be at least 3m wide

- where the plate surface is not flush with the surrounding floor, lead on and off ramps must be located at least 600mm from any doorway

- a clear run off distance of 3.0m shall be provided after the PBT working surface (this must not include any part of the lift or lead on ramps)

- in the case of a ‘drive-through’ layout where the plate tester is fitted AFTER the lift or pit there shall be a clear distance of 4.5m between them. Lead-off ramps from floor mounted lifts shall not encroach on this area

- the console is positioned to be easily read whilst performing the test

Brake tester standing area drawings

Class 4 - Brake standing area dimensions

Emissions testing

All class 4 testing stations must have the following emissions testing equipment.

Spark ignition engine emissions

Exhaust gas analysis equipment will be considered suitable for all spark ignition engine vehicles if the following is provided:

- a calibrated exhaust gas analyser on DVSA’s latest list of acceptable equipment suitable for all spark ignition vehicles

- gas analyser user/operator instructions

- confirmation that the analyser contains the current up to date database

Diesel engine emissions

Diesel smoke test equipment will be considered suitable if the following is provided:

- a calibrated diesel smoke meter on DVSA’s latest list of acceptable equipment

- smoke meter user/operator instructions

Connected equipment

Some types of MOT equipment are enabled to transfer test results from the test equipment to the MOT testing service (MTS).

The equipment types this applies to are:

| Equipment type | Mandatory from | Classes | ||

|---|---|---|---|---|

| Roller brake testers | 1 October 2019 | 4, 5, 7 | ||

| Decelerometers | 1 February 2020 | 4, 5, 7 | ||

| Exhaust gas analysers | 1 May 2021 | 4, 5, 7 | ||

| Diesel smoke meters | 1 May 2021 | 4, 5, 7 |

Who needs connected equipment

Connected equipment is required to be fitted and used by a garage where approval is sought:

- for a garage that hasn’t previously conducted MOT tests (new)

- for a currently testing VTS that is undergoing a change of ownership (where the site is transferred to a different AE)

- at a garage that has previously been a MOT test station but has ceased to test (regardless of how long ago it tested)

It will also be required if a VTS is:

- making a voluntary upgrade of a piece of equipment listed in the table in a VTS

- adding an additional test lane including a piece of equipment listed in the table

- replacing broken equipment listed in the table

Where either an Exhaust Gas Analyser or a Diesel Smoke Meter that a part of a combined unit is replaced by the same make and model this is classed as a repair to the combination unit.

How to connect equipment to the MOT service

A software code (a key) is required to connect the equipment to the MOT testing service. The key can be requested by the AEDM, AE Delegate or Site Manager via the MOT testing service using the ‘Request a key’ link.

The key should be kept securely and given to the installation engineer who will connect the equipment to the MOT testing service.

A check must be made on the first test after the equipment is installed that the results have been sent through to the MOT testing service.

Contact the equipment supplier immediately if results are not sent through.

Class 3 only testing

Where only Class 3 testing is conducted the requirements for Class 4 are varied as follows:

Premises

There are no variations to the premises requirements - they are the same as those for class 4

Test bay

The test bay must have:

- vehicle entrances and exits at least 2.3m wide and 2.0m high

- bay width at least 3.2m

- bay headroom at least 2.1m

- headroom over a lift of at least 3.2m

Equipment layout

There must be a clearance of at least 900mm to the front and rear of a lift or pit to any entrance/exit door or wall.

Lift

The lift must have:

- platforms at least 3.00m long

- a safe working load (SWL) of at least 1.5 tonnes clearly marked on the lift

- a suitable method of supporting the ‘single wheel’ of any three wheeled vehicle on a firm surface with a captive bearing based turning plate - a SWL of at least 500kg must be clearly marked on the support

- jacking equipment clearly marked with a minimum SWL of 500kg

- captive bearing based turning plates, positively secured to the platforms, which permit the steered wheels to be turned freely from lock to lock - the turning plates must move laterally across the full platform width

- when installed there must be a minimum distance of 2.35m from the centre of the turning plates to the drive on end of lift platforms

Pit

The pit must have:

- an uninterrupted working length of at least 3.0m with a single bridge and turning plate

- a suitable method of supporting the ‘single wheel’ of any three wheeled vehicle on a firm surface with a captive bearing based turning plate - a safe working load SWL of at least 500kg must be clearly marked on the support

- jacking equipment clearly marked with a minimum SWL of 500kg

Headlamp aim testing

It must have a designated vehicle standing area at least 3.0m long and 1.8m wide.

Brake testing

It must have a calibrated Category A decelerometer on DVSA’s latest list of acceptable equipment.

A roller brake tester must be installed so that it is centrally located in an unobstructed working area at least 7m long and 3.2m wide.

A plate brake tester must be installed so that:

- it is located in a substantially level test area which (including the approach and run-off area) is at least 3.6m wide.

- it is situated with at least 2.0m clear space, on the side of the measuring plate, from the PBT centre line

- doorways positioned within the 4.5m approach to the plate brake tester must be at least 3.6m in width (to enable vehicles to be off-set to test the single wheeled axle)

The brake testing facility must be able to cater with either a single front or rear wheel configuration.

Emissions testing

Emissions testing is not required for Class 3 testing.

Dual class premises (Class 3 and 4)

Premises and equipment considered suitable for Class 4 testing will also be accepted for Class 3, and 3-wheeled Class 4 testing if the underside inspection facility has a suitable method of supporting the ‘single wheel’ of any three wheeled vehicle on a firm surface and on a turning plate. A single wheel support must cater for single front or rear wheel configuration and there must be acceptable arrangements for testing headlamp aim, if applicable, for both wheel layouts.