Timber in construction roadmap

Updated 28 December 2023

Applies to England

Photo credit: Forestry Commission

Ministerial foreword

Alongside increasing tree planting rates, we need to make good use of the timber arising from the trees we grow, both hardwood and softwood. We have identified that increased use of timber in the construction industry would make a significant difference to stimulate demand for domestic planting stock in England.

Increasing our home grown supply of wood, importantly, will reduce our reliance on imported timber. More and safe use of timber in construction will be a key step in supporting the forestry and wood processing sectors to grow and innovate, creating new green jobs and helping level up rural economies.

We have committed to growing and maintaining a sustainable and long-term supply of domestic timber and wood products in the 2023 Environmental Improvement Plan. We have awarded £7.6 million through the Woodlands into Management Forestry Innovation Funds to develop new technologies and working practices that boost homegrown timber. Our new statutory woodland cover target to increase tree canopy and woodland cover in England to 16.5% by 2050 will also stimulate tree planting of both hard and softwoods.

Alongside these benefits utilising timber in the built environment will support progress towards the Net Zero Target. The built environment is responsible for approximately 25% of total UK greenhouse gas emissions. Reducing these emissions is a priority for government, in order to deliver our carbon budgets and net zero target. The Net Zero Strategy set out our plans for decarbonising whilst growing the economy, and further detail was published in Powering Up Britain earlier this year.

Archaeological evidence indicates that we have been using timber as a building material in the UK since the Mesolithic era. Parliament’s very own Westminster Hall is a fantastic case in point, boasting the largest medieval timber roof in Northern Europe – and this document signals the next evolution in our use of timber and wood products to meet changing societal priorities.

Exciting initiatives such as the Department for Education’s Gen Zero project, which has created a prototype ultra-low carbon classroom from UK sourced and manufactured timber products, show the opportunity to connect people with our nation’s forests in new ways - through the very fabric of the buildings they live, study and work in.

We recognise that an increase in demand for timber can be encouraged by strong market signals from government and a conscious shift from industry to use alternative materials. This document sets out actions to drive demand for domestic timber in the construction sector supporting delivery of our new statutory woodland cover target and creating new green jobs in our forestry and wood processing sectors.

This document has been co-created with significant input from industry partners and academia and sets out the actions needed to ensure we can safely utilise timber in construction as part of this decarbonisation journey.

It sits alongside wider government-industry action on industrial decarbonisation, such as the ongoing work on the decarbonisation of cement as well as the publication of the low carbon concrete routemap and the establishment of the Low Carbon Concrete Group, which has been led by the Green Construction Board. It is important that the actions we take on timber are aligned to this wider work, for example encouraging hybrid building design that makes the best use of all building material.

I hope this publication supports the production and use of our home-grown timber whilst boosting associated jobs throughout the country. I look forward to seeing an increasing number of timber framed homes, public buildings and offices being built into the future. I want to thank all stakeholders for their input in creating this document and look forward to continuing to work together to implement the actions outlined within it.

Rebecca Pow, Parliamentary Under Secretary of State (Minister for Nature)

Executive summary

Government has introduced a statutory tree and woodland cover target which commits to increasing the tree canopy and woodland cover in England to 16.5% by 2050. But not only do we need to plant trees, we also need to make good use of the materials they provide to us. We have therefore also committed in the Net Zero Strategy, the England Trees Action Plan and the 2023 Environmental Improvement Plan to increase the safe use of timber in construction (TiC) in England, to help reduce embodied carbon in the built environment and drive investment into tree planting, forest management and domestic supply chains, creating new green jobs and industries.

We need to promote the use of safe, best practice, high performing timber construction that will provide the most benefit in supporting delivery of the net zero pathway, alongside other low carbon products and resource efficiency measures.

We must also ensure that any increases in the use of timber are sustainable and do not contribute to greater rates of global forest degradation or deforestation.

The document outlines the opportunities and barriers to the use of timber in construction in England, centred around seven priority themes:

- priority theme 1: improving data on timber and whole life carbon

- priority theme 2: promoting the safe, sustainable use of timber as a construction material

- priority theme 3: increasing skills, capacity, and competency across the supply chain

- priority theme 4: increasing the sustainable supply of timber

- priority theme 5: addressing fire safety and durability concerns to safely expand the use of engineered mass timber

- priority theme 6: increasing collaboration with insurers, lenders, and warranty providers

- priority theme 7: promoting innovation and high performing timber construction systems

Introduction

We prize our forests and trees for their beauty and as homes to our native flora and fauna. We have also become more and more appreciative of woodlands’ contribution to climate change, sequestering carbon emissions from the air, and helping us to adapt to more extreme weather. Woodlands can shade our rivers from overheating and slow the flow of rain to reduce flooding. In addition to all these contributions to our lives, woodlands have vast untapped potential to grow our economics and help our buildings – homes, schools and more – to transition to a net zero future.

Timber in construction can reduce the Whole Life Carbon, the full carbon impact, of our built environment. The carbon impact of the built environment is made up of both operational carbon from the type of energy or heating systems within the building and the embodied carbon resulting from the manufacture, maintenance and disposal of the construction products that comprise the building or structure. Use of timber can reduce the embodied emissions in a single building by 20% to 60%.

Where timber has been harvested from sustainably managed forests, timber products also act as a carbon store, locking away carbon for the duration of that product’s life, (and the life of any recycled wood products made from the original product). At the individual building level, carbon storage is approximately 50% higher in timber framed homes than in masonry homes and can be up to 400% higher for larger buildings that use engineered timber products such as Cross-Laminated Timber (CLT) instead of concrete.

As part of our efforts to achieve net zero by 2050, government has committed in the England Trees Action Plan to increase tree planting rates across the UK to 30,000 hectares a year by the end of this Parliament. In 2023 government also introduced a statutory tree and woodland cover target which commits to increasing the tree canopy and woodland cover in England to 16.5% by 2050. Increased safe use of timber in construction in England will create an opportunity to increase demand for domestic timber, creating new green jobs, as well as stimulating further investment into domestic timber and wood processing supply chains.

Only 9% of English new build homes were timber framed in 2019 in contrast to Scotland where this figure was 92%. With England’s low rates of building with timber relative to other countries, there is an opportunity to unlock this industry at scale and at speed.

As a result of this, the Climate Change Committee recommended that government develop new policies to increase the use of wood in construction. Government subsequently committed in the England Trees Action Plan, Net Zero Strategy and Environmental Improvement Plan to create a document for increasing the safe use of timber in construction in England.

This document assesses both the opportunities and constraints for increasing the safe use of timber in construction in England and should be considered alongside wider government-industry initiatives for industrial decarbonisation, such as the low carbon concrete route map, led by the Green Construction Board.

Timber as a construction material

Timber has a wide range of both structural and non-structural uses in construction.

Structural timber

Structural timber relates to using timber in the load bearing structure of a building.

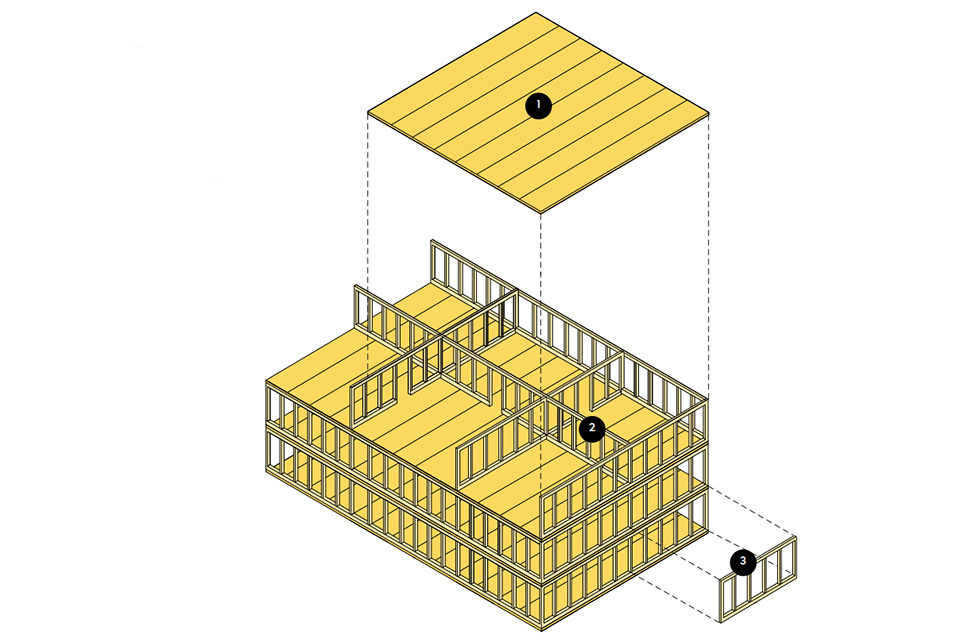

Diagram 1: Timber frame system structural components (source: Timber Typologies - Waugh Thistleton Architects/Timber Development UK 2023)

- Floor panels

- Internal walls

- External walls

The most established use of structural timber in England is in open or closed panel timber frame systems manufactured off site (although there are also other forms of timber frame such as post and beam construction). Diagram 1 shows the structural components and assembly of a timber frame system.

Mass timber systems

Mass timber systems are an emerging form of timber construction in England, with UK expertise helping to identify best practice in mass timber design. They use engineered mass timber products, and by virtue of the laminations also stronger, stiffer and more consistent. This opens up opportunities for its use larger open internal spaces, such as in offices or retail and leisure buildings.

Modular or volumetric timber systems

Modular or volumetric timber systems are another emerging form of timber construction in England (although more commonly used in other parts of the world). They are used in house building, flats and hotels. In volumetric systems, 3D modules are assembled in a factory to set specifications including insulation, windows, doors and other internal fittings before being assembled at the construction site.

Trussed rafter roofs or roof trusses

Trussed rafter roofs or roof trusses are another form of structural timber, most commonly made from sawn timber connected by metal plates in a factory. This has been a very common form of roof construction in the UK since the 1960s.

Wider non-structural uses of timber in construction

Timber also has a wide range of non-structural uses, including flooring, framing of internal partitions, doors, windows and stairs. It is also used extensively as part of the construction process itself, for example in temporary works and wood pallets. These uses form a key part of the wood value chain by utilising sawn wood from smaller logs that would not be suitable for structural purposes. Similarly, wood fibre, taken from waste wood and sawmill coproducts, can also be used to make insulation boards and quilting for walls, roofing and below floor screeds. Wood-based panel products (OSB, particleboard, MDF and plywood) are used as part of the structural timber frame (for example as sheathing and as part of i-joists) as well as having a range of non-structural uses (for example flooring, cladding and stairs).

Priority themes

This document has been divided into seven priority themes which must be addressed to increase use of timber in construction in England in a safe, targeted and sustainable way. These themes have been identified through discussion with the Timber in Construction Working Group members and through a systems map survey assessing views of barriers to timber construction in England across the supply chain.

Priority theme 1: improving data on timber and whole life carbon

Efforts to reduce the embodied carbon emissions of new builds are a key driver for the increased use of timber in construction in England. In the Net Zero Strategy, government committed to help the construction sector improve reporting on embodied carbon in buildings and committed to exploring the potential of maximum embodied carbon levels in new buildings in the future.

Approach to measurement is central to this and industry standards for whole life carbon assessment methodology (BS EN 15978) and for producing Environmental Product declarations (BS EN 15804) already exist. Sector led initiatives to address embodied carbon emissions are also already underway, such as the Future Homes Hub’s Embodied and Whole Life Carbon: 2023 to 2025 Implementation plan for the homebuilding industry, the update to the Royal Institute of Chartered Surveyors (RICS) Professional Statement for assessing whole life carbon in the built environment, and the development of the Built Environment Carbon Database.

As part of gathering this evidence base, we need to ensure that the carbon impact data for all construction materials, including timber, is robust and used consistently. For timber specifically, this includes ensuring that environmental product declaration data for timber products is comprehensive and consistent; understanding the impact of timber construction on a building’s lifespan and subsequent impact on demolition or construction rates and associated carbon emissions; and understanding the impact of timber construction on transport emissions.

The treatment of construction products at the end of a building’s life can also have a significant impact on the overall carbon impact of that product. Government has set out its aims to reduce construction waste and increase the reuse of construction materials at their highest value in the 2023 Waste Prevention Programme for England: Maximising Resources, Minimising Waste. Already fewer than 1% of UK timber and wood products go to landfill, which is a significant achievement. However, industry and government need to work together to further increase the opportunities for re-use and recycling of timber, such as promoting new approaches to design.

Government will:

- engage industry and seek advice on our approach to measuring and reducing embodied carbon in new buildings by 2025

- by 2025, explore the potential of embodied carbon limits for buildings in the future

- explore effective and proportionate ways of deploying a broad carbon assessment, including what they should measure, what evidence could underpin them, and how they may be used in a plan-making context or as a tool for assessing individual developments

- work with industry and academia to expand and improve the evidence base for timber and embodied carbon by 2025

- work with industry to explore options to reduce carbon emissions associated with timber construction at “end of life” and encourage greater circularity in the supply chain

Industry will:

- continue voluntary work to measure and reduce embodied carbon through the Future Homes Hub Delivery Plan and through initiatives such as the Built Environment Carbon Database

- encourage the inclusion of data, on projects that use timber, in the Built Environment Carbon Database once it launches in 2024, to enable improved benchmarking and information sharing on the carbon performance of timber construction projects

- improve the quality of timber environmental product declarations (EPDs) by 2028 including through creation of a new, free to use timber EPD database being developed by Timber Development UK

Priority theme 2: promoting the safe, sustainable use of timber as a construction material

A lack of understanding and awareness of the properties of timber as a building material has been highlighted as a challenge. There are misconceptions around the use of timber in the non-structural elements of buildings, such as the cost and maintenance requirements. Despite this, 82% of the public supported the use of wood in construction as a strategy to meet the UK’s net zero commitments at the 2020 UK Citizens Assembly. There is also evidence that private developers and investors are increasingly interested in “green buildings,” including timber buildings. The government committed in the England Trees Action Plan and Net Zero Strategy to increase public demand for sustainably sourced timber through procurement policies.

Industry and government can build on this momentum to promote the appropriate use of timber through already established industry initiatives, such as the Construction Leadership Council’s Construct Zero campaign which promotes low carbon construction more widely. The Department for Education led Gen Zero project created a prototype ultra-low carbon classroom from UK sourced and manufactured timber products. The National Retrofit Strategy has also identified opportunities to use wood and wood products to reduce carbon emissions and improve energy efficiency in existing buildings.

Government will:

- consider options to measure and reduce embodied emissions in major public construction projects as part of the Industrial Deep Decarbonisation Initiative and announce this commitment at COP28. This may include assessing the impacts of this policy on use of timber in government construction projects

- build three small school buildings that use the full GenZero system by 2025

- develop five new-build pathfinder projects which develop key themes taken from GenZero by 2028

- support the use of modern methods of construction (MMC) to deliver quality homes more quickly and more sustainably though Home England’s strategic plan. The plan includes a renewed focus on enabling sustainable homes and places, including delivering more homes that are resource efficient both in-use and across their whole life, with MMC bring key enabler of this (ongoing)

- continue Homes England’s MMC research study to drive innovation in the industry. This research will explore a range of themes and seek to learn lessons about how MMC technologies might be improved upon in future (ongoing)

- work together to assess options and explore opportunities for scaling innovations in housing construction using English timber by 2025

- work with industry and academia to identify opportunities and barriers to the use of timber in retrofit and promote best practice and innovation by 2027

Industry will:

- promote timber through campaigns such as ‘Time for Timber’ and the ‘Transforming Timber’ web platform which showcases collaboration and best practice (ongoing)

Priority theme 3: increasing skills, capacity and competency across the supply chain

Increasing the use of timber in construction will require an appropriately skilled and competent workforce which is confident in the use and application of a range of timber systems. Attracting new entrants and up-skilling and re-skilling existing workforce practitioners will be essential to do this.

Forestry and wood supply

An increase in afforestation to meet the government’s statutory target is likely to lead to an estimated 1,400 additional jobs being required in the nursery and forestry sectors by 2035. However, in recent years, the provision and uptake of forestry-related education at further and higher education levels has fallen considerably. This lack of new entrants, combined with other structural needs in the sector, has created significant challenges in recruiting and retaining skilled professional foresters, supervisors and other operatives. The government is working with the forestry sector to address these issues. For example, through the £2.5million Forestry and Arboriculture Training Fund, which covers the costs of short technical skills courses. Also, government’s support of the Forestry Skills Forum, a cross-sector body which works together to identify and address skills issues in the industry.

Engineering, architecture and design

There is more to be done, but engineering, architecture and design education and training institutions have begun to rise to the challenge of developing innovative and relevant training and guidance, such as:

- New Model Institute for Engineering and Technology (NMITE) will launch a new BSc (Hons) in the Sustainable Built Environment in 2024, which equips people with a deeper insight into timber construction

- The Royal Institute of British Architects (RIBA) launched its 2030 Climate Challenge in 2019

- Timber Development UK (TDUK) and NMITE have also published a Timber in Construction Skills Action Plan, which provides an industry-agreed competency framework outlining essential skills and knowledge for practitioners

- The British Standards Institution (BSI), supported by government, has also developed a suite of Built Environment competence standards to raise competence levels across built environment occupations

- the level 2 wood product manufacturing operative apprenticeship established in 2019, training more people in MMC and related manufacturing skills

Carpentry, joinery, woodworking and timber frame erection or installation

While apprenticeships in carpentry and joinery are widely available and exist at both level 2 and level 3, specific courses focused on timber frame construction are limited and will need to be encouraged. The Structural Timber Association (STA) provides a series of industry specific training, including through its Timber Frame Competency Award Scheme (TFCAS). Educational provision across carpentry, joinery, woodworking and timber frame erection or installation occupations will need to be reviewed to assess where an increase in provision is required to meet future anticipated demand.

Increasing skills and capacity

Key opportunities to increase skills, capacity and competency across the timber construction supply chain are as follows:

- improve visibility of forestry and timber construction as careers or career specialisms at school and throughout further and higher education

- promote Design and Technology (D&T) qualifications in schools and colleges

- expand the workforce to represent all of society, bringing dynamism and new ideas

- develop clear construction career pathways to entice the ambitious

- broker creative solutions to the often more expensive to run apprenticeship and National Vocational Qualification (NVQ) offerings due to the space, specialist equipment and (for forestry) locations required, etc

- broaden the availability of short course modular training provision – increasing the opportunities to up-skill or re-skill the existing workforce

- facilitate apprentice schemes that suit small and medium-sized enterprises, which typify the sector

- collate and bring together new and emerging Continued Professional Development (CPD) requirements – allowing industry to keep pace with advances in forestry practices, timber engineering and design, whole life carbon, retrofit and fire safety, etc

- improve data regarding the number of professionals trained in different skills and modelling of workforce size, skills and competencies required to meet future demand

Industry and government will:

- establish a representative multi-stakeholder industry forum to drive forward initiatives and align existing activity across all timber supply chain professions to close occupational skills gaps and address the growing demand for skilled labour and competent professionals by 2025

- conduct research to quantify additional workforce requirements for a range of scenarios of increased use of timber in construction by December 2024

- work together to better understand and resolve funding challenges in educational provision

- ensure alignment between work to promote timber construction skills with implementation of the wider industry-led Forestry Skills Action Plan

Industry will:

- map routes to competency for each relevant timber occupation, including training and qualification requirements, current levels of training and education provision, and grant and funding availability by 2025

- based on mapping, review curriculums and explore what further training or educational provision (for example, CPD, T Levels, Skills Bootcamps, Apprenticeships, Institutes of Technology engagement, etc.) may be required, including considering the potential merits of creating a timber in construction apprenticeship trailblazer group

- improve its CPD offering to up-skill and re-skill the existing workforce by 2027, including through:

- development of a new toolkit for designers to support and promote timber in efficient design

- launching a Transforming Timber website platform to support the specification of timber construction products

- providing expertise and resources to architects and engineers looking to build with timber via the Structural Timber Association’s technical helpline

- improving timber competency levels across wider stakeholder groups, such as fire risk assessors, fire engineers, building control officers and insurance, warranty and lending professionals

- continue to promote timber-related careers in schools, colleges and more widely, for example through the British Woodworking Federation’s ‘WOW! I made that’ initiative, Go Construct!, Amazing Apprenticeships and the next phase of the Timber Industry College Hubs programme (ongoing)

Priority theme 4: increasing the sustainable supply of timber

The World Bank has forecast that the global demand for timber could quadruple by 2050 with demand for timber in construction anticipated to be a key driver for this. According to joint analysis conducted by Defra with the timber industry, UK timber demand would increase by between 0.2 million m^3^ and 1.3 million m^3^ for sawn timber (requiring an increase of sawn wood supply of 2 to 14%) if the proportion of UK low-rise residential buildings built with timber frame increased from around 20% today to 40% to 80% by 2050. Increasing the available supply of sustainable timber products and the development of a sustainable timber and wood processing sector will be important for increasing timber in construction in England.

International supply of timber

The UK is the third largest net importer of timber and wood products in the world. As of 2022 there were three tropical countries in the top 21 suppliers of non-furniture products to the UK – Indonesia (2.6%), Brazil (1.5%) and Malaysia (1.2%). Ensuring that our imported timber supply continues to be sourced from sustainable forests is vital as the carbon sequestration benefits of timber construction can only be claimed in whole life carbon assessments of buildings if that timber is from sustainably managed forests.

The UK committed to halt and reverse forest loss and land degradation by 2030 through the Glasgow Leaders’ Declaration on Forests and Land Use launched at COP26, and supports the Forest and Climate Leaders’ Partnership launched at COP27, which includes an initiative on greening construction through sustainable wood. These and other international initiatives build ambition and create mechanisms to trade sustainable timber.

Domestic supply of timber

Increased timber construction in England is also an opportunity to increase demand for homegrown timber, driving more domestic tree planting. Diversifying the softwood and hardwood species that we plant is increasingly important for woodland resilience to climate change, pests and disease, as well as for achieving wider biodiversity objectives. To maximise the potential of wood from English forests, we will need to balance wood production to meet the current market demand with encouraging the diversification of supply chains to utilise a wider variety of products.

Increasing demand for homegrown softwoods in construction is limited by a lack of market demand for C16 timber which is the strength class most domestic softwoods are graded to. C16 timber is strong enough for the demands of most construction, but the current greater market familiarity with the higher grade C24 timber — the common grade of imported timber — leads to overspecification.

More work is needed to better promote and utilise the strength and density of homegrown C16 softwood in construction. There is also potential for research and development to produce higher strength grades from the current and future forest resource and make use of existing and new strength grading routes for the wider range of softwood species being planted. Research is also needed to monitor the effects of changing growth conditions (both climate and forest management) to ensure existing strength grading routes continue to work effectively.

Hardwood in structural timber construction in England is minimal, with greater (albeit relatively small) use in non-structural construction products. This is due to the lack of uniformity and greater weight and density of hardwoods, and more complex hardwood supply chains, among other factors. The quality of English hardwoods is also significantly impacted by damage from grey squirrels and deer. The forthcoming deer and squirrel strategies will play an important role in this. We need to explore tree breeding programmes to encourage untapped species such as beech and sweet chestnut as an innovative additional resource. Engineered timber products such as thermally modified wood and mass timber are creating new opportunities for British hardwoods, which could increase their market potential for both structural and non-structural uses.

Ensuring a long-term supply of timber

UK softwood availability is expected to start to reduce in the next 25 years. The government has set out its commitment to maintain and grow a sustainable long-term supply of domestic timber in the 2023 Environmental Improvement Plan and has also introduced a statutory tree and woodland cover target for England, which will stimulate greater planting of both hard and soft woods in England.

Government will:

- deliver against the statutory woodland cover target to increase the available domestic timber supply, as set out in the England Trees Action Plan and Environmental Improvement Plan

- explore options to support more productive planting of both softwoods and hardwoods in England by 2024 to meet increased demand from the construction sector now and in the future, building on the commitments in this publication

- continue to promote greater rates of woodland management and explore how incentives for increasing woodland management could support increased yield of timber that can be used in construction. This will include implementing the commitments in the forthcoming deer and squirrel strategies over the next 5 years and 10 years respectively

- review regulatory processes for woodland creation by 2024 to identify opportunities to streamline application times for new forestry proposals

- review the government’s Timber Procurement Policy in 2024, including assessing the Grown in Britain Certification Scheme against the criteria to be considered Category A evidence of legality and sustainability. If successful, this would ensure British Timber certifications are included in the list of approved sustainability standards

- explore options for engaging with international governments to promote the use of sustainable timber in construction, including through the Forest and Climate Leaders’ Partnership launched at United Nations Framework Convention on Climate Change (UNFCCC) COP27 (ongoing)

- assess options for monitoring impact of policies promoting timber, to ensure they are in line with wider goals for tackling global deforestation and degradation

Industry will:

- identify blockers that are preventing the use of more homegrown timber

- endeavour to plant and manage productive tree species that will increase the future supply of wood products to the construction sector and contribute to the long-term resilience of productive forests

- provide guidance to construction professionals on the use of homegrown wood-based construction products (for example to support better use of strength grades)

- invest in manufacturing of new wood-based construction products where there is a viable market opportunity (for example in the areas of mass timber and insulation)

- invest in the additional capacity or infrastructure needed for processing homegrown timber in line with increased production from UK forests

Government and industry will:

- promote homegrown wood-based construction products as a positive contribution to net zero and promote English forestry as a “green investment opportunity.”

- understand how we can improve data on end-uses of UK timber (for example update the timber utilisation report) by 2025 and undertake these improvements by 2030

- Commence improved tree breeding programmes for selected timber producing tree species to diversify the range of English tree species that could be used in construction (for example structural characteristics) by 2030

- invest in accelerated research, development and manufacturing of long-term products made from a range of English wood species by 2030, using evidence generated from the tree breeding programmes

- improve the long-term availability forecast by 2025, making further improvements by 2030, and explore how the renewed forecast can be best communicated by 2030 to facilitate a coordinated, long-term investment in planting and infrastructure

- commission an audit of the supply chain in England and the UK by 2028 to better understand the current and potential circularity of wood and carbon stored within it

Priority theme 5: addressing fire safety and durability concerns to safely expand the use of engineered mass timber

Timber frame structures have long been used in low rise construction and as a result industry is well able to pursue timber in construction in these structures, whilst accounting for fire safety, durability and structural considerations. Meanwhile, emerging engineered mass timber products present the opportunity to expand the use of timber in construction beyond low-rise.

Since the Grenfell Tower tragedy there has, rightly, been a renewed focus on building safety. Timber is combustible and can contribute to fire spread with impacts on the structural stability of buildings which can inhibit evacuation and fire response procedures. The potential delamination (splitting apart into layers) of engineered mass timber can contribute to the unpredictability of fire outbreaks. We therefore need to work with industry, academia, and the Building Safety Regulator to further investigate outstanding fire safety, durability, and competence questions, and to better understand the longevity of engineered mass timber products in the UK, regarding the impacts of water ingress, humidity and UV exposure.

Despite these outstanding concerns, it is possible to safely increase the use of mass engineered timber in some mid-rise commercial buildings and other non-residential buildings where the risks are adequately assessed, and the consequences of failure accounted for. Approaches that may mitigate the risks include measures such as full encapsulation of timber to prevent contribution to the fuel load and using sprinklers to suppress the growth of fires.

We welcome industry initiatives to improve the evidence base around the safe uses of engineered mass timber, such as the recently launched Fire Hub, which is an industry led web-based platform that will keep pace with changes in regulations and collate all test data for use by building professionals.

Government and industry will:

- work with industry, academia and the Building Safety Regulator to research outstanding safety, durability, and competency questions towards closing the evidence and competence gaps for the expansion of engineered mass timber beyond low-rise buildings over the next five years

Industry will:

- continue to support the Fire Safety Hub web platform to promote data sharing and best practice guidance on timber construction and fire safety that aligns with building regulations (ongoing)

- develop and share best practice from demonstrator projects which meet functional building regulations, expanding the evidence base of domestic construction using mass timber (ongoing)

Priority theme 6: increasing collaboration with insurers, lenders and warranty providers

Insurer and warranty provider concerns go beyond the life-safety objectives considered in the Building Regulations and relate to the wider impact of use of engineered mass timber or volumetric timber systems on the potential for property damage and length of time to restore business function following an insurable event. For buildings using engineered mass timber key risks to be mitigated relate not only to potential for fire spread but also the potential impacts of water damage and of the durability and repairability of engineered mass timber products. This means that clear evidence needs to be provided of longevity of the timber system without need for frequent repair or replacement. Insurers, lenders, and warranty providers need to have increased confidence in the use of engineered mass timber products, including how they are used and insured in international markets, as well as known claims data regarding how buildings perform in the event of a fire or flood.

Work is already ongoing to increase collaboration, most notably with the recently launched Mass Timber Insurance Playbook, which sets out guidance for profiling and mitigating risk in mass timber buildings in order to ‘facilitate and streamline the process of obtaining insurance for both construction and ongoing occupations of mass timber buildings’ within the parameters of current building regulations. New developments involving mass timber need to engage with insurers, lenders, and warranty providers as early as possible to enable effective collaboration.

Government and industry will:

- explore the feasibility of creating a risk register of anonymised data relating to mass timber buildings, including international data by 2028

- work together to facilitate greater dialogue between the insurance sector and developers to foster collaboration during and post construction by 2028

Priority theme 7: promoting innovation and high performing timber construction systems

Increased use of timber in construction will involve the wood product sector continuing to innovate and produce cost-competitive systems that are high performing, reduce operational and embodied carbon emissions and maximise sustainability and resource efficiency.

We also need to encourage innovation in building practices within the construction sector and promote methods and materials that have potential to increase efficiency and productivity. This includes more off-site manufacturing and use of digital technologies that can increase quality and reduce waste. For example, one housing project using a volumetric timber system constructed on top of steel frame stilts demonstrated a 50% faster build time compared to traditional construction methods, with 90% of the build time completed in the factory requiring minimal onsite work.

Further research is needed to better understand any wellbeing benefits associated with timber and to promote timber design that maximises these benefits. For example, the Department for Education is building the UK’s first biophilic primary school, designed so that buildings focus on connecting those inside with nature, with the goal of promoting better physical and mental health. Timber systems, therefore, need to demonstrate cost effectiveness alongside reduced environmental impact. Innovation to increase efficiency and productivity will support with this.

Government will:

- publish a new universally recognised Publicly Available Specification (PAS) standard (created by the BSI), for homes built using Modern Methods of Construction, which will include references to timber and is set to be published by 2025

- promote the results from the Timber in Construction Innovation fund projects so that learning can be used and applied more widely by 2025

Government and industry will:

- working with academia undertake research and innovation for timber in construction as part of a sustainable bioeconomy to identify evidence gaps in knowledge by 2028, dependent on funding, which will include research on the following:

- optimising carbon and operational performance of timber construction systems

- increasing the efficiency and productivity of timber construction methodologies, for example focusing on increasing pre-manufactured value (PMV) and use of digital technologies in line with government’s drive to promote MMC

- identifying opportunities for the re-use of timber products and encouraging circularity

- increasing and expanding understanding of how to build safely with timber construction systems

Industry will:

- continue to publish, promote and maintain best practice technical standards for structural and non-structural timber enabling procurers in the construction sector to specify, and manufacturers to deliver, with confidence (ongoing)

- maintain and promote TDUK’s Resource Library Search and the Transforming Timber web portal for disseminating best practice and the latest research into timber construction by 2025

- create a cost-comparison guide for timber systems vs. other construction systems by 2025 to help developers and others understand the costs of working with timber

Implementation, monitoring and evaluation

The Timber in Construction Working Group will continue to meet regularly to track delivery of the actions outlined in this document and to scope and implement new actions as needed. We will also develop a framework for monitoring and evaluation of progress towards this document’s objectives and ensure this is aligned to wider net zero and resource efficiency monitoring and evaluation frameworks.

The timber in construction working group

This document was produced in collaboration with the Timber in Construction Working Group, which consisted of:

- Association of British Insurers

- Bangor University

- British Insurance Brokers’ Association

- British Standards Institution

- British Woodworking Federation

- Building Regulations Committee

- Building Research Establishment

- Built By Nature

- Built Environment – Smarter Transformation

- Building Safety Regulator

- Confederation of Forest Industries

- Department for Business & Trade

- Department for Energy Security & Net Zero

- Department for Environment, Food and Rural Affairs

- Department for Levelling Up, Housing and Communities

- Department for Science, Innovation and Technology

- Edinburgh Napier University

- Forestry Commission

- Green Construction Board

- Health and Safety Executive

- Home Builders Federation

- National Fire Chiefs Council

- New Model Institute for Technology and Engineering

- Royal Institute of British Architects

- Royal Institution of Chartered Surveyors

- Structural Timber Association

- Timber Development UK

- University College London

- Wood Panel Industries Federation

Throughout creation of this publication we have received input from a wide range of stakeholders across the sector and across academia and thank them for their input.