NDA strategic position on radioactive waste treatment:August 2023

Updated 16 November 2023

Executive summary

Treatment is key to enabling effective waste management, converting the variety of our operational wastes, retrieved legacy wastes and decommissioning arisings into feed stock for reuse or recycling, or waste packages that can be safely handled, stored, transported and disposed of. We need to build on our existing treatment capabilities to develop a broader range of technologies, (that we refer to as the toolkit) to ensure waste producers have choice, flexibility and agility. We need to continue to ensure that our strategy development activities identify and pursue issues and opportunities to ensure the skills, capability and infrastructure are in place to deliver the decommissioning mission. We need to do this in ways that optimise our use of those skills, capabilities and infrastructure, across the NDA group. This document explains what work we are currently undertaking to support this aim.

It describes the work we as an industry have been focusing on to deliver those aspects of strategy, what progress has been made in key areas and highlights any areas of future strategy development or emerging themes. The purpose of this strategic position is to clearly articulate why waste treatment is an important part of the NDA mission and why we invest significant time and effort on it. This supports the approach taken by waste producers who are developing and implementing enhanced waste treatment techniques and supports the pursuit of strategic opportunities.

In summary, implementation of the treatment aspects of the NDA’s Strategy means:

- Moving away from the reliance on a narrow range of options to a broader toolkit of viable treatment solutions that responds to the wide range of wastes that waste producers need to manage now and into the future

- Implementing a risk-informed approach to treatment that considers the properties of the waste and applies the waste hierarchy, considering the full lifecycle to fulfill the principles of Best Available Techniques (BAT) or Best Practicable Means (BPM) in Scotland and As Low As Reasonably Practicable (ALARP), with support from Nuclear Waste Services (NWS)

- Pursuing opportunities to add value and reduce costs via waste minimisation and reclassification

- Actively investigating and supporting greater use of the supply chain whilst acknowledging the need for robust on-site solutions and the benefits of sharing infrastructure, where the case can be made

- Sponsoring innovation in key areas and recognising that the NDA and Site Licence Companies (SLCs) need to invest to secure enhanced treatment solutions for specific challenges

- Preparing waste packages appropriate for lifecycle management, i.e. for Higher Activity Waste (HAW), packages that can cope with uncertainties in respect to disposal timeframes and therefore support robust storage arrangements

- Developing wider systems and architectural based improvements that are needed to ensure that waste producers have in place appropriate capability and capacity to enable decommissioning.

Introduction

The NDA’s mission is to ensure that the NDA-owned sites in England, Wales and Scotland are decommissioned and cleaned up safely, securely, cost effectively and in ways that protect people and the environment.

Effective and optimised waste management is an essential requirement for the delivery of the mission and is a significant part of the programme. The UK has been producing and managing radioactive waste for many decades.

Over 90% of the UK Radioactive Waste Inventory (UKRWI) by volume is generated by the NDA estate, with waste types covering the full spectrum of contaminated and/or activated wastes. The treatment of waste arising from the NDA mission is strategically significant and represents a future investment of several £billions over a period of many decades to come. Viable treatment capability needs to be available in a timely fashion with sufficient resource to deal effectively with waste arisings.

The NDA’s strategic objective for the management of radioactive waste is ‘To ensure that wastes are managed in a manner that protects people and the environment, now and in the future, and in ways that comply with government policies and provide value for money’ from [NDA’s Strategy]. This applies at all stages within the waste lifecycle below:

Planning and preparation

- Integrated waste management strategies

- Waste management plans

- Waste characterisation

- Waste inventories

Treatment and packaging

- Retrievals

- Sorting and segregation Size reduction Decontamination

- Treatment – thermal/ chemical/physical

- Conditioning/immobilisation Packaging

Storage

- Raw waste storage

- Conditioned waste storage

- Buffer storage

- Decay storage

Disposal

- Landfill

- In situ

- On-site

- Surface

- Near-surface Geological

This strategic position relates to the treatment aspects of the lifecycle. Treatment is an intermediate step. It is the subject of careful planning and robust decision making that considers the requirements of all lifecycle steps.

It is informed by characterisation and assay and may be preceded by a number of operations that can generate waste, including activities such as, decommissioning, routine nuclear processing facility operations or legacy waste retrievals.

Other lifecycle stages, including those relating to characterisation and disposal, are addressed elsewhere, for example, within the NDA Radioactive Waste Strategy and strategy development work for those stages is not specifically discussed here.

This document sets out the NDA’s strategic position with respect to the treatment stage of the lifecycle, as applied to the categories of waste described below. Emphasis is given to those wastes that span radioactive waste category boundaries and are key areas for optimisation and opportunity.

The following waste categories are used:

High Level Waste (HLW)

Waste in which the temperature may rise significantly as a result of its radioactivity and has to be taken into account in the design of storage or disposal facilities. HLW only exists at the Sellafield site and it is important to differentiate the term HLW from the broader term Higher Activity Waste (HAW) and from spent fuels and nuclear materials. The HLW management approach is mature and the majority of HLW has been treated so this strategic position document does not apply to HLW.

Intermediate Level Waste (ILW)

Waste exceeding the upper boundaries for LLW that does not generate sufficient heat for this to be taken into account in the design of storage or disposal facilities. ILW presents the greatest opportunity to improve radioactive waste management through the development of treatment options.

Low Level Waste (LLW)

Waste having a radioactive content not exceeding 4 gigabecquerels per tonne of alpha activity, or 12 gigabecquerels per tonne of beta/gamma activity.

Very Low Level Waste (VLLW)

A sub-category of LLW, comprising waste that can be safely disposed of with municipal, commercial or industrial waste, or can be disposed of to specified landfill sites, subject to limits on radioactivity content.

Additionally, HAW is a collective term that includes the categories HLW, ILW and a relatively small volume of LLW that is unsuitable for disposal at the Low Level Waste Repository (LLWR) or the LLW disposal facility at Dounreay. The term Low Activity Waste (LAW) is sometimes used to refer to LLW and VLLW.

Although the categories exist as discrete definitions, the waste itself exists on a spectrum of radioactivity and a wastestream may span a number of categories and include non-radioactive waste.

Another potential component of the inventory for treatment and disposal is spent fuel and nuclear material that is not currently classified as waste but could be at some point in the future, if it is deemed to have no further use. The strategy for management of this material is not addressed in this strategic position and is described in the NDA Strategy.

Non-radioactive wastes, gaseous emissions and liquid discharges are not specifically addressed in this document as they are the subject of separate strategy development work as described in the NDA Strategy. It is important to note that some pre-treatment and treatment activities generate non-radioactive wastes, gaseous emissions and liquid effluent that need to be managed appropriately.

Radioactive Waste Policy

The NDA’s treatment strategic position aligns with the policies of the UK government and devolved administrations for the management of solid radioactive waste. It recognises that policy on managing radioactive waste is devolved and that the four nations have different policies for the long-term management of HAW.

These policies promote robust decision making as part of planning and preparation to ensure that solid radioactive waste is managed appropriately. The UK government and devolved administrations have consulted on updating and consolidating policies covering the management of solid radioactive waste. One key proposal is to adopt a risk-informed approach to managing all categories of solid radioactive waste where waste is managed according to the properties of the waste (radiological, chemical, physical) and the hazard these properties pose to people and the environment, together with the radioactive waste classification. Should this approach be adopted it would allow SLCs greater flexibility and a wider range of potential solutions in the selection of treatment and disposal options. It would provide SLCs further opportunities to optimise the management of radioactive waste, particularly that which is close to a waste category boundary, where treatment can open up the use of new routes, subject to the outcome of the consultation and agreement by the regulators.

Radioactive Waste Strategy

The NDA Radioactive Waste Strategy consistent with the UK government policy to drive improved delivery of waste management and the decommissioning of sites by ensuring waste producers across the estate have sustainable, effective, and efficient solutions available at the right time. The strategy sets out the key principles of integrated radioactive waste management:

- Supporting key risk and hazard reduction initiatives by enabling a flexible approach to long-term waste management

- Taking into consideration the entire waste management lifecycle, including how waste management is needed to support other NDA strategic or wider UK initiatives such as large-scale decommissioning programmes

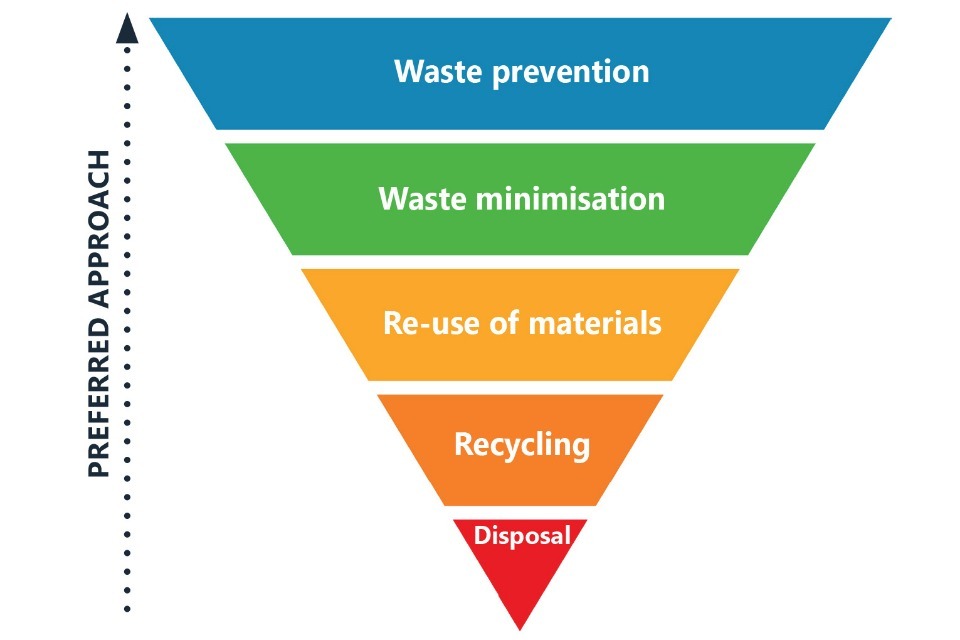

- Applying the waste hierarchy which is recognised as good practice and should be used as a framework for waste management decision making, enabling an effective balance of priorities including value for money, affordability, technical maturity, and the protection of health, safety, and the environment

- Promoting timely characterisation and segregation of waste, which delivers effective waste management

- Where appropriate, provide leadership by encouraging greater integration across the estate and supply chain, in particular by seeking opportunities to share treatment and interim storage assets, capabilities and learning

- Supporting and promoting the use of robust decision-making processes to identify the most advantageous options for waste management

- Enabling the availability of sustainable, robust infrastructure for continued operations, hazard reduction and decommissioning.

The NDA Radioactive Waste Strategy promotes making best use of existing waste management infrastructure, while developing new solutions when required. Ensuring that waste is made passively safe in a timely manner, consigned to the most appropriate route and (where applicable) disposed of, or made disposable is key to achieving stakeholder confidence in the NDA group’s ability to deliver the mission.

The NDA Radioactive Waste Strategy also sets out our vision for timely availability of fit-for-purpose disposal capability, ranging from in situ management, to licensed landfills, to a Geological Disposal Facility (GDF) for materials requiring geological isolation.

It is the role of the NDA to set out strategic expectations, that will deliver the UK government and devolved administrations’ policies and support NDA waste producers in fulfilling them.

Nuclear Waste Services

NWS plays a vital role in implementation of the NDA’s strategy.

The formation of NWS has brought together our waste management organisations Low Level Waste Repository Limited and Radioactive Waste Management Limited, and in doing so provides a wide range of specialist skills and services for integrated waste management including characterisation, treatment, recycling, volume reduction, packaging and disposal.

NWS is responsible for provision of waste management advice and services, operation of the LLWR and the development a GDF for disposal of HAW.

Waste producers

Waste producers at NDA sites are responsible for implementing NDA Strategy and the NDA Radioactive Waste Strategy considering local factors and the context of their operations as part of the wider NDA group throughout the lifecycle of the waste. This will be undertaken in accordance with nuclear site license conditions, environmental permit requirements, Guidance on Requirements for Release of nuclear sites from Radioactive Substances Regulation and the joint regulatory guidance.

Through the NDA Radioactive Waste Strategy, the NDA is also advocating that waste producers adopt a ‘toolkit’ approach to treatment, recognising that there are a broad range of wastes that require management and that there are currently limited treatment options available to waste producers. Therefore, technology development is required to help deliver an appropriate range of treatment technologies and routes that enable the timely and effective management of the variety of wastes in the inventory. The NDA is working closely with waste producers to understand where there is potential opportunity to develop treatment technology and enhance capability. This is consistent with Scottish Government’s Implementation Strategy that describes how research and development will be initiated to investigate potential technical solutions for HAW which, under current technology and regulation, are understood to be unsuitable for near-surface disposal. Later in this document, the NDA presents the focus areas, summarising what work has been done, the status and future plans.

‘Treatment’ and related terms

For the purposes of this document, ‘treatment’ is used as a generic term describing aspects of pretreatment, treatment and conditioning and includes retrieval, handling, and processing of wastes, before they have been packaged in containers.

Sometimes the terms treatment, conditioning and packaging are used interchangeably, e.g. in reference to waste treatment facilities, but they are different process steps as defined by the International Atomic Energy Agency (IAEA) below. In a UK context, the terms treatment and conditioning are used to describe processes that can result in passivation of the waste.

Treatment

Operations intended to benefit safety and/or economy by changing the characteristics of the waste. Three basic treatment objectives are:

- Volume reduction

- Removal of radionuclides from the waste

- Change of composition.

Treatment may result in an appropriate waste form. If treatment does not result in an appropriate waste form, the waste may be immobilised.

Conditioning

Those operations that produce a waste package suitable for handling, transport, storage and/or disposal.

Conditioning may include the conversion of the waste to a solid waste form, enclosure of the waste in containers and, if necessary, provision of an overpack.

Packaging

Preparation of radioactive waste for safe handling, transport, storage and/or disposal by means of enclosing it in a suitable container.

Typically, treatment can involve several steps undertaken at the workface or at another location, once waste has been retrieved or generated and can incorporate a range of activities, including:

- Sorting and segregation: where types of waste or material are separated or are kept separate, on the basis of radiological, chemical and/or physical properties, to facilitate waste handling and/or processing and to initiate the practical application of the waste hierarchy

- Size reduction: a treatment method that decreases the physical size of an item, e.g. by cutting or crushing to make subsequent packaging or treatment easier

- Decontamination: the removal or reduction of contamination by a physical or chemical process to achieve reclassification of the waste, to enable further treatment, to meet specific waste management facility acceptance limits or to reduce dose uptake for subsequent operations

- Thermal/chemical/physical processes: to change the waste characteristics to facilitate subsequent management steps, such as recycling or disposal

- Conditioning/immobilisation/passivation: to change the form of the waste so the resulting product can be safely handled, transported, stored, and disposed of

- Packaging and containerisation: the process of loading waste into a container suitable for handling, storage (potentially long term), transport and disposal. This could also include void filling to minimise any voidage in a waste package.

The purpose of treatment

The purpose of treatment is to convert waste from its unconditioned form (considering its characteristics) into a form that is suitable and beneficial for subsequent lifecycle management activities, including handling, storage, transport, and disposal.

As an enabling step, treatment including characterisation, handling is key to NDA mission delivery. Treatment is also an important step in the management of hazards, to reduce the potential for waste to harm people or the environment. This includes passivation of reactive constituents of the waste and taking measures to reduce potential radionuclide mobilisation, now and in the future. The magnitude of benefit of treatment is proportionate to the hazard and risk posed by waste.

Treatment is key to enabling the lifecycle end point for waste, whether that is reuse, recycling or disposal. Increasingly, sustainability is becoming a focus in waste management, driving us to pursue more sustainable ways of treating wastes and responding to broader changes, introduced through sustainable practices in our supply chain. This trend is set to continue and we need to be creative in our pursuit of more sustainable practices in waste management. For those wastes that cannot be reused or recycled, treatment is an important step in enabling safe disposal. NWS evaluate waste packaging proposals, to understand how the resulting waste packages will satisfy requirements of storage, transport and disposal.

Depending on the properties of the waste and the requirements for transport or acceptance criteria of the intended store, treatment facility or disposal endpoint, treatment could have one or more objectives, as highlighted in the IAEA definitions above. Some of those treatment objectives can be achieved through different physical and chemical processes, to:

- reduce the volume of the waste

- fix contaminants, manage liquids or powders and immobilise activity

- manage distribution within a waste package

- decontaminate, separate or remove parts of the wastestream with different radiological or physicochemical properties

- reduce or eliminate chemical reactivity

- change the size and/or geometry of the waste

- ensure that waste packages have sufficient integrity for storage and disposal

- remove voidage from the waste

These actions ultimately aim to enable the application of the waste hierarchy by allowing avoidance, recycling, or reuse. Where this cannot be achieved, waste is prepared for disposal to ensure passivity and predictability over the long term, meaning that the waste will not require further unplanned intervention, treatment, or rework and that the packaged waste will not evolve in a manner that creates subsequent need for unplanned intervention, treatment, or rework.

The packaged waste also needs to behave in a manner that does not compromise the ability of any receiving disposal facility to protect future generations from harm. The treatment step is a valuable opportunity to learn more about the waste properties through assay and characterisation, generating information to produce appropriate waste package records to support disposability. More details of the specific requirements for LLW can be found in the LLWR Limited (now Nuclear Waste Services) Waste Acceptance Criteria, and for HAW in the Generic Waste Package Specifications and Guidance developed by RWM (now Nuclear Waste Services).

Volume reduction

There are treatment techniques that can achieve waste volume reduction e.g. incineration, compaction, supercompaction and thermal treatment. This can reduce volumes for disposal, optimise the amount of waste in a container and it can reduce the number of waste packages that require transfer, storage, transport, and disposal leading to potential cost savings.

Fix contaminants and reduce mobile components

Free liquids are a concern due to the potential for radionuclide mobility, chemical reactivity, and corrosion. For this reason, they are typically removed from wastestreams and managed via effluent routes prior to treatment. It is also possible to undertake in-container drying to condition waste and remove excess liquid. Encapsulation through in-drum mixing, flood-grouting (using an encapsulant with sufficient fluidity to penetrate the waste) or the use of polymer encapsulation can be effective ways of reducing the mobility of residual liquid, powdery, loose or friable substances, especially in cases where nuclear material is present. Techniques such as encapsulation and vitrification will encapsulate and immobilise radionuclides within a solid and stable matrix. It is also possible to use chemical coatings and fixatives to fix contamination to a surface to aid decommissioning and waste management operations. The presence of any added material, e.g. encapsulants, glass formers or fixatives will need to be assessed to ensure that they do not compromise performance in subsequent management steps, such as disposal. Radionuclide mobility is an important consideration during storage, transport, and disposal under operational and accident conditions. Mobility is also a key factor in the post closure environmental safety of a disposal facility.

Manage distribution

The lifecycle of the waste package created as a result of treatment and packaging can be determined in part by the way that a specific substance, radioactivity, or specific radionuclides are distributed within the package or an overall consignment. For example, there are specific requirements for waste packages with respect to maximum dose rates, changes in dose rates across the surface of a package, and criticality safety. These requirements can be partly fulfilled through ensuring radioactivity and specific radionuclides are controlled or evenly distributed within a package.

Sorting and segregation

Sorting and segregation are typically applied at or close to the point of waste generation, i.e. during decommissioning operations, to find, sort and separate (by cutting for example) components of the waste that have different properties and so are best managed differently. Sorting and segregation enables proportions of the waste to be managed using different approaches including potentially lower classification treatment routes, such as recycling or disposal as VLLW. It can also be used to limit the waste package content of specific material or radionuclides to meet facility acceptance criteria. It is important to consider the lifecycle impact of these operations to ensure doses are ALARP and to ensure that the waste management routes for the segregated components of the waste stream are BAT/BPM.

Decontamination

Chemical and physical decontamination processes, such as scabbling, swabbing, water-jetting, washing, and strippable coatings are examples of processes that can be used to remove radionuclides from bulk solid waste so that they can be processed separately or accepted at treatment facilities. This can be undertaken in situ to minimise the potential for contaminant transfer in subsequent operational steps. In this way decontamination can assist in contamination control and potentially reducing the classification of the waste. Decontamination can also be undertaken ex situ whereby waste items are moved to a different work area.

Reduce reactivity

Chemical or thermal processes can be used to passivate or minimise reactivity and form stable compounds e.g. through the use of chemical additives, encapsulant formulations or oxidation through thermal treatment. Reactivity is undesirable in packaged waste as it can lead to waste evolution and possible degradation of the waste package, deformation of the waste package, movement of radionuclides or other deleterious effects. Reactivity can lead to corrosive expansion of waste packages or generation of gases that can be hazardous, e.g. hydrogen.

Size reduction and changing geometry

Metal melting, cutting, shredding, compaction and supercompaction are used to reduce size and change the geometry of wastes. This could be to obtain more efficient packing fractions by increasing waste loading per package, to enable segregation, to reduce waste handling operations or even for security reasons. It could be simply to ensure that the waste items can be removed from a facility and will fit in the waste container. Size reduction often improves packing efficiency, but it can also introduce the potential to cause harm to workers, particularly those operations involving manual cutting or handling.

Ensure physical integrity

Some treatment processes are carefully developed to ensure that a stabilising and immobilising matrix penetrates throughout the waste or is otherwise intimately mixed through the waste, thus forming a monolith. The combined properties of the waste, the matrix, and the container work together to give physical integrity and robustness that, in some cases, is key to waste package performance under both normal operations and accident scenarios, e.g. stacking, and specified fire and impact accident scenarios. The physical integrity of the package (a combination of wasteform and container) provide the first two layers of containment within an engineered barrier system.

Remove voidage

Conditioning steps can be taken in order to reduce unwanted voidage in the waste package. This can include some of the techniques already described above, including compaction, flood grouting and the potential use of capping grouts. This is to ensure that for example, waste packages maintain structural stability and to avoid potential pathways for radionuclide migration.

Application of the waste hierarchy and sustainability

Waste producers must take into account sustainability and demonstrate application of the waste hierarchy to manage waste effectively and help preserve disposal capacity, using BAT (or BPM in Scotland) to achieve the best overall outcomes for people and the environment by optimising the management of radioactive waste. This should minimise the environmental impacts of waste treatment including through reuse or recycling materials wherever possible and provide for the effective and safe management of waste which is generated.

The waste hierarchy prioritises approaches to waste management based on its impact on the environment in terms of climate change, air quality, water quality and resource depletion. In addition, SLCs are obliged to consider the proximity principle, and to ensure that risks are ALARP. The application of the waste hierarchy and the principles of BAT (BPM in Scotland) and ALARP[footnote 1] should also consider the NDA value framework, to ensure robust decision making that appropriately evaluates and balances the full range of factors that are important. Sustainability considerations include protecting and enhancing the lives of people and the environment and creating sustainable local and regional economies. From a treatment perspective, sustainability is encompassed in the application of the NDA’s waste management principles, application of BAT/BPM and ALARP, our work to develop and enhance the supply chain for delivery of waste treatment solutions and the NDA group Sustainability Strategy.

In applying the waste hierarchy, the NDA encourages the use of sorting, segregation, decontamination, and other forms of pretreatment to drive waste to the lowest possible waste category that is demonstrably BAT/BPM and ALARP.

The effective treatment and packaging of radioactive waste allows us to achieve the strategic preference to reduce overall waste volumes and maximise long term package performance.

Developing a ‘toolkit’

Nuclear decommissioning across the NDA group requires a toolkit of options to allow treatment of the range of wastes that must be managed.

The nature and volume of the range of wastes that need to be managed varies significantly and there is no single technology or facility that can deal with that variability. An important part of the development of this toolkit is addressed in the planning and preparation lifecycle steps where characterisation and inventory information enable waste producers to better understand the nature and quantity of waste requiring treatment and therefore, the demands on treatment capability.

The toolkit approach continues to utilise and develop those techniques already in use while actively pursuing enhanced treatment capability and seeking innovation to offer a broad range of options for waste producers to deploy. This position is stated in the NDA Strategy that has been subject to stakeholder engagement, public consultation and then approved by government. The consultation sought the views of stakeholders who were supportive of investment to develop the toolkit that waste producers need to improve the approach to waste management.

Historically, industry has employed a range of cement encapsulation techniques but as a chemical system, cements and grouts are not necessarily readily compatible with all wastes and this can present challenges. Cement powder manufacturing is also changing to adapt to net-zero targets for carbon emissions and this affects the use of cement encapsulation.

More recently wastes have been packaged in robust shielded containers, conditioned through drying to reduce water content and thereby minimise potential chemical reactivity to a level acceptable for on-site interim storage followed by disposal. Having a broader range of approaches available to waste producers will give increasing flexibility and adaptability, to enable optimisation and the efficient use of management routes.

Within the LAW categories and the lower end of the ILW category, NWS is facilitating access to a range of existing services to help waste producers manage their waste throughout the lifecycle. The range of services offered through this route continues to expand to give greater flexibility to waste producers and to further enable risk-informed waste management and application of the waste hierarchy.

They currently include:

- Pre-treatment (sorting, segregation, size reduction and decontamination)

- Characterisation, assay, and assurance

- Metallic waste surface treatment, volume reduction and smelting

- Thermal treatment for combustible waste

- Supercompaction

- Alternative treatments

- LLW and VLLW disposal (excluded from this treatment strategic position).

The NDA, working with the operating companies, are driving the future development of innovative technologies, and are supporting their implementation through our research and development portfolio, and a range of targeted commercial approaches. Technologies such as thermal treatment are a good example of the NDA’s intervention to support the development and implementation of the toolkit as a strategic preference. Another example is the consideration of waste requirements and capability development at group level rather than site/SLC level.

This approach has been adopted in several areas such as the Problematic Waste Integrated Project Team (IPT) and the thermal treatment work. The business case and anticipated benefits of working as a group are evaluated along with the practicalities of delivering such solutions, ensuring site needs are met. Robust decision making is necessary to ensure benefits can be realised in a manner that addresses legislative and stakeholder aspects

Progress in strategy development

This section describes a number of areas within the field of waste treatment that have been identified as key to NDA strategy development.

The majority of these were described in the Higher Activity Waste treatment framework. Work on the development of thermal treatment technologies, coordination of activities around the use of encapsulation and the development of an improved approach to the management of problematic radioactive wastes are all NDA strategic commitments. This means that the NDA is committed to developing and implementing strategy, pursuing opportunities in these areas with the potential for these projects to progress through to strategy change.

In addition to the areas covered in the previous Higher Activity Waste treatment framework and consistent with the approach to integrated waste management, this strategic position takes an integrated approach and is covering all radioactive waste. This is a direction that the NDA will continue to build upon as the Integrated Waste Management (IWM) approach and the Radioactive Waste Strategy continue to mature, pursuing the treatment challenges, risks and opportunities that continue to exist for integrated waste management. This will involve continued engagement with the Integrated Waste Management Programme (IWMP) being delivered by NWS to pursue a wide range of waste management initiatives across the NDA group.

Waste encapsulation

The nuclear industry has been using cement encapsulation for treatment and conditioning of waste for some decades, but this approach can be challenging to implement. There is a security of supply problem associated with some of the constituent materials used in the current cement formulation (as they are byproducts of the steel industry (ground granulated blast-furnace slag GGBS) and coal burning power generation (pulverised fuel ash PFA)) affecting both LLW and ILW lifecycles. Work is ongoing to find potential alternatives to these supplementary cementitious materials and alternatives to current cementitious encapsulants, e.g. geopolymers and calcium sulphoaluminate cements. This includes a range of trials being led by Sellafield Limited to investigate the properties and performance of new encapsulants and new cement formulations.

Cement powders may represent a low-level cost to the nuclear industry, but the potential impact of their unavailability could be far reaching and expensive. Formulation dictates cement properties that are fundamental to both the operation of a waste treatment plant and performance of resulting waste packages. This applies to both HAW and LLW where cement is used as a stable matrix in waste packages or as a void filler, but the requirements on formulation are subtly different. NWS is delivering work to investigate PFA replacements that will work with LLW operations and the safety cases for disposals at the LLWR site, while HAW producers are focused on formulation development to satisfy operational requirements and disposability requirements for a GDF.

The production of conventional cement is harmful from a sustainability perspective, producing high volumes of CO2. Sustainability targets and the resulting changes in wider industry are driving the need for the nuclear sector to keep pace with the cement powder industry in ensuring that waste treatment facilities can use emerging low-carbon cement powders and that the resulting waste packages are disposable. This trend is set to continue, and significant effort has been put into ensuring that waste producers can move away from bespoke powders to adopt standard cement powders that are widely used in construction industry. As the nuclear industry prepares to transition from one powder type to the next, the cement industry is already looking further ahead.

It is also recognised that the wide variety of wastes that require treatment may not be compatible with cement chemistry or processes in all cases, and so a range of alternative encapsulants are being investigated.

The NDA has formed an industry expert group on encapsulation, the Encapsulation Coordination Group (ECG), to ensure coordination across the NDA group in the development of technical work in this area. This includes sharing information regarding efforts to transition to new powders, keeping up to date with wider cement powder industry developments and the development of alternative encapsulants. Updates on previous studies, current projects and future R&D are an important means of coordinating activities across the group. The NDA is currently working with the group to develop an R&D roadmap; signposting completed work such as formulation trials, providing a status update on active research tasks and setting out a forward programme of planned activities and milestones. This is intended to provide a focal point and ensure that work on encapsulants is timely, coordinated, and efficient, delivering research outputs to enable continued use of encapsulants.

Thermal Treatment

Since the early 2000s the nuclear industry has been investigating the potential use of thermal treatment for ILW. Specifically, since 2015 the NDA has led work coordinating effort to investigate the potential of thermal treatment and has funded R&D to demonstrate the effective operation of a pilot thermal treatment system under nuclear licensed site conditions, within the National Nuclear Laboratory Central Laboratory. Inactive and active trials were undertaken using a range of surrogate wastes to investigate the viability of thermal treatment in immobilising these wastes and creating a suitable waste product for onward management and disposal. The work also investigated operational aspects, such as the fate of radionuclides and sought to prove assumptions regarding parameters including waste volume reduction. Sellafield Limited has also undertaken successful trials on surrogate wastes using a plasma treatment process. Based on progress to date, the NDA remains committed to further investigation of the potential benefits of thermal treatment, including:

- Volume reduction, leading to reduced costs for transport storage and disposal

- Destruction of reactive waste constituents, leading to improved waste passivity and less waste package evolution

- Waste product integrity, giving good safety performance in storage and disposal facilities.

Sellafield Limited has undertaken a Tiger Team[footnote 2] approach to build on the successful outcomes of the trials programme which concluded that thermal treatment is technically and economically viable for a number of types of HAW. Based on the outputs from the Tiger Team, Sellafield Limited has established a programme to take a stepwise approach to the implementation of thermal treatment technologies. This will be done using a range of studies, trials and experiments designed to answer the outstanding technical and economic questions and address the challenges to full-scale implementation. Specifically, the following three waste types were considered most suitable for thermal treatment and applicability of thermal treatment technologies to these wastes is being investigated in the HAW Thermal Treatment Programme:

- Plutonium Contaminated Material (PCM)

- Pumpable waste, e.g. sludge and resin

- Mixed beta/gamma waste, e.g. decommissioning wastes.

There are a range of key strategic decisions that will make use of the findings from the pilot scale development work to determine if there are significant benefits of implementation of thermal treatment at scale. The programme will seek to address technical challenges that have hindered adoption of thermal treatment technologies for these ILW streams. This includes issues such as waste feed systems, offgas systems, glass formulation for mixed waste streams and criticality safety. Programme constraints and the need for waste producers to take decisions about treatment technology selection are also factored into the HAW Thermal Treatment Programme. Solving these aspects could unlock thermal treatment technologies for application in the next generation of treatment facilities at Sellafield. A successful outcome would pave the way for thermal treatment to be considered as a credible option for HAW as part of the toolkit of technologies. The work is also considering potential applicability of thermal treatment to wastes across the estate, including problematic radioactive wastes.

Problematic radioactive waste

Problematic radioactive wastes are typically small volumes of waste that do not have well-defined waste treatment and/or disposal routes available, or for which existing routes are significantly suboptimal. These wastes exist at sites across the nuclear industry and can often be considered problematic by virtue of their physical, chemical and / or radiological properties. The NDA has formed an IPT, led by NWS, to improve the understanding of the total inventory of problematic wastes, working collaboratively across the industry to develop a coordinated approach to their management. This improved approach could include developing or promoting new technologies, sharing treatment capability across the group, sharing knowledge, and learning from experience (LFE), and working to identify and address common constraints. This work has been ongoing since 2016 and is delivering benefit across the NDA group, and the wider industry.

The IPT is strengthening our position with respect to the management of these wastes through:

- Improving the quality of data regarding the inventory of problematic radioactive wastes with a longer-term view of ensuring that they are adequately detailed within the UKRWI and site plans

- Sharing relevant good practice with regards to inventory development, characterisation (plant walk-arounds), innovative management techniques, knowledge management and reporting

- Maintaining industry support and momentum through collaborative engagement with a community of practitioners

- Working collaboratively to open up new opportunities, e.g. demonstrating disposability of adsorbents for stabilisation of oils and oily sludges in cemented waste products; investigating techniques for identification of unknown laboratory chemicals to enable treatment; and sharing information on non-NDA projects that can offer relevant learning.

The IPT continues to drive the programme of activities and develop solutions for waste producers to put into effect, focused on progressing the opportunities that have been identified, developing appropriate commercial approaches to engage the supply chain, and engaging with waste producers across the nuclear industry.

Decontamination

Several pretreatment techniques can be deployed to manage the activation or contamination present in a wastestream. Decontamination is used to remove of a proportion of fixed and/or loose surface contaminants (these could be radiological, hazardous, or otherwise unwanted contaminants) to deliver a waste management or safety benefit. This technique is used as part of decommissioning and waste management to enable safe operations, to reduce conventional and radiological safety risks associated with handling of wastes and to apply the waste hierarchy.

Surface decontamination techniques may consist of abrasive cleaning, blasting, scabbling, machining, milling, chemical cleaning, or water jetting and can be carried out at the workface or another location. The techniques are typically applied to hard surfaces e.g. metals and concrete, and may also remove a proportion of the substrate material along with the contamination. The process will generate wastestreams that can then be managed through separate routes, to enable more optimal management of the radioactive component and remaining bulk waste material.

Alternatively, coatings can be applied to fix contamination to the surface of the waste to limit the potential for mobilisation and possible spread of contaminants. Again, this is principally done to give safety and operational benefits in subsequent waste management steps where the coating can either remain in place for later management stages or the coating can be peeled off to remove loose contaminants.

The presence of chemical decontamination agents, strippable coatings and/or other fixatives must be taken into consideration in terms of secondary waste arisings and from a disposability perspective to ensure that waste meets acceptance criteria and the chemicals do not compromise disposability safety, particularly in the post-closure phase of a repository.

There is an existing body of guidance around the use of decontamination, decontamination agents, decontamination operations and disposability. This includes decontamination principles that have been developed by Sellafield Limited (2020) and guidance regarding disposability of decontamination agents that has been developed by NWS (formerly RWM).

The NDA considers that there may be benefit in reviewing the need for consolidated guidance on this theme to leverage the value of the good work done in this area, encourage the application of relevant good practice and promote information sharing.

NWS offers access to a range of treatment services including decontamination and size reduction of all main metal types such as carbon steel, stainless steel, iron, lead, aluminium, copper, and brass for recycling, or, in higher contamination cases, for volume reduction and disposal. Treatment processes are available via this route for waste with varying degrees of contamination, from suspect-clean mixed-scrap to items beyond the top of LLW range, including items used for spent fuel handling such as skips and flasks. Waste streams can comprise mixed materials, requiring sorting and segregation, or large single items.

Decontamination activities can involve workers coming into contact with or close proximity to waste and it is necessary to demonstrate principles of BAT/ BPM and ALARP are being applied. While it is important to implement the waste hierarchy, there are circumstances where it is appropriate to accept that greater volumes of higher category waste are inevitable where certain decontamination activities could lead to unacceptable safety risks to workers.

Sorting and segregation

Physical sorting and cutting techniques can be used to segregate activated or contaminated components of waste arisings such that they can be managed separately from bulk wastes that may have overall different physical, chemical, or radiological characteristics. Under some circumstances, mixing and blending of wastes can be undertaken to manage the activity within a consignment as part of a risk-informed lifecycle and the NDA will work with our stakeholders including the regulators, to develop guidance on when this is an appropriate management technique.

Following sorting and segregation, some components of the waste may even be suitable for recycling. As highlighted previously, NWS offers metal treatment services including the sorting and segregation of large metallic items and mixed metallic streams to enable further treatment, including potentially recycling. Recycling of segregated waste has been widely adopted in the UK, and internationally, for several decades and can be the next best option where items cannot be directly reused. Smelting allows segregated metals to be recycled or reused (e.g. shielding blocks) or volume reduced and sent for disposal. This technique may offer significant benefit in the management of high-volume metal wastestreams such as heat exchangers from decommissioned reactors.

As noted previously, these activities can involve workers handling waste and it is necessary to demonstrate principles of BAT/BPM and ALARP are being applied.

Decay storage

Decay storage effectively uses time as a treatment step. This approach means putting waste into storage for a period to allow radioactivity to decay to enable a specified retrieval or treatment step, or to allow a change in disposal route. This management step can be expressed as decay storage at the outset of packaging for storage or it can be a management step that is selected after a period of interim storage. Adopting a strategy of decay storage management for radioactive waste can be part of a BAT/BPM, ALARP, or other optimisation case, as an enabling step that increases the range of potential treatment options and end points for a given waste stream (e.g. disposal as LLW, VLLW or reuse).

Decay storage is recognised in the NDA Radioactive Waste Strategy to be suitable for wastes mainly comprising radionuclides with a relatively short half-life (approximately 30 years or less). This waste management approach is consistent with existing NDA strategy and regulatory guidance, for example, concerning application of the waste hierarchy.

The Joint Guidance encourages the application of decay storage management in the context of application of the waste hierarchy. It also recommends effective characterisation of waste and segregation of short-lived waste streams, so that decay storage opportunities may be identified. Decay storage is recognised as a management strategy that would underpin arguments not to condition wastes to a passively safe form as soon as is reasonably practicable. This would be described in a radioactive waste management case (RWMC).

The NDA has reaffirmed this position in published Stores Guidance and is considering the findings of a recent a broad storage review. This review has examined potential storage strategic options including the role of decay storage in light of the current mission and recent strategic developments including the anticipated availability of a GDF, decommissioning plans developing within Magnox, the potential development of near-surface disposal facilities and preparations for decommissioning at Sellafield. All of these strategic projects could influence the potential benefits derived from decay storage.

Supply chain development

One challenge facing decommissioning and waste management projects is the timely availability of skills, experience, facilities, and capability within the supply chain. Uncertainty around the nature and extent of waste, its characteristics and the timing of waste arisings means that there is inherent uncertainty in requirements for its management. As a result, it can be challenging to find treatment routes within the supply chain. This uncertainty can also impact ancillary services around characterisation, sample analysis, technical and safety assessments. These are aspects that the nuclear industry is dependent on and therefore to support successful delivery of the mission it is vital that we work as an industry to improve the accuracy of inventory estimates and that supply chains are maintained and developed. Waste producers also need to understand where potential legislative and economic threats could impact on the availability of treatment and disposal routes.

To build and maintain a healthy supply chain and ensure treatment routes are available to waste producers, there have been several successful LAW framework recompetitions delivered by NWS (formerly LLWR Limited), enabling continuity of access to LAW treatment capabilities in the supply chain. There has been a valuable increase in the number and range of metallic treatment capabilities available for LAW. LLWR Limited also relaunched the alternative treatment framework, offering access to a range of bespoke treatments for challenging wastes and these initiatives have the effect of increasing the range of options available to waste producers and driving innovation through increased competition.

There is broad use of these treatment routes across the NDA group and specifically, Dounreay site has piloted use of the metals and combustible framework routes for treatment of LLW. Work is ongoing to continue to expand the envelope of treatment services available to waste producers by exploring supply chain capability and waste compatibility at the lower end of HAW.

Looking to the future, it will be important to work with the supply chain, to recognise the direction of strategy where future needs are emerging, to support development in a way that meets commercial and legal obligations. It will also be important to continue to seek a range of commercial models that allow waste producers to optimise waste treatment in the supply chain, e.g. committed orders and aggregated waste volumes. This combined with the results of ongoing inventory improvement work will assist the supply chain in positioning itself to meet the demands of nuclear decommissioning and waste management.

Through our supply chain interactions, and broader interactions with industry and academia, the NDA supports and promotes skills development. We recognise that in addition to technologies and capability, skilled workforce is essential for successful deployment of the technologies and the supporting capabilities vital to the delivery of our mission.

Packaging and containers

Typically, as part of the treatment and conditioning step, waste is placed into a container that is designed to meet handling and containment requirements throughout all subsequent phases of the waste management lifecycle. The procurement of containers represents a significant investment over a period of several decades. The design or selection process is influenced by a variety of factors including the radiological, chemical, and physical characteristics of the waste, as well as the proposed available treatment, storage, and disposal routes. Characterisation is vital in informing container choices and ensuring that the resulting waste packages are appropriate for their lifecycle, e.g. to ensure that the type of container (and potentially transport container) will meet requirements at the point of transport.

Currently, waste producers develop, procure, and deploy waste containers based on their own waste packaging demands and strategies informed by the waste properties, existing waste treatment routes, supply chain capability and industry guidance.

The current approach to the development and implementation of waste containers across the NDA estate has been sub-optimal and limitations have been identified. Significant work has been undertaken to review and develop an improved strategy for the future management of waste containers, working towards a set of aspirational outcomes which could deliver potential benefits, including cost savings.

These outcomes could include the capability to more accurately forecast baseline demand for containers, across the NDA estate and for other waste producers. This would enable the identification of potential synergies and opportunities to collaborate. It would also potentially enable different manufacturing and procurement arrangements to deliver economies of scale. It is also desirable to manage the development of new containers as this is the source of significant cost throughout the lifecycle as initial designs are developed and their impact on subsequent lifecycle stages is assessed. There is an optimum combination of waste containers for inclusion in a catalogue of standardised container designs for the management of LLW and ILW that will meet the needs of waste producers and deliver value. Some of these containers could be optimised to meet the needs of multiple stages of the management lifecycle through interim storage, transport, and disposal.

NWS play a key role in setting requirements for containers and developing container designs for industry to use, to ensure that they will be transportable and disposable.

The NDA will continue to promote the coordinated approach to container design, manufacture and use through development and implementation of the waste container strategy.

Containerisation

An alternative to conventional treatment options is the containerisation of waste, which is the direct placement of untreated waste into a container to allow handling, further treatment, or direct disposal. Generally, the NDA has a strategic preference towards treating waste as early as practicable, into a form that is suitable for long-term storage and/or disposal. However, this still allows the option for pursuing containerisation, where there are strong drivers to do so. For instance:

- For some legacy facilities, waste may be removed before treatment facilities are constructed in a multi-phase waste management approach that allows the hazard and risk to be addressed more quickly

- Additionally, for inherently passive, dry HAW, arising from decommissioning where hazard and risk are demonstrably low, it could be appropriate to defer final treatment or packaging to facilitate alternative management options that result in a lifecycle that is BAT/BPM and ALARP.

Any decision to store unconditioned waste must be demonstrably BAT/BPM and ALARP, clearly setting out proposals for any future measures that are required to bring about a disposable package. Such proposals will be considered on a case-by-case basis, involving appropriate regulatory and stakeholder engagement.

Containerisation can offer benefits as it allows acceleration of decommissioning programmes by decoupling the decommissioning activities from construction of treatment facilities which can often take several years to implement. The duration of typical design, construction and commissioning of nuclear facilities including treatment plants is typically ten years or more and this has an impact on site decommissioning timescales. Adopting a staged process avoids commitment to a complete solution where waste producers have an incomplete picture of the wastes. Importantly, containerisation can present an opportunity to reduce uncertainty and learn more about the waste, enabling more effective development of options to prepare the waste in a form suitable for disposal.

During the period where final conditioning for disposal is deferred, continued engagement between the regulators, SLC and NWS is required along with an agreed forward programme to underpin the journey from an interim or raw waste form to the final product.

As part of a decay storage strategy, containerisation could enable future waste re-categorisation (to lower radiological classification) and management via alternative routes (e.g. to LLW or near surface environment). Diverting a proportion of HAW away from a GDF or LAW away from a LLW repository could provide lifecycle cost benefits.

Systems approach

As nuclear decommissioning programmes scale up across the estate, the waste management infrastructure and capability will see steadily increasing demands placed upon it. There is a need for a systems approach that reflects the scale of the challenge of the mission, able to keep pace with decommissioning and match the volumes of waste arisings with the scale of solutions provided. This applies across the spectrum of waste arisings. Wider system and architectural-based improvements will be needed to ensure that the waste producers have access to the requisite capability and capacity to optimise waste flow in terms of type, volume, and rate.

This changing emphasis could drive a change in the scale, ambition and scope of trials and R&D, for example into:

- Treatment to support large-scale demolition

- Treatment of bulk quantities of demolition arisings

- Scaled up sorting and segregation

- High-volume and throughput assay capability.

The NDA will look to this emerging area of strategy development to map capability and capacity in our plans and understand how this compares with the overall system demand profile to highlight opportunities to improve resilience, flexibility and agility. Initial areas for investigation include:

- The use of strategic BAT assessments to enable waste producers to quickly take advantage of group knowledge for technology selection or waste route development. This will allow waste producers to follow a common approach while BAT cases are adapted to take cognisance of waste specific factors and local circumstances

- The potential development of a technology selection and decision frame work that steps through the decision logic to be applied when considering waste treatment options, to aid waste producers in their decision making. Such a decision logic would consider waste properties, technology choices, the NDA value framework, benefits, established principles, prioritisation, and factors to check and consider.

The role of NDA waste producers

In delivering the mission and implementing the NDA Radioactive Waste Strategy, NDA waste producers are actively progressing work in the areas described the previously.

To fulfil the strategic objectives and advance overall progress in these areas, it is important to set out expectations to provide strategic direction to the approaches being developed by waste producers. This will ensure that waste producers tackle decommissioning and waste management in a manner that drives forward implementation of the mission in alignment with this strategic position.

Waste producers also capture key knowledge and information on their waste treatment approaches including implementation, to inform future NDA radioactive waste strategy development. The NDA expects waste producers across the group to identify and escalate specific radioactive waste treatment challenge areas such that they can be addressed at a group-level. This could include for example, where disposal appears to be cheaper than a treatment option that might be more appropriate from a waste hierarchy perspective.

In many cases these are ways of working that are not specific to the technical areas described above, but focused on leveraging NDA group capability, working with other SLCs and with subsidiaries including NWS and Nuclear Transport Services to progress the NDA group mission. Historically, this has not been an approach commonly adopted as the UK nuclear industry was fragmented, but the NDA group operating model and the formation of IWMP has promoted collaborative working, sharing knowledge, capability, and technology.

In addition, there are aspects of other lifecycle steps, e.g. planning and preparation being implemented by waste producers, that will significantly affect the treatment capability that is needed and how it should be delivered. It is recognised that ongoing work across the NDA group to improve the UK’s radioactive waste inventory will continue to enhance our understanding of potential volumes of waste requiring treatment. This improved understanding will positively impact several areas described in this Treatment Strategic Position.

The potential for group-wide coordination of waste management activities should be considered by NDA waste producers as a matter of course. This includes active participation in NDA expert groups, consideration of centres of excellence, evaluation of the potential for mobile technology, technology transfer and waste transfers, where appropriate. The development of strategic BAT positions may be utilised to enable such group-wide coordination.

The NDA’s treatment strategic position is to develop and enhance group capability by broadening the range of viable technologies that are available, to build the toolkit, solve problems and provide real choice to the waste producer. Technologies should be developed with a wide envelope within Conditions for Acceptance, rather than a sharp focus on only those wastes within the scope of a project.

The NDA is also seeking an increased level of agility; whereby waste producers can easily access the most advantageous route for the waste. In addition to the toolkit of options, supply chain sustainability and the role of flexible, proportionate (and where necessary, innovative) commercial models are important vehicles to enable this.

The goal is to provide flexibility within the estate treatment capability such that waste producers have good options when it comes to technology selection and are not reliant on the only option that will work.

Appendix

The table below shows the high-level strategic approach for the range of wastes across the inventory.

| Waste type | Areas of strategic focus | How is this enacted |

|---|---|---|

| HLW | Vitrification: Highly active liquor from the reprocessing of spent fuel is vitrified to produce HLW which is stored pending disposal to a GDF. HLW is only produced and managed at the Sellafield site. | The strategy is mature in this area and Sellafield Limited. are expecting to complete the programme. No alternative options for the treatment of such wastes are required. |

| ILW | Treatment: The baseline treatment option for radioactive wastes is often cement encapsulation, which is unlikely to be the optimal solution for all future waste streams. The NDA is exploring the strategic opportunities where additional treatment technologies could offer advantages in terms of cost savings, risk reduction, waste product quality, and volume reduction. The NDA strategy drives greater integration by sharing existing and future assets and capability where it is appropriate to do so. | The NDA continues to invest in a portfolio of research and development in this area. Broadening the available technology options also provides a level of contingency to the baseline treatment position. |

| ILW | Retrieval: At some facilities where the immediate priority is near-term risk reduction wastes are being retrieved and packaged for interim storage in modern facilities knowing that further waste treatment steps may be necessary prior to disposal. | The NDA will continue to provide strategic direction in this area to help SLCs with planning and preparation. To achieve this aim, the NDA is reviewing the current approach to the development and use of waste packages and will report its findings in due course. NWS will ensure appropriate guidance on the selection and use of container types is available to waste producers. |

| ILW | Problematic Wastes: These are wastes that have no defined waste treatment and/or disposal route available, or for which existing routes are significantly suboptimal. These wastes are considered problematic by virtue of their physical, chemical and / or radiological properties. | The NDA has formed an Integrated Project Team, led by NWS, to evaluate the inventory of problematic wastes, sharing information and identifying solutions to develop a coordinated approach to their management. This work delivers benefits across the NDA estate, and the wider industry. |

| LLW and ILW | Boundary Waste: Many opportunities to optimise the waste lifecycle and apply the waste hierarchy occur where wastes are close to the boundary between categories. This is anticipated to be an increasing proportion of the inventory of waste arisings as industry moves in to decommissioning and final site clearance. Through effective characterisation and targeted treatment, it is possible to take a risk-informed approach, minimising the volumes of waste destined for geological disposal and reducing the number of ISO containers disposed of at the LLWR. | The NDA will continue to build our understanding of the overall system requirements, in terms of the capability and capacity required to deliver our decommissioning mission across the group. |

| VLLW, LLW | LLW Treatment Services: Where practicable VLLW and LLW should be treated to reduce the volume of waste requiring disposal. VLLW and LLW have a range of treatment options such as high force compaction, metal recycling, decontamination, and incineration. | NWS facilitates a range of waste treatment services to maximise diversion from disposal at the LLWR, to reduce LLW volumes and preserve disposal capacity. |

-

Application of BAT in waste management means using economically and technically viable techniques that prevent or minimise impacts on the environment as a whole. BPM is an equivalent term to BAT and is applied in Scotland to optimise management of radioactive waste. Application of ALARP is the process of ensuring that risk is reduced to a level that is deemed to be as low as reasonably practicable. ↩

-

A tiger team is a specialised, cross-functional team brought together to solve or investigate a specific problem or critical issue. The term “Tiger Team” originates from the military and was made famous by NASA who deployed a tiger team during the Apollo 13 mission in 1970. ↩