Dalton Cumbrian Facility: 10 years of collaboration

Published 18 September 2017

Background

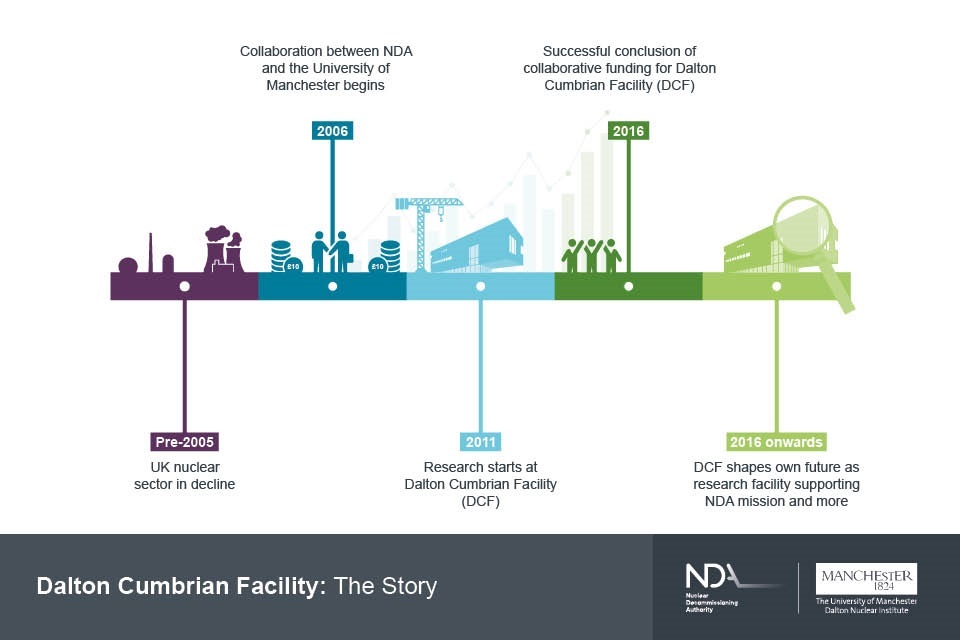

The £20 million Dalton Cumbrian Facility (DCF) was built in 2011 to fill a UK research gap and improve the UK’s high-level nuclear decommissioning expertise.

DCF Construction Time Lapse to Aug 2011

Located in west Cumbria, the world-class research facility was developed jointly by the NDA and The University of Manchester. Now firmly established as an important contributor to nuclear expertise both in the UK and internationally, we celebrate the conclusion of the 10-year agreement that established DCF and reflect on its achievements.

When the NDA was established in 2005, the UK’s nuclear industry had been in decline for some years: there were no new reactors on the horizon, political commitment had tailed off and nuclear research had declined significantly.

But as the NDA began developing its strategy for dismantling 17 of the UK’s oldest nuclear sites, the gaps in decommissioning expertise and technical skills were starkly apparent.

The University of Manchester’s Dalton Nuclear Institute was one of the few UK academic institutions to retain a serious nuclear research focus, and was a natural partner to help address the deficit. The DCF vision was launched in 2006 and the two parties each contributed £10 million to develop the cutting-edge research facility.

Based at Westlakes Science Park, DCF is close to the heart of the UK’s most hazardous, complex decommissioning challenges on the nearby Sellafield site.

2006 to 2016: successful collaboration between Nuclear Decommissioning Authority and The University of Manchester created The Dalton Cumbrian Facility

The DCF’s core purposes are to:

- pursue scientific excellence in nuclear research

- develop high-level technical skills that support the NDA mission and add to the international body of expertise in all branches of the nuclear sector

- develop innovative technical solutions to some of the challenges facing the NDA and the wider nuclear industry

- bring benefits to the west Cumbrian economy through contract opportunities, employment, attracting world-class academics and establishing the region as a centre for international research

Dalton Cumbrian Facility: 10 years of successful collaboration

Dalton Cumbrian Facility’s unrivalled facilities

The DCF boasts unique features that are unrivalled in the UK and among the best world-wide. These include:

- 2 particle accelerators

- a gamma irradiator with 8 tonnes of lead shielding

- a suite of extensive laboratories

The particle accelerators allow a single sample to be subjected to 2 forms of radiation at once. This is being developed into the world’s highest-energy dual-beam particle accelerator system.

The self-shielded gamma irradiator can supply a dose rate equivalent to spent fuel, while a suite of extensive analytical laboratories complete the bespoke setup. These enable replication, in laboratory- controlled conditions, of the damage caused to materials by ionising radiation. This means an understanding of how damage occurs can be developed and future behaviour can be predicted.

Support for NDA’s mission

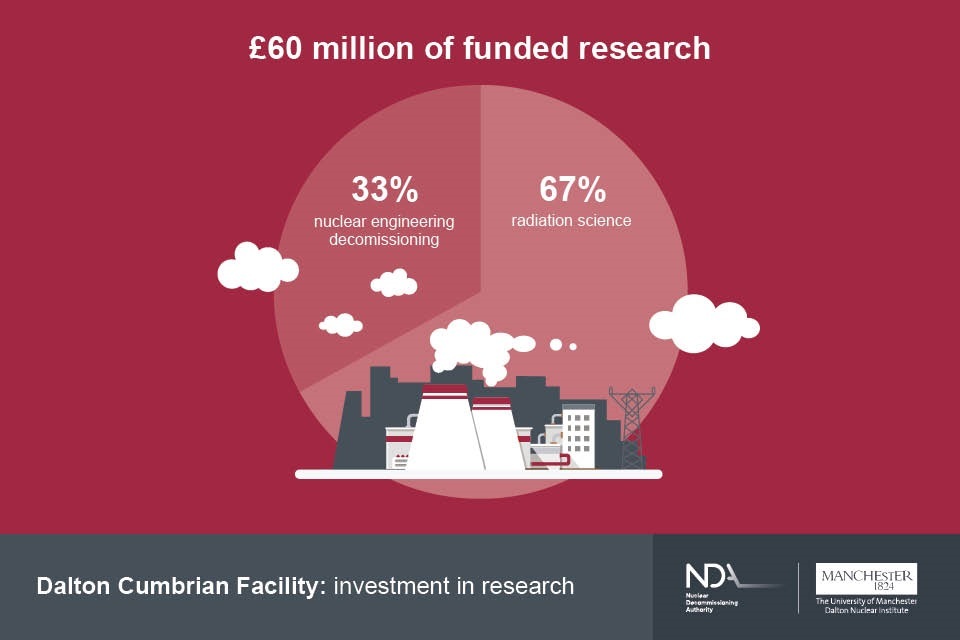

Research is targeted at 2 scientific disciplines that are critical to nuclear decommissioning and are supported by DCF’s specialised range of equipment:

- radiation science

- nuclear engineering decommissioning

Dalton Cumbrian Facility has conducted £60 million research in nuclear engineering decommissioning (33%) and radiation science (67%)

Radiation sciences

Radiation sciences focus on understanding exactly how materials are affected by radiation. This is vital to predicting how packaged material will behave over future decades, including those encapsulated in cement or other materials such as polymers.

DCF’s work has reinvigorated the UK’s research base in this field, pushing the UK right to the forefront of global expertise.

The research activities are developing and maintaining specialist skills, creating a new generation of radiation scientists who would otherwise be impossible to recruit within the UK.

DCF’s Pelletron particle accelerator is a smaller version of the Large Hadron Collider at CERN

Nuclear Engineering Decommissioning

Nuclear engineering decommissioning focuses on developing new technologies, particularly robotics, to characterise and dismantle facilities. This includes characterising radiation fields and assessing fault tolerance of robotic components to ionising radiation.

Technology developed at DCF has already been deployed on Sellafield site.

Outputs from the nuclear engineering decommissioning element have the potential to accelerate decommissioning, improve worker safety and decrease costs across the NDA estate.

The future direction for the Dalton Cumbrian Facility (DCF)

Support for the wider nuclear industry and academia

DCF has already supported completion of 21 PhD projects, worked with 15 industry research partners and 12 global partners, and a further 28 PhDs are in progress.

Links with the commercial nuclear sector are now substantial, with 15 businesses now using DCF’s facilities. Industry has funded a number of PhD studies covering a range of projects associated with specific problems experienced at site level.

Through its collaboration with other institutions, the DCF is available for use by the whole UK nuclear energy R&D community.

These include its status as part of the National Nuclear User Facility (NNUF). In 2013, the government launched the NNUF as part of its Nuclear Industrial Strategy, aiming to provide the UK nuclear R&D community with better research facilities. Supported by an initial investment £15 million from the Engineering and Physical Sciences Research Council (EPSRC), the NNUF covers three complementary facilities: the Central Laboratory of the National Nuclear Laboratory (NNL), the Culham Centre for Fusion Energy (CCFE), and the DCF.

These NNUF facilities are available for use by the whole UK nuclear energy R&D community.

The DCF is also a partner in two other strategically important research initiatives: the EPSRC National Ion Beam Centre and the Henry Royce Institute for Advance Materials.

The UKNIBC is a collaborative partnership between The University of Huddersfield, The University of Manchester’s Dalton Cumbrian Facility and The University of Surrey. It provides a single point of access for the UK research community to world-leading ion beam modification and analysis infrastructure and expertise.

The DCF has been used by 19 different universities from across the UK and overseas. As members of an IAEA programme involving cross-facility use, it is developing links with research organisations in 12 different countries.

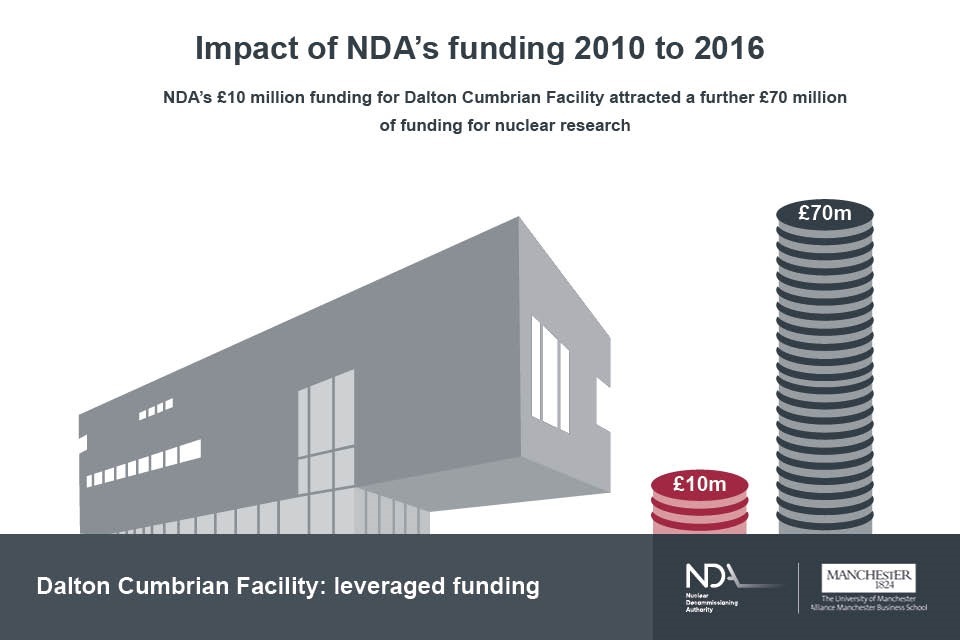

Leveraged funding

Additional research funding from outside the NDA and UoM has been secured for DCF from:

- The Health and Safety Executive

- EU 7th Framework Programme

- CARBOWASTE

- The Atomic Weapons Establishment

- National Nuclear Laboratory

- Sellafield Ltd

- The Engineering and Physical Sciences Research Council

- the Biotechnology and Biological Sciences Research Council

- Britain Energy Coast

- Forth Engineering

- Serco

- AREVA

- Rolls-Royce

NDA's initial £10 million funding for Dalton Cumbrian Facility has attracted a further £70 million of funding for nuclear research

Support for Cumbrian Community

The institute has 120 associated academics and visiting industrial staff. Many of the DCF’s technical staff and academics live in Cumbria. Other academics that are based in Manchester, estimate that 60% of their research effort is based in Cumbria.

Regionally, benefits of the DCF include:

- employment, particularly in creating high-value jobs

- education/skills, supporting decommissioning and diversification

- economic diversification, including support for the supply chain

- hosting a world-class research facility

Working with NNL, the DCF was instrumental is setting up the Innovus initiative in 2013, to support innovation in the Cumbrian economy.

Supported by funding from the NDA and the government’s now abolished Regional Growth Fund, Innovus invested in hundreds of technical projects, from those in the early stages to others that are ready for a commercial deployment.

To date, more than £1.35 million has been invested through Innovus, largely related to decommissioning technologies. SMEs and start-ups are among the businesses that have benefited.

The work of Innovus is now being developed through Sellafield’s Energy Game Changer work. The DCF also contributes to Britain’s Energy Coast and the Centre of Nuclear Excellence initiatives, helping to foster a highly skilled workforce for the future and a supply chain that can deliver innovative solutions.

NDA is focused on supporting the local community to:

- enhance the local post-14 education system to drive aspirations in young people, and thus improve results, with a view to careers in the west Cumbria nuclear community

- develop infrastructure and initiatives that improve high quality vocational skills in the current and future workforce

- through the outreach and Innovus programmes, develop a technology-driven supply chain that provides high value employment and is able to deliver solutions to decommissioning challenges

DCF benefits west Cumbrian and nationally it benefits the UK working with its national partners

Case study: Vitrified waste and novel encapsulants (Laura Leay)

Laura Leay

Laura Leay’s academic background may seem rather curious, given her present role at the DCF and her particular interest in the vitrification of high level waste.

She started her academic life with an earth sciences and astronomy degree from Durham University, followed by a Masters at Newcastle in process analytics and quality technology, a combination that would have been ideal for a career in manufacturing or the food industry.

Instead, she moved to west Cumbria, taking a project-based contract at the National Nuclear Laboratory (NNL) and dipping into nuclear for the first time. Up until then, her familiarity with the sector had been a vague recollection of an old TV advert for BNFL boasting the catchphrase Science Never Sleeps.

Her technical activities supported waste projects as she interfaced between the experimental and operational teams, analysing and reporting data, writing method statements together with a range of other activities. It marked the start of an interest in vitrification.

Continuing to Manchester following completion of the contract, she took on a safety consultancy role in the private sector, but returned to academia with a PhD in atomist modelling of polymers for carbon capture. Her earlier interest in nuclear was rekindled by a leaflet on the DCF advertising a post-doctoral position, funded through the EPSRC’s Impact Acceleration Account which provides financial support, allocated through universities, to bridge the gap between the lab and the marketplace.

For two and a half years, Laura’s work as a Knowledge Exchange Research Fellow focused on building links with industry including short-term scoping trials using DCF facilities. The initial aim was to secure interest from Cumbrian businesses but the scope soon broadened to other parts of the country and further afield.

Now in a different role funded by a BNFL endowment to the University of Manchester, Laura has re-focused on academic research, with interests including vitrification, novel materials and operational research. She oversees these research programmes, striking a fine balance between conducting fundamental research and delivering solutions for industry.

On the industrial front, she continues to extend the DCF’s links with companies in the nuclear sector, understanding their specific challenges and matching them up with capability to develop commercially viable solutions, which could take the form of PhD or post-doctoral research. These wider links with industry and international partners are vital to broaden the nuclear research base and ensure that solutions developed are applicable to real on-site challenges.

Laura said:

Personal contacts in building up such links are important, and that’s part of my mission. The DCF’s collaboration with industry is gathering momentum and it is the only UK organisation to offer bespoke specialist facilities through the National Nuclear User Facility, the National Ion Beam Centre and most recently the Henry Royce Institute.

Case study: Computer modelling of fuel cladding oxides and hydrogen radiolysis (Jenny Schofield)

Jenny Schofield

Jenny Schofield has always loved physics and when she spent a year in Grenoble as part of her undergraduate studies, the nuclear option on offer proved fascinating. After graduating from The University of Manchester, she chose to continue her studies through a PhD at the DCF.

Now at AWE, where she provides scientific technical support on nuclear issues for the government, Jenny’s doctoral studies began in 2012 and were divided between Manchester and west Cumbria.

The computer modelling work in Manchester focused on materials used as fuel cladding in nuclear power generation, such as zirconium dioxide and other oxides, together with how proton and helium ions lose energy when in a material such as uranium.

The second part of her work, based in Cumbria, where she was able to use the Cobalt-60- gamma irradiator, looked at hydrogen radiolysis, particularly with regard to silicon carbide, a potential cladding material that could be used in a geological disposal facility. How would it react when in contact with water and when encountering radiation?

Her findings contribute to the body of knowledge that will help inform future technical options around the management of radioactive waste, one of many vital pieces of work in a complex jigsaw.

Jenny said:

I loved it at the DCF.

Much of my work was based in Manchester, but I visited Cumbria frequently and lived there for 7-8 months. The facilities are absolutely amazing and the staff are so enthused about science. It’s rare to find such access to an accelerator or irradiator in any other university, and I’m also really pleased to see that academics and scientists from other institutions, as well as from NNL are now using its facilities, as that is exactly what was intended.

Jenny completed her PhD in 2015 and, after a six-month secondment with the NDA’s R&D Team, took up a post with AWE, remaining in the nuclear industry. Her studies were invaluable in helping to secure the post and informing her current activities.

Jenny added:

I quite simply wouldn’t be here without my work at DCF. It has been invaluable.

Case study: Small remotely operated vehicles with multiple capabilities (Arron Griffiths)

Arron Griffiths

Robots are a vital part of the toolkit for dealing with radioactive waste stored at inaccessible or hazardous facilities on ageing nuclear sites.

Post-Doctoral Research Associate Arron Griffiths is at the cutting edge of developing highly specialised but small-scale robots that can be cleverly adapted for a range of uses including high-definition underwater imaging, gamma spectrometry and pushing radioactive waste around.

His journey to nuclear robotics engineering began with an electronics BTEC in the Midlands followed by a BSc at Plymouth, where he submitted a project for a 3ft robot goalkeeper that could save penalties in a charity competition.

He described his work as:

Technical but fun.

He spent a further 2 and a half years as a research assistant at Plymouth, and, by now highly specialised, moved on to The University of Manchester, working on cutting-edge robotics.

The UoM was already engaged in a partnership with Sellafield, pursuing a project called AVEXIS. Arron became a Post-Doctoral Research Associate at the DCF, on an 18-month contract to continue developing the small underwater vehicle that could be deployed in inspection work at ponds or silos.

AVEXIS needed to squeeze through a six-inch access pipe at one of the site’s most hazardous facilities, the First Generation Magnox Storage Pond, to assess the condition inside.

Such small remotely operated vehicles (ROVs) are not available commercially, so we aimed to scale down, using a 3D printer we’d bought for just £2,000, and other off-the-shelf components, together with little tricks we’d picked up along the way. The whole vehicle was less than £5,000 in total, including the tether that attaches to the remote computer - ideal for a single-use disposable ROV.

Funded by EPSRC, Sellafield and Innovus, a working prototype was further developed by small local business Forth Engineering, based in Maryport, so the components became more robust and able to be reproduced.

AVEXIS, with a high-definition camera, is now being deployed at the Magnox Swarf Storage Silo (MSSS) where a small hook attachment enables it to reposition some of the swarf so the water level can be drained down.

A modified version of the robot, AVEXISDamsel, is the subject of a joint project to support the clean-up of Fukushima. The partners are the universities of Lancaster and Manchester, with the JAEA and National maritime Institute in Tokyo – the aspiration is to deploy AVEXIS Damsel in the open fuel ponds, to understand how far the melted fuel has dropped through the floor of Reactor 1.

Arron is now working on a new project CARMA, Continuous Autonomous Radiometric Monitoring, a ground-level wheeled robot that monitors storage areas, barrels, boxes and glove boxes. Completely autonomous, it produces a 2D map that indicates areas of high dose levels, and is ideal for alpha particle detection where equipment needs to be very close to pick up readings. Attachments can include sensors, gamma spectrometer 3D camera, laser scanner and more. A working prototype has just been completed and discussions are under way with Sellafield for possible trials with a view to deployment at THORP.

Although working so far on fixed-term grant-funded projects, Arron hopes to remain in Cumbria at a specialist robotics lab being developed jointly by a number of universities and NNL.

Arron says:

Although robots are used widely in the automotive and food industries, nuclear is one of the very few other applications that are real and tangible – it’s exciting.

Case study: Reprocessing of spent nuclear fuel (Greg Horne)

Greg Horne

Greg Horne was among the very first PhD students to arrive as the DCF opened its doors in 2011, and relished the opportunity to have an influence on the selection of equipment and fittings. He had studied for an integrated MSc in chemistry with a year in the pharmaceutical industry, but had always been drawn to the nuclear industry. He arrived via the Nuclear FiRST Doctoral Training Centre, a collaboration between the universities of Manchester and Sheffield to train the next generation of nuclear scientists, launched with a grant from the EPSRC in 2009. The previous year, the UK government had announced plans for a new generation of nuclear power stations, signaling new opportunities for investment and associated research.

Specialising in radiation chemistry and the reprocessing of spent nuclear fuel, Greg spent around half his time at the (back then) new gamma irradiator, looking at cobalt-60 gamma radiolysis, and the remainder working on plutonium and americium alpha radiolysis at NNL’s laboratories on the Sellafield site.

It was, he says, ”brilliant”, and, together with a six-month placement on picosecond pulse radiolysis equipment in Paris, the DCF doctoral work helped to secure his current post as a Radiation Science Post-doctoral Research Fellow at the Idaho National Laboratory, America’s premier nuclear science and technology institute, where he has been working since June 2017. He had earlier taken a joint postdoctoral position at California State University Long Beach and the University of Notre Dame’ Radiation Laboratory, researching the radiation chemistry of advanced spent nuclear fuel reprocessing schemes.

He continues to build his expertise in decommissioning and reprocessing, skills that are vital in the global nuclear industry where knowledge-sharing is an integral part of the many collaborative initiatives under way.

We work with labs across the US and Europe, including the UK. There’s an excellent co-operative spirit in the nuclear industry internationally. Everyone is keen to share, especially in decommissioning.

Greg has been part of the DCF’s journey from the start of construction to its present success in research and working with industry.

Greg added:

In the 1960s and 70s, radiation science simply closed down and many people from that era have now retired. So it’s wonderful to see the DCF flourish, employing more staff and carrying out more research. There are very few places in the world that train radiation chemists today, but the DCF is right there at the forefront – one of the best. This group of specialists is absolutely critical and I am thrilled to be part of it.

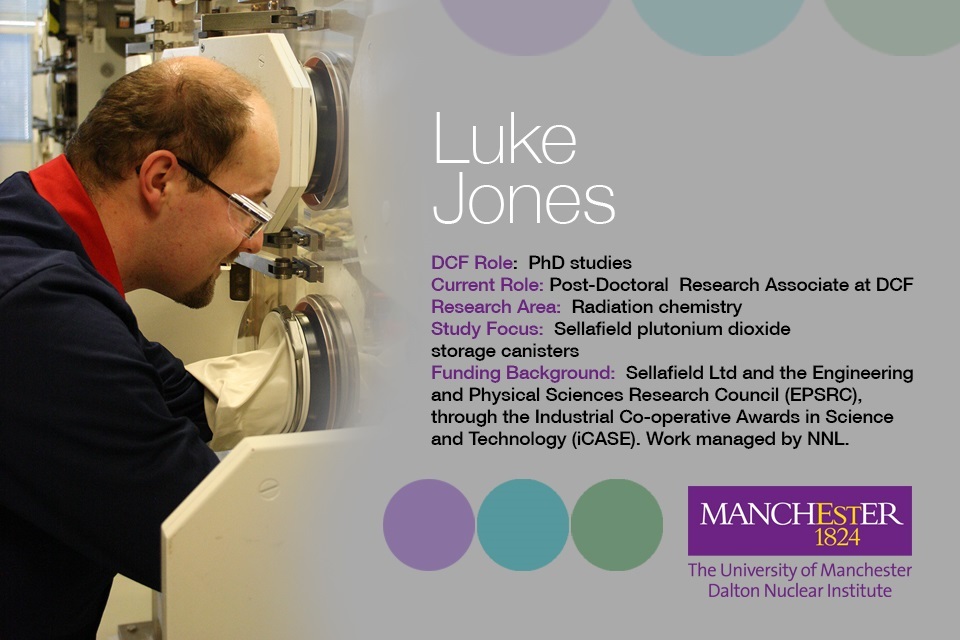

Case study: Sellafield plutonium dioxide storage canisters (Luke Jones)

Luke Jones

Luke Jones’ interest in the nuclear industry began with a 12-month industrial placement part-way through his chemistry degree at The University of Manchester.

The work for AMEC in Warrington included projects with one of Sellafield’s effluent management facilities, the Site Ion Exchange Effluent Plant (SIXEP), and decommissioning associated with fast reactors for Dounreay Site Restoration Ltd (DSRL), an experience that brought him into contact with the nuclear sector and has influenced his studies ever since.

I became interested in nuclear through the placement, having previously not really considered it, and wanted to continue.

He opted for a radiochemistry module in his final undergraduate year before embarking on a PhD at the DCF where he is now a Post-Doctoral Research Associate (PDRA).

His studies focused on the plutonium dioxide storage canisters at Sellafield, in particular the mechanisms by which gas could be generated inside the canisters.

Ionising radiation introduces a new set of challenges and obstacles to overcome experimentally, which was appealing to me. The University of Manchester has world-class research facilities in this area and a number of projects were based up in West Cumbria, near Sellafield, which I hadn’t managed to visit during my placement.

For my PhD, I was studying the effects of radiation on gases inside the canisters at the interface with ceramic oxides, inactive surrogates for plutonium dioxide. The plutonium residues have been in storage for 20-30 years and will remain so for the foreseeable future. Whilst in storage, they are required to be dry; however, a small level of moisture is still present. It is known that water will react with radiation emitted by plutonium, producing hydrogen and oxygen, my research aimed to investigate the reverse reaction and to what extent they would recombine back into water.

Plutonium dioxide is one of the products from the reprocessing of spent fuel at the THORP and Magnox reprocessing plants.

Luke’s research, managed by NNL, was funded jointly through Sellafield and one of the Industrial Co-operative Awards in Science and Technology (ICASE) provided by the Engineering and Physical Sciences Research Council (EPSRC). ICASE funding is aimed at PhD studentships where businesses take the lead – Sellafield in Luke’s case - in arranging projects with an academic partner and ensuring the research is focused on a specific business issue.

His PhD studies, which concluded in 2015, began to build a body of valuable new data and uncovered further areas for study, which he is now pursuing as a PDRA – with the added opportunity to work at an NNL active facility.

Luke’s time is divided between the NNL active labs and the DCF, while Sellafield are also seeking support on researching the external chemistry associated with the stainless steel canisters used to store plutonium dioxide. After developing highly specialised expertise through the DCF, Luke aims ultimately to deploy his knowledge in a technical capacity, spending his foreseeable future career within the nuclear industry.

Case study: Sellafield plutonium dioxide storage canisters (Laura Murtagh)

Laura Murtagh

Laura Murtagh, from Whitehaven, has just finished three years of undergraduate chemistry studies at Lancaster before embarking on an MChem.

A DCF outreach campaign offering placements for local STEM students reached Laura, via her old head of sixth form, and she is now part-way through her second summer at the facility.

She has loved the opportunity to immerse herself in an academic atmosphere and use the gamma Co60 gamma-irradiator for her first project on ion exchange resins.

There was a choice of three topics with different supervisors for the summer placement, all contributing to studies that were already under way.

Laura was tasked with making up a variety of samples containing cationic exchange resins under different atmospheres and in different solvents. Her work focused on quantifying the effects of irradiation on these samples; including hydrogen gas production, monitoring of the proton and sulphate degradation products from resins, and determining the total exchange capacity. Ion exchange resins are widely used to clean up radioactively contaminated water.

For her second spell at DCF, now under way, Laura was thrilled to be able to get involved with graphene research.

Graphene is generating lots of excitement. Together with other carbon-based materials, it’s already being trialled in water decontamination so potentially, and probably a long way into the future, there’s a possibility that it might replace ion exchange resins.

What has really excited me about the DCF is that, for me, it was real research, not doing something for the sake of it, as often happens with student work placements.

I enjoyed using the irradiator, making up samples with different resin ratios, irradiating them and analysing the results with different lab equipment. I’ve learned how to use many different pieces of analytical equipment during my time here.

I love the fact that it’s just a 10 minute walk away from home and that the atmosphere is relaxed but buzzing with science conversations, even at lunch-time. There are people from so many different scientific backgrounds, working on a wide variety of different projects.

As a science student, although I haven’t decided where my future lies, it has really opened my eyes to the possibilities of going into research rather than opting immediately for a job. And in a region where Sellafield dominates the economy, it’s wonderful that other choices are opening up. If any other students are offered the opportunity, take it. It’s a brilliant place to be and I’d definitely recommend it to anyone!