Bradwell nuclear site: celebrating 60 years at the heart of the community

Published 29 November 2018

Introductions

Brian Main: Local Community Liaison Council Chairperson

Bradwell Power Station has been a good neighbour to our community for almost 60 years. It has been engaging regularly with stakeholders and providing much needed socio-economic support around the local area.

As Local Community Liaison Council Chairperson, I would like to thank Magnox for providing long-term stable employment in an area where it isn’t always easy to secure that type of work.

I look forward to working with the Nuclear Decommissioning Authority (NDA) and Magnox as we decide on the best way to engage with stakeholders now the site is in care and maintenance.

Brian Main: Local Community Liaison Council Chairperson

Tony Moore: Magnox Managing Director

I am incredibly proud of the work done at Bradwell to prepare the site for care and maintenance. This is a first and it is a fantastic achievement for Magnox, the NDA and the UK nuclear industry.

There has been a tremendous amount of effort put in by so many people, not only from Magnox, but also our contractors, the NDA and our regulators who have collectively made this happen. I want to congratulate everyone who has made a contribution to this shared success.

Bradwell’s experience will inform the way forward for decommissioning for the rest of the Magnox fleet and help progress the UK’s decommissioning mission into the future.

Tony Moore, Managing Director of Magnox Ltd

Bob Nichols: Bradwell Site Closure Director

I have had the pleasure of being the Site Closure Director here at Bradwell before the site enters care and maintenance. I am immensely proud to have been able to work with such a dedicated team of people. To make this UK first happen in the timescales we had is something we should all be proud of.

The decommissioning of Bradwell has been a challenging but rewarding programme of work for those who have been involved over the years. We have undertaken innovative decommissioning techniques here and shared these across the fleet, helping others to develop their future plans.

As the site enters the next phase of its life, the team here can look back and say it was the first to reach care and maintenance at a Magnox nuclear power station in the UK, now that’s an achievement to shout about!

Bob Nichols, Bradwell Site Director

David Peattie: Nuclear Decommissioning Authority Chief Executive Officer

Bradwell becoming the first of the UK’s legacy sites to enter care and maintenance is a historic moment, not just for Magnox and the NDA, but for the country. I’d like to give my thanks to all who have been involved in the collaborative effort to deliver this significant achievement.

Together we have developed a vision for our 17 sites around the UK, with ambitious targets to accelerate decommissioning and secure savings.

Within this, Bradwell has pioneered methods for tackling the challenges we face at many of our Magnox reactor sites, and has contributed to an important body of expertise that is being shared across the NDA Group.

David Peattie, NDA CEO

November 2018: entry into care and maintenance

In 2009, Bradwell was one of two Magnox sites selected for accelerated decommissioning. Less than a decade later, it has become the first UK nuclear site to reach care and maintenance (C&M) – a truly momentous milestone.

C&M is one of the lifetime phases of a nuclear site. During C&M nuclear sites are managed remotely by a specialised team. The sites are monitored continuously, with planned maintenance and inspection activities undertaken.

The sites, and any structures that remain, are kept in a passively safe and secure state for a number of decades. This allows radiation levels within buildings, such as the reactor safestores, to naturally decay over time before the reactors are dismantled and the site is cleared.

To commemorate such a huge achievement, this brochure looks back over the journey that Bradwell has taken since construction began in 1957.

Entry into care and maintenance for Bradwell, November 2018

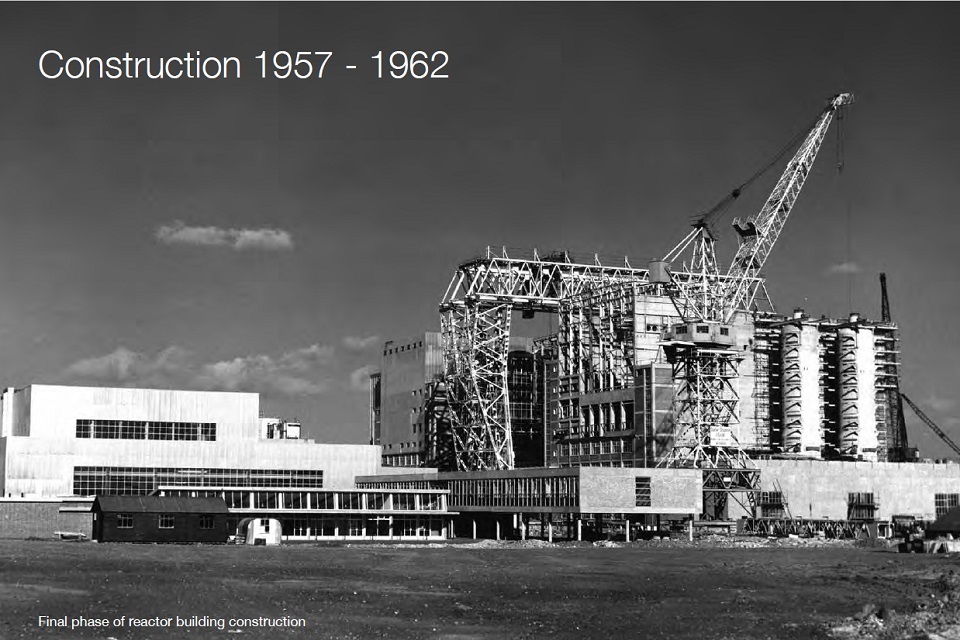

January 1957: construction began

The 24-acre site was a former World War II airfield.

The adjacent Blackwater Estuary provided the 222 million litres of cold water per hour for cooling.

Bradwell construction 1957 - 1962

Construction began at Bradwell in January 1957: the 24-acre site was a former World War II airfield.

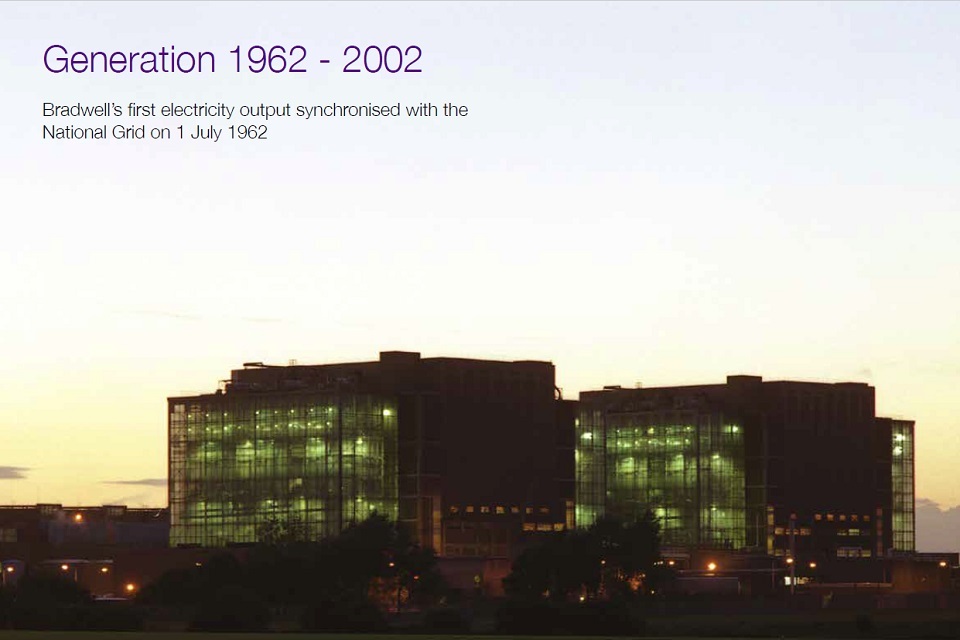

1962 to 2002: electricity generation

Bradwell’s first electricity output synchronised with the National Grid on 1 July 1962.

During its lifetime, Bradwell generated nearly 60 terawatt hours (TWh) of electricity - enough to power 15 million homes for one year.

On an average day the site generated enough electricity to power three towns the size of Chelmsford, Colchester and Southend put together.

Bradwell power station with lights on.

Bradwell official opening day: 5 April 1963

2002 to 2018: decommissioning work

Bradwell site before decommissioning.

Bradwell’s reactors shut-down on 30 and 31 March 2002 ending generation of electricity at the site.

Defuelling the reactors began in 2002 and was completed in 2006, removing more than 99% of radioactivity from the site. The huge task of decommissioning the site then began.

Bradwell was a pathfinder site for decommissioning. The projects undertaken there provide a good insight into what will need to be done at other Magnox sites during decommissioning. This has meant many first-of-a-kind projects have been trialled at the site and learning from these will be used at other sites.

To achieve C&M, Bradwell pioneered groundbreaking decommissioning work, such as removing historically-stored legacy wastes and deplanting redundant nuclear plant.

Conventional hazard removal of asbestos and demolition of buildings and redundant assets have also been completed.

Construction of new facilities has ensured that the site will remain safe and secure throughout the C&M period, demonstrating that Britain’s nuclear legacy is being managed safely.

The innovative techniques employed on site have ensured that Bradwell is internationally recognised as a leader in nuclear decommissioning.

Key facts about Bradwell - see text.

Key tasks involved in achieving Care and Maintenance at Bradwell

Timeline and facts: see text.

May 2010: essential equipment rewiring and cable cutting

The removal of the turbine hall marked the first major skyline change at Bradwell since the station was built. In excess of 12,000 tonnes of waste were removed, 94 per cent of which was recycled, and more than 130,000 hours were worked without a lost time accident. This project won the World Demolition Collaboration Award alongside the contractor Erith in 2012.

September 2011: turbine hall deplant and demolition

The first major project on the journey to C&M provided Bradwell with an alternative electrical system that segregated the site into 6 clearly defined electrical islands, allowing for safe C&M preparations.

In total, 948 legacy electrical cables were cut once the new system was installed.

March 2012: barrier wall removal

The corroded east and west wing walls on the barrier wall were removed to eliminate the potential environmental and safety hazard. In excess of 56,000 hours were worked on the removal of the 185 metres of wing wall either side of the central structure.

March 2014: pile cap deplant

Deplanting and removing the site’s four charge machines and other items of plant from the pile cap area of both reactor buildings. Ancillary rooms, which were associated with pile cap operations during the site’s operational phase, were also deplanted. More than 3,500 tonnes of waste were removed during this project and more than 351,000 hours were worked without any lost time accidents or reportable events.

August 2014: north end remediation

Remediating an area of land that had become contaminated by a historical leak from the original active effluent discharge line. Contaminated soils were removed with an engineered capping solution applied to the area.

In excess of 28 tonnes of soil were excavated.

December 2014: drains renewal

Renewing the site drainage system that had numerous faults and defects. In total, more than 800 metres of drainage had to be renewed to provide a fit-for-purpose system that would last throughout C&M. Completed ahead of schedule without any safety incidents.

March 2015: administration building demolition and removal

Removing the main Bradwell administration building and associated buildings, including the original site canteen, welfare block, medical centre and other offices. A total of 235 temporary buildings have also been removed.

July 2016: boiler house deplant

Deplanting the site’s four boiler houses, each containing 3 boilers and associated plant. This included the removal of services (electrical and instrumentation equipment, cabling and cable trays) and the boiler high-pressure and low-pressure drums, headers and associated steam and feed water pipework. All pipework was cut and capped and more than 250,000 hours were worked without incident and 2,500 tonnes of pipework removed.

July 2016: safestore cladding

The project which has had the most visual impact on the Bradwell site. It has been one of the largest scaffolding jobs in Europe.

The cladding is designed to safely encompass the reactors throughout C&M. It is a structure that is designed to withstand the elements for 100 years and be resilient to any seismic or future extreme weather conditions.

29,000m2 of cladding

29,000m2 of insulation

67,575 metres of insulation tape

288,000 of cladding fixings

1,200 tonnes of scaffolding

Over 800,000 hours worked

900 people worked on the project

February 2017: vaults decontamination

In excess of 240 tonnes of legacy fuel element debris (FED) were removed from the vaults and packaged safely into 2,900 drums for processing.

The 18 vaults were subsequently deplanted and decontaminated. A total area of 972m² was decontaminated – the equivalent size of 5 tennis courts.

May 2017: ponds decontamination and demolition

Around 3,000m3 of pond water, more than would fill an Olympic pool, was removed safely prior to the decontamination of more than 10,000m2 of walls, floors and ceilings.

Eleven ponds complex buildings were demolished, generating 1,461 tonnes of rubble. The remaining buildings were enclosed in weatherproof cladding ready for C&M.

July 2017: fuel element debris dissolution

The dissolution of legacy FED at Bradwell involved dissolving the FED in a nitric acid solution to separate the radioactive material from the inert waste. This reduced the volume by 90 per cent and mitigated the requirement to dispose of the harmless waste. The remaining effluent was treated and discharged within permitted levels and the items of higher activity packaged and stored.

More than half of the FED at Bradwell was reclassified as suitable for disposal as Low Level Waste (LLW) in a first-of-a-kind collaboration between Magnox, the Low Level Waste Repository (LLWR) and specialist contractor Tradebe-Inutec. More than 140 tonnes of FED were sent to Tradebe-Inutec as LLW for treatment and eventual disposal at the LLWR in Cumbria – saving around two years of dissolution operations.

September 2018: security upgrade

New security systems, including more than one mile of high-security perimeter fencing, have been installed at Bradwell to keep the site secure throughout C&M. Alarm systems and cameras will be remotely controlled and observed by Sizewell A in Suffolk.

November 2018: waste clearance

The clearance of waste on a nuclear site is a highly-regulated process. Where possible at Bradwell, demolition material was reused as backfill for redundant voids. This reduced the requirement for imported fill material and the associated cost, as well as reducing the number of vehicle journeys on local roads. All other wastes were segregated, sorted and monitored prior to leaving site for disposal or recycling.

November 2018: interim storage facility

The interim storage facility (ISF) was constructed to house intermediate level waste (ILW) final disposal packages until a national Geological Disposal Facility becomes available. Under a revised ILW storage strategy, up to £200 million could be saved across the Magnox fleet through the importation of waste from Sizewell A in Suffolk and Dungeness A in Kent, removing the need to construct stores at those sites.