New studies for manufacturing advanced materials in orbit

Life-saving medicines, optical fibres and semiconductors could be made in space to benefit people and businesses across the UK.

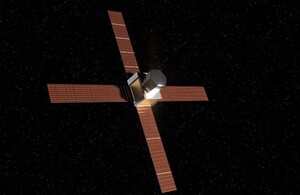

Credit: Space Forge.

The UK Space Agency has awarded contracts to three UK companies to investigate producing these advanced materials in Low Earth Orbit, where the conditions – including microgravity, natural vacuum, and extreme temperatures – can create products that are difficult, expensive, or impossible to manufacture on Earth.

The research supports in-orbit servicing, assembly and manufacturing (ISAM), which the government identifies as a priority capability area for UK leadership, growth, and national security.

Each study will assess technical feasibility, mature key technologies, and develop credible routes to market.

Space Minister Liz Lloyd said:

Space isn’t just about exploration, it’s about innovation that improves everyday lives here on Earth.

These pioneering studies show how British ingenuity is pushing the boundaries of what’s possible - leveraging space conditions to innovate the development of life-saving medicines and advanced materials that will power future technologies. By investing in in-orbit manufacturing, we’re backing the jobs and industries of tomorrow while cementing the UK’s position as a global leader in the space economy.

The three contracts are:

BioOrbit Ltd (£250,000) – The ‘PHARM’ study will design an end-to-end mission to manufacture drugs in microgravity. Microgravity enables the formation of more perfect, reproducible protein crystals for drug formulations that cannot be achieved on Earth, enabling cancer treatments to be given at home. BioOrbit is working with relevant regulatory bodies to ensure that this mission can be readily commercialised.

Space Forge Ltd (£300,000) – The ‘2Forge2Furious’ study will demonstrate how semiconductor seed crystals could be produced commercially in orbit, with the aim of improving the efficiency, reliability and power density of high-power electronic devices, including telecommunications, data centre infrastructure, EV charging and quantum computing.

OrbiSky Ltd (£295,000) – The ‘SkyYield’ study will design a payload to process ZBLAN fluoride glass in microgravity. ZBLAN is a specialist optical fibre that can transmit light with up to 100 times less signal loss than traditional silica fibre, with significant potential for telecommunications and medical imaging.

Dr Paul Bate, Chief Executive of the UK Space Agency, said:

By backing these innovative companies to explore manufacturing in orbit, we’re positioning the UK to capture new markets and bring tangible benefits back to Earth—from better medicines to more efficient electronics. These studies demonstrate the government’s ambition to drive forward one of the most exciting frontiers of space technology.

The investment is jointly funded by the UK Space Agency’s Sustainability & ISAM and Unlocking Space programmes. The Unlocking Space portfolio supports UK space sector growth by tackling systemic barriers and driving demand, investment readiness, and public sector adoption of space‑based services, data, and technologies by new stakeholder groups. This includes engagement with public and private sector end-users of pharmaceuticals manufactured in microgravity, and identifying interventions which support commercialisation of these products.

Dr Katie King, CEO of BioOrbit, said:

Space made pharmaceuticals will have a dramatic impact on all of our lives. BioOrbit’s PHARM study ensures that we can produce drugs in space under the same regulation as drugs made on Earth – which will be a world first.

Josh Western, Space Forge CEO and Co-Founder said:

Space Forge is pleased to be a part of this national effort to place the UK at the forefront of in-space manufacturing.

The UK Space Agency has seen the opportunity that this high potential sector has, and placing a contract such as this is a key indicator of the UK’s support for innovation and growth. Space Forge has proven our technology with the ForgeStar-1, generating plasma on a commercial free flying platform for the first time. This study will allow us to progress that development towards true commercialisation.

Sylvester Kaczmarek, Chief Executive Officer at OrbiSky, said:

SkyYield is about turning the unique conditions of microgravity into real-world capability. With UK Space Agency support, we’ll define a credible, end-to-end payload concept for manufacturing ultra-low-loss ZBLAN optical fibre in orbit, including the process controls and verification needed for commercial adoption.

This is an important step towards new UK-led markets in space manufacturing, with clear benefits for telecoms and medical imaging.