Appendix 8: Disciplinary procedures

Reasons for cessation of authorisation for authorised examiners and testers, informal appeal hearings, notice of cessations.

Test results

‘Recording a test result’ means either:

- recording if the vehicle passed or failed its MOT on the MOT testing service

- completing a CT20 or CT30 certificate if you’re carrying out a contingency test

A. Authorised examiners

Normally an authorised examiner’s (AE’s) authorisation will be subject to cessation for disciplinary reasons following a single instance of the types mentioned under sections 1, 2 and 3 below, whether committed by the AE or their employee or agent.

Where fraud has been committed, prosecution may be considered.

Authorisation may also be subject to cessation following a single instance of the types mentioned in sections 4 and 5 below, again whether committed by the AE or their employee or agent.

1. Fraud, dishonesty or gross negligence

| Shortcoming | Points |

|---|---|

| Improper recording on the MOT testing service of the test result of a vehicle or issue of a VT20 or a VT30 involving some act of fraud, including misuse of the MOT testing service, dishonesty, or gross negligence | 500 points |

For example:

- a tester records a pass or fail test result without personally taking any active part in the examination of the vehicle

- a duplicate VT20 is issued unjustifiably

- unjustified changes are made to a test record

- a bribe is accepted to record a pass result for a vehicle

- the recording of a test result to vehicles which have attended a VTS in which their start and finish test time recorded in the MOT testing service would not allow a full examination to be carried out

- CT20 or CT30 issued for vehicles when there was no contingency testing (CT) incident

2. Conviction

| Shortcoming | Points |

|---|---|

| Convictions, as defined in Appendix 7: Convictions and repute, to any persons involved in the MOT scheme under the authorisation | 500 points |

This includes:

- AE principals (AEPs) - directors, partners, and sole traders

- authorised examiner designated managers (AEDMs)

- AE delegates (AEDs)

- site managers (SMs)

- site admin

- testers

3. Repute

| Shortcoming | Points |

|---|---|

| Loss of good repute, as defined in Appendix 7: Convictions and repute | 500 points |

4. Other very serious offences

| Shortcoming | Points |

|---|---|

| a. A test is carried out by a person who is not properly authorised to carry out tests at the VTS - a person is properly authorised to test at a particular VTS if they are acceptable as set out in Section E - Tester | 500 points |

| b. Testing is carried out on a vehicle that the VTS is not authorised to test. For example, wrong class or inappropriate emissions test group. The normal penalty will be reduced to 50 points if the vehicle is not obviously of a type that the VTS is not authorised to test provided that the documentation has not been incorrectly completed in a way that tends to disguise the vehicle’s correct classification | 500 points |

| c. The improper recording of a pass result to a vehicle operated by, or on behalf of, the AE or which the AE has an interest in selling or seeking to sell | 500 points |

| d. Assault (either physical or verbal) on, serious threats against, or deliberate intimidation of vehicle presenters or DVSA staff or contractors | 500 points |

| e. Involvement in offering a service that undermines MOT test standards and/or the integrity of the MOT testing service, such as removing or bypassing emission control equipment or the clocking of odometer instruments | 500 points |

| f. Testing of vehicles with major equipment known to be faulty or known to be out of calibration. Major items of equipment are defined in section D2 | 500 points |

5. Other serious offences

The following single acts may also result in cessation of authorisation. If the circumstances are not considered sufficiently serious to justify single-case cessation then the penalty will be 100 points.

| Shortcoming | Points |

|---|---|

| a. Failure to notify DVSA of a conviction, as required in Section B4 - General responsibilities, to any persons involved in the MOT scheme under the authorisation, this includes: AEPs (directors, partners and sole traders), AEDMs, AEDs, site managers, site admin and testers, as defined in Appendix 7: Convictions and repute | 500 or 100 points |

| b. Breaches of security leading to improper recording of a vehicle test result or where the system has been accessed. Or breaches of security that could enable unauthorised system access, such as passwords written down | 500 or 100 points |

| c. False statement made on an application for authorisation. Confirming details when required to do so, that are known to be false | 500 or 100 points |

| d. Failure to notify DVSA of a change in the constitution or operation of a business, a change to, or of an approved site, or the failure to cease testing after such a change pending DVSA’s written confirmation that testing may resume. Further information can be found in sections B3 - Cessation of authorisation and other changes to business and B4 - General responsibilities | 500 or 100 points |

| e. The AE is no longer in control of the VTS or an AE ceased for disciplinary reasons is involved in the management of a VTS | 500 or 100 points |

| f. A vehicle and/or tester are not present on the premises for the duration of time that a test is registered on the MOT testing service | 500 or 100 points |

| g. Abuse or misuse of the MOT testing service free text option(s) which could cause loss of good repute to the MOT service -this provision will be used only in serious cases where urgent action is essential to preserve the integrity of the MOT service | 500 or 100 points |

| h. The improper recording on the MOT testing service of a test outcome, or the failure to correctly record a test result, which may have caused a complaint about data integrity (where there is evidence of incorrectly identifying the true vehicle identity) | 500 or 100 points |

| i. Other cases of loss of good repute as defined in Appendix 7: Convictions and repute | 500 or 100 points |

| j. Deliberate obstructive behaviour towards vehicle presenters or DVSA staff or contractors | 500 or 100 points |

Examples of deliberate obstructive behaviour towards vehicle presenters or DVSA staff or contractors include:

- failure to offer an appointment for a test within a reasonable period of a request, bearing in mind existing test bookings and the availability of the vehicle concerned

- unjustified refusal to test a vehicle presented or to honour, within a reasonable time, an appointment previously made

- refusal to allow a test to be watched

- failure to allow or preventing a reinspection taking place where a reasonable request has been made

- preventing a DVSA activity being conducted, as permitted in the MOT testing guide, that has been reasonably requested

B. Testers

Normally a tester will be subject to cessation if they are personally involved in any act that could lead to single offence cessation of the authorisation of an AE.

Where fraud has been committed, prosecution may be considered.

The points penalties for such acts are listed above for AEs. A tester will also usually be subject to cessation for acts of the type covered below.

Additionally it is normal practice for a tester to be subject to cessation where there are significant procedural omissions (e.g. non-use of designated equipment), and cessation may be applied for a single major incident of substandard testing that could have significant road safety implications.

Penalty points will be calculated from Appendices 8.1 to 8.3 and the action level determined in accordance with Appendix 8.8.

Additional very serious offences for testers

1. Fraud, dishonesty or gross negligence

| Shortcoming | Points |

|---|---|

| The improper recording of a pass result to a vehicle operated by, or on behalf of, the tester or which the tester has an interest in selling or seeking to sell | 500 points |

2. Conviction

| Shortcoming | Points |

|---|---|

| a. Conviction for any offence as defined in Appendix 7: Conviction and repute | 500 points |

| b. Conviction for any offence involving violence or intimidation which DVSA considers could put customers or DVSA staff at risk | 500 points |

3. Repute

| Shortcoming | Points |

|---|---|

| Loss of good repute, as defined in Appendix 7: Conviction and repute | 500 points |

4. Other serious offences

| Shortcoming | Points |

|---|---|

| Production of false documents and/or false statements to DVSA or MOT training providers | 500 points |

General

When investigating possible incorrect test standards DVSA will judge what the condition of the particular item would have been at the time of test. Points will be attributed based on what that condition was judged to be.

A single defect will not be double counted. For example, only one score is merited by a single area of corrosion covering adjacent body panels or components within 30cm of two critical components, but two separate areas of corrosion in a similar position draw a double score.

Disciplinary points

Disciplinary points will be awarded as follows for each defect when DVSA judges that the defect was in the condition described below at the time of test.

| Shortcoming | Points |

|---|---|

| 1.Any defect categorised as dangerous within the relevant inspection manual that is missed on a testable item | 40 points |

| 2. Any defect categorised as major within the relevant inspection manual that is missed on a testable item | 20 points |

| 3. Item failed is not testable | 20 points |

| 4. Item failed has no defect (i.e. not a case involving an error of judgement) | 20 points |

| 5. Any defect categorised as minor within the relevant inspection manual that is missed or incorrectly added | 10 points |

| 6a. Error of judgement – dangerous defect (e.g. dangerous item ‘advised’, or ‘advisory’ item failed or wrong defect classification) | 10 points |

| 6b. Error of judgement – major defect (e.g. major failure item ‘advised’, or ‘advisory’ item failed or wrong defect classification) | 5 points |

| 6c. Error of judgement – minor defect (e.g. minor item ‘advised’, or ‘advisory’ item failed or wrong defect classification) | 0 points |

Scoring methods

Items that the presenter may have difficulty observing during a mystery shopper check are marked with an asterix in the associated tables. DVSA will take this into account if disciplinary action is to be considered.

The following methods are used to report shortcomings noted during an observed test:

Major and minor error scoring method

The major and minor error scoring method will be used for:

- new candidates who have attended a group A or group B testers training course

- testers returning to testing following a 2 or 5 year cessation or following a lapse of 5 years and have successfully re-attended an initial tester training course

- following a lapse in testing of six months

- following the issue of a formal warning, short term cessation or wish to resume testing following a lapse of two years

- when an additional test class is wanted (class 3 or 5)

Shortcomings of method noted during this type of assessment will be scored according to the major and minor errors demonstration table for group A and group B.

Disciplinary points error scoring method

The disciplinary points error scoring method will be used for the assessment of a tester to ensure continuing competence.

Shortcomings of method noted during this type of assessment will be scored according to the point tables for group A and group B.

Where no testable item within a section or sub-section is assessed the section or sub-section scores will be applied.

The term assistant for a VTS authorised to use an ATL or OPTL means the appropriate equipment used to replace the assistant.

Retests

The extent of test required is set out in Section B - Testing responsibilities. For such retests, disciplinary points will only be awarded for shortcomings in those parts of the test that you were required to do (excluding non-testable advisories).

Split testing

Split testing occurs when a tester records the test result but only personally assesses some of the testable items. For the remaining items, another person’s assessment is relied upon.

Items assessed by the other person will be considered as not examined, and the maximum points for those items will be limited to 50.

Tester recording the test result

The tester who records the result will be liable for:

- incorrect test methods (whether by the tester or the other person)

- inappropriate standards applied (whether by the tester or the other person)

- items that were not examined at all

The penalty for failing to carry out the part of the test done by the other person will be subject to a maximum of 50 points.

Tester who carries out part of the test

The tester who carries out part of a test but allows another tester to record the test will receive disciplinary points for:

- incorrect test methods in the part they conducted

- incorrect test standards in the part they conducted

The penalty for failing to carry out the part of the test done by the other person will be subject to a maximum of 50 points.

Responsibility for test results

Only the score assigned to the tester who recorded the test result will be considered against the relevant AE (Authorised Examiner).

Seeking advice and guidance

Testers can seek advice from another tester in marginal decisions or when the second tester is more familiar with a particular vehicle type.

However, the tester conducting the test must make the final decision on whether to pass or fail a specific item.

Cases where the tester who recorded the test result had not personally made any of the pass/fail assessments are dealt with under Appendix 8.1.

General

A graduated sanction level will be applied for shortcomings in this section rather than following the traditional disciplinary points method. The levels will be applied consecutively for each occurrence within a 5-year period. The sanction may increase in severity on each occurrence, within 5 years.

The sanction levels to be applied are as follows.

Level 1 (L1)

Advice will be issued to the AE and/or tester in writing via an MOT advisory warning letter/notice and recorded as an MTS event.

Level 2 (L2)

Testing will be suspended until the case has been answered and rectified satisfactorily. Issued via a temporary suspension notice and recorded as an MTS event.

Level 3 (L3)

A disciplinary case will be submitted for:

- previous or repeating failures to adhere to MOT testing service rules or test standards, regardless of the previous role or disciplinary outcomes

- failure to follow DVSA guidance that has been reasonably requested

- other cases of loss of good repute as defined in Appendix 7: Convictions and repute

Sanctions

The following table lists the graduated sanction level which will be applied to each shortcoming. Where more than one level sanction is noted both will apply.

All items and sanctions will be considered against the AE and/or tester.

A. Equipment calibration and maintenance

The level of action is determined by the number of occurrences of the shortcoming as indicated by levels L1, L2 or L3 in the columns.

Some test equipment requires periodic calibration checks, as defined in Appendix 2: Facilities and security. It is the AE’s responsibility to provide valid calibration records to DVSA staff. Failure to produce these records will result in the following sanctions being applied.

| Shortcoming | First occurrence | Second occurrence | Third occurrence | Fourth or more occurrence |

|---|---|---|---|---|

| 1. One or more items of equipment on which calibration is overdue or calibration certificate not available | L2 | L2 | L2 and L3 | L2 and L3 |

Where the calibration certificate is not available and there is no evidence to suggest the calibration is overdue or that the equipment is inaccurate, DVSA may permit pre-booked vehicles to be tested for no more than 24 hours before the suspension is applied.

Unless DVSA has been notified that testing has been suspended, test equipment which is clearly malfunctioning, inoperative or missing a mandatory upgrade/inspection, regardless of its calibration status, will also attract the following sanction level.

| Shortcoming | First occurrence | Second occurrence | Third occurrence | Fourth or more occurrence |

|---|---|---|---|---|

| 2. Any major items of equipment clearly unable to fulfill their prescribed testing functions or missing mandatory upgrade/inspection. For major items of equipment see section D | L2 | L2 | L2 and L3 | L2 and L3 |

| 3. Any equipment with minor faults where the defect may reduce the effectiveness or accuracy with which it carries out required testing functions, such as seized turn plates or defective play detectors - this shortcoming also covers missing or defective tyre tread depth gauges | L1 | L2 | L2 and L3 | L2 and L3 |

B. Other items

The level of action is determined by the number of occurrences of the shortcoming as indicated by levels L1, L2 or L3 in the columns.

| Shortcoming | First occurrence | Second occurrence | Third occurrence | Fourth or more occurrence |

|---|---|---|---|---|

| 1.Mandatory notices, and signs required by MOT guide not displayed in required manner or illegible | L1 | L2 | L2 | L2 and L3 |

| 2.Viewing area or access to it unusable or viewing facility provides a restricted view of all the testing area | L1 | L1 | L2 | L2 and L3 |

| 3.Emissions records not readily retrievable for previous 3 months | L1 | L1 | L1 | L3 |

| 4.An adequate appointment system was not provided on request. For example, full details of vehicle and presenter are not contained | L1 | L1 | L1 | L3 |

| 5. Displaying or asking customers to sign a loss or damage disclaimer | L1 | L1 | L1 | L3 |

| 6. Where a new vehicle record has been created on the MOT testing service, that does not match the presented vehicle and a test record has been recorded (where this is not covered in Appendix 8.1) | L1 | L1 | L1 | L3 |

| 7. Inappropriate reason for rejection or incorrect location recorded | L1 | L1 | L1 | L3 |

| 8. Incorrect manual entry of measured test values onto the MOT testing service, where overall test result remains unchanged (where the incorrect manual entry has been deliberately entered to change the overall test result, refer to Appendix 8.1) | L1 | L1 | L1 | L3 |

| 9. VT20/CT20 certificate or VT30/CT30 notice not issued when required or on request | L1 | L1 | L1 | L3 |

| 10. CT30 notice showing failures issued for non testable items | L1 | L1 | L1 | L3 |

| 11. Where the vehicle and tester are still on the premises - failure to register a vehicle at the start of the test and / or the result is not entered within one hour of the test being completed | L1 | L1 | L1 | L3 |

| 12. Charging more than the statutory fee for the class of vehicle tested | L1 | L1 | L1 | L3 |

C. Training

When records cannot be produced, or the produced records do not comply with the listed requirements the shortcomings will be subject to graduated sanctions that are applied to the AE and tester.

The level of action is determined by the number of occurrences of the shortcoming as indicated by levels L1, L2 or L3 in the columns.

| Shortcoming | First occurrence | Second occurrence | Third occurrence | Fourth or more occurrence |

|---|---|---|---|---|

| 1. One or more training year records incomplete, not completed correctly or not produced | L1 | L1 | L1 | L3 |

Where the tester has been in continuous service at the same VTS corresponding to the shortcoming and has received advice/advisory notice previously, consideration should be given to applying the same sanction to the AE. Testers with less than 4 weeks service with an AE should not impact the AE.

| Shortcoming | First occurrence | Second occurrence | Third occurrence | Fourth or more occurrence |

|---|---|---|---|---|

| 2. A tester not completing the annual assessment as required (completing the assessment without help or assistance), they will attract the following sanction level | L2 | L2 | L2 and L3 | L2 and L3 |

The tester will have to successfully complete the annual assessment and demo test before being allowed to return to testing.

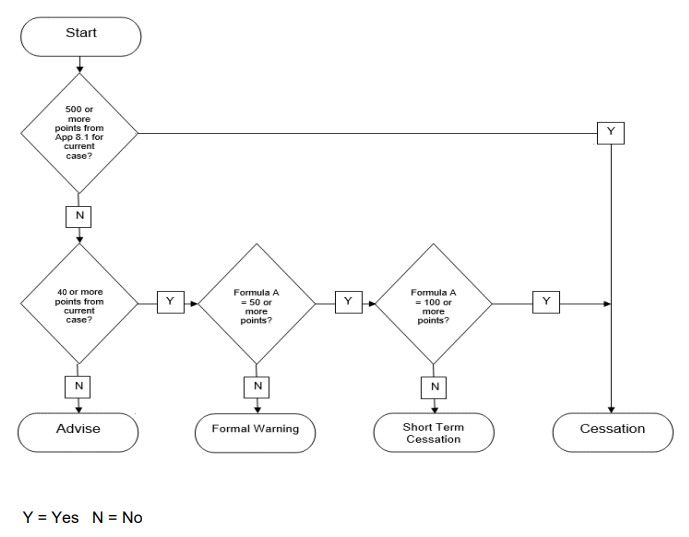

There are 4 normal sanction levels for testers:

- advise

- formal warning

- short term cessation

- cessation

Advise

The tester should be given advice if they have between 1 and 39 points from the current case.

Formal warning

The tester will be subject to a formal warning if they have:

- 40 points or more for the current case

- less than 50 points in total from the current case, unspent formal warnings, and unspent short term cessation

Short term cessation

The tester will be subject to a short term cessation if they have:

- 40 points or more for the current case

- between 50 and 99 points in total from the current case, unspent formal warnings and unspent short term cessation

Cessation

The tester will be subject to cessation if they have 500 or more points from Appendix 8.1 for the current case.

The tester will also be subject to cessation if they have:

- 40 points or more for the current case

- 100 points or more in total from the current case, unspent formal warnings, and unspent short term cessation

Formula A

Formula A is the total number of points from:

- the current case

- unspent formal warnings

- unspent short-term cessation.

Formal warnings and short-term cessations become spent after 5 years.

All relevant mitigation will be taken into consideration before deciding on any level of disciplinary action.

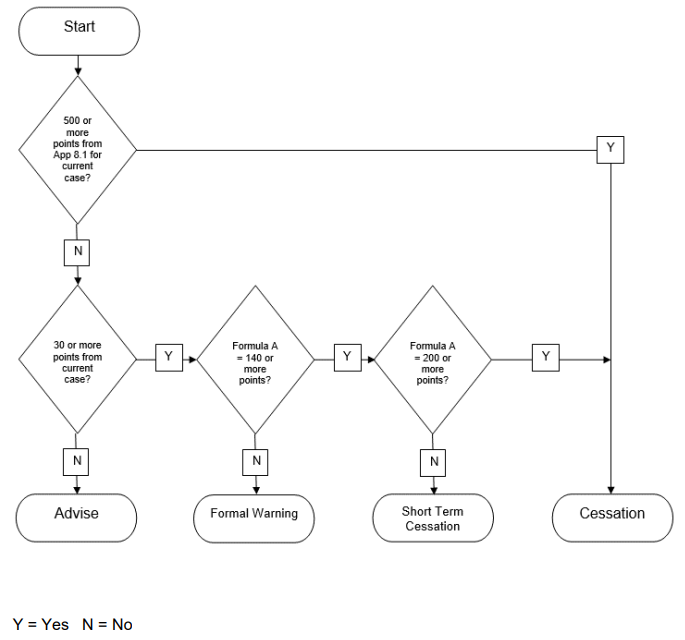

There are 4 normal sanction levels for authorised examiners:

- advise

- formal warning

- short term cessation

- cessation

Advise

The AE should be given advice if they have between 1 and 39 points from the current case.

Formal warning

The AE will be subject to a formal warning if they have:

- 40 points or more for the current case

- less than 140 points in total from the current case, unspent formal warnings, and unspent short term cessation

Short term cessation

The AE will be subject to a short term cessation if they have:

- 40 points or more for the current case

- between 140 and 199 points in total from the current case, unspent formal warnings and unspent short term cessation

Cessation

The AE will be subject to cessation if they have 500 or more points from Appendix 8.1 for the current case.

The AE will also be subject to cessation if they have:

- 40 points or more for the current case

- 200 points or more in total from the current case, unspent formal warnings, and unspent short term cessation

Formula A is the total number of points from:

- the current case

- unspent formal warnings

- unspent short-term cessation

Formal warnings and short-term cessations become spent after 5 years.

All relevant mitigation will be taken into consideration before deciding on any level of disciplinary action.

Notes for guidance and code of practice for informal hearings

Informal hearings foreword

These notes explain the procedures for informal hearings which may be held as part of the process of determining appeals from:

- authorised examiners (AE), designated councils (DC), testers and designated council inspectors (DCI) who have been served with a statutory notice of cessation of their authorisation, designation or approval to test

- applicants who have been served with a notice of intent to refuse their application for authorisation, designation or approval to test

These notes should be read in conjunction with Section D. Requirements for authorisation, Section E. Tester and Section I. Discipline.

The statutory requirements in relation to appeals are contained in the Motor Vehicles (Tests) Regulations 1981 as amended. The regulations provide that where those who have been served with a statutory notice wish to make representations to the effect that either:

- their authorisation, designation or approval should not cease or should be restored

- their application for authorisation, designation or approval to test should be approved

they should make such representations in writing within 14 days from the date of the notice (regulations 10 (1) (c) and 8 (9) respectively). All written representations or statements should fully set out your case and all the evidence you wish to rely upon. The availability of informal hearings does not affect the terms of the regulations.

Informal hearings provide an additional process whereby cases may be put personally to officials in DVSA’s appeals section.

Requests for a hearing

Requests for a hearing are at the discretion of DVSA and may be granted if there are exceptional circumstances.

If you wish to present your case at a hearing, you should submit your request preferably to the email address on the decision letter. We will accept postal hearing requests, however, this might cause a delay in processing the appeal if you use this method.

This request must be submitted as soon as possible after you have received the notice of cessation or intent to refuse to authorise, approve or designate. If a date for the hearing is offered by the Appeals team, you will be permitted to refuse the first date offered.

Who may attend the hearing

You may attend and/or be represented by your trade association, consultant or legal representative. The appeals section may arrange for DVSA personnel involved in the disciplinary or intended refusal action to attend the hearing where their evidence is at issue.

Prior to the hearing

An important element of this procedure is that the appeals officer must be fully aware of the relevant issues and arguments so that they can properly lead the discussion. Your written representations or statement should contain full particulars of the case you wish to make at the hearing including a list of any documents to which you wish to refer.

The provision of your written representations or statement within 14 days of the issue of the notice of cessation or intent to refuse is a necessary procedure. If you are appealing against a notice of cessation you may however, within the 14 day period, state in writing that you wish to rely, at hearing, on the written representations made earlier to the DVSA office that issued the decision.

To assist you the grounds of appeal have been categorised. The following list is not exhaustive, and it is recognised that there are some overlapping grounds:

- the disciplinary procedures have not been followed by DVSA at each and every stage

- the technical evidence is disputed

- other evidence is disputed

- the wrong interpretation has been placed upon the facts

- the sanction imposed and/or the number of disciplinary points allotted is not in accordance with the MOT testing guide

- the penalty is not proportionate to the offence

- there are mitigating circumstances

- the intent to refuse is unreasonable

The venue

Appeals will, where possible, be heard via Microsoft Teams. In extreme circumstances where this is not possible, we will consider conducting them in person at a mutually convenient location.

The hearing will be held by a senior officer of the appeals team who will have a thorough knowledge of the MOT service and the relevant procedures. The procedures will be fully explained to you at the start of, and throughout, the hearing.

The appeals officer will first set out the case as it appears from their reading of the papers, outlining what they consider are the main issues. In some cases, this might take the form of an agenda. They will also indicate those matters on which further information is needed. This will not preclude you from referring to other aspects you consider to be relevant.

All evidence will have been disclosed beforehand so that you will have had time to understand it and it will not normally be necessary to read this out at the hearing. If further documents are made available at the hearing the appeals officer may ask or allow questions on any points which emerge which may need further information or clarification.

The hearing will take the form of a discussion which you or your representative will be invited to start. You may, if you wish, decline to do so. The parties will be encouraged to ask questions informally throughout the proceedings, subject only to the discussion being conducted in an orderly manner.

Cross-examination will not be permitted unless the appeals officer considers that cross-examination is required to ensure a thorough examination of the main issues. You will be given the opportunity to make any final comments before the hearing is closed.

If a hearing needs to be adjourned this will be at the discretion of the officer holding the hearing. If a date for the resumption of the hearing cannot be set at the time of the adjournment, the date will be notified to the appellant within 5 working days.

The appeals officer may close the proceedings if, at any time during the hearing, matters are in their judgement not progressing satisfactorily. The appeal will then be determined on the basis of any written representations submitted. Full reasons for the closure of the hearing will be given in the appeal decision letter.

A recording will be made of the hearing (audio only). A copy of the recording and a transcript will be available as evidence in the event of subsequent court proceedings.

The decision

Decisions will not be made at the hearing as they are made by DVSA’s chief executive on behalf of the Secretary of State. The administrative target for determining appeals after hearings will be the same as that for appeals determined by written representations - 95% of appeals to be determined within 5 weeks.

In the case of written representations, the target date is calculated from the date the written representations are received. The target date following a hearing will be calculated from the date of the hearing. The decision letter will be issued by the appeals section on the date the appeal is determined.

Notice of cessation - effective date of cessation

If you wish your case to be heard at a hearing you should bear in mind that it is unlikely that your appeal can be determined prior to the notice of cessation becoming effective. The date the notice comes into effect cannot be deferred pending the outcome of the appeal. Whilst the appeals section will try to determine your appeal as quickly as possible, there may be a period during which you/your testing station must cease testing pending the determination of the appeal.

The following tables are for use during observed demonstration tests.

For further details see Appendix 6.8: Demonstration tests.

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not. Testers will also be asked questions on procedures, standards, and vehicles classes within this test group.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Defect missed on a testable item | 1 major error |

| 2. Item failed is not testable or has no defect | 1 major error |

| 3. Motorcycle not correctly identified or entered onto MOT testing service correctly. | 1 major error |

| 4. Candidate unable to correctly use test facilities | 1 major error |

| 5. Candidate unable to answer a question correctly | 1 minor error |

Section 0 - Identification of vehicles

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Rear registration plates

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check rear registration plate for compliance, condition and security | 1 minor error per check omitted |

Vehicle identification number - VIN

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check vehicle identification number | 1 minor error |

Section 1 - Brakes

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Brake controls

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check the presence, security and condition of the foot brake and handlebar brake lever and mountings | 1 minor error per control |

| 2. Did not check the brake pedal and lever for wear on pivots, reserve travel, or damage and smoothness of operation | 1 minor error per control |

| 3. Did not check hydraulic systems, a control for creep under load or for sponginess of operation | 1 minor error per control |

Brake systems

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check the brake disc for condition | 1 minor error one or more discs not checked |

| 2. Did not check mechanical brake components | 1 minor error per item not checked |

| 3. Did not check hydraulic brake components | 1 minor error per item not checked |

| 4. Did not check the hydraulic brake components while held under pressure for leaks and hose bulging | 1 major error no system pressure checks carried out 1 minor error one or more pressure checks not done |

Use of equipment

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not carry out the brake test using the appropriate test using the appropriate, approved, brake test equipment | 1 major error |

| 2. Unable to correctly use the brake testing equipment | 1 major error |

Brake performance checks

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not carry out a brake test on the primary system | 1 major error |

| 2. Did not carry out a brake test on the secondary system | 1 major error |

| 3. Did not ascertain the weight of the machine | 1 minor error |

| 4. Did not calculate the brake efficiency | 1 minor error |

Roller brake tester

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not hold the front brake steady at about half the maximum reading and check for fluctuation | 1 minor error |

| 2. Did not hold the rear brake steady at about half the maximum reading and check for fluctuation | 1 minor error |

Sidecar brake, if applicable

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check side car brake | 1 major error |

Brake fluid reservoir

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check transparent reservoirs for contaminated fluid | 1 minor error |

Section 2 - Steering

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Steering controls

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess steering controls/system | 1 major error |

| Did not raise front of machine from floor | 1 major error |

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check handlebars/grips/clamps/fork yoke for security, condition or weakness. | 1 minor error |

| 2a. Lock to lock check: did not check for fouling fixed parts or impede controls | 1 minor error |

| 2b. Lock to lock check: did not check whether control cables/hydraulic hoses were pulled taught on full lock | 1 minor error |

| 2c. Lock to lock check: did not check security and adjustment of steering lock stops | 1 minor error |

| 2d. Lock to lock check: did not check security of steering damper (where fitted) | 1 minor error |

| 2e. Lock to lock check: did not check for engine speed change during lock to lock check | 1 minor error |

Steering system

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1a. Did not check steering head bearing for tightness and roughness | 1 minor error |

| 1b. Did not check steering head bearing for free play | 1 minor error |

Wheel alignment

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check wheel alignment | 1 major error |

| 1. Did not fully complete all elements of wheel alignment check | 1 minor error |

| 2. Did not check alignment of sidecar relative to motorcycle (if fitted) | 1 major error - no alignment completed 1 minor error - vertical alignment not assessed |

Section 4 - Lamps and reflectors

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Headlight aim and use of headlamp aim equipment

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Headlamp aim tester not used to assess headlamp aim | 1 major error |

| 2. Headlamp tester not correctly aligned to the headlamp being tested | 1 minor error - one or more lamps incorrectly aligned |

| 3. Headlamp aim checked on the incorrect beam | 1 minor error - one or more lamps checked on incorrect beam |

| 4. Did not check light source and lamp are compatible | 1 minor error |

Lights including, headlamps, front and rear position lamps, stop lamp, indicators, reflectors , number plate lamps

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check and assess all front and rear lights | 1 major error |

| 1a. Did not check and assess all front and rear lights for operation | 1 minor error - one or more system operation not checked |

| 1b. Did not check and assess all front and rear lights for security | 1 minor error - one or more unit security not checked |

| 1c. Did not check and assess all front and rear lights for condition | 1 minor error - one or more unit condition not checked |

Lighting switch(es), indicator switch and tell-tale(s)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check and assess a switch/control | 1 major error |

| 1a. Did not check and assess a switch/control for operation | 1 minor error per switch or control not checked |

| 1b. Did not check and assess a switch/control for security | 1 minor error per switch or control not checked |

| 1c. Did not check and assess a switch/control for condition | 1 minor error per switch or control not checked |

Section 5 - Wheels, tyres and suspension

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Wheel bearings

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check condition of the front and rear wheel bearings by rocking the wheel. (Check wheel bearing on any side car) | 1 minor error - one or more bearings not checked |

| 2. Did not check condition of the front and rear wheel bearings by spinning the wheel. (Check wheel bearing on any side car) | 1 minor error - one or more bearings not checked |

Wheels

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check road wheels | 1 major error |

| 1a. Did not check front road wheel for security | 1 minor error for one or more checks not carried out |

| 1b. Did not check front road wheel for condition of wheel/spokes | 1 minor error for one or more checks not carried out |

| 1c. Did not check front road wheel for buckling / eccentricity | 1 minor error for one or more checks not carried out |

| 2a. Did not check rear road wheel for security | 1 minor error for one or more checks not carried out |

| 2b. Did not check rear road wheel for condition of wheel/spokes | 1 minor error for one or more checks not carried out |

| 2c. Did not check rear road wheel for buckling / eccentricity | 1 minor error for one or more checks not carried out |

Tyres

| 1. Did not check tyres | 1 major error |

| 1a. Did not check tyre for type and suitability | 1 minor error per tyre not checked |

| 1b. Did not check tyre for condition, correct fitment | 1 minor error per tyre not checked |

| 1c. Did not check tyres on twin wheels are not of a different structure | 1 minor error |

| 1d. Did not check tyres on twin wheels are not different sizes | 1 minor error |

| 2. Did not check tyres for signs of fouling of tyres on other components | 1 minor error - one or more tyre not checked for fouling |

Sidecar when fitted

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess sidecar when fitted | 1 major error |

| Did not check the sidecar wheel / tyre condition | 1 minor error |

Suspension

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess suspension | 1 major error |

| 1. Did not check suspension components | 1 major error - front of machine not raised from floor 1 major error - rear of machine not raised from floor |

| 1a. Did not check suspension components for security | 1 minor error |

| 1b. Did not check suspension components for condition (including suspension joint dust covers) | 1 minor error |

| 1c. Did not check suspension components for presence (note rear suspension is not mandatory on motorcycles) | 1 minor error |

| 1d. Did not check suspension components for any unsafe modifications | 1 minor error |

| 2. Did not check shock absorbers | 1 major error |

| 2a. Did not check shock absorbers for security | 1 minor error |

| 2b. Did not check shock absorbers for presence | 1 minor error |

| 2c. Did not check shock absorbers for operation | 1 minor error |

Section 6 - Structure and attachments

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess condition of structure | 1 major error |

| 1. Did not check the structure for cracks/damage/distortion/corrosion | 1 minor error - one or more areas not checked |

| 2. Did not check joining/attachment plates or fastenings for security | 1 minor error - one or more areas not checked |

Exhaust system

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess exhaust system | 1 major error |

| 1. Did not check security, condition and completeness of the exhaust system | 1 minor error |

| 2. Did not check silencer for any unacceptable markings | 1 minor error |

Fuel system

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess fuel system | 1 major error |

| 1. Did not check fuel tank (s), all visible fuel hoses, pipes, unions and system components for damage, leaks or insecurity | 1 minor error |

| 2. Did not check fuel tank cap for presence and effectiveness | 1 minor error |

Transmission

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check transmission related components, condition and operation | 1 minor error |

Engine mountings (only when engine is a stressed member)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check for presence, condition and excessive movement | 1 minor error |

Seats

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check the presence and security of the seats | 1 minor error |

Clutch and throttle controls

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check operation of throttle controls | 1 minor error |

| 2. Did not check condition and operation of clutch control | 1 minor error |

Footrests

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check condition and security of machines footrests | 1 minor error |

Section 7 - Audible warning

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not asses audible warning (horn) | 1 major error |

| 1a. Did not check and assess a switch/control for operation | 1 minor error |

| 1b. Did not check and assess a switch/control for security | 1 minor error |

| 1c. Did not check and assess a switch/control for condition | 1 minor error |

Section 8 - Nuisance

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess exhaust noise | 1 major error |

| 1. Did not check noise from exhaust (at approximately half maximum engine speed) | 1 minor error |

| 2. Did not check security of exhaust | 1 minor error |

The following tables are for use during observed demonstration tests.

For further details see Appendix 6.8: Demonstration tests.

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not. Testers will also be asked questions on procedures, standards, and vehicles classes within this test group.

| Checks and assessments not completed by the candidate | major or minor errors |

|---|---|

| 1. Defect missed on a testable item | 1 major error |

| 2. Item failed is not testable or has no defect | 1 major error |

| 3. Vehicle not correctly identified or entered onto MOT testing service correctly | 1 major error |

| 4. Candidate unable to correctly use test facilities | 1 major error |

| 5. Candidate unable to answer a question correctly | 1 minor error |

Section 0 - Identification of vehicles

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check front and rear registration plates | 1 major error |

| 1. Did not check condition and security of front registration plate | 1 minor error - one or more registration plate not checked (1, 2, 3) capped at 1 error |

| 2. Did not check condition and security of rear registration plate | 1 minor error - one or more registration plate not checked (1, 2, 3) capped at 1 error |

| 3. Did not check front and rear number plates match | 1 minor error - one or more registration plate not checked (1, 2, 3) capped at 1 error |

Vehicle identification number

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check vehicle identification number | 1 minor error |

Section 1 - Brakes

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Parking brake mechanism

For class 5, you should also refer to Section 11.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check the presence, security and condition of parking brake lever or control | 1 minor error |

| 2. Did not check handbrake components | 1 minor error |

Service brake mechanism, servo, ABS, ESC system

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check service brake control for condition, security, creep or sponginess | 1 minor error |

| 2. Did not check service brake control for condition and operation of the vacuum servo with the engine running | 1 minor error |

| 3. Did not check and assess a warning lamp for correct operation | 1 minor error |

| 4. Did not check brake system components, hoses and pipe work with the brake system pressurised and engine running in the case of servo assisted brakes | 1 major error - no system pressure checks carried out |

| 5. Did not check systems for mechanical wear whilst being operated. | 1 minor error |

| 6. Did not check brake fluid for contamination | 1 minor error |

Prescribed areas

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check relevant vehicle bodywork within a prescribed area | 1 minor error one or more check not done |

Use of equipment

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not carry out the brake test using the appropriate test using the appropriate and approved brake test equipment | 1 major error |

Performance checks

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not carry out a service brake test | 1 major error |

| 2. Did not carry out a test on front service brakes | 1 major error |

| 3. Did not check maximum effort on each wheel | 1 minor error - one or more maximum effort not assessed |

| 4. Did not check unapplied effort with both wheels rotating | 1 minor error - one or more unapplied effort not assessed |

| 5a. Did not run both the front wheels together and gradually increase and release the brake effort and assess grabbing | 1 minor error for one or more checks not carried out (a, b, c, d) – capped at 1 error |

| 5b. Did not run both the front wheels together and gradually increase and release the brake effort and assess lag in operation | 1 minor error for one or more checks not carried out (a, b, c, d) – capped at 1 error |

| 5c. Did not run both the front wheels together and gradually increase and release the brake effort and assess fluctuation in brake effort | 1 minor error for one or more checks not carried out (a, b, c, d) – capped at 1 error |

| 5d. Did not run both the front wheels together and gradually increase and release the brake effort and assess imbalance | 1 minor error for one or more checks not carried out (a, b, c, d) – capped at 1 error |

| 6. Did not carry out a test on rear service brakes | 1 major error |

| 7. Did not check maximum effort on each wheel | 1 minor error - one or more maximum effort not assessed |

| 8. Did not check unapplied effort with both wheels rotating | 1 minor error - one or more unapplied effort not assessed |

| 9a. Did not run both the rear wheels together and gradually increase and release the brake effort and assess grab or judder | 1 minor error for one or more checks not carried out (a, b, c, d) – capped at 1 error |

| 9b. Did not run both the rear wheels together and gradually increase and release the brake effort and assess uneven application | 1 minor error for one or more checks not carried out (a, b, c, d) – capped at 1 error |

| 9c. Did not run both the rear wheels together and gradually increase and release the brake effort and assess uneven release | 1 minor error for one or more checks not carried out (a, b, c, d) – capped at 1 error |

| 9d. Did not run both the rear wheels together and gradually increase and release the brake effort and assess imbalance | 1 minor error for one or more checks not carried out (a, b, c, d) – capped at 1 error |

| 10. Did not record the maximum reading for each wheel and carry out the service brake efficiency calculation when appropriate | 1 minor error |

| 11. Did not check brake performance test on a vehicle with servo assisted or power brakes with engine idling | 1 minor error |

| 12. Did not carry out a test on the parking brake | 1 major error |

| 13. Did not record maximum reading for each wheel (parking brake) | 1 minor error - one or more maximum effort not assessed |

| 14. Did not carry out the parking brake efficiency calculation when appropriate | 1 minor error |

Section 2 - Steering

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Steering control and system

For class 5, you should also refer to Section 11.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not assess steering control for excessive free play | 1 minor error |

| 2. Did not assess operation of steering lock(when required) | 1 minor error |

| 3. Did not asses electronic power steering operation and warning/fly by wire operation | 1 minor error |

Steering system

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check steering components for condition and security whilst assistant ‘rocked’ the steering wheel firmly against the resistance of the road | 1 minor error |

| 2. Did not check the operation/condition of the power steering system components which could be inspected from under vehicle, while the engine was running | 1 minor error |

| 3. Did not check steering for fouling and condition, with the suspension in normal running position, front wheels turned lock to lock on unlocked turning plates (if appropriate for suspension type) | 1 minor error |

| 4. Did not check sector shaft condition, (if applicable) steering gear fixing holes elongated | 1 minor error |

Section 3 - Visibility

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

View to rear

For class 5, you should also refer to Section 11.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check interior mirror or indirect vision device for presence, security and condition | 1 minor error |

Wiper and washers system

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1a. Did not check operation and effectiveness of wipers | 1 minor error |

| 1b. Did not check operation and effectiveness of washers | 1 minor error |

View to the front, windscreen and view of obligatory exterior mirrors

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check drivers view of the road through windscreen swept area | 1 minor error |

| 2. Did not check driver’s view of obligatory exterior mirror or mirrors | 1 minor error |

Wiper blades

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check wiper blades for condition and security | 1 minor error - one or more wiper blade not checked |

Exterior mirrors

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check exterior mirror for presence, security and condition | 1 minor error - one or more exterior mirror not checked |

Bonnet

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check bonnet security, condition of retaining devices | 1 minor error |

Section 4 - Lamps, reflectors and electrical equipment

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Lighting switch(s), indicator switch and tell-tale(s)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess lighting switch(es), indicator switch and tell-tale(s) | 1 Major error |

| 1a. Did not check and assess a switch/control for operation | 1 minor error per switch or control not checked (a, b, c) – capped at 1 error |

| 1b. Did not check and assess a switch/control for security | 1 minor error per switch or control not checked (a, b, c) – capped at 1 error |

| 1c. Did not check and assess a switch/control for condition | 1 minor error per switch or control not checked (a, b, c) – capped at 1 error |

Lights including front and rear position lamps, stop lamps, indicators, reflectors, DRL’s, reversing lamps, front fog lamps, marker lamps where appropriate

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess lights including front and rear position lamps, stop lamps, indicators, reflectors, DRL’s, reversing lamps, front fog lamps, marker lamps where appropriate | 1 major error |

| 1a. Did not check and assess all front and rear lights for operation (also not affected by other lights) | 1 minor error - one or more cluster operation not checked |

| 1b. Did not check and assess all front and rear lights for security | 1 minor error - one or more cluster operation not checked |

| 1c. Did not check and assess all front and rear lights for condition | 1 minor error - one or more cluster operation not checked |

Headlight aim and use of headlamp aim equipment

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Headlamp aim tester not used to assess headlamp aim | 1 major error |

| 2. Headlamp tester not correctly aligned to the headlamp being tested | 1 minor error - one or more lamps incorrectly aligned |

| 3. Headlamp aim checked on the incorrect beam | 1 minor error - one or more lamps checked on incorrect beam |

| 4. Did not check HID and LED headlamps for mandatory levelling and cleaning devices | 1 minor error |

| 5. Did not check light source and lamp are compatible | 1 minor error |

Electrical wiring and battery

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check battery for condition and security | 1 minor error |

| 2. Did not check condition and security of all visible wiring | 1 major error no assessment carried out 1 minor for one or more areas of visible wiring not checked |

| 3. Did not check tow bar socket as required for security, condition and operation | 1 minor error |

Section 5 - Axles, wheels tyres and suspension

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Jacking of vehicle – front

For class 5, you should also refer to Section 11.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Front of vehicle not jacked | 1 major error |

| 2. Did not check suspension components with front end of vehicle appropriately jacked for suspension type | 1 minor error - one or more sides not checked and/or jacked appropriately |

| 3. Did not check suspension components using a suitable bar under the wheel | 1 minor error - one or more sides not checked and/or jacked appropriately |

Wheel bearings – front

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check condition of the front wheel bearings and suspension components by the rocking wheel | 1 minor error - one or more sides not assessed |

| 2. Did not check condition of the front wheel bearings by spinning the wheel | 1 minor error - one or more sides not assessed |

Jacking of vehicle – rear (N/A for large vehicles DGW over 5000kg)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Rear of vehicle not jacked | 1 major error |

| 2. Did not check condition of the rear wheel bearings and suspension components by rocking wheel. | 1 minor error - one or more sides not assessed |

Wheels

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check road wheels | 1 major error |

| Did not check road wheel security and condition | 1 minor error for one or more road wheels not checked |

Tyres

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check tyres (including load and speed rating - class 5 and 7 only) | 1 major error |

| 1. Did not check tyre for condition, correct fitment and type, including structure and size | 1 minor error for one or more tyres not checked |

| 2. Did not check tyres for fouling a part of the vehicle. | 1 minor error for one or more tyres not checked |

| 3. Did not check tyre pressure monitoring system (when fitted) for malfunctioning or tyre obviously underinflated | 1 minor error |

Suspension

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Suspension checks done without the engine running in the case of hydro pneumatic suspension | 1 minor error |

| 2. Did not check suspension components for fouling and condition, with the suspension in normal running position, front wheels turned lock to lock on unlocked turning plates (if appropriate for suspension type) | 1 minor error |

| 3. Did not check suspension components for condition whilst the front wheels are rocked at the 3 and 9 o’clock position with the front wheels resting on unlocked swivel plates (if appropriate for suspension type) | 1 minor error |

| 4. Did not check that spring is not missing | 1 minor error |

Shock absorbers

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check presence, security and condition of shock absorbers | 1 minor error - one or more not assessed |

Section 6 - Body structure and attachments

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Structure and attachments

For class 5, you should also refer to section 11.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check vehicle structure for fracture, damage, corrosion outside prescribed areas | 1 minor error - one or more areas not checked |

| 2. Did not check if the strengthening plates or fastenings are insecure | 1 minor error - one or more areas not checked |

Exhaust

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check security of the exhaust system | 1 minor error |

| 2. Did not check system components for leaks with the engine running. | 1 minor error |

| 3. Did not check that fumes are not entering cab | 1 minor error |

Fuel system including cap(s)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check visible fuel hoses, pipes and system components security and condition | 1 minor error |

| 2. Did not check fuel system components for leaks (including holes above the fuel line) | 1 minor error |

| 3. Did not check fuel tank cap/filler neck condition and seal | 1 minor error |

| 4. Did not check for any part of the LPG/CNG/LNG or hydrogen system defective | 1 minor error |

| 5. Did not check that any missing heat shield does not present a fire risk | 1 minor error |

Bumper

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check security and any damage not likely to cause injury | 1 minor error |

External Spare wheel carrier (if fitted)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check security of spare wheel and carrier | 1 minor error |

Coupling mechanisms and towing equipment

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not check tow bar and mountings | 1 minor error |

| 2. Did not check operation of tow bar coupling indicator | 1 minor error |

Transmission

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not asses transmission | 1 major error |

| a) Did not check and inspect all prop shafts | 1 minor error per component not checked (a, b, c, d) – capped at 1 error |

| b) Did not check and inspect all drive shafts | 1 minor error per component not checked (a, b, c, d) – capped at 1 error |

| c) Did not check and inspect all prop shaft and drive shaft couplings and bearings | 1 minor error per component not checked (a, b, c, d) – capped at 1 error |

| d) Did not check and inspect all drive chains or belts | 1 minor error per component not checked (a, b, c, d) – capped at 1 error |

Engine mountings

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check engine mounts for presence, condition and security | 1 minor error |

Body and interior

This inspection is for all vehicles and includes:

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| a) Did not check all body panels | 1 minor error; one or more areas not assessed (a, b, c, d) – capped at 1 error |

| b) Did not check undertrays | 1 minor error; one or more areas not assessed (a, b, c, d) – capped at 1 error |

| c) Did not check spoilers | 1 minor error; one or more areas not assessed (a, b, c, d) – capped at 1 error |

| d) Did not check mirror housings | 1 minor error; one or more areas not assessed (a, b, c, d) – capped at 1 error |

Cab and body mounting (vehicles with a separate body and/or cab)

Check cab/body for:

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| a) Did not check security | 1 minor error; one or more areas not assessed (a, b, c) – capped at 1 error |

| b) Did not check mountings | 1 minor error; one or more areas not assessed (a, b, c) – capped at 1 error |

| c) Did not check corrosion at mounting points | 1 minor error; one or more areas not assessed (a, b, c) – capped at 1 error |

Doors (drivers, passengers & emergency doors/exits)

Check:

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| a) Did not check all doors will not open using the relevant control and close properly | 1 major error - one or more doors not assessed |

| b) Did not check a door hinge, catch or pillar for presence and condition | 1 minor error - one or more areas not assessed |

Seats

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check seat security | 1 major error |

| 1. Did not check driver and all passenger seats for security | 1 minor error for one or more front seat security not checked |

| 2. Did not check all seat backrests for security in upright position | 1 minor error for one or more rear seat security not checked |

| 3. Did not check driver’s seat for fore and aft adjustment | 1 minor error if not checked |

Cab steps (If fitted)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check if a cab step or step ring is secure and not likely to cause injury | 1 minor error per component not checked |

Handgrips and footrests (quads and trikes)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check if a handgrip or footrest missing or insecure | 1 minor error |

Section 7 - Other equipment

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Seat belts and supplementary restraint systems (SRS)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check seat belts | 1 major error |

| a) Did not check all seat belts fitted for condition and operation (functioning as intended) | 1 minor error |

| b) Did not check all seat belts fitted for security | 1 minor error |

| c) Did not check all seat belts fitted are of the correct type | 1 minor error |

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| a) Did not check seat belt load limiter not missing or deployed | 1 minor error |

| b) Did not check seat belt pre-tensioner not missing or deployed | 1 minor error |

| c) Did not check for fitment and condition of airbags | 1 minor error |

Anti-theft device (if appropriate)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check if steering lock missing or not functioning correctly | 1 minor error |

Audible warning horn

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1a. Did not check and assess a switch/control for operation | 1 minor error per switch or control not checked (a, b, c) – capped at 1 error |

| 1b. Did not check and assess a switch/control for security | 1 minor error per switch or control not checked (a, b, c) – capped at 1 error |

| 1c. Did not check and assess a switch/control for condition | 1 minor error per switch or control not checked (a, b, c) – capped at 1 error |

Speedometer

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check speedometer fitment, condition, illumination and operation if road test carried out | 1 minor error |

Electronic stability control (ESC)

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess electronic stability control (ESC) | 1 major error |

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| a) Did not check wheel speed sensors | 1 minor error per switch, component, sensor wiring or warning not checked |

| b) Did not check ESC wiring | 1 minor error per switch, component, sensor wiring or warning not checked |

| c) Did not check if other ESC component missing or damaged | 1 minor error per switch, component, sensor wiring or warning not checked |

| d) Did not check if ESC switch damaged or not functioning correctly | 1 minor error per switch, component, sensor wiring or warning not checked |

| e) Did not check if ESC MIL indicates a system malfunction | 1 minor error per switch, component, sensor wiring or warning not checked |

Section 8 - Nuisance

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess noise suppression system | 1 major error |

| a) Did not check that the exhaust noise levels are not excessive | 1 minor error |

| b) Did not check security of the noise suppression system | 1 minor error |

| c) Did not inspect exhaust silencers and under bonnet sound deadening material | 1 minor error |

Engine emissions control equipment

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| a) Did not check original emission control equipment is not missing, obviously modified or defective | 1 minor error |

| b) Did not check for induction or exhaust leak that could affect emissions | 1 minor error |

| c) Did not check for evidence that a diesel particulate filter has been tampered with | 1 minor error |

Use of equipment - emission procedure

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not carry out emissions test using the appropriate, approved equipment | 1 major error |

| 2. Carried out an inappropriate emissions test e.g. Cat test of non cat vehicle | 1 major error |

| 3. Used incorrect limits | 1 major error |

Test pre-checks

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| 1. Did not ensure the vehicle has clearly reached normal temperature before carrying out an exhaust check | 1 minor error |

| 2. Omitted a stage (including elements of pre checks on diesels) in the emissions test appropriate to the vehicle | 1 minor error for one or more stage omitted |

Fluid leaks

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check for fluid leaks | 1 minor error |

Section 9 - Supplementary tests for buses and coaches

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Doors

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not asses doors | 1 major error |

| 1a. Did not check entrance and exit doors for operation | 1 minor error |

| 1b. Did not check entrance and exit doors for condition | 1 minor error |

| 1c. Did not check entrance and exit doors for operation of emergency control condition | 1 minor error |

| 1d. Did not check entrance and exit doors for operation of remote control or warning device | 1 minor error |

| 2a. Did not check operation of emergency exits | 1 major error |

| 2b. Did not check if emergency exit does not meet requirements | 1 minor error |

| 2c. Did not check emergency exits for presence of break glass hammer where applicable | 1 minor error |

| 2d. Did not check emergency exits for presence/access to emergency exit | 1 minor error |

Passenger grab handles

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check for presence and condition of a passenger grab handle | 1 minor error |

Steps and Stairs

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check condition of steps and stairs | 1 major error |

| Did not check operation of retractable step | 1 major error |

Section 10 - Seat belt installation checks

Notes only.

Section 11 - Additional information for class 5 vehicles

The tester should personally assess the following items during a demonstration test. They will be awarded major or minor errors if they do not.

Driving controls

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not assess driving controls | 1 major error |

| a) Did not check clutch | 1 minor error |

| b) Did not check accelerator | 1 minor error |

| c) Did not check gear selector | 1 minor error |

Brake performance

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| a) Did not check if the correct weight has been used in any brake performance calculation | 1 minor error if not calculated correctly |

| b) Did not carry out applied brake test (if appropriate) | 1 minor error |

Steering

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| Did not check that tester is aware that use of turning plates is not mandatory for class 5 vehicle but they should be used if suitable | 1 minor error |

Visibility

| Checks and assessments not completed by the candidate | Major or minor errors |

|---|---|

| a) Did not check if windscreens and windows on either side of the driver’s seat made from safety glass | 1 minor error |

| b) Did not check if all other windows made from safety glass or safety glazing | 1 minor error |

Items that the presenter may have difficulty observing during a mystery shopper check are marked with an asterix in the associated tables. DVSA will take this into account if disciplinary action is to be considered.

1. Using the designated MOT inspection area

| Shortcoming | Points |

|---|---|