4. Lamps, reflectors and electrical equipment

Headlamp, position lamps, daytime running lamps, stop lamps, indicators, hazard warning lamps, fog lamps, reversing lamps, lighting ‘tell-tales’, trailer electrical socket, electrical wiring and battery rules and inspection for car and passenger vehicle MOT tests.

In this section

- 4.1.1. Presence, condition and operation

- 4.1.2. Headlamp alignment

- 4.1.3. Switching

- 4.1.4. Compliance with requirements

- 4.1.5. Levelling devices

- 4.1.6. Headlamp cleaning devices

4.1.1. Presence, condition and operation

You must test all mandatory headlamps.

‘Mandatory headlamps’ are a matched pair of main beam headlamps and a matched pair of dipped-beam headlamps. These can be separate or a single pair of headlamps.

Lamps are matched if they:

- emit light of substantially the same colour and intensity

- are the same size and shape that they are symmetrical to each other

You do not need to test headlamps on vehicles that are not fitted with position lamps, or have such lamps permanently disconnected, painted over or masked, that are:

- only used during daylight hours, and

- not used at times of seriously reduced visibility

Vehicles first used before 1 January 1931 do not need headlamps.

Buses first used before 1 October 1969 only need one headlamp. If 2 are fitted, neither the main beam or dipped beams need to be a matched pair.

You must assess damaged or repaired lamps for security, colour, light output and durability.

Tricycle and quadricycle headlamps must be:

- mounted centrally - if there’s only one lamp

- mounted symmetrically about the centre - if they’re adjacent to another lamp, such as there’s one dipped beam lamp and one main beam lamp

- mounted symmetrically - if there’s 2 lamps

The following must have a pair of main beam headlamps and a pair of dipped beam headlamps – can be separate or a single pair of headlamps:

- tricycles and quadricycles with a maximum width over 1,300mm

- motorcycle derived tricycles with a maximum width over 1,700mm

Tricycles and quadricycles classed as mopeds do not need a main beam headlamp.

A ‘light source’ means any bulb, LED or other means of emitting light.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | A headlamp with up to ½ light sources not functioning in the case of LED | Minor |

| (a)(ii) | A headlamp missing, inoperative or more than ½ not functioning in the case of LED | Major |

| (b)(i) | Headlamp reflector or lens slightly defective | Minor |

| (b)(ii) | Headlamp reflector or lens seriously defective or missing | Major |

| (c) | Lamp not securely attached | Major |

4.1.2. Headlamp alignment

You must inspect all dipped beam headlamps fitted.

The type of headlamp will determine whether the aim must be checked on dipped or main beam (see Diagrams 1, 2 and 3).

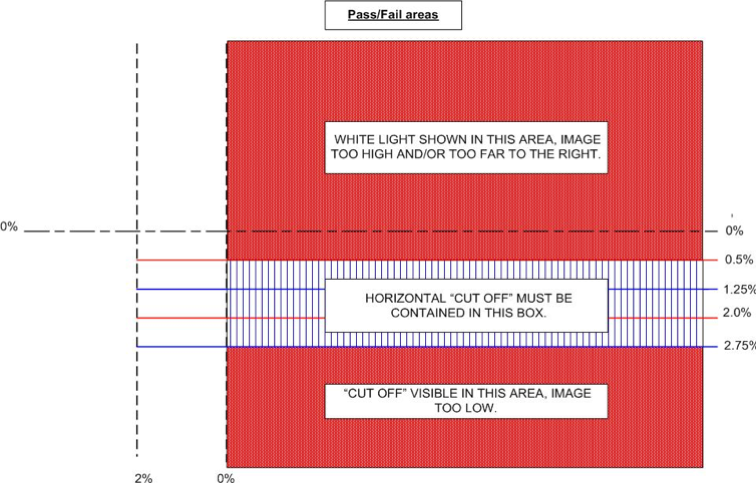

A flat top or other alternative headlamp dipped beam pattern is acceptable as long as all of the beam upper edge, including any ‘peak’ is contained within the appropriate tolerance band.

It’s acceptable for masks or converter kits to be fitted to right hand dip headlamps to temporarily alter the lamp for use in the UK by removing the beam ‘kick-up’ to the right.

If driver’s beam aim controls are fitted, you should test the beam aim without altering the control setting. If this would result in failure for beam aim being too low, you should re-check the beam aim with the control set at its ‘highest’ position.

On vehicles with hydro-pneumatic suspension systems, it’s necessary to have the engine running when checking headlamp aim.

To check the aim:

-

Position the vehicle on the designated headlamp aim standing area.

-

Align the headlamp aim testing equipment to the vehicle in accordance with the manufacturer’s instructions.

-

Determine the appropriate headlamp beam image and its aim (see Diagrams 1, 2 and 3).

For complex lens systems - meaning those that have more than one lamp behind a single lens - make sure the test equipment is aligned exactly on the centre of the dipped beam pocket.

You must not carry out repairs during an MOT test, but you can make minor adjustments to the headlamp aim.

European type - check on dipped beam

European type lamps have one of the following:

- an asymmetric dipped beam pattern with

- a horizontal cut-off on the right

- a wedge of light above the horizontal towards the left, known as the ‘kick up’

- lens may have European approval mark

For European type lamp to pass, you must make sure that:

- beam image ‘kick up’ is visible on the screen, unless it has been masked or it has a flat top beam pattern

- for headlamps with centres at 850mm or less from the ground, the beam image horizontal cut-off is between the 0.5% and 2.75% horizontal lines

- for headlamps with centres more than 850mm from the ground, the beam image horizontal cut-off is between the 1.25% and 2.75% horizontal lines

- white light does not show in the zone formed by the 0% vertical and 0.5% horizontal line

Diagram 1. Criteria for European beam headlamp aim

British American headlamp - check on main beam

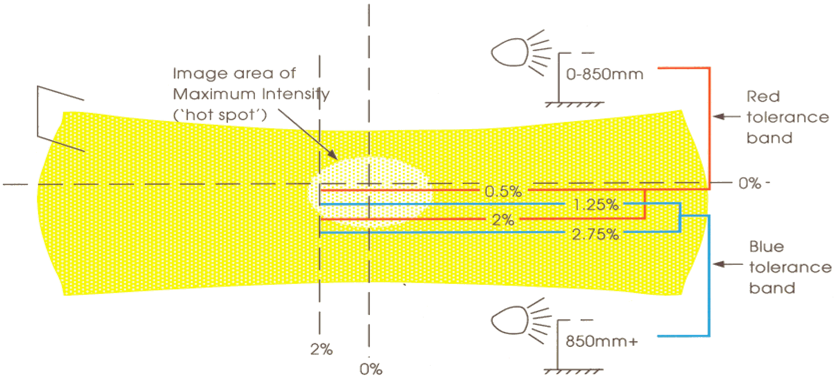

British American type headlamps are checked on main beam if they have an asymmetric main beam pattern with a central area of maximum intensity, known as a ‘hot spot’.

The generally also have a circular lens marked with a figure ‘1’ followed by an arrow indicating the direction of dip.

You must fail a British American type lamp if its ‘hot spot’ centre is any of the following:

- above the horizontal 0% line

- below the horizontal 2% line for headlamps with centres at 850mm or less from the ground

- below the horizontal 2.75% line for headlamps with centres more than 850mm from the ground

- to the right of the vertical 0% line

- to the left of the vertical 2% line

For a British American type lamp to pass, you must also make sure the brightest part of the image moves downwards when the lamp is dipped.

Diagram 2. Main beam image

British American headlamp - check on dipped beam

Check British American headlamps on dipped beam if they have:

- an asymmetric dipped beam pattern with a flat-topped area of high intensity extending above and parallel with the horizontal 0% line on the nearside

- a circular lens marked with the figure 2 – it might also have an arrow showing the direction of dip

You must fail this lamp if the upper edge of the ‘hot spot’ is:

- above the horizontal 0% line

- below the horizontal 2.75% line

You must fail this lamp if the right-hand edge of the ‘hot spot’ is:

- to the right of the vertical 0% line

- to the left of the vertical 2% line

Diagram 3. Dipped beam image

“Not tested” or “Unable to be tested” must only be used where it becomes apparent during the test that the particular item cannot be tested, and this could not have been identified prior to starting the test. The reason for selecting the failure must be included in the additional information box.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | The aim of a headlamp is not within limits laid down in the requirements | Major |

| (b) | Headlamp aim unable to be tested | Major |

| (c) | Beam image obviously incorrect | Major |

4.1.3. Switching

Dipped or main beam headlamps must immediately light up when they’re switched on (depending on the position of the dip switch).

Headlamps must switch immediately between main beam and dipped beam when you move the dip switch.

Moving the dip switch must do one of the following:

- extinguish all main beam headlamps and leave on at least one pair of dipped-beam headlamps

- deflect the main beams to make them dipped beams

Dipped beam headlamps can remain on or switch off when main beam is selected.

Headlamps are not needed on vehicles first used before 1 January 1931.

When optional headlamps are fitted:

- if one is fitted it must dip

- if 2 are fitted, either both must dip or one must dip and the other switch off

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Headlamp ‘on’ switch does not operate in accordance with the requirements | Minor |

| (b) | Headlamp ‘dip’ switch does not operate in accordance with the requirements | Major |

4.1.4. Compliance with requirements

You must inspect all ‘mandatory’ headlamps fitted.

Mandatory headlamps consist of a matched pair of main beam headlamps and a matched pair of dipped-beam headlamps. These can be separate or a single pair of headlamps.

Lamps are matched if they:

- emit light of substantially the same colour and intensity

- are the same size and shape that they are symmetrical to each other

Vehicles first used before 1 January 1931 do not need headlamps.

Buses first used before 1 October 1969 only need one headlamp. If 2 are fitted, neither the main beam or dipped beams need to form matched pair.

The colour of the light headlamps emit must be one of the following:

- white

- predominantly white with blue tinge

- yellow

In a four-headlamp system the outer headlamps do not need to emit the same colour light as the inner pair.

The precise position of lamps is not part of the inspection, but you should check visually that they are at about the same height and the same distance from each side of the vehicle.

Existing halogen headlamp units on vehicles first used on or after 1 April 1986 must not be converted to be used with high intensity discharge (HID) or light emitting diode (LED) bulbs. If such a conversion has been done, you must fail the headlamp for light source and lamp not compatible.

This does not refer to complete replacement headlamp units which may be constructed with HID or LED light sources.

If a complete headlamp unit has been replaced with a unit that was manufactured with HID or LED light sources, it must not be failed for ‘Light source and lamp not compatible’ but it must meet all other requirements detailed in section 4 of this manual specific to the type fitted at the time of test.

You can identify HID headlamps from:

- ‘DCR’ mark on the headlamp lens or body

- an igniter module or inverter behind the headlamp

- taking a few seconds to reach full intensity

- a bluish tinge to the light

HID headlamps use high voltage. You should take care when inspecting these headlamps.

Tricycle and quadricycle headlamps must be:

- mounted centrally - if there’s only one lamp

- mounted symmetrically about the centre - if they’re adjacent to another lamp, such as there’s one dipped beam lamp and one main beam lamp

- mounted symmetrically - if there’s 2 lamps

The following must have a pair of main beam headlamps and a pair of dipped beam headlamps – can be separate or a single pair of headlamps:

- tricycles and quadricycles with a maximum width over 1,300mm

- motorcycle derived tricycles with a maximum width over 1,700mm

Tricycles and quadricycles classed as mopeds do not need main beam headlamps.

A ‘light source’ means any bulb, LED or other means of emitting light.

You must assess damaged or repaired lamps for security, colour, light output and durability.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Headlamp emitted colour, position or intensity not in accordance with the requirements | Major |

| (b) | Product on the lens or light source which obviously reduces light intensity or changes emitted colour to other than white or yellow | Major |

| (c) | Light source and lamp not compatible | Major |

| (d) | Mandatory headlamps, intended to be a matched pair, are not the same shape, size or colour | Major |

4.1.5. Levelling devices

Make sure any manual headlamp levelling devices (driver controls) work by:

- switching on the dipped beam headlamps

- operating the manual levelling device

- checking that the headlamp beams move up and down

- returning the levelling device control to its original position

Vehicles with high intensity discharge (HID) or LED dipped beam headlamps may be fitted with a suspension or headlamp self-levelling system. If these systems have been fitted, they must work.

Sometimes it is not easy to determine if the self-levelling systems work. In such cases you should give the benefit of the doubt.

You can identify HID headlamps from:

- ‘DCR’ mark on the headlamp lens or body

- an igniter module or inverter behind the headlamp

- taking a few seconds to reach full intensity

- a bluish tinge to the light

HID headlamps use high voltage. You should take care when inspecting these headlamps.

The check of headlamp levelling devices does not apply to motor caravans.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Headlamp levelling device inoperative | Major |

| (b) | Manual levelling device cannot be operated from the driver’s seat | Major |

4.1.6. Headlamp cleaning devices

You must inspect vehicles first used on or after 1 September 2009 equipped with headlamp washers.

You can identify HID headlamps from:

- ‘DCR’ mark on the headlamp lens or body

- an igniter module or inverter behind the headlamp

- taking a few seconds to reach full intensity

- a bluish tinge to the light

HID headlamps use high voltage. You should take care when inspecting these headlamps.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | Headlamp cleaning device inoperative | Minor |

| (a)(ii) | Headlamp cleaning device inoperative in the case of LED or gas discharge systems (HID) | Major |

In this section

4.2.1. Presence, condition and operation

This inspection is for:

- mandatory position lamps

- mandatory end-outline marker lamps

- daytime running lamps (DRLs) fitted to M1 vehicles first used on or after 1 March 2018

Vehicles do not need to be fitted with position lamps, or may have such lamps permanently disconnected, painted over or masked if they are:

- only used during daylight hours, and

- not used at times of seriously reduced visibility

In this situation, you should issue an advisory. These vehicles do not need end-outline marker lamps.

All lamps

Check the presence, condition, security and function of the required lamps.

Assess any damaged or repaired lamps for security, colour, light output and durability.

Front and rear position lamps

Vehicles must have 2 front and 2 rear position lamps, except for tricycles or quadricycles that are less than 1,300mm wide.

Daytime running lamps (DRLs) or headlamps may function as front position lamps. If the DRLs function as front position lamps, they may or may not dim when rear position lamps are switched on and may dim or turn off when headlamps are switched on.

Front position lamps can switch off when the front fog lamps are switched on.

The front and rear position lamps must light up at the same time with the registration plate lamps and end-outline marker lamps.

Tricycles and quadricycles less than 1,300mm wide must have at least one front and one rear position lamp. However, if the maximum vehicle width is more than 1,300mm, it must have 2 front and 2 rear position lamps.

Tricycle and quadricycle lamps must be:

- mounted centrally - if there’s one lamp

- mounted symmetrically - if there’s 2 lamps

- mounted symmetrically about the centre - if there’s a single front position lamp next to another front lamp, such as a headlamp

Buses first used before 1 April 1955 only need one rear position lamp. The lamp must be on the centre line or to the offside.

End-outline marker lamps

You must inspect end-outline marker lamps on vehicles first used on or after 1 April 1991 that are wider than 2,100mm, excluding side mirrors.

Class 3 vehicles do not need end-outline marker lamps.

The front and rear end outline marker lamps on each side can be combined in one lamp.

Daytime running lamps

You only need to inspect daytime running lamps (DRLs) if they’re fitted as original equipment to vehicles first used on or after 1 March 2018.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | Lamp multiple light source up to a half not functioning | Minor |

| (a)(ii) | Lamp missing, inoperative or in the case of a multiple light source more than a half not functioning | Major |

| (b) | Defective lens | Major |

| (c)(i) | Lamp not securely attached | Minor |

| (c)(ii) | Lamp likely to become detached | Major |

4.2.2. Switching

It must be possible to switch on the position lamps from the driver’s seat with a single operation of the switch. The position lamps must light up at the same time as the registration plate lamps and any end-outline marker lamps where they are fitted.

Some vehicles have position lamps that come on automatically when the engine is running.

Daytime running lamps (DRLs) or headlamps may function as front position lamps. If the DRLs function as front position lamps, they may or may not dim when rear position lamps are switched on and may dim or turn off when headlamps are switched on.

The front position lamps may turn off when the headlamps or front fog lamps are switched on. If position lamps are combined with direction indicators, position lamps may or may not switch off when the relevant direction indicator is flashing.

The front and rear position lamps must light up at the same time with the end-outline marker lamps where they are fitted.

You only need to inspect daytime running lamps (DRLs) if they’re fitted as original equipment to vehicles first used on or after 1 March 2018.

DRLs must switch on and off when the engine is switched on and off.

DRLs might not operate when:

- the parking brake is on

- the park position is selected on automatic transmissions

If DRLs have been manually switched off, sometimes they do not light up until the vehicle is travelling faster than 10 kilometres per hour (6.2mph) or the vehicle has travelled 100m (328ft).

Military vehicles may have a multi-position switch which cannot turn the front and rear position lamps on with a single operation of the switch. This should not be regarded as a defect.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Switch does not operate in accordance with the requirements or the rear position lamps can be switched off when the headlamps are on | Major |

| (b) | Function of the switch impaired | Major |

4.2.3. Compliance with requirements

You must inspect:

- mandatory position lamps

- mandatory end-outline marker lamps

- daytime running lamps (DRLs) fitted to M1 vehicles first used on or after 1 March 2018

All lamps

The precise position of lamps is not part of the inspection. You should check visually that they are at about the same height and distance from each side of the vehicle.

A ‘light source’ means any bulb, LED or other means of emitting light.

You must assess damaged or repaired lamps for security, colour, light output and durability.

Switch on the position lamps and daytime running lamps and operate all the other lamps in turn. Check if the position lamps, end-outline marker lamps or daytime running lamps are adversely affected.

Position lamps

Rear position lamps must emit a steady red light.

For front position lamps, the following colour of light is acceptable:

- white light

- predominantly white light with a blue tinge

- yellow light - if combined in a yellow headlamp

If position lamps are combined with direction indicators, position lamps may or may not switch off when the relevant direction indicator is flashing.

Daytime running lamps (DRLs) or headlamps may function as front position lamps. If the DRLs function as front position lamps, they may or may not dim when rear position lamps are switched on and may dim or turn off when headlamps are switched on.

End-outline marker lamps

Vehicles first used on or after 1 April 1991 that are wider than 2,100mm, excluding the side mirrors, must have their end-outline marker lamps inspected.

Class 3 vehicles do not need end-outline marker lamps.

There must be:

- 2 white lamps visible from the front and positioned at windscreen upper edge level or higher

- 2 red lamps visible from the rear and positioned as high as is practicable

The front and rear end outline marker lamps on each side can be combined in one lamp.

Daytime running lamps

You only need to inspect daytime running lamps (DRLs) fitted as original equipment to M1 vehicles first used on or after 1 March 2018.

Vehicles do not need to be fitted with daytime running lamps, that do not have front and rear position lamps, or have such lamps permanently disconnected, painted over or masked that are only used during daylight hours and not used at times of seriously reduced visibility.

There must not be more than 2 DRLs fitted and they must emit white light.

DRLs might not operate when:

- the engine is not running

- the parking brake is on

- the park position is selected on automatic vehicles

If DRLs have been manually switched off, sometimes they do not light up until the vehicle is travelling faster than 10km/h (6.2mph) or the vehicle has travelled 100m (328ft).

A DRL is permitted to switch off when the same side indicator is operating.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | Lamp emitted colour, position or intensity not in accordance with the requirements | Minor |

| (a)(ii) | Lamp showing red light to the front, white light to the rear or has heavily reduced light intensity | Major |

| (b)(i) | A lamp with a product on the lens or light source which obviously reduces light intensity or changes emitted colour | Minor |

| (b)(ii) | A lamp with a product on the lens or light source which shows red light to the front, white light to the rear or has heavily reduced light intensity | Major |

| (c) | A lamp adversely affected by the operation of any other lamp | Major |

In this section

4.3.1. Presence, condition and operation

You must inspect all stop lamps fitted.

Stop lamps must show a steady red light.

Stop lamps are not required on vehicles:

- first used before 1 January 1936

- that do not have front and rear position lamps, or have such lamps permanently disconnected, painted over or masked that are only used during daylight hours and not used at times of seriously reduced visibility.

Vehicles first used on or after 1 January 1971 must have 2 stop lamps, one on each side.

Vehicles first used before 1 January 1971 may be fitted with only 1 stop lamp, which can be mounted centrally or towards the offside.

Additional stop lamps, over and above the mandatory requirements, must be tested. However, if you are not sure if they are connected, you should give the benefit of the doubt.

A ‘light source’ means any bulb, LED or other means of emitting light.

You must assess damaged or repaired lamps for security, colour, light output and durability.

On some vehicles with LED rear lamps, a proportion of the stop lamp LED’s may extinguish when the rear fog lamp is illuminated. This is not to be regarded as a defect.

Tricycles and quadricycles:

- not wider than 1,300mm can have only one stop lamp

- with 2 service brake controls - both controls must operate the stop lamp(s)

- with 2 stop lamps - must be mounted symmetrically

- with 1 stop lamp - must be mounted centrally

| Defect refence | Defect | Category |

|---|---|---|

| (a)(i) | Stop lamp(s) with a multiple light source up to 1/2 not functioning | Minor |

| (a)(ii) | Stop lamp(s) missing, inoperative or in the case of a multiple light source more than 1/2 not functioning | Major |

| (a)(iii) | Stop lamp(s) all missing or inoperative | Dangerous |

| (b)(i) | A lens defective which has no effect on emitted light | Minor |

| (b)(ii) | A lens defective such that the emitted light is adversely affected | Major |

| (c)(i) | A stop lamp not securely attached | Minor |

| (c)(ii) | A stop lamp likely to become detached | Major |

4.3.2. Switching

All stop lamps must light up immediately when the brake is applied and switch off immediately when the brake is released.

Vehicles first used on or after 1 January 1971 must have 2 stop lamps, one on each side.

Vehicles first used before 1 January 1971 can be fitted with only 1 stop lamp. The lamp can be mounted centrally or towards the offside.

Additional stop lamps, over and above the mandatory requirements, must be tested. However, if you are not sure that they’re connected, you should give the benefit of the doubt.

Vehicles first used before 1 September 1965 may have a stop lamp combined with a direction indicator lamp.

Tricycles and quadricycles:

- not wider than 1,300mm can have only one stop lamp

- with 2 service brake controls - both controls must operate the stop lamp(s)

- with 2 stop lamps - must be mounted symmetrically

- with 1 stop lamp - must be mounted centrally

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | Stop lamp(s) switch does not operate in accordance with the requirements | Minor |

| (a)(ii) | Stop lamp(s) switch with a delay in operation | Major |

| (a)(iii) | Stop lamp(s) remain on when the brakes are released | Dangerous |

4.3.3. Compliance with requirements

You must inspect all stop lamps.

Stop lamps must show a steady red light.

Stop lamps are not required on vehicles:

- first used before 1 January 1936

- that do not have front and rear position lamps, or have such lamps permanently disconnected, painted over or masked that are only used during daylight hours and not used at times of seriously reduced visibility

Vehicles first used on or after 1 January 1971 must have 2 stop lamps, one on each side.

Vehicles first used before 1 January 1971 can be fitted with only one stop lamp. The lamp can be mounted centrally or towards the offside.

Additional stop lamps, over and above the obligatory requirements, must be tested. However, if you are not sure that they’re connected, you should give the benefit of the doubt.

You must assess damaged or repaired lamps for security, colour, light output and durability.

On some vehicles with LED rear lamps, a proportion of the stop lamp LED’s may extinguish when the rear fog lamp is illuminated. This is not to be regarded as a defect.

Tricycles and quadricycles:

- not wider than 1,300mm can have only one stop lamp

- with 2 service brake controls - both controls must operate the stop lamp(s)

- with 2 stop lamps - must be mounted symmetrically

- with 1 stop lamp - must be mounted centrally

Press the brake pedal to light up the stop lamps and operate all the other lamps in turn to see if the stop lamps are adversely affected.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | A stop lamp position or intensity not in accordance with the requirements | Minor |

| (a)(ii) | A stop lamp not showing a steady red light or has significantly reduced light intensity | Major |

| (b) | A stop lamp adversely affected by the operation of any other lamp | Major |

In this section

- 4.4.1. Presence, condition and operation

- 4.4.2. Switching

- 4.4.3. Compliance with requirements

- 4.4.4. Flashing frequency

4.4.1. Presence, condition and operation

You must inspect all direction indicators and hazard warning lamps.

Direction indicators and hazard warning lamps are not required on vehicles:

- first used before 1 January 1936

- that do not have front and rear position lamps, or have such lamps permanently disconnected, painted over or masked that are only used during daylight hours and not used at times of seriously reduced visibility

Direction indicators must be amber.

Vehicles first used before 1 September 1965 may have white front indicators and red rear indicators, if the direction indicators are combined with stop lamps or combined with front or rear position lamps.

Vehicles first used before 1 April 1986 do not need to have hazard warning devices.

Vehicles first used on or after 1 April 1986 must be fitted with an amber side repeater indicator on each side.

The side repeater can be part of the front direction indicator if it has one of the following:

- a wraparound lens marked either with an ‘E’ mark in a circle or an ‘e’ mark in a rectangle with a number 5 above it

- an amber light coming through the front lens when viewed from 1m to the side of the rear bumper

Semaphore arms may flash but do not need to.

A ‘light source’ means any bulb, LED or other means of emitting light.

You must assess damaged or repaired lamps for security, colour, light output and durability.

Direction indicators that function sequentially/dynamically are not to be considered a reason to fail.

Tricycles and quadricycles do not need side repeaters.

Tricycles and quadricycles classed as mopeds do not need hazard warning lamps. Only ‘bodied’ mopeds must have direction indicators.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | A direction indicator lamp with a multiple light source up to 1/2 not functioning | Minor |

| (a)(ii) | A direction indicator lamp missing, inoperative or in the case of a multiple light source more than 1/2 not functioning | Major |

| (b)(i) | A lens defective which has no effect on emitted light | Minor |

| (b)(ii) | A lens defective such that the emitted light is adversely affected | Major |

| (c)(i) | A lamp not securely attached | Minor |

| (c)(ii) | A lamp likely to become detached | Major |

| (d) | Mandatory hazard warning device not fitted | Major |

| (e) | Mandatory hazard warning device inoperative | Major |

4.4.2. Switching

Hazard warning lamps must operate using only one switch and with the engine or ignition switch in both the on and off positions.

For tricycles and quadricycles, hazard warning lamps must work both with the engine running and switched off. This may be by use of an engine kill switch or by turning the ignition off.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | Indicator or hazard warning switch does not operate in accordance with the requirements | Minor |

| (a)(ii) | Indicator or hazard warning switch inoperative | Major |

4.4.3. Compliance with requirements

Direction indicators must be amber.

Vehicles first used before 1 September 1965 may have white front indicators and red rear indicators, if the direction indicators are combined with stop lamps or combined with front or rear position lamps.

Switch on the direction indicator lamps and operate all the other lamps in turn to see if the direction indicator lamps are adversely affected.

On vehicles first used on or after 1 September 1965 with direction indicators combined with position lamps, the position lamp may or may not go out when its direction indicator is flashing. The direction indicator must flash amber only, with no white or red light.

A semaphore arm must light up when switched on, but it does not need to flash.

The precise position of lamps is not part of the inspection. You should check visually that they are at about the same height and distance from each side of the vehicle.

You must assess damaged or repaired lamps for security, colour, light output and durability.

Direction indicators that function sequentially/dynamically are not to be considered a reason to fail.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Lamp emitted colour, position or intensity not in accordance with the requirements | Major |

| (b) | A direction indicator lamp adversely affected by the operation of any other lamp | Major |

4.4.4. Flashing frequency

Indicators must flash at between 60 and 120 times per minute. Semaphore type direction indicators do not need to flash.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Rate of flashing not between 60 and 120 times per minute | Minor |

In this section

- 4.5.1. Presence, condition and operation

- 4.5.2. Not in use

- 4.5.3. Switching

- 4.5.4. Compliance with requirements

4.5.1. Presence, condition and operation

You only need to inspect:

- front fog lamps fitted to vehicles first used on or after 1 March 2018

- the 1 rear fog lamp which must be fitted to the centre or offside of vehicles first used on or after 1 April 1980

Fog lamps are not needed on:

- vehicles not fitted with front and rear position lamps

- vehicles with permanently disconnected, painted over or masked front and rear position lamps

- tricycles and quadricycles

Front and rear fog lamps are permitted to operate independently of any other lamps or ignition systems.

Fog lamps must produce a steady light which is:

- white - for front fog lamps

- red - for rear fog lamps

Front fog lamps that are not wired up and do not have a corresponding switch are not required to work. If you are not sure that they’re connected, you should give the benefit of the doubt.

Rear fog lamps may be combined with the rear position lamps.

A ‘light source’ means any bulb, LED or other means of emitting light.

You must assess damaged or repaired lamps for security, colour, light output and durability.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | A front or rear fog lamp with a multiple light source up to 1/2 not functioning | Minor |

| (a)(ii) | An obligatory rear fog lamp missing, or a front or rear fog lamp inoperative or in the case of a multiple light source more than 1/2 not functioning | Major |

| (b)(i) | A lens defective which has no effect on emitted light | Minor |

| (b)(ii) | A lens defective such that emitted light is adversely affected | Major |

| (c)(i) | A front or rear fog lamp not securely attached | Minor |

| (c)(ii) | A front or rear fog lamp likely to become detached | Major |

4.5.2. Not in use

4.5.3. Switching

Front and rear fog lamp switches may be combined or independent switches.

The switch or switches must:

- be secure

- be able to be operated from the normal driving position

- operate the fog lamps as intended

Rear fog lamps may be combined with the rear position lamps. Front and rear fog lamps are permitted to operate independently of any other lamps or ignition systems.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | front or rear fog lamp switch inoperative or not operating in accordance with the requirements | Major |

4.5.4. Compliance with requirements

You must inspect:

- all front fog lamps fitted to vehicles first used on or after 1 March 2018

- the 1 rear fog lamp which must be fitted to the centre or offside of vehicles first used on or after 1 April 1980

Fog lamps must produce a steady light which is:

- white - for front fog lamps

- red - for rear fog lamps

Rear fog lamps may be combined with the rear position lamps.

A rear fog lamp is not needed on:

- vehicles not fitted with front and rear position lamps

- vehicles with permanently disconnected, painted over or masked front and rear position lamps that are

- tricycles and quadricycles

Switch on the rear fog lamps and operate all the other lamps in turn to see if the rear fog lamps are adversely affected.

Rear fog lamps may extinguish when main-beam is switched on or when dipped beam headlamps are switched off.

You must assess damaged or repaired lamps for security, colour, light output and durability.

| Defect refence | Defect | Category |

|---|---|---|

| (a) | Front or rear fog lamp emitted colour or position not in accordance with the requirements | Major |

| (b) | A rear fog lamp adversely affected by the operation of any other lamp | Major |

In this section

4.6.1. Condition and operation

You must inspect all reversing lamps fitted to vehicles first used from 1 September 2009 other than quadricycles and three-wheeled vehicles.

Reversing lamps must show a white light to the rear. On some vehicles it may be necessary to have the engine running before the reversing lamps will work.

At least one reversing lamp must be fitted.

Buses over 6m long may have 4 reversing lamps which may be:

- all showing white light to the rear

- 2 showing white light to the rear and one on each side

| Defect reference | Defect | Category |

|---|---|---|

| (a) | A reversing lamp inoperative | Major |

| (b) | A reversing lamp lens defective | Major |

| (c)(i) | A reversing lamp not securely attached | Minor |

| (c)(ii) | A reversing lamp likely to become detached | Major |

4.6.2. Compliance with requirements

You must inspect all reversing lamps fitted to vehicles first used from 1 September 2009 other than quadricycles and Class 3 vehicles.

Vehicles do not need to be fitted with reversing lamps, that do not have front and rear position lamps, or have such lamps permanently disconnected, painted over or masked that are only used during daylight hours and not used at times of seriously reduced visibility.

Reversing lamps must show a white light to the rear. On some vehicles it may be necessary to have the engine running before the reversing lamps will work.

At least one reversing lamp must be fitted.

Buses over 6m long may have 4 reversing lamps which may be:

- all showing white light to the rear

- 2 showing white light to the rear and 1 on each side

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Reversing lamp emitted colour or position not in accordance with the requirements | Major |

4.6.3. Switching

You must inspect all reversing lamps fitted to vehicles first used from 1 September 2009 other than quadricycles and Class 3 vehicles.

Reversing lamps must operate automatically when reverse gear is selected and extinguish when reverse gear is deselected.

On some vehicles it may be necessary to have the engine running before the reversing lamps will work.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Reversing lamp switch not operating in accordance with the requirements | Major |

In this section

4.7.1. Presence, condition and operation

You must inspect the registration plate lamps on all vehicles fitted with front and rear position lamps.

Registration plate lamps must light up the rear registration plate. Some vehicles may have these lamps fitted behind the number plate.

A ‘light source’ means any bulb, LED or other means of emitting light.

Tricycles and quadricycles classed as mopeds do not need a rear registration plate lamp.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | A rear registration plate lamp throwing direct white light to the rear | Minor |

| (b)(i) | A rear registration plate lamp or light source missing or inoperative when rear registration plate has 2 or more lamps or light sources | Minor |

| (b)(ii) | A rear registration plate lamp or light source missing or inoperative when rear registration plate has only one lamp or all lamps not working | Major |

| (c)(i) | A registration plate lamp not securely attached | Minor |

| (c)(ii) | A registration plate lamp likely to become detached | Major |

4.7.2. Compliance with requirements

You must inspect the registration plate lamps on all vehicles fitted with front and rear position lamps.

Registration plate lamps must operate at the same time as the position lamps.

Tricycles and quadricycles classed as mopeds do not need a rear registration plate lamp.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | Rear registration plate lamp does not illuminate simultaneously with the position lamps | Major |

In this section

4.8.1. Presence, condition and operation

You must inspect the 2 mandatory red rear reflectors that must be fitted.

Rear reflectors are not required on vehicles not fitted with front and rear position lamps, or have such lamps permanently disconnected, painted over or masked that are:

- only used during daylight hours, and

- not used at times of seriously reduced visibility

Reflective tape is not an acceptable substitute for a rear reflector.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | Reflector defective or damaged by up to 50% of the reflecting surface | Minor |

| (a)(ii) | Reflector defective or damaged by more than 50% of the reflecting surface | Major |

| (b)(i) | Reflector not securely attached | Minor |

| (b)(ii) | Reflector likely to become detached | Major |

4.8.2. Compliance with requirements

You must inspect the 2 mandatory red rear reflectors that must be fitted.

Rear reflectors are not required on vehicles not fitted with front and rear position lamps, or have such lamps permanently disconnected, painted over or masked and are:

- only used during daylight hours, and

- not used at times of seriously reduced visibility

Reflectors must be symmetrically mounted. Although the precise position of mandatory rear reflectors is not part of the inspection, check visually that they are at about the same height and distance from each side of the vehicle.

Tricycles and quadricycles:

- wider than 1,000mm must have 2 rear reflectors mounted symmetrically

- not more than 1,000mm wide only need one centrally mounted rear reflector

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | Reflector colour or position not in accordance with the requirements | Minor |

| (a)(ii) | Reflector missing or reflecting white to the rear | Major |

In this section

4.9.1. Presence, condition and operation

You must inspect the following lighting ‘tell-tales’:

- headlamp main beam

- direction indicators

- hazard warning lamps

- rear fog lamps

A main beam ‘tell-tale’ is only required on vehicles first used on or after 1 April 1986. Class 3 vehicles do not need to have the main-beam tell-tale inspected.

A direction indicator ‘tell-tale’ can be audible or visual.

A hazard warning ‘tell-tale’ must be a flashing light.

A rear fog ‘tell-tale’ is only required where a rear fog lamp is mandatory.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | A mandatory tell-tale for direction indicators or hazard warning missing or inoperative | Minor |

| (a)(ii) | A mandatory tell-tale for main beam headlamp or rear fog lamp missing or inoperative | Major |

4.9.2. Compliance with requirements

You must inspect the ‘tell-tale’ for hazard warning lamps, which must be a flashing light.

| Defect reference | Defect | Category |

|---|---|---|

| (a) | A hazard warning lamp tell-tale is not a flashing light | Minor |

You must only inspect the trailer electrical socket on vehicles fitted with a towing coupling.

If there’s no tow ball or pin, but the attachment brackets are still in place, you must assess the electrical sockets if the tow ball or pin has been:

- detached

- unbolted

- otherwise removed

You do not need to assess the electrical sockets if the attachment brackets have been deliberately made unfit for further use.

You do not need to assess the trailer electrical socket if you need tools or specialist equipment to remove access panels in the bumper or bodywork to gain access to the socket.

A trailer electrical socket with a defective or missing cover flap that incorporates a lug and spring to hold the plug in place is not considered to be a defect.

13 pin Euro-socket

On vehicles fitted with a trailer 13 pin Euro-socket, use an approved device to check that the socket is wired to correctly operate the trailer:

- position lamps

- stop lamps

- direction indicators

Some 13-pin test tools may continually flicker when plugged into the socket of a vehicle that uses controller area network bus (CANbus) systems.

Where this happens, it generally indicates that there’s continuity at each pin on the vehicle’s socket. When the lamps are operated in turn you will usually see that each individual LED will function correctly.

Provided the self-test facility on your tester does not show any faults, then you should pass the socket test.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | A trailer electrical socket insecure | Minor |

| (a)(ii) | A trailer electrical socket likely to become detached | Major |

| (b)(i) | Trailer electrical socket wiring insulation damaged or deteriorated | Minor |

| (b)(ii) | Trailer electrical socket wiring insulation damaged or deteriorated and likely to cause a short-circuit | Major |

| (c)(i) | A 13-pin trailer socket not functioning correctly | Major |

| (c)(ii) | A 13-pin trailer socket not functioning at all | Dangerous |

You must carry out a visual only inspection of all visible electrical wiring. The check does not apply to Class 3 vehicles.

You should be mindful of high voltage components and cabling as if these are damaged they may be capable of delivering a fatal electric shock.

This inspection does not apply to electrical wiring to brake pads.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | Electrical wiring insecure or inadequately secured | Minor |

| (a)(ii) | Electrical wiring insecure and in contact with sharp edges or connectors likely to become disconnected | Major |

| (a)(iii) | Electrical wiring likely to touch hot or rotating parts, drag on the ground or the connectors for braking or steering disconnected | Dangerous |

| (b)(i) | Electrical wiring slightly deteriorated | Minor |

| (b)(ii) | Electrical wiring so damaged or deteriorated it is likely to cause a short-circuit | Major |

| (b)(iii) | Electrical wiring for braking or steering components extremely deteriorated | Dangerous |

| (c)(i) | Electrical wiring insulation damaged or deteriorated | Minor |

| (c)(ii) | Electrical wiring insulation heavily deteriorated | Major |

| (c)(iii) | Electrical wiring insulation in such a condition there is an imminent risk of fire or formation of sparks | Dangerous |

You must inspect the battery(ies) on all vehicles including electric and hybrid vehicles. The check does not apply to Class 3 vehicles.

Batteries used for propulsion of electric or hybrid electric vehicles carry high voltage and additional care should be taken when testing them.

The propulsion batteries are unlikely to be accessible, but if they are they should be assessed visually only. If the batteries are leaking, you should refuse to test the vehicle using Item 4 reason ‘h’ of the Introduction section.

You should be mindful of high voltage components and cabling as if these are damaged they may be capable of delivering a fatal electric shock.

| Defect reference | Defect | Category |

|---|---|---|

| (a)(i) | A battery insecure but not likely to fall from carrier | Minor |

| (a)(ii) | A battery insecure and likely to fall from carrier or cause a short circuit | Major |

| (b) | A battery leaking | Major |