Consolidated code of practice: enforcement weighing of vehicles

Updated 24 May 2024

Applies to England, Scotland and Wales

1. Introduction

This non-statutory code of practice provides best practice guidance for Driver and Vehicle Standards Agency (DVSA) examiners conducting vehicle weight checks using single and multi plate weighbridges, other non-dynamic weighing equipment, dynamic axle weighers (including in static mode), and portable weighpads.

While this code represents best practice for those undertaking enforcement weight checks, producing results which can be relied upon, it is recognised that alternative methods, equipment and sites do exist. This code does not, therefore, preclude an enforcement officer from using alternatives provided that a court can be satisfied as to the accuracy of the results obtained.

2. Purpose of weighing

2.1 Background

The main aim of check weighing is to enforce UK law concerning the maximum permitted weight limits for vehicles. These exist to reduce damage to roads and bridges, to improve road safety and to help ensure fair competition.

Vehicles may be weighed by either:

- an authorised enforcement examiner on behalf of the Department for Transport

- an authorised officer of a highway authority, normally an inspector of weights and measures

- a police officer authorised by a chief constable

These officers must have written authority to check and weigh vehicles and, as authorised officers, may require vehicles to be weighed at any time.

2.2 Requirements at check-weighing

Weighings can be carried out on various types of equipment. These must have been tested by:

- an inspector of weights and measures

- an authorised officer of an approved body

- persons approved by DVSA

There are fuller details of specific requirements for different types of weighing equipment.

A vehicle on the highway may be stopped or directed for the purposes of weighing by a uniformed police officer or an accredited DVSA stopping officer. However, an authorised enforcement examiner (but not an accredited stopping officer) may, on production of their authority direct a stationary vehicle to a weighing site at any time without the need for a police officer to be involved.

Drivers must comply with any lawful instruction given by an authorised officer. Failure to do so will constitute an offence and may lead to prosecution of the offender. It is the driver’s responsibility to inform the authorised officer requiring the vehicle to be weighed of any unusual characteristics of the vehicle or load.

Vehicles which will receive special consideration include:

- vehicles carrying passengers, livestock, perishables or loads which rapidly deteriorate

- high value loads

- dangerous loads

- abnormal indivisible loads

- fluid loads

- loads sealed by customs

If a vehicle is directed more than 5 miles to a weigh site and is found to be within the permitted weight limits, certain provisions for payment of expenses may apply. The 5 miles distance is measured along a practical route on roads suitable for the vehicle.

2.3 Enforcement action in the event of an overload

If the weight recorded is above the permitted limit, the driver, or any other person who uses, causes or permits the use of the vehicle which may include the consignor, may be issued with a fixed penalty notice or reported for prosecution.

An authorised officer may prohibit movement of a vehicle if it is overweight. If this occurs, a prohibition notice, which may contain particular conditions, will be issued to the driver and will come into effect immediately. A copy of any prohibition notice issued will be sent to the owner or the operator of the vehicle, or to the driver’s employer.

While a prohibition notice is in force it is an offence for the vehicle to travel on a road. A prohibition notice must be cleared in writing by an authorised officer before the vehicle can proceed. The vehicle may have to be reweighed to establish that it is within the legal weight limits. An authorised officer has discretion to give a written direction that a prohibited vehicle may be moved to a place where it can be parked or where offloading of excess weight may safely be carried out. Conditions may be imposed on this movement. Such written directions must only be given in exceptional circumstances.

Where a prohibition is issued, it is the responsibility of the driver and their employer to make satisfactory arrangements for, and meet the costs of, the offloading of the excess weight and the security and safe-keeping of any offloaded goods. Authorised officers will ensure that prohibitions are removed as soon as reasonably practicable.

In the case vehicles subject to an operator licence, any or all of these matters should be notified to the appropriate traffic commissioner.

3. Types of weighing equipment and their use

3.1 General instructions on weighing procedure for enforcement officers

Before commencing an enforcement weight check, authorised officers must familiarise themselves with the operation of the weighing equipment at that site, and must ensure that:

- the equipment has been tested for accuracy within the preceding 6 months

- all displays are reading zero

- the equipment shows no signs of damage that could affect the accuracy of the weighing

- the weighing area is clear of any debris (for example, stones) and shows no signs of deterioration or damage that could affect the accuracy of the weighing

- any computer being used is connected and appears to be working properly

- the equipment is suitable for weighing the type of vehicle

Axles forming part of a group are often connected by mechanical, pneumatic or hydraulic means, in order to balance the axle loads applied to the road surface. These are known as compensating axles, and form part of a compensating axle group.

When weighing a vehicle the authorised officer must ensure that:

- the driver is given clear instructions

- the driver and any passengers remain in the vehicle during the weighing

- if requested and practicable the driver can be shown the indicated weights

- a certificate of weight is issued to the driver with weights recorded

If the results of the weight check are recorded, this must be dated and kept by the authorised enforcement staff for 2 years.

In addition to these general instructions, particular requirements, depending on the type of weighing equipment being used, must be observed as detailed from section 3.3 onwards below.

3.2 Single plate weighbridges

This equipment comprises a single weighing plate connected to an indicator. Vehicles are weighed whilst stationary.

If a single plate weighbridge is to be used for separately weighing axles and bogies or to summate those results to produce the gross vehicle weight or gross train weight of the vehicle, the weighbridge must have been approved for that purpose by an inspector of weights and measures. The authorised officer must be aware of any particular requirements relating to such use as determined by the inspector of weights and measures.

Prior to weighing on a single plate weighbridge, care should be taken to ensure that the weighbridge plate is not binding against the surround.

When weighing on a single plate weighbridge, the following specific requirements must be observed:

- all of the tyres on the axles being weighed must be wholly on the plate

- where the whole of the vehicle is not being weighed and the vehicle is fitted with compensating axles, care must be taken to weigh the compensating axles together as one unit

- where only part of the vehicle is being weighed, the driver must be instructed to comply with the following sequence: stop the vehicle, release all brakes, apply the parking brake, put the gearbox into neutral

If a single plate weighbridge has been used to weigh individual axles or bogies or to add up those results to produce the gross vehicle weight or gross train weight of a vehicle, the accuracy limit is +/- 50kg per axle or as specified for that weighbridge by an inspector of weights and measures.

3.3 Multi-plate weighbridges

This equipment typically comprises 2 or more independent static weighing plates connected to a single console. Vehicles are weighed whilst stationary.

Prior to weighing on a multi-plate, care should be taken to ensure that the weighbridge plates are not binding against the plate housings or other components of the weighing equipment.

The following specific requirements must also be observed:

- all of the tyres on the axles being weighed must be wholly on the weighbridge

- when weighing vehicles fitted with compensating axles, care must be taken to weigh the compensating axles together as one unit on the same plate

- the driver must be instructed to comply with the following sequence: stop the vehicle, release all brakes, apply the parking brake, put the gearbox into neutral

The accuracy limit for gross or train weights of a multi-plate weighbridge is +/- 50kg multiplied by the number of plates used for the weighing. Where an axle or group of axles is weighed on the same plate the accuracy limit is +/- 100kg.

The equipment can also be used to weigh vehicles longer than the total length of the weighbridge provided it has been approved for that purpose by an inspector of weights and measures. The authorised officer must be aware of any particular requirements or limitations relating to such use as determined by an inspector of weights and measures.

3.4 Axle weighers

This equipment comprises of a single axle weighing platform (also known as the ‘weighbeam’) with flat, level concrete approaches (also known as ‘aprons’) leading to and from it. Vehicles can be weighed whilst in motion at a speed of up to 2.5 mph. Vehicles without compensating axles may also be weighed statically.

Prior to weighing on an axle weighbridge, the following specific requirements must be observed:

- ensure the concrete aprons either side of the weighbeam have been tested for levels compliance in the preceding 12 months

- ensure the weighbeam is not binding against the surround

3.4.1 Axle weigher in dynamic mode

Vehicles being weighed in dynamic mode must be weighed in accordance with the following procedure and the authorised enforcement officer must ensure that:

- the vehicle to be weighed is stopped a minimum distance of 6 metres from the weighbeam

- the driver of the vehicle is instructed to drive across the weighbeam at a steady speed not exceeding walking pace and once at a suitable speed the driver must not accelerate, brake or change gear

- the vehicle is observed at all times during the weighing procedure to monitor that a consistent speed is maintained and that all wheels pass over the weighbeam

- if at any time during the weighing the vehicle accelerates above the permitted speed or decelerates, the weighing must be disregarded and the vehicle weighed again until a satisfactory weighing and printout is achieved

- the accuracy limit for an axle weigher in dynamic mode is +/- 150kg per axle, with a consequent accuracy limit on gross vehicle weight or gross train weight of +/- 150kg, multiplied by the number of axles: compensating axles are to be assessed as a combined weight, applying the +/- 150kg for each axle included

3.4.2 Axle weigher in static mode

Vehicles being weighed in static mode must be weighed in accordance with the following procedure and the authorised enforcement officer must ensure that:

- during the weighing procedure all axles not being weighed are on the concrete apron

- each axle is weighed statically in turn

- the tyres of the axle being weighed are wholly on the weighbeam

- the driver is instructed to comply with the following sequence: stop the vehicle, release all brakes, apply the parking brake, put the gearbox into neutral

- the accuracy limit of an axle weigher in static mode is +/- 50kg per axle, with a consequent accuracy limit on gross vehicle weight or gross train weight of +/- 50kg, multiplied by the number of axles: compensating axles must not be weighed statically on a single axle weighbridge

3.5 Portable weighpads

Portable weighpads provide the opportunity to weigh vehicles in those locations not normally subjected to weight checks due to the absence of fixed weighing facilities. They have the advantage of being easily transported and can be operated at any designated weighsite.

Compensating axles must be weighed together as a group, but this can only be done if there are sufficient weighpads to accommodate all the axles in a group at the same time.

Before weighing of vehicles commences, the authorised officer must ensure that the designated weighing area has been tested for levels compliance in the preceding 12 months or that the level of the site has been measured by an authorised enforcement examiner. This will be classed as a surveyed site. Prosecution or fixed penalty action can only be taken on a surveyed site.

When weighing on portable weighpads the following procedure is to be observed and the authorised officer must ensure that:

- the vehicle is within the designated weighing area and reasonably parallel with the centre line (see appendix 2 for site specification)

- the weighpads are placed in appropriate positions within the designated weighing area

- the driver is instructed to drive onto the weighpads: each wheel being weighed must be positioned to make sure that the weight bearing area of the tyre is correctly located on the active weighing surface of the weighpad

- the driver must be instructed to comply with the following sequence: stop the vehicle, release all brakes, apply the parking brake, put the gearbox into neutral

- axles forming part of a compensating group must not be weighed individually but as a group

- after weighing, the driver is instructed to drive slowly off the weighpads, apply the parking brake, put the gearbox into neutral and not move the vehicle until instructed to do so (this to enable safe removal of weighpads if appropriate)

- the accuracy limits of portable weighpads is +/- 100kg per axle, with a consequential accuracy limit on gross vehicle weight or gross train weight of +/- 100kg multiplied by the number of axles on the vehicle: compensating axles are to be assessed as a combined weight (applying the +/- 100kg accuracy limit for each axle included)

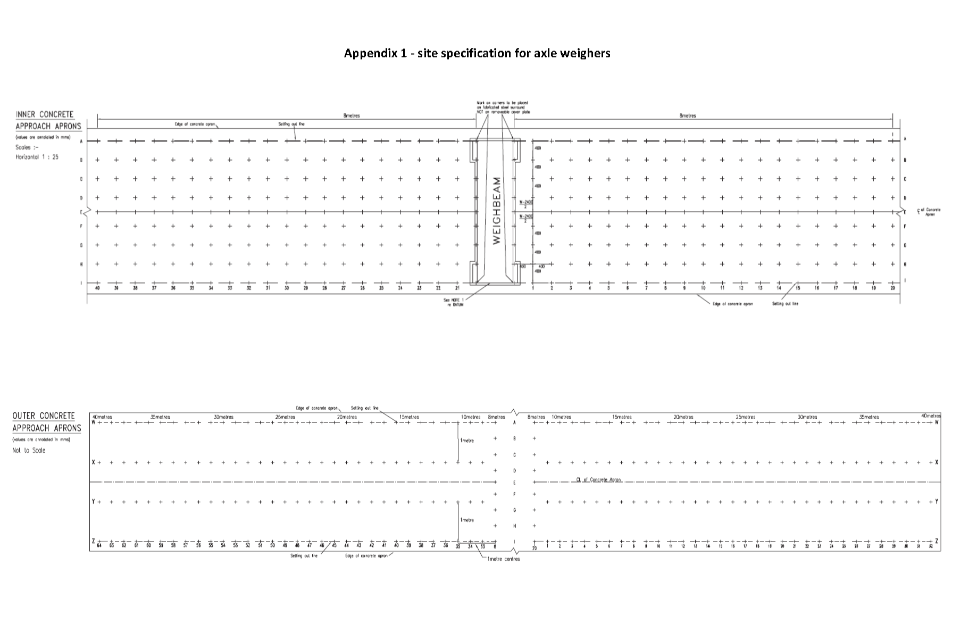

Appendix 1: Site specification for axle weighers

A1.1: Introduction

To achieve the required accuracy, axle weighers must be installed and used with perfectly flat concrete approaches (also known as ‘aprons’) leading to and from the weighbeam. Sites must satisfy the following requirements:

- the concrete approach aprons within 8 metres of the weighbeam must be flat and level to within 3mm of a single datum point within that area

- the concrete approach aprons more than 8 metres from the weighbeam must be flat and level to within 6mm of the same datum

A1.2: Initial certification

Compliance with the surface level requirements of the code of practice is to be determined by a suitably qualified person when construction is complete and before the site is first used for enforcement purposes.

A level datum is to be taken at a suitable point on the fabricated steel surround of the weighbeam pit or within the ’16.775 metre level area’ and its position marked on the drawing referred to in the paragraph below. Its position is to be determined by taking levels using a precise level and staff, and choosing the point which minimises the extent of any remedial work having regard to the code of practice level requirements.

A 400 mm x 400 mm grid of level control points is to be marked out on the concrete aprons for 8 metres either side of the fabricated steel surround of the weighbeam pit. A 1 metre x 1 metre grid of level control points is to be marked out for the remainder of the concrete apron, for a distance of at least a further 8 metres from the pit surround. Setting out lines for the control points are shown on the DVSA drawing attached to this appendix in reduced form. Levels must be taken on all those points using the precise level and staff.

A1.3: Routine compliance checks

Surface level compliance checks must be repeated using the same level control points at least once every 12 months when in use and at any other time deemed necessary by DVSA or an inspector of weights and measures.

Appendix 1 - site specification for axle weighers

Appendix 2: Site specification for portable weighpads

A2.1: Levels compliance

Designated weighing areas

To achieve the necessary levels of accuracy for weighing, portable weighpads must be used at sites (designated weighing areas) that satisfy the following requirements:

- the site is to be suitably segregated from passing traffic so as to ensure safety: police advice may be sought, if necessary

- the designated weighing area of the site is to be of appropriate width and length for the vehicle being weighed and the perimeter within which weighpads are to be positioned for use must be measured (perimeter markings at the corners and at 5m intervals along the length would be acceptable)

- the designated weighing area is to be surveyed by a suitably qualified person before initial use and thereafter at intervals not exceeding 12 months when in use or at any other time deemed necessary by DVSA or an inspector of weights and measures or a person authorised by a notified body operating under the Non-automatic Weighing Instruments Regulations 2016 (as amended) to verify the following requirements:

- (i) the appropriate centre line of the designated area in the direction of vehicle travel (longitudinal) is to be measured at the perimeter of the site and at every 5m interval: the slope between any 2 adjacent markings must not exceed 1%

- (ii) the slope of the designated area across the direction of the vehicle travel (transverse) is to be measured at right angles to the centre line and each position measured as in (i) above and must not exceed 4%

- (iii) the surface irregularity of the designated area, when measured along the centre line and at right angles to the centre line at 2m intervals, must not exceed 10mm at any point along the 2m length, when using a straight edge

- (iv) a site may exceed the levels criteria in (i), (ii), and (iii) above provided an inspector of weights and measures or a person authorised by a notified body operating under the Non-automatic Weighing Instruments Regulations 2016 (as amended) can demonstrate by vehicle weighing that the accuracy limits specified in section 3.5 portable weighpads are not exceeded

Sites surveyed by an authorised enforcement examiner

To achieve the necessary levels of accuracy for weighing on portable weighpads at sites surveyed by an authorised enforcement examiner, sites must satisfy the following requirements:

- the site is to be suitably segregated from passing traffic so as to ensure safety: police advice may be sought, if necessary

- the weighing area of the site must be the appropriate width and length for the vehicle being weighed and the perimeter within which weighpads are to be positioned for use must be measured

- the weighing area is to be measured by an authorised enforcement examiner who has been suitably trained before initial use to verify the following requirements:

- (i) the appropriate centre line of the designated area in the direction of vehicle travel (longitudinal) is to be measured at the perimeter of the site and at every 5m interval: the slope between any 2 adjacent markings must not exceed 3% - frequency of the measurements will depend on the calibrated equipment used

- (ii) the slope of the designated area across the direction of the vehicle travel (transverse) is to be measured in 2 metre intervals and the slope between 2 adjacent markings must not exceed 4%

- (iii) a site may exceed the levels criteria in (i) and (ii) above provided an authorised enforcement examiner operating under the Non-automatic Weighing Instruments Regulations 2016 (as amended) can demonstrate by vehicle weighing that the accuracy limits specified at section 3.5 portable weighpads are not exceeded

A2.2: Accuracy testing for single plate weighbridges

All weighbridges used for enforcement purposes must satisfy the legislative requirements that were applicable when they were first used for enforcement purposes. Weighbridges will need to be compliant with the Non-automatic Weighing Instruments Regulations 2016 (as amended). The accuracy requirements are the same irrespective of when the instrument was first used and are found in the designated standard BS EN 45501:2015 and repeated in A5.2: Methods of testing.

To demonstrate compliance with these regulations the instruments must have type examination certificates and be marked with either a CE mark, or UKCA mark followed by a capital letter M in a square and the identification number of the approved or notified body. If the instrument has been re-qualified after any repair, replacement, addition alteration of adjustment it may also bear a crown mark. These markings will be on the indicator.

Where any doubt as to the suitability of a weighbridge exists, the local weights and measures authority for the area should be contacted to provide clarification.

A2.3: Methods of testing

The weighbridge must be tested in accordance with the requirements of the regulations as applicable. The tests must be carried out by an inspector of weights and measures, a person authorised by an approved body operating under the Non-automatic Weighing Instruments Regulations 2016 (as amended), or by persons approved by DVSA.

A record of the test results must be kept for at least 2 years.

Appendix 3: Accuracy testing for multi-plate weighbridges

A3.1: Introduction

All weighbridges used for enforcement purposes must satisfy the legislative requirements that were applicable when they were first used for enforcement purposes. Weighbridges will need to be compliant with the Non-automatic Weighing Instruments Regulations 2016 (as amended). The accuracy requirements are the same irrespective of when the instrument was first used and are found in the designated standard EN45501(2015) and repeated in A5.2: Methods of testing.

To demonstrate compliance with these regulations the instruments must have type examination certificates and be marked with either a CE mark, or UKCA mark followed by a capital letter M in a square and the identification number of the approved or notified body. If the instrument has been re-qualified after any repair it may also bear a crown mark. These markings will be on the indicator.

Where any doubt as to the suitability of a weighbridge exists, the local weights and measures authority for the area should be contacted to provide clarification.

A3.2: Methods of testing

The multi-plate weighbridge must be tested in accordance with the regulations as applicable. The tests must be carried out by an inspector of weights and measures, a person authorised by an approved body operating under the Non-automatic Weighing Instruments Regulations 2016 (as amended), or by persons approved by DVSA.

A record of the test results must be kept for at least 2 years.

a. Weight test:

- each plate of a multi-plate weighbridge is to be treated as a separate weighing machine and must be tested as such in accordance with the requirements of the regulations

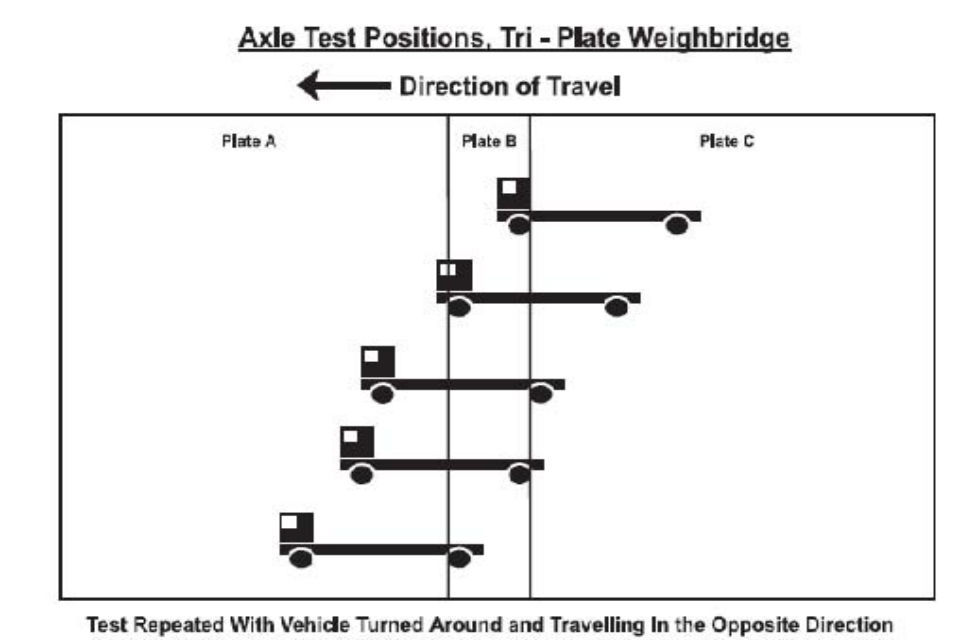

b. Vehicle tests:

- a 2-axle rigid vehicle (nominally 17-18 tonnes) loaded as near as practical to maximum legal weight is to be used

- the vehicle’s gross weight is ascertained in a single weighing using one of the plates of the multi-plate weighbridge: a series of test weighings must be taken, with the number of those test weighings determined by the number of weighing plates the weighbridge has; during those weighings all the vehicle axles must be on an active weighing surface; during the test weighings the engine and brakes must be off, the vehicle in gear and positioned so that, in sequence, one of its axles is placed as near as practical to the edges of all adjoining weighplates; a diagrammatic indication of vehicle positions for a tri-plate weighbridge can be seen attached to this appendix; a similar basis is to be used for axle positions on weighbridges with other numbers of plates

- the vehicle must be turned around and the series of weighings repeated in the opposite direction: equivalent axle positions are to be used

- the multi-plate weighbridge is to be deemed accurate provided that the gross weight of the vehicle on each test weigh, as determined by the aggregation of each axle weight, is within a tolerance of +/- 50kg when compared with the gross weight established when on one plate: further, the individual weights recorded for each axle must not vary by more than 75kg from the average weight when all the results for each individual axle recorded by the weighbridge are averaged

c. Vehicle repeatability tests:

- an articulated vehicle with a tri-axle semi-trailer loaded as near as practical to maximum legal weight is to be used: all axles that form part of a compensating bogie arrangement must be fitted with a steel suspension system

- the vehicle must either, first be weighed in a single weighing on a conventional weighbridge of known accuracy, and then taken to the multi-plate weighbridge, or the component parts (for example, tractor and trailer) must be weighed on the same plate of the multi-plate weighbridge provided that plate has been tested in accordance with paragraph A.3.2.a weight test: 3 repeatability test weighs must then be undertaken; the wheels of the vehicle must be placed in the same position on the weighplates for the 3 test weighings and the vehicle must be removed entirely from all active weighing surfaces between the test weighings

- the multi-plate weighbridge is to be deemed accurate provided the vehicle’s train weight on each test weigh is within a tolerance of +/-50kg when compared with the weight established on the conventional weighbridge or the weight established by totalling the tractor and trailer weights found: further, the individual weights recorded for each axle must not vary by more than +/- 50kg from the average weight when all the results for that axle as recorded by the weigher are averaged; vehicles provided with compensating arrangements are to have their axle loadings assessed as a combined weight, the tolerance being +/- 50kg multiplied by the number of axles in the compensating arrangement

A record of test showing the results of the weights and vehicle lists must be completed by an approved body operating under the Non-automatic Weighing Instruments Regulations 2016 (as amended) or by persons approved by DVSA and retained for at least 2 years.

Appendix 3 - accuracy testing for multi-plate weighbridges

Appendix 4: Accuracy testing for axle weighers

A4.1 Introduction

The equipment is to be tested by the direct application of weights distributed evenly across the weighbeam and also by static and dynamic testing using 3 test vehicles. When the equipment is new or following a repair, adjustment, alteration or replacement which, in the opinion of an inspector of weights and measures, a person authorised by an approved body operating under the Measuring Instruments Regulations 2016, or by persons approved by DVSA, could have affected its accuracy, the weigher must indicate the weight applied to within the tolerance +/-10kg. When otherwise tested the weigher must indicate the weight applied to within a tolerance of +/- 20kg.

When the equipment is tested by the passage of vehicles whose weights have previously been determined on a conventional weighbridge, the total weight of the vehicle as determined by the aggregation of the weights recorded for its individual axles must not differ from that indicated on the conventional weighbridge by more than +/- 100kg multiplied by the number of axles.

A4.2: Methods of testing

The accuracy of axle weighers are to be assessed in accordance with the following procedure. Both the static and vehicle tests must be carried out by an inspector of weights and measures, a person authorised by an approved body operating under the Measuring Instruments Regulations 2016, or by persons approved by DVSA. This is to be done when the instrument is first installed, or following any repair, adjustment, alteration or replacement which, in the opinion of an inspector of weights and measures, a person authorised by an approved body operating under the Measuring Instruments Regulations 2016, or by persons approved by DVSA, could have affected its accuracy, and thereafter at 6 month intervals when the equipment is in use.

a. Static test:

- weights used for the test must be traceable to national standards

- the weigher must be tested at 1 tonne intervals by the direct application of weights up to 14 tonnes, with both increasing and decreasing loads: the load is to be, as reasonably as practical, evenly distributed on the weighbeam throughout the test; the digital readout, print roll and any remote readouts must be checked at each stage, and must be within the limits of accuracy stated in paragraph A4.1 introduction

b. Vehicle tests:

- 3 vehicles loaded to their maximum legal weight or as near thereto as practicable must be used: these must be a 2-axle rigid weighing between 17 and 18 tonnes, a 4-axle rigid and an articulated vehicle with a tri-axle semi-trailer; these vehicles must be fitted with a steel suspension system on all axles which form part of a compensating bogie arrangement

- each vehicle must be first weighed in a single weighing on a conventional weighbridge of known accuracy

- the weigher must be placed in static mode and the 2-axled rigid vehicle used for a static test: each axle of the vehicle is weighed with only the parking brake applied, the gross weight determined by the total of the 2 axle weights; this test must be repeated on 2 further occasions and the 3 determined gross weights must not differ by more than 60kg from the gross weight of the vehicle established on the conventional weighbridge

- the weigher must be placed in dynamic mode and each of the vehicles used for a series of 10 test runs at various speeds across the weighbeam, 9 of these test runs must be within the speed for which the machine is designed to operate such that no error indication is given and one run must be faster to ensure that the overspeed indication is operating: the passage of the vehicles during the 9 ‘in-speed’ runs is to be aligned such that there are 5 test runs take place in the centre of the weighbeam, 2 to the offside and 2 to the nearside

- the 9 ‘in-speed’ runs for each vehicle are used to determine the dynamic accuracy of the machine: the weigher must be deemed to be accurate provided that the total weight of each vehicle as determined by the aggregation of the weights recorded for each of its individual axles is within a tolerance calculated at the rate of +/100kg per axle, when compared with the initial weight established on the conventional weighbridge: further, for each vehicle the individual weights recorded for each axle must not vary by more than +/- 100kg from the weight obtained when all the results for each individual axle recorded by the weigher are averaged; axles linked by compensating arrangements must have their loadings assessed as a combined weight, the tolerance being +/- 100kg multiplied by the number of axles in the compensating arrangement

A record of test showing the results of the tests must be completed by an inspector of weights and measures, a person approved under the Measuring Instruments Regulations 2016), a person approved by DVSA, or a person approved under section 11a (schedule 3a) of the Weights and Measures Act 1985 and kept for at least 2 years together with the print roll for each test.

Appendix 5: Accuracy testing for portable weighpads

A5.1: Introduction

All portable weighpads must meet the accuracy requirements in the Non-automatic Weighing Instruments Regulations 2016 (as amended) and must denote the markings as per the guidance on Non-automatic Weighing Instruments Regulations 2016 (as amended).

Where any doubt as to the suitability of weighpads exists, the local weights and measures authority for the area should be contacted to provide clarification.

A5.2: Methods of testing

All weighpads must be tested in accordance with the requirements of the Non-automatic Weighing Instruments Regulations 2016 (as amended) as applicable together with the following out of level test:

- out of level testing is to be carried out as near as practicable to the maximum capacity of the instrument by 2 test weighings, one at 1% and one at 4% (to replicate the gradient levels in the site specification)

In order to ensure the accuracy of results obtained during enforcement weighings, weighpads must have the same limits of error irrespective of whether they are new, repaired or in use and this must not exceed (where e is the value of a scale interval):

- up to 50e +0.5e/-1.0e

- more than 50e to 200e +1.0e/- 2.0e

- more than 200e to 1000e +1.5e/- 3.0e

A record of test must be completed and kept for at least 2 years.