Urgent Safety Advice 02/2020: Maintenance arrangements for wagons that primarily carry dangerous goods

Published 5 November 2020

1. Safety issue

Suitable processes, facilities, tools and equipment may not be in place to prevent safety critical system components becoming unsafe due to insecure fastenings.

2. Safety advice

Entities in Charge of Maintenance (ECMs) should review their system of inspection and maintenance for wagons that primarily carry dangerous goods, to ensure that they have appropriate arrangements in place to manage the safety risk associated with malfunction of the braking system. This should include an assessment of the adequacy of:

- facilities, tools and equipment at all maintenance locations

- systems for assuring the competence of those involved

- management systems and instructions for assuring the quality of work undertaken

- methods for initial and ongoing assurance of the security of fastenings

- processes for the identification and tracking of safety critical components.

This assessment should take into account the particular hazards associated with conveying dangerous goods

3. Issued to:

ECMs responsible for the maintenance of wagons which primarily convey dangerous goods in the UK.

4. Background

At about 23:15 hrs on 26 August 2020, train 6A11, the 21:52 hrs freight service from Robeston (Milford Haven) to Theale, conveying 25 tank wagons, each containing up to 75.5 tonnes of diesel or gas oil, derailed on the ‘Up District’ line near Llangennech, in Carmarthenshire. The derailment and the subsequent damage to the wagons resulted in a significant spillage of fuel and a major fire. Subsequent examination of the site revealed that a total of 10 wagons (positioned 3rd to 12th in the train) had derailed, and that around 330,000 litres of fuel had been spilt.

RAIB’s preliminary examination found that, although all the wheels of the train were probably rotating freely when the train left Robeston, at some point during the journey the brakes on all wheels of the third wagon of the train had become applied, and remained so until the derailment. Although their brakes were dragging, three of the four axles of this wagon continued to turn. At some point in the journey the leading axle ceased to rotate altogether, as evidenced by a CCTV camera located at Pen-y-Bedd level crossing (12 miles (19 km) from Morlais Junction), and marks on the railhead.

CCTV image showing the third wagon passing Pen-y-Bedd level crossing

The locking of the leading axle of the third wagon caused the development of a flat spot around 230 mm long on both of the wheels on this axle. This in turn created substantial ‘false flanges’ (raised lips on the outer side of the wheel treads). When the train reached the crossover at Morlais Junction, travelling at about 30 mph (48 km/h), the false flange on the right-hand wheel caught on the converging stock rail and distorted the track, leading to derailment of both wheels. Around 100 metres further on, the partly derailed wagon encountered facing points set to route the train to the right. The locomotive and the two leading wagons went to the right and the derailed third wagon went straight ahead. The third wagon turned over onto its right-hand side and became detached from the wagon in front of it. This caused the points and the track beyond them to be destroyed, and derailment of another nine wagons followed.

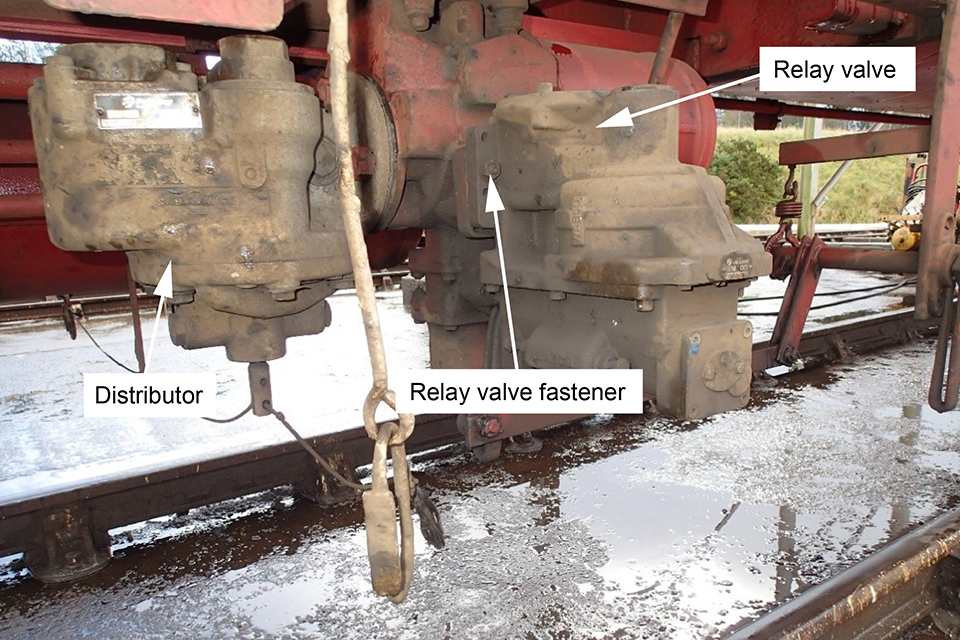

Examination of the brake group on the third wagon (TEA wagon GERS89005) found that the relay valve was loose on the pipe bracket. A sealing ring from one of the ports in the mating face had migrated to a position where it lodged between two other ports, distorted the sealing rings of those ports, and probably created a route for air to pass directly from the auxiliary reservoir to the wagon brake cylinder. This would have had the effect of applying the brakes on the wagon, producing the result described above.

Brake group on TEA wagon

The ECM for the wagon was unable to identify with any degree of certainty where and when the fastenings of the relay valve had last been disturbed. However, this may have taken place during routine repairs in the sidings at Robeston terminal or during scheduled maintenance elsewhere. There was no record of any check on the tightness of the fastenings ever having been made, and no process requiring such checks or provision of any measures, such as witness markings, which would have indicated that fastenings were becoming loose.