Individual Vehicle Approval (IVA): vehicle side guards (lateral protection devices)

Published 18 February 2016

Applies to England, Scotland and Wales

1. Introduction

This guide is to encourage best practice, by showing examples of good and bad practice.

To help you identify the common errors and direct you to the current published required standards.

Many of these examples will apply equally to:

- lorries and other vehicles in the N2/3 category

- heavy trailers and other vehicles in the O3/4 category

The lateral protection device (LPD) is there to help reduce the likelihood of injury to ‘unprotected road users’ when struck by a vehicle travelling in a forward direction.

The Individual Vehicle Approval (IVA) manual takes the definition from Directive 89/297/EEC for ‘unprotected road users’ as:

Pedestrians, cyclists and motorcyclists using the road in such a way that they are liable to fall under the sides of the vehicle and be caught under the wheels.

LPD is there to deflect people as opposed to stopping vehicles (eg motorcycles and cars) going underneath the sides of the vehicle.

DVSA will check to make sure that lateral protection devices do what they are intended to do and that it meets the required standards of section 42 (lateral protection) of the IVA inspection manual.

Where your vehicle is presented with evidence of a base vehicle approval and that, both:

- the LPD hasn’t been modified

- the vehicle hasn’t been modified in such a way as to invalidate the installation of the LPD

DVSA will not need to reassess during IVA.

Other equipment may be incorporated into, or even take the place of parts of the LPD.

When this happens, to meet the required standards, the outer surface of components forming the LPD must have an outer surface that is either:

- smooth and substantially flat

- horizontally corrugated

The body or design of body may be acceptable as LPD eg car transporters where the sides of the body also act as the LPD removing the need for a separate unit.

The guide will identify common problems and advise on simple solutions.

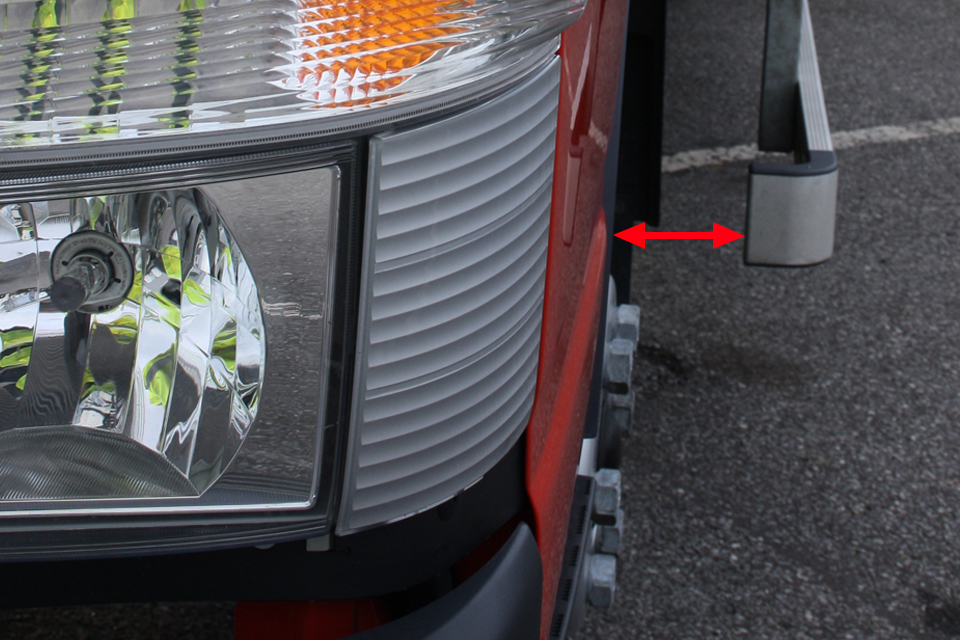

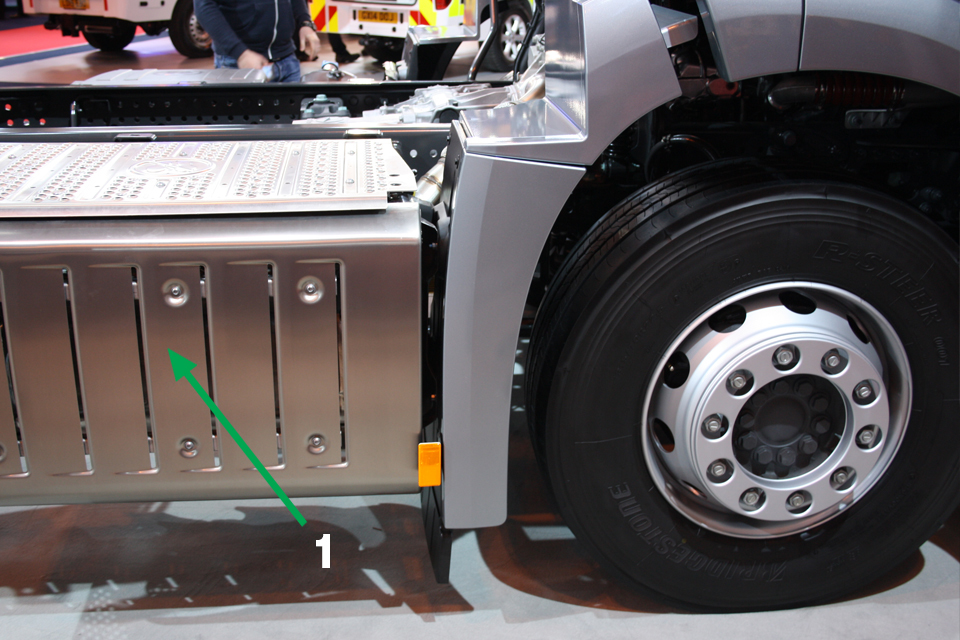

2. Where the vehicle cab is narrower than the body

The vehicle cab is narrower than the body.

Where the cab is narrower than the body, the leading edge of the lateral protection must be within 100mm of the cab. The LPD may be turned or angled in towards the cab by no more than 45 degrees to meet the required standard.

There is no requirement for the body itself to be angled in.

As shown in the image above:

- no requirement for the body to be angled in (1)

- lateral protection may be angled in (2)

The vehicle cab is narrower than the body.

As shown in the image above:

- the body is wider than the cab (1)

- the LPD doesn’t have to be angled in towards the cab, however the gap between LPD and cab may be no more than 100mm, where necessary the LPD may be angled in if it needs to meet the 100mm gap (2)

The vehicle cab is narrower than the body.

In the image above, on the N/S of the vehicle, the gap is more than 100mm. The LPD is angled in towards the cab to meet the 100mm dimension, less chance of injury to unprotected road users, more likely to deflect and glance off.

This meets the required standard.

Where the LPD is angled in towards the cab, an upright is still required, but no longer needs to meet the 100mm turn-in criteria.

Lateral gap

The 100mm gap can be lateral as in this image.

Diagonal gap

The 100mm gap can also be diagonal as in this image.

3. Definition of ‘Cab area’

Cab area

Here the 300mm falls within the cab, the cab has its own requirements in Section 49 of the IVA inspection manual.

DVSA sees this area as part of the cab, whether or not it is actually attached to the cab itself. (1)

The LPD must start within 100mm of the rear of the cab. (2)

Steps are part of cab

In this example, the cab clearly ends above the area required to be protected by the LPD.(1)

The LPD must start within the 300mm dimension - as above the steps are considered part of the cab, however, DVSA would expect the lower LPD rail to meet the 300mm dimension. (2)

4. Definition of ‘open space’

Definition of 'Open space'

Open space is a gap of more than 25mm measured from the rear edge of a fixed component within a defined area.

Here the gap is less than 25mm so no vertical member is required. (1)

LPD must be continuous. Open space does not apply here, this is a gap and can be no bigger than 25mm. There is no requirement for an upright here. (2)

Gap less than 25mm not defined as 'Open space'

A gap of 25mm or greater equals open space and requires an upright of relevant dimensions.

A gap of up to 25mm isn’t defined as open space and doesn’t require an upright.

5. The Dimensions of LPDs

Dimensions of LPD.

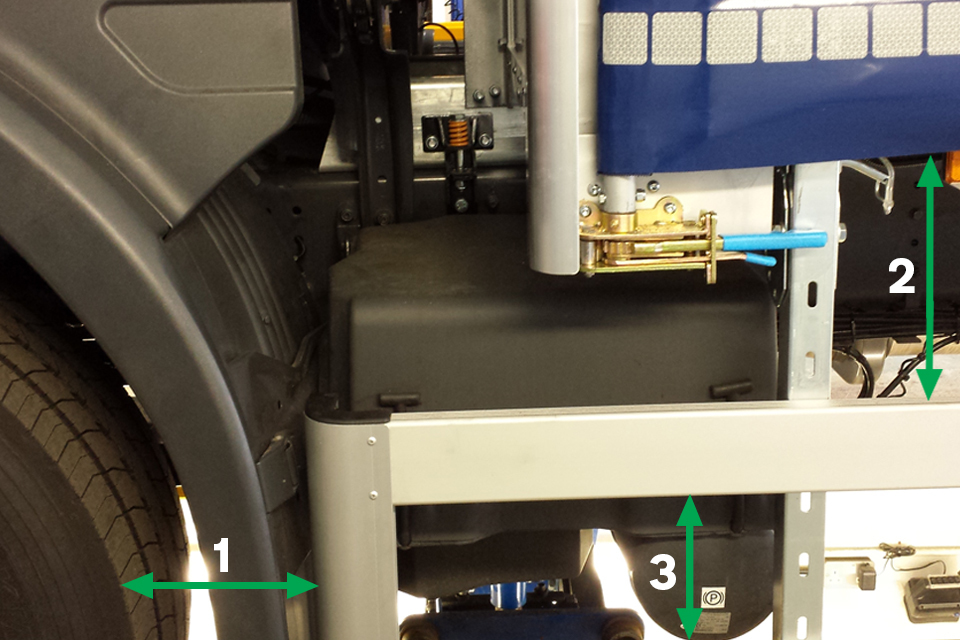

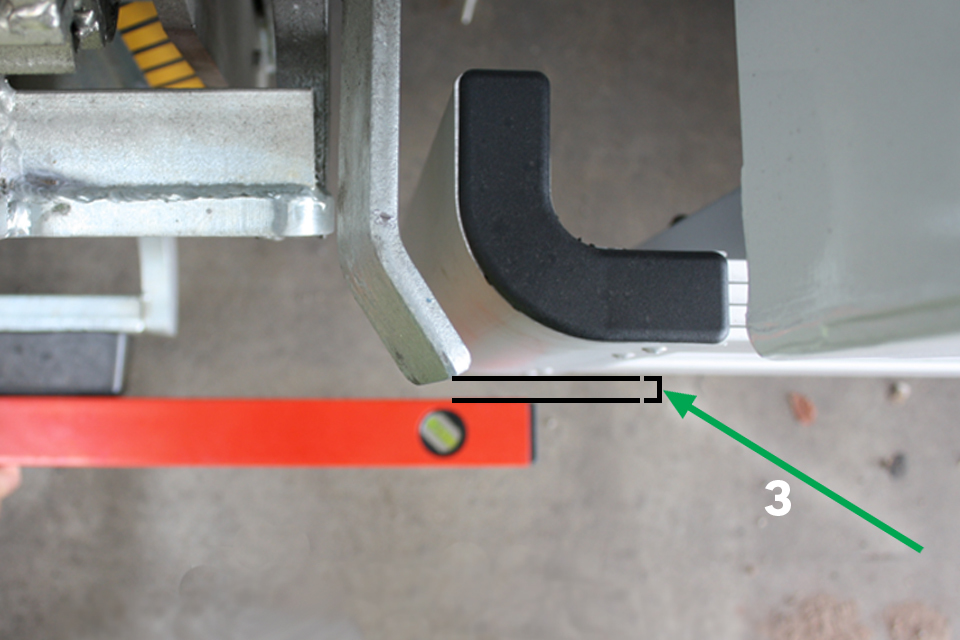

As shown in the image above the:

- front edge of the LPD must be within 300mm of the tyre at its closest point (1)

- LPD must be within 350mm of the body line (2)

- vertical gap between rails must be no more than 300mm (3)

This meets the required standard.

6. LPD Approvals

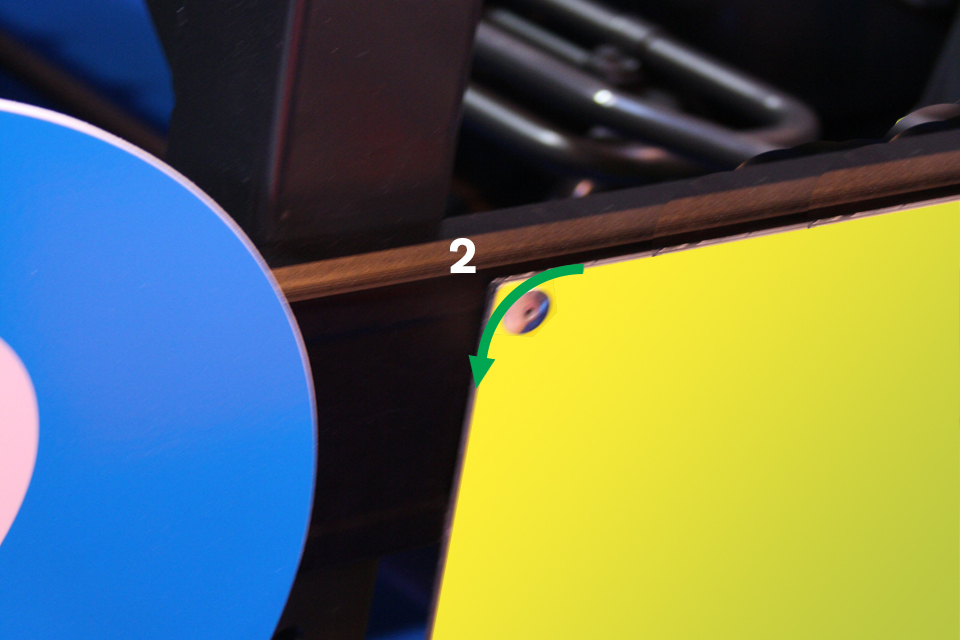

LPD Approvals.

DVSA will ask to see the original approval documents and look at the diagrams to check if a cap or radiused edge is specified.

As shown in the image above:

- when the LPD is approved, it may still not meet the requirements of a radius of 2.5mm on an external edge, but as it has an approval, it will pass (1)

- in this case, when the original approval was consulted, no end cap had been specified (2)

This approved LPD meets the required standard.

7. LPD and the radius of edges

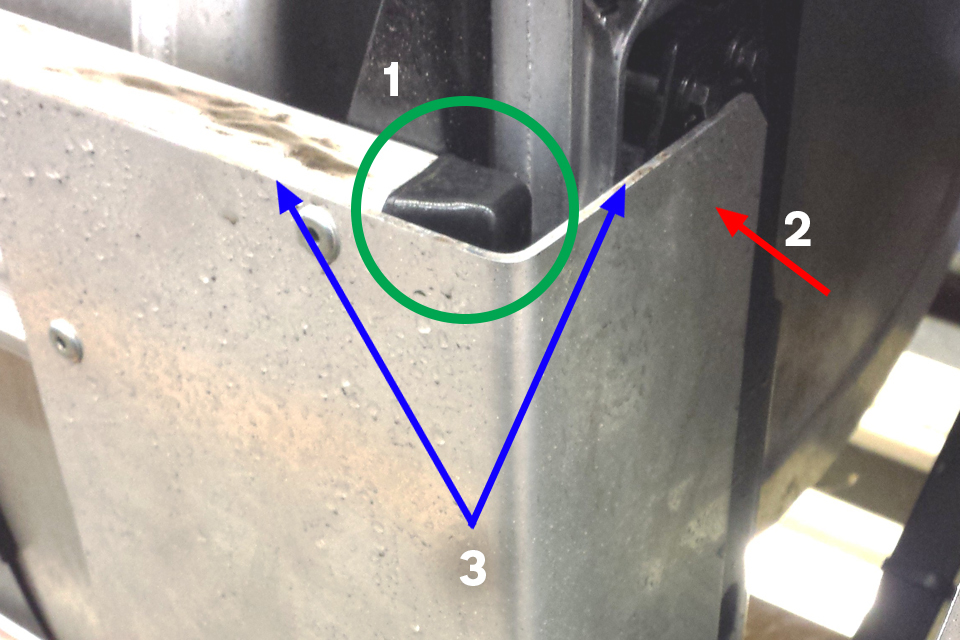

Radius of edges.

As shown in the image above:

- the original LPD has an end cap that is radiused to 2.5mm (1)

- the front end lies in open space, where an unacceptable method has been used to provide an upright (aluminium angle riveted in place) (2)

- for Individual Vehicle Approval (IVA) the external edges are considered to be here only (3)

Had there been end caps fitted it may have met the required standard.

8. When an LPD isn’t subject to IVA

LPD not subject to IVA.

Lateral protection isn’t required behind the rear axle for IVA.

As shown in the image above it may be fitted for a specific operators requirement. For example, Construction Logistics and Cyclist Safety (CLOCS).

Any optional LPD isn’t subject to IVA examination.

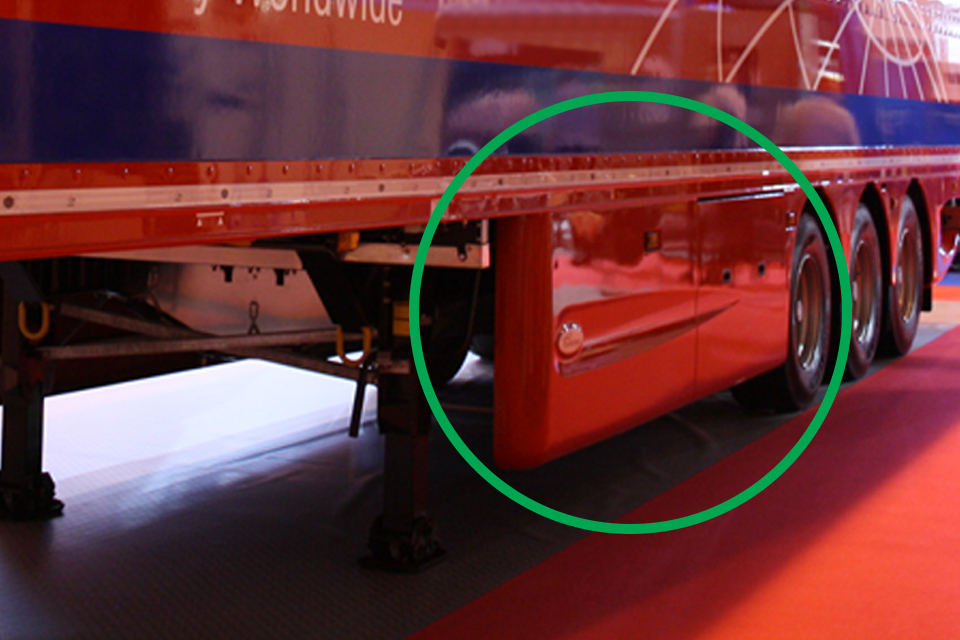

LPD not subject to IVA.

The image above shows that:

- LPD is required here and may comprise of rails and/or solid panels (1)

- no LPD where the distance between centre of consecutive axles is less than 3 metres (2)

This meets the required standard.

9. What may be considered part of an LPD

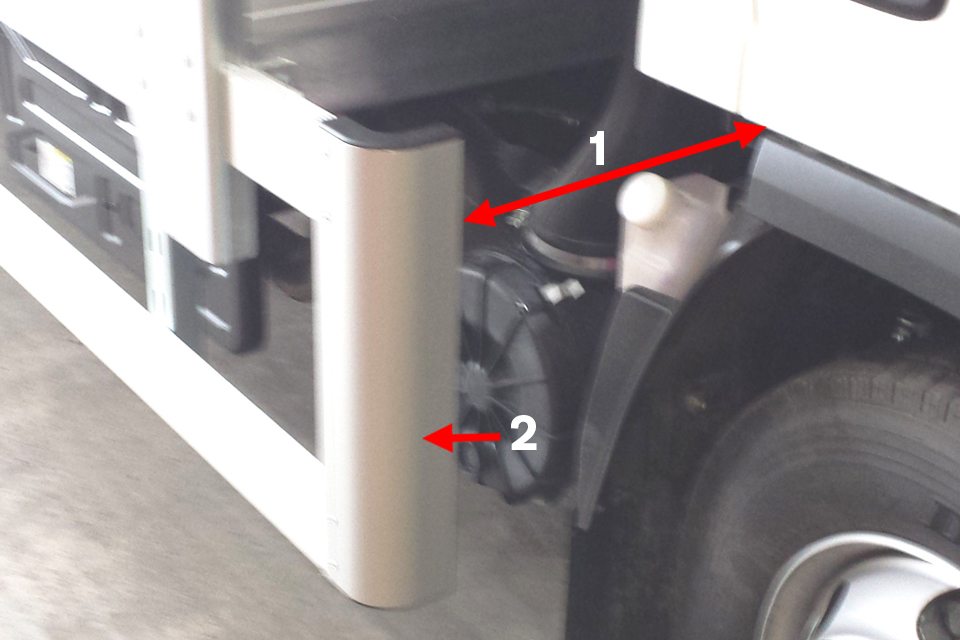

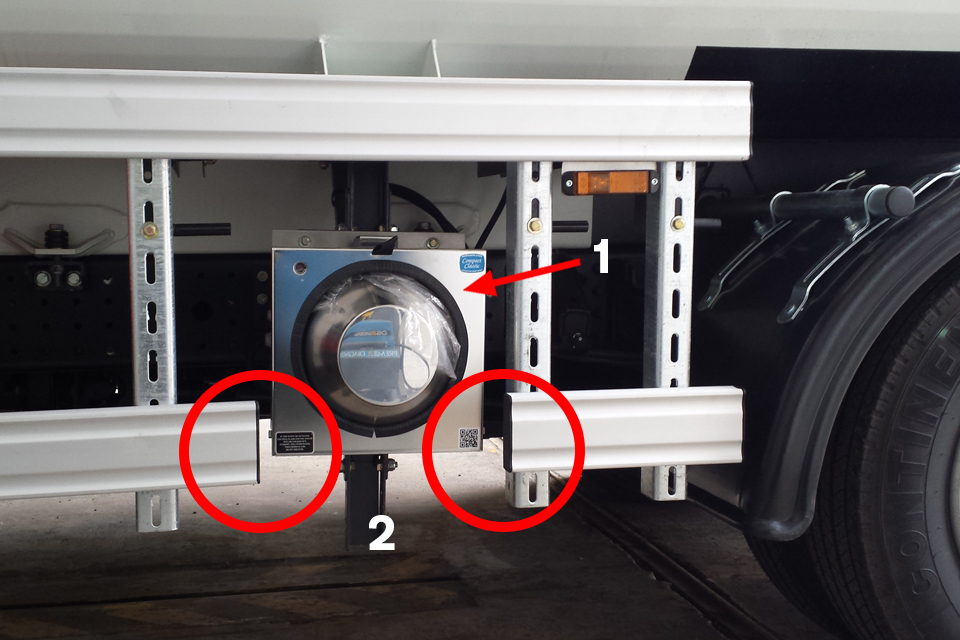

What may be part of the LPD.

The image above shows that the:

- original LPD finishes here (1)

- top rail fitted is required due to gap between cab and body rail (2)

- silencer protection and air tank can be considered as part of the lateral protection (3)

Between them, the original LPD, the rail, tank and silencer will deflect unprotected road users they are unlikely to fall under the vehicle.

The above meets the required standard.

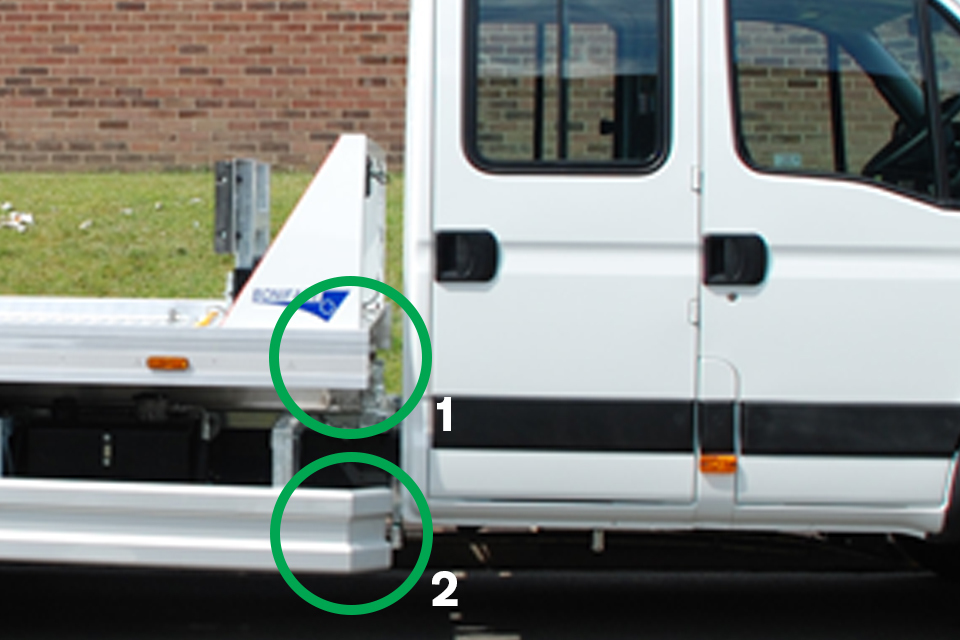

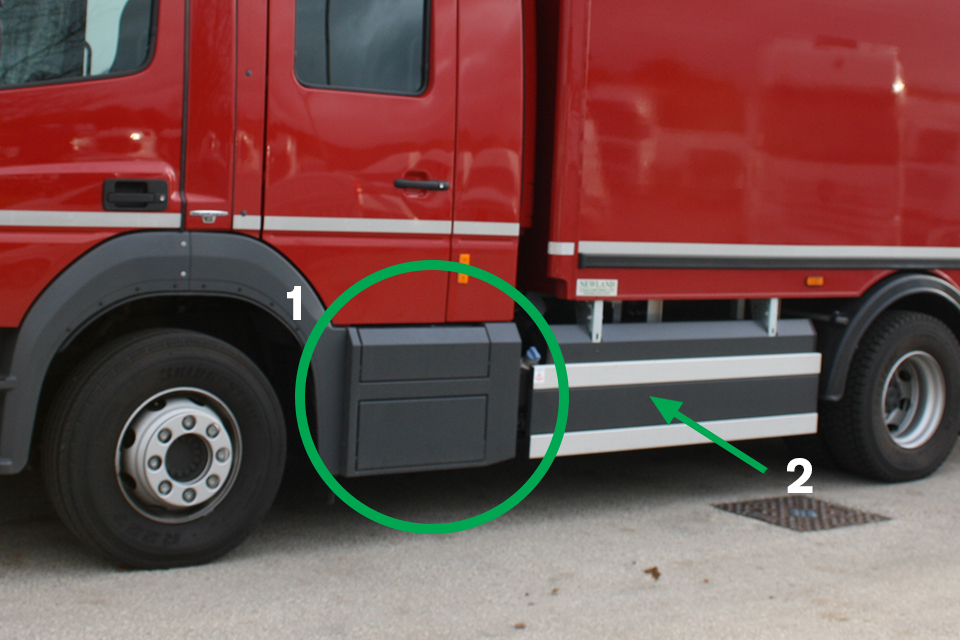

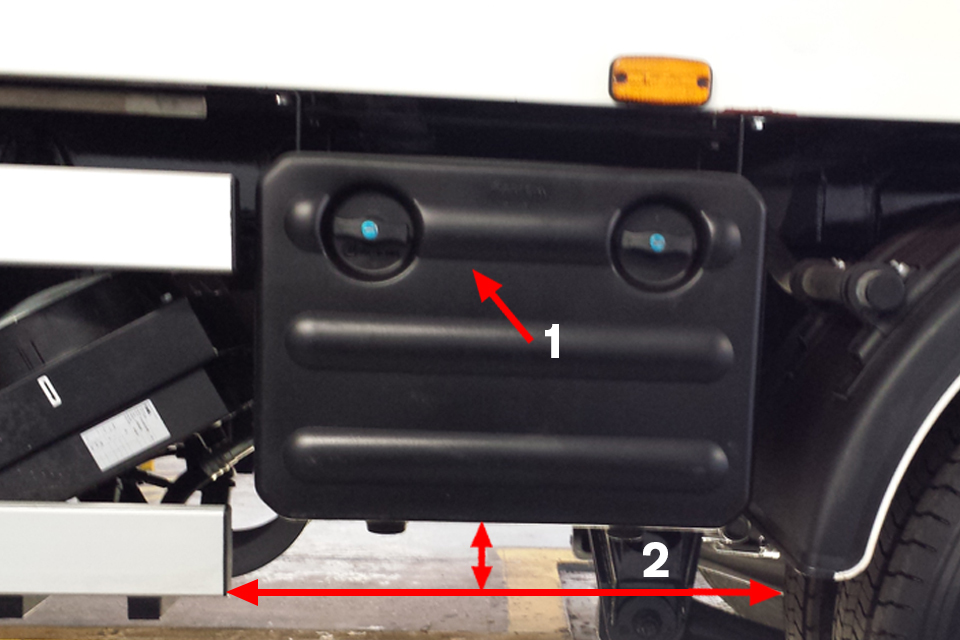

What may be part of the LPD.

The above image shows that the tool box may be considered as part of the LPD (1) but the LPD:

- doesn’t meet the height requirements (1)

- doesn’t protect road users from being caught under the rear wheels (2)

This example doesn’t meet the required standard.

What may be part of the LPD.

The image above shows that the addition of the rail starts to solve the problem (1)

but the outer surface of the additional rail isn’t:

- in line

- doesn’t overlap, front to rear, the original LPD (2)

This example still doesn’t meet the required standard.

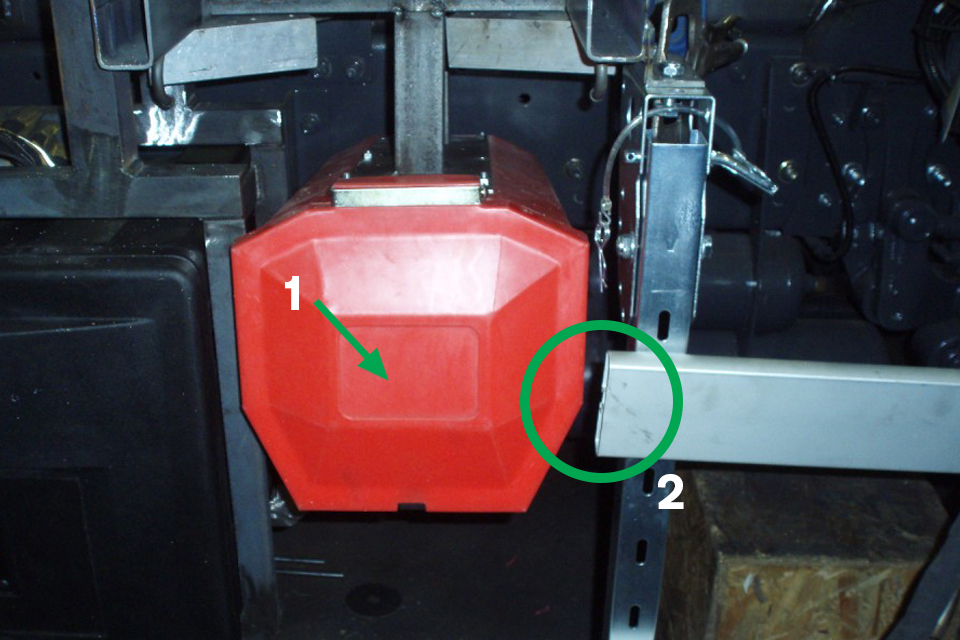

What may be part of the LPD.

What may be part of the LPD.

The first image above shows that:

- a fire extinguisher box has been incorporated into the LPD (1)

- the original LPD has been cut and shortened (2)

The second image above shows that the box is:

- radiused

- level with the LPD

- of sufficient strength, and would be acceptable (3)

This is a good example that meets the required standard.

What may be part of the LPD.

The above image shows a hand wash unit has been incorporated into the LPD. This doesn’t meet the required standard as the:

- hand wash unit is set back from the LPD (1)

- LPD rails have been cut and are no longer continuous (2)

It may have met the required standard if the wash unit had:

- been brought further out

- been lowered into line with the LPD

- gaps either side less than 25mm

- met the radius criteria

10. Leading edge of the LPD

Leading edge of LPD.

Where the forward edge of the LPD lies in open space (see definition above) there needs to be a continuous vertical member extending over the whole height of the device.

The size depends on the vehicle type, for:

- N2 and O3 category vehicles the upright needs to be 50mm rearwards and 100mm inwards

- N3 and O4 category vehicles the upright needs to be 100mm rearwards and 100mm inwards

11. Body line and the LPD

Only the lateral protection needs the vertical member, it doesn’t need to continue to the body line.

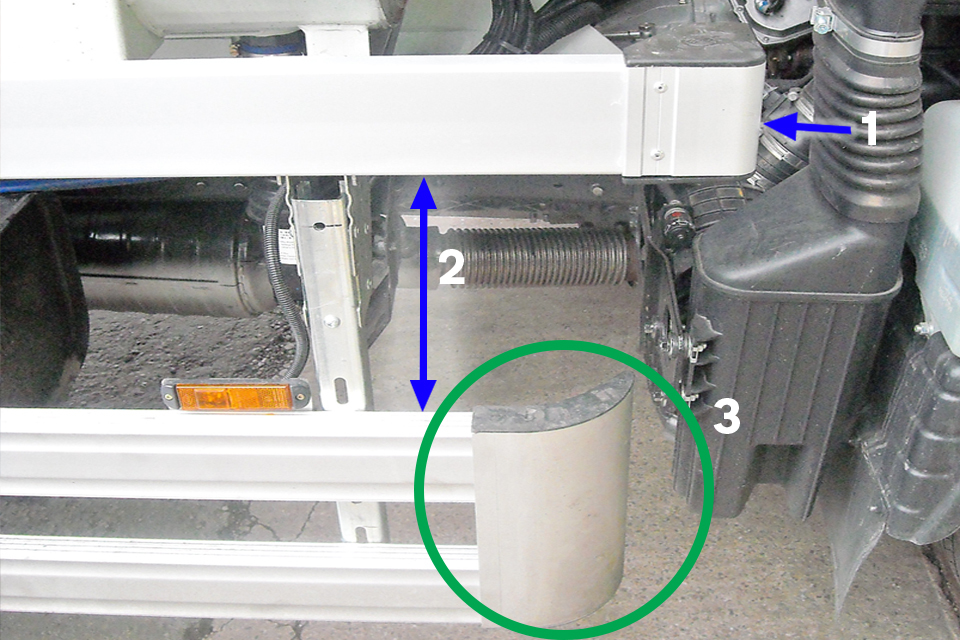

Body line and LPD

The image above shows:

- body line (1)

- that as long as the gap between the lateral protection and the body line is no more 350mm, there is no need for a vertical member here (2)

The LPD lies in open space and requires a vertical member (3).

This example does meet the required standard.

12. Continuity of a LPD

Lateral protection must be continuous.

Continuity of LPD.

The image above shows that:

- the rails have been cut in numerous places, here to accommodate a side reflector and fuel filler neck (1), this is unacceptable

- a rail has been added around a filler neck and now isn’t continuous (2)

This example doesn’t meet the required standard.

13. Where the width of the vehicle body is increased by LPD

LPD mustn’t increase the width of the vehicle.

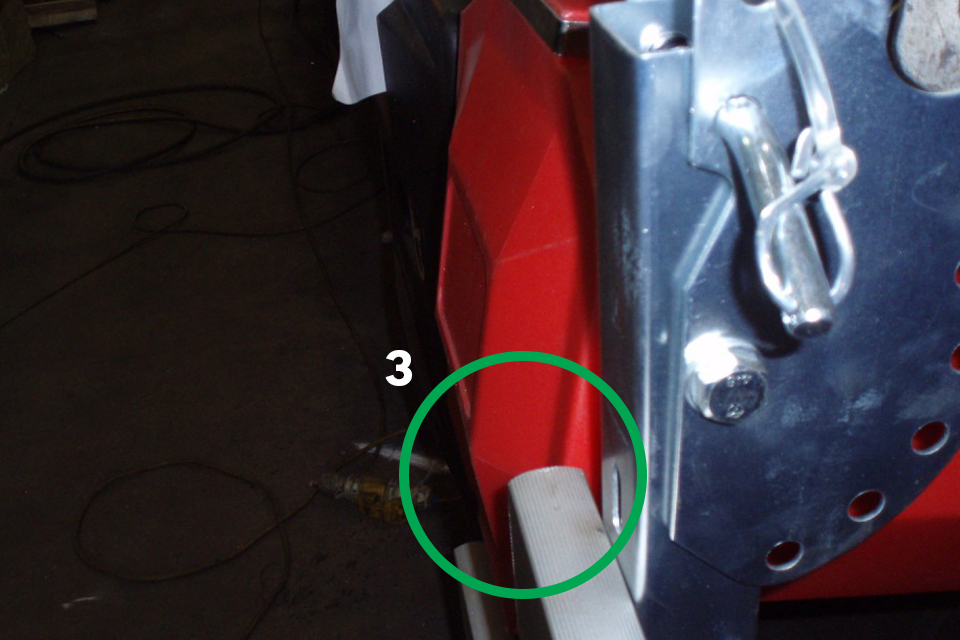

Width of body increased by LPD.

Width of body increased by LPD.

In the first image above it shows that an unnecessary LPD has been added (1).

The design of the bodywork would be sufficient and the LPD isn’t required in this position. It’s too close to the landing legs.

The second image above shows that:

- it increases the width of the trailer by 50mm (2)

- the external edge is unradiused (3)

This example doesn’t meet the required standard.

14. Items added to the outside of an LPD

For safety reasons some council and local authorities insist on items being added to the LPD, for example, Transport for London’s Safer Lorry Scheme (PDF, 420KB).

Items added to the outside of an LPD.

Where items that project less than 5mm are added to the outside of LPD, the edges need to be blunted only.

Items added to the outside of an LPD

Corners of items eg signs will need a radius of 2.5mm in two planes only.

15. Where design of vehicle body takes place of a LPD

Where design of body takes the place of LPD.

The design of the side of the vehicle or trailer can be considered as LPD where it meets the criteria for lateral protection in section 42 of the IVA inspection manual.

16. Original manufacturers design

A stage one approval may cover the LPD.

If a vehicle has stage one approval then as long as the LPD hasn’t been altered or had anything added then it will meet the required standard.

Original manufacturers design.

In the image above an original fitting on a stage one exhaust shield is less than 25mm to the rear of a fixed component, it doesn’t lie in open space and will be acceptable as part of the LPD.

If the gap were to be more than 25mm, a vertical member of the required dimensions would be required.

This meets the required standard.

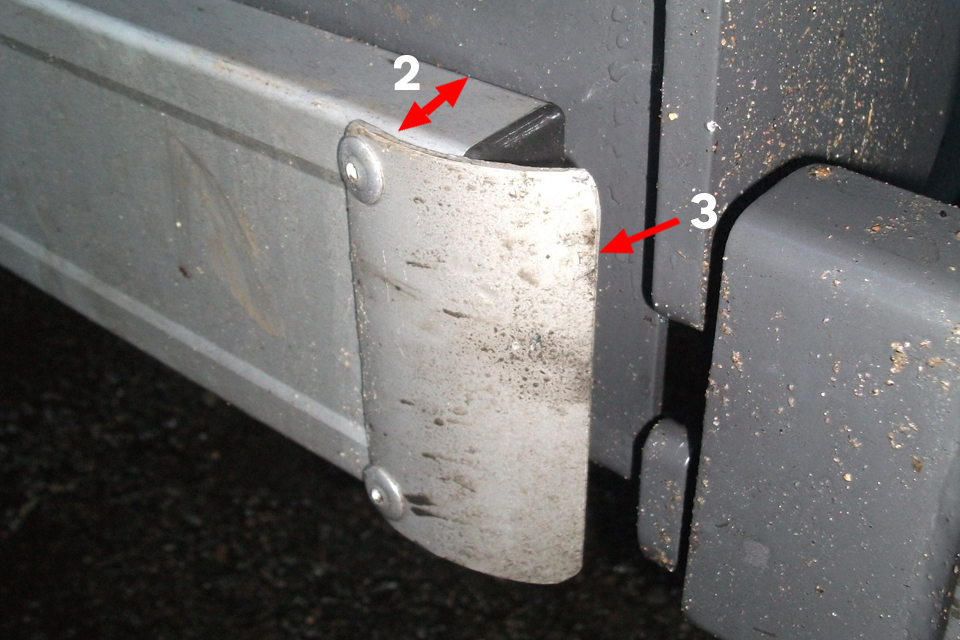

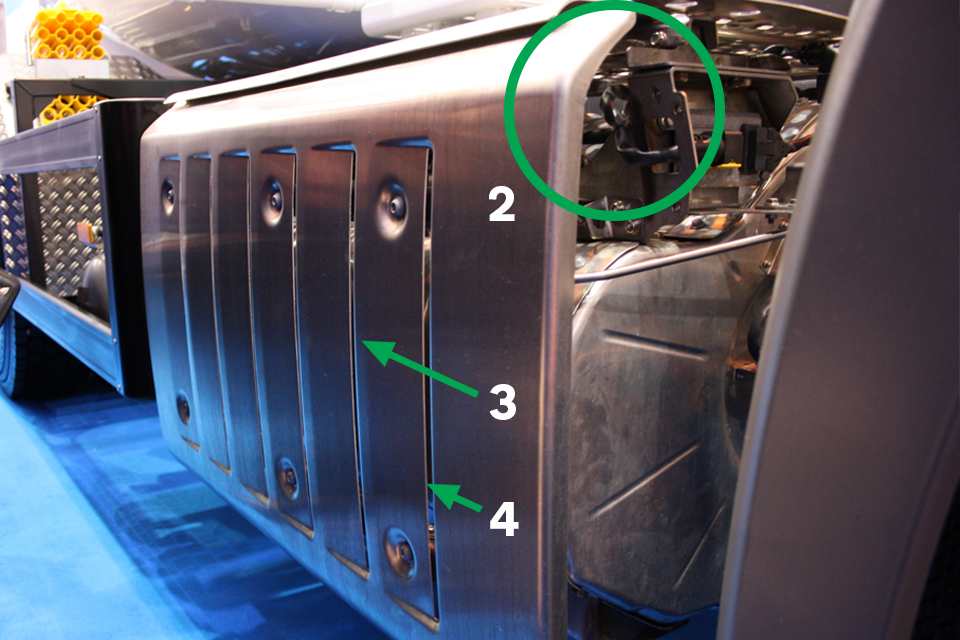

Original manufacturers design.

The above images shows that:

- the leading edges are radiused (2)

- the trailing edges don’t need to be radiused or blunted (3)

- each ‘louvre’ or ‘slat’ is radiused at the front edge (4)

17. Specially designed vehicle maybe exempt from having a LPD

Exempt by incompatible with its use.

Some vehicles may be considered exempt from LPD when they have been specifically designed and constructed for a purpose, and fitment of an LPD would prevent use of the equipment fitted.

For example, in the image above the vehicle has been designed to load bins from the pavement (1).

Exempt by incompatible with its use.

In the image above, even though the bin loader isn’t radiused and leaves a large gap in the LPD, the manufacturer has fitted LPD that complies with the dimensions and measurements in the IVA inspection manual. (2)

Exempt by incompatible with its use.

The bin loader protrudes outside of the LPD, but doesn’t increase the width of the vehicle to more than 2.5m. (3)

This is acceptable and meets the required standard.

18. Glass carriers and LPDs

Glass carriers.

This vertical member isn’t required but bearing in mind what an LPD should do - protect unprotected road users, this is a good compromise that works well. (1).

The lower glass shelf becomes the LPD, but still does need to meet the radius criteria to meet the required standard. DVSA will only check it in the folded position (2).

This example doesn’t meet the required standard.

Glass carriers.

In the above image, of a glass carrier, you can see there is an LPD fitted behind the glass rack. DVSA doesn’t ask for evidence of strength (1).

The rack itself may meet the required standard for IVA if it:

- meets the radius and height requirements

- is fitted with a turned in upright of the correct dimensions

- is of adequate strength

Glass carriers

Even though the vehicle may travel with the rack down, DVSA wouldn’t check the rack in its folded out position. The edge wouldn’t need to meet the radius requirements.

Glass racks are taken into account for maximum width only when they are in the folded position.

19. Unusual vehicles and LPDs

Unusual vehicles.

The above image is of a vehicle that may present many problems.

It has LPD fitted but does it meet the criteria?

Below we take a closer look at each part of the vehicle and the LPD.

Unusual vehicles.

DVSA will check this part of the LPD meets the space and height requirements.

In this example the vehicle above meets the required standard.

Unusual vehicles.

In the image above the tank, could be considered part of the LPD if it met the radius and height from the ground dimensions

In this example the vehicle above doesn’t meet the required standard.

Unusual vehicles.

In the image above the equipment presents a problem.

DVSA will check to see if it’s either:

- impossible to fit an LPD due to its special purpose

- of design and construction to make it not possible for practical reasons to fit an LPD

In this example the vehicle has legs for stability. DVSA would check for a gap of no more than 130mm for their extension.

When DVSA considers there is no reason why an LPD can’t be fitted then your vehicle needs to have one.

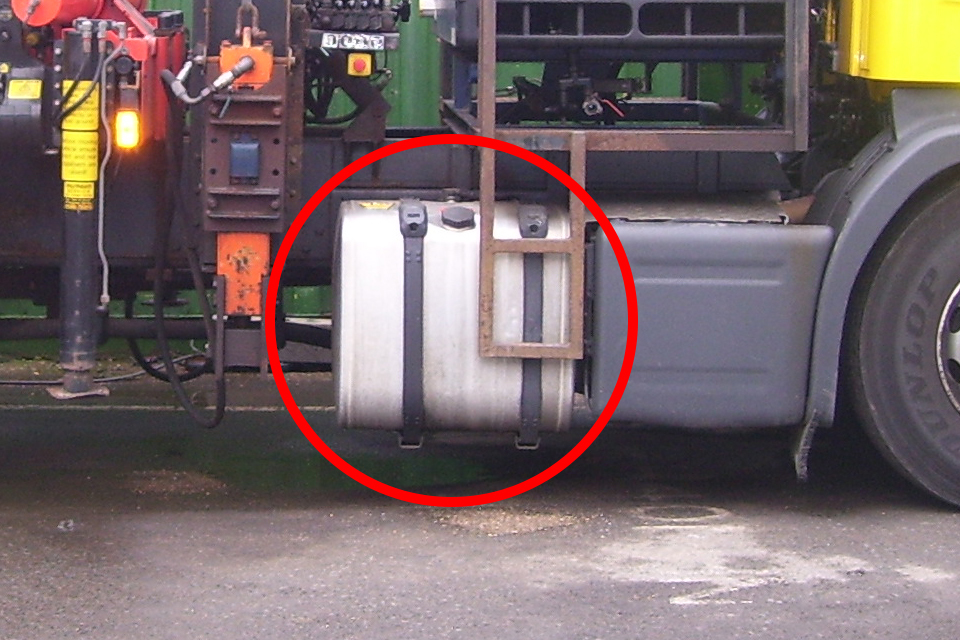

Unusual vehicles.

In the image above the fuel tank may be considered part of the LPD if it meets all the relevant criteria (radius, height, etc).

In this example it wouldn’t meet radius on the edges and straps.

DVSA would also question whether the ladder:

- is essential to reach the generator

- could be repositioned

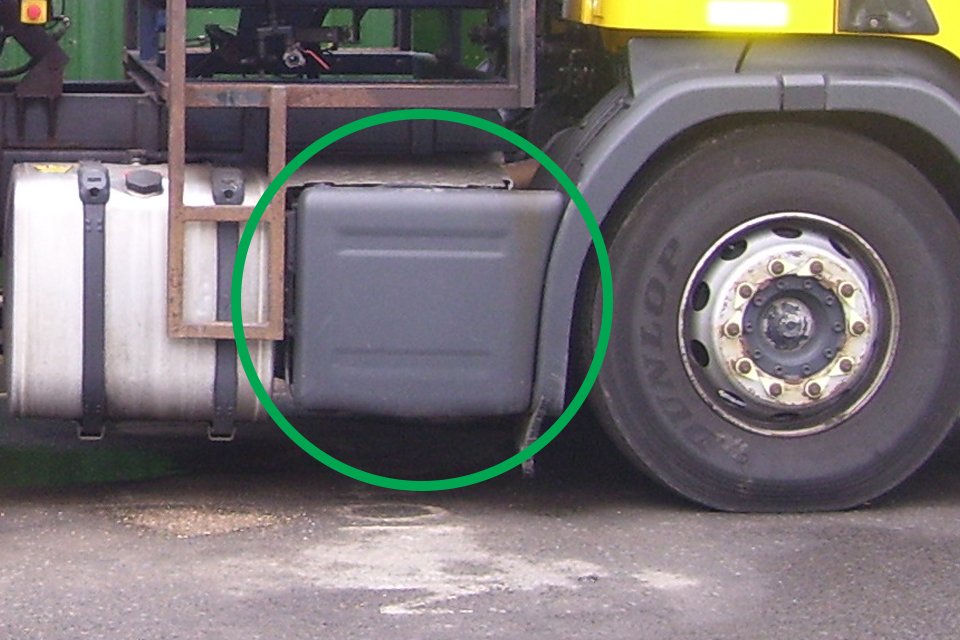

Unusual vehicles.

In the above image the unit meets the required standard for:

- distance

- height

- radius criteria

However the tank must be flush (level) or in board of the first unit and the gap between them no more than 25mm. Any overlapping parts must face rearwards or downwards.

Good basic example of LPD.

As shown in the image above, LPD can be as basic as this:

- rails with the correct spacing and dimensions

- correct distance from the relevant wheel

- correct height from the ground

This is a good example of a vehicle that meets the required standard.