Runaway of an engineering train at London Liverpool Street station, 2 October 2022

Updated 7 March 2024

1. Important safety messages

This incident demonstrates the importance of:

-

drivers checking that their train is correctly secured before leaving it unattended, especially if working outside of their usual routine

-

freight train drivers following the Rule Book and any supporting instructions issued by their employer to ensure that:

-

handbrakes are applied on at least the minimum number of wagons in the train

-

locomotives attached to the train are secured by applying the locomotive’s parking brake.

-

2. Summary of the incident

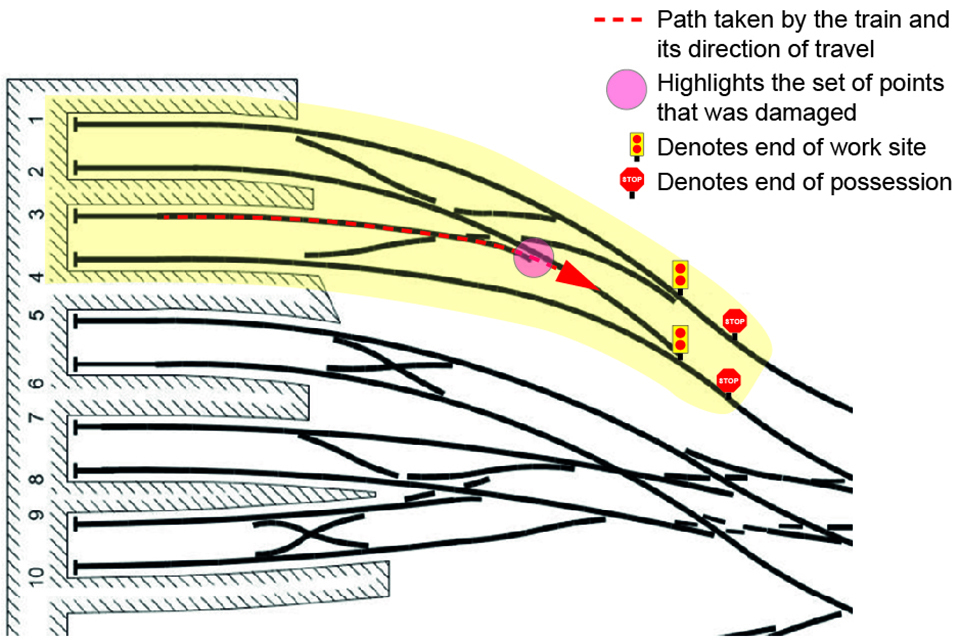

At about 11:52 hrs on 2 October 2022, an unattended engineering train ran away from platform 3 at London Liverpool Street station. The signaller was alerted to the train’s movement by track sections in the throat of the station unexpectedly showing occupied on the signaller’s display. The incident happened within a part of the station that was, at the time, under possession for engineering work. The unattended train travelled about 150 metres, before coming to a stop within the limits of the possession. No one was injured, although the train damaged a set of points.

The engineering train post-incident, stopped in the throat of the station (courtesy of Network Rail).

3. Cause of the incident

The engineering train, operated by Freightliner, had departed from Whitemoor Yard, Cambridgeshire, at 22:03 hrs on Friday 30 September and was brought into platform 3 at the station by driver A at 00:47 hrs on Saturday 1 October. It comprised a class 66 diesel-electric locomotive (number 66955), three two-axle open box wagons, and a second class 66 locomotive (number 66953) at the rear. The rear locomotive was shut down with its batteries isolated before the train had departed Whitemoor Yard and had remained so throughout the train’s journey to the station (the locomotive’s service brakes can remain operational in this condition).

The train was to be used as part of work on the station’s roof, that was planned to take place in a possession over the weekend. The possession, which was from 00:40 hrs on Saturday to 04:00 hrs on Monday, included the closure of platforms 1 to 4 and the railway lines leading into these platforms.

The extent of the railway lines under possession for the engineering work.

Shortly after arriving in the early hours of Saturday morning, driver A shut the engine down on leading locomotive 66955 and applied its parking brake, in advance of receiving further instructions. The documentation issued to the drivers working this train had instructed them that locomotives’ engines must not be allowed to run idle for more than 20 minutes. This was to reduce the volume of diesel fume emissions within the station.

About an hour later, staff responsible for the engineering work told driver A that the planned work was cancelled as they were unable to obtain isolations of the 25 kV overhead line equipment. These isolations were needed for the work to the station’s roof to take place. As there was now no need for the train to be moved, driver A isolated the batteries on the leading locomotive (66955). This happened at 01:47 hrs, when the data recorder on the locomotive stopped recording. Driver A then followed his normal routine for securing a train which included checking the locomotive’s parking brake was applied, and walking alongside the train to apply the handbrakes on all three wagons. Driver A then remained with the train until 05:00 hrs, which was when his duty ended.

The train was then left unattended until driver B arrived at about 21:30 hrs on Saturday evening. Driver B found a note left in the cab of locomotive 66955 by driver A that explained the parking brake was applied on one locomotive and the handbrakes were applied on the three wagons. No one had told driver B that the work was cancelled so he prepared the train ready for it to be moved. This included releasing the handbrakes on the three wagons, leaving just the parking brake applied on locomotive 66955, the one closest to the buffer stop.

At about 03:00 hrs on Sunday 2 October, driver A called driver B as he was rostered to return to the station to relieve driver B. They arranged to meet at one of the station’s entrances at 04:30 hrs. At 04:03 hrs, the data recorder on the locomotive furthest from the buffer stop, 66953, recorded data for 12 seconds. This indicated its batteries were reinstated for a short period of time, before being isolated again, although it is unknown why battery power was briefly restored at this point.

The drivers met as planned and during their handover driver B told driver A that both locomotives were shut down and the handbrakes were released on all three wagons. The status of the parking brakes on the locomotives was not discussed by the drivers. At the end of the handover, driver A told driver B that he would prepare the train for its journey back to Whitemoor Yard the next night, as he knew driver B was rostered for that duty.

Once back at the train on platform 3, driver A went to locomotive 66953 and placed his bag in the cab. He then took the taillight off this locomotive, walked down the platform and placed it on the end of locomotive 66955, facing the buffer stop. At 04:43 hrs, the data recorder on locomotive 66955 recorded data for 12 seconds. This indicated its batteries were reinstated for a short time, which was when driver A released the locomotive’s parking brake. Driver A then isolated the batteries again, after which he walked back to locomotive 66953 and sat in the front cab. Closed-circuit television (CCTV) footage shows driver A then stayed with the train until about 08:30 hrs, apart from a short time when he had a personal needs break away from the train.

At 11:34 hrs, CCTV footage shows the unattended train started to roll out of the platform very slowly. The signalling system recorded the train passing the signal at the end of the platform at 11:36 hrs, which is when the signaller was first alerted to a track section unexpectedly being shown as occupied. The signaller contacted the member of staff responsible for the work site within the possession to ask if someone was working in this area and might have caused the track section to become shown as occupied. The member of staff went to the platform and reported back that the train had moved and was no longer in the platform.

A mobile operations manager, whose role is to provide Network Rail’s first response to incidents, attended. He confirmed that no one was with the train and secured it using wheel scotches. Freightliner also sent a member of staff to the train, and they established that the parking brakes were released on both locomotives and the handbrakes were released on all three wagons. The status of the parking brake on each locomotive was assessed by checking the tightness of a chain which is connected to the parking brake motor and which pulls two brake blocks onto one of the wheels.

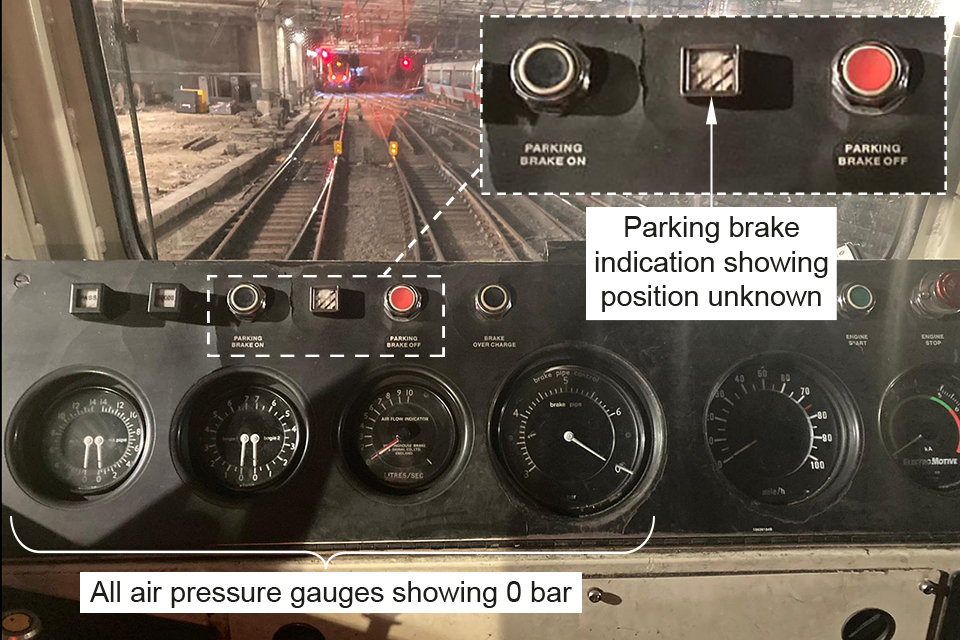

The parking brake indicator in the cabs of both locomotives showed an ‘unknown’ indication. However, the parking brake indicator is controlled by an onboard computer, and about 30 minutes after the batteries have been isolated, the indicator reverts to showing the ‘unknown’ indication, irrespective of the actual state of the parking brake.

The parking brake indicator and pressure gauges on locomotive 66953 (courtesy of Network Rail).

After locomotive 66955 was shut down at 01:47 hrs on Saturday 1 October, neither locomotive engine was restarted. While the drivers had instructions about not allowing a locomotive’s engine to run for more than 20 minutes at a time if they were not moving the train, there was no instruction in place relating to drivers starting up a locomotive engine to run its air compressor to replenish the supply to the train’s air systems. Consequently, the air that was trapped within the train’s pneumatic braking system slowly leaked off over the weekend. This was evidenced by post-incident photographs of the gauges in the cab of locomotive 66953 all showing 0 bar of air pressure. Once sufficient air had leaked from the pneumatic brakes on the locomotives and wagons, the remaining brake force was insufficient to hold the train and it rolled away.

As the train ran away, the signalling system recorded track sections becoming occupied or clear during its movement. Using this data, RAIB calculated that the train moved at an average speed of about 2.2 mph (3.6 km/h) as it rolled out of platform 3. This slow speed suggests that the brakes on the train were still applying a small amount of braking force.

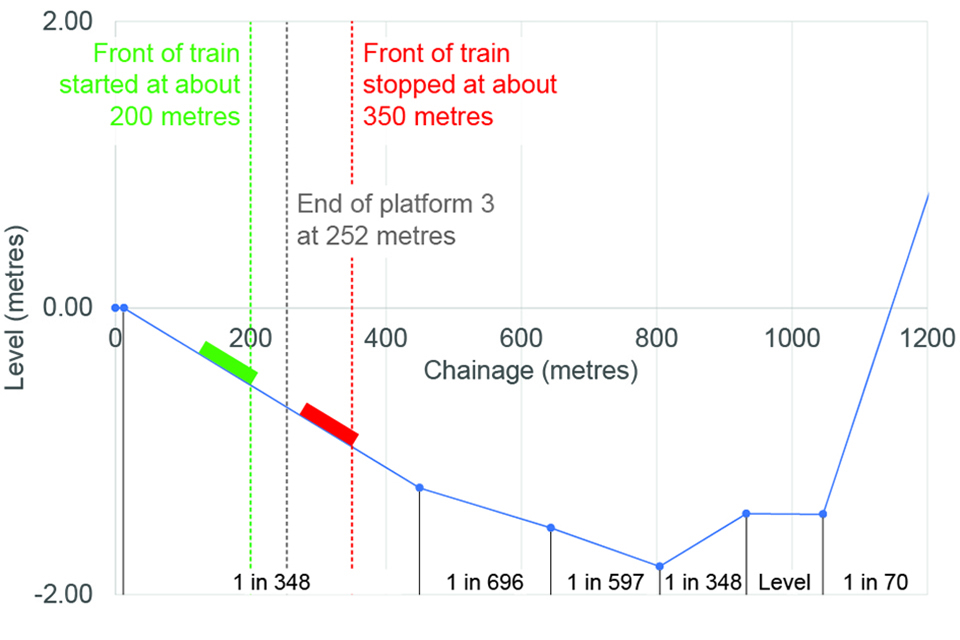

Network Rail data sources state that there is an average falling gradient of 1 in 348 (0.29%) from the position where the train was left in platform 3 to where it stopped. RAIB calculated that the train would not move on this gradient with more than 9.5 kilonewtons (kN) of brake force available, suggesting that less than this amount was available on 2 October. With just under 9.5 kN of brake force available, RAIB calculated that, on plain line track, the train would roll away very slowly and stop about 450 metres from the station, soon after the gradient changed to a shallower falling gradient.

Track gradients in the area.

However, the train only travelled about 150 metres when it ran away, with locomotive 66953 stopping on the set of points that it damaged. These points were in the opposite position for the train’s movement, so the train ran through them in the trailing direction. It is likely that, when the leading wheels of locomotive 66953 forced their way through the closed switch rail at the points, this additional resistance caused the train to slow to a stop, meaning it did not run away for the full distance calculated. This stopped the train from exiting the area under possession and entering open lines where trains were running.

The position of the train on the set of trailing points as found afterwards (image looking back towards the station platform courtesy of Network Rail).

The parking brake on a class 66 locomotive is required to hold the locomotive on a gradient of 1 in 30 (3.33%). To fulfil this requirement, the parking brake is designed to provide a minimum of around 42 kN of brake force when fully applied. Had the parking brake been applied on at least one of the locomotives, this amount of brake force would have been sufficient to prevent the train from running away. Had the handbrakes been applied on the three wagons, as required by Rule Book module TW4, ‘Preparation and working of freight trains’, then this too would have provided sufficient brake force to prevent the runaway.

Rule Book module TW1, ‘Preparation and movement of trains’, includes rules about leaving a locomotive unattended. In section 36.2, it instructs drivers that each time they leave a locomotive unattended, they must make sure it is properly secured. After the incident, driver A accepted that he had not left the train properly secured before he left it, as he had not checked the parking brake on locomotive 66953 or applied any of the wagon handbrakes, and he had released the parking brake on locomotive 66955. Although driver B had told driver A about the status of the wagons’ handbrakes at handover, driver A stated that he forgot that the handbrakes were not applied on the wagons.

Driver A had not followed his usual routine when leaving a train unattended, as both locomotives were already shut down with their batteries isolated. Normally he would have shut the engine down on the leading locomotive, applied the parking brake on that locomotive, isolated the batteries on it, and then walked alongside the train and applied the handbrakes on at least three wagons. Instead, driver A had spent a long period of time with very little to do. He stated that when he came to leave, he also thought that the train was secure because that was how he had left it at the end of his previous shift, and the train had not moved since then.

4. Previous similar occurrences

In August 2005, just before RAIB became operational, a class 66 locomotive ran away from Blake Street, Sutton Coldfield, after it had been uncoupled from an engineering train. It ran away for over 11 miles (18 km), passing over eleven level crossings (seven for road vehicles and four footpath crossings), before it derailed on trap points near to Alrewas signal box, to the north of Lichfield, Staffordshire. This happened because the driver had not pressed the pushbutton in the cab for long enough to apply the locomotive’s parking brake, while another member of staff had isolated the batteries on the locomotive before the parking brake had fully applied. This led to a design change so the parking brake motor would continue to run to fully apply the parking brake, even if the batteries were isolated.

RAIB report 04/2015 describes the runaway of an unattended train on the Great Central Railway. The train involved, which ran away for around 1.8 miles (2.9 km) and subsequently collided with a rake of unoccupied coaches, ran away because a wheel scotch had been positioned against the locomotive’s wheel in a way which made it ineffective. The handbrakes on the locomotive, had they been used, would have provided sufficient braking force to have held the train.

RAIB report 09/2021 describes the runaway of a rake of wagons that were left unsecured in Old Bank sidings, Toton. The rake of wagons ran away because no one had secured it with either handbrakes or scotches after it was stabled in the sidings the previous evening. This meant that the wagons were only being held by air trapped in their brake systems, which subsequently leaked away. The wagons were free to move because the incoming train they were part of had not been secured before its locomotive was uncoupled and because there was miscommunication between the staff on duty, who were responsible for securing the train, about who would do that task.

v2. March 2024