Signals passed at danger due to reduced brake performance, near Crofton West Junction, West Yorkshire, 7 May 2020

Published 18 August 2020

1. Important safety messages

This incident demonstrates the importance of:

-

freight operating companies ensuring that access to trains is effectively managed, so that the integrity of the brake continuity test is not undermined after it is carried out. This is particularly important where local instructions allow there to be a delay between preparation of the train and departure

-

drivers carrying out an effective running brake test early in the journey to demonstrate that the train brakes are fully operational

-

drivers using the GSM-R REC function, or alerting the signaller promptly, in a situation where they are unable to effectively control the brakes on a train, so that any conflicting train movements can be stopped

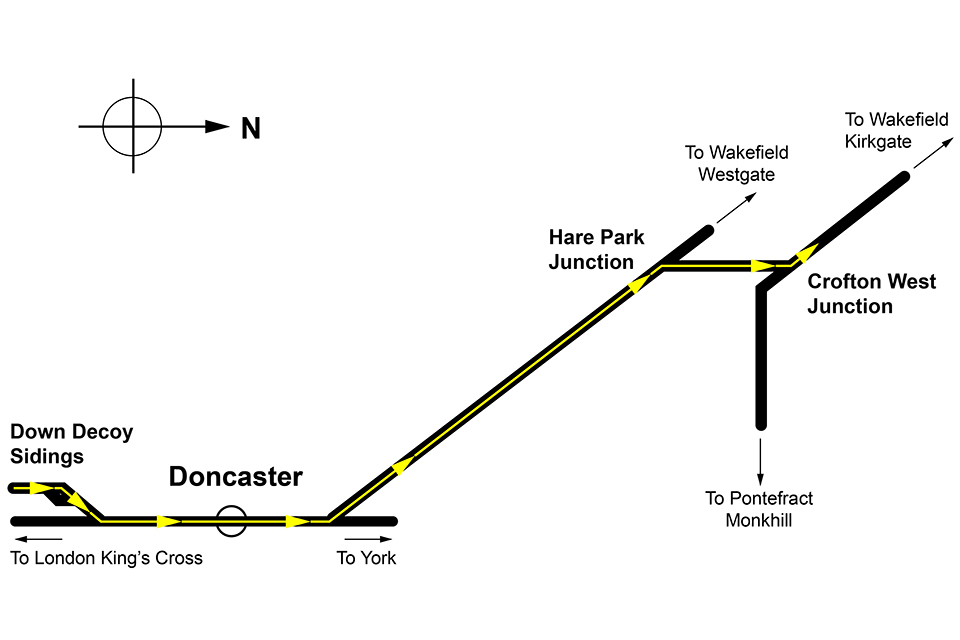

2. Summary of the incident

At around 09:54 hrs, the driver of a freight train applied the brakes on the approach to a red signal at Hare Park Junction, near Wakefield but was unable to stop. The train continued with the brakes applied and passed a second red signal, about 2200 metres later, that was protecting Crofton West Junction. The train came to a stop 250 metres beyond the junction. A passenger train that was approaching Crofton West Junction on a conflicting route was stopped by signals when it was approximately 3 km away.

Route of the train

The train was service 6M31, operated by GB Railfreight and hauled by a class 66 locomotive. It was taking 22 empty hopper wagons from Doncaster Down Decoy sidings to Arcow quarry near Horton-in-Ribblesdale.

3. Cause of the incident

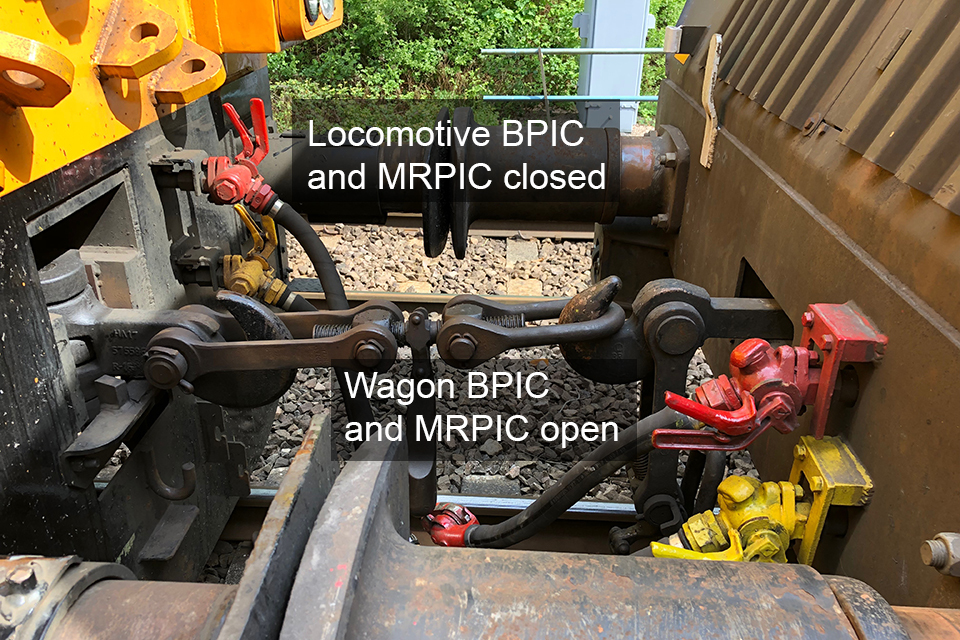

The incident occurred because the brake pipe isolating cock (BPIC) and the main reservoir pipe isolating cock (MRPIC) on the rear of the locomotive had been closed prior to the train departing from Doncaster Down Decoy sidings, with no air pressure in the brake system on the wagons. This meant that none of the brakes on the wagons were operational, and that only the locomotive brakes were available to control the train’s speed. An ineffective running brake test failed to alert the driver to this reduced brake performance.

Position of the BPIC and MRPIC after the incident (image courtesy of GB Railfreight)

The BPIC and MRPIC were in the closed position because the train condition was altered after completion of train preparation, and after a successful static brake continuity test.

The train was prepared for departure the previous evening, and the night team leader for the sidings undertook a successful brake continuity test at about 23:45 hrs. This verified that the wagon brakes were operational and confirmed that the BPIC and MRPIC were open. The locomotive was then shut down for the night with the handbrakes applied on three wagons and the brake distributors vented on all wagons. This was in line with a GB Railfreight procedure for train preparation, although the steps had been undertaken in a different order to that intended.

Module TW1 of the Rule Book (Preparation and Movement of Trains) states:

‘You must carry out a brake continuity test … after a train has been left unattended and the traction unit shut down (except where authorised in local instructions)’.

GB Railfreight Local Operations Manual for Doncaster Down Decoy sidings (September 2019) states:

‘When trains are stabled with the locomotive shut down at Doncaster Down Decoy they can depart without the need for a brake test, providing that the formation is not changed … and the train is not left immobilised for more than 10 hours.’

The local procedure is based on a risk assessment that concluded that the sidings were sufficiently secure to adequately mitigate the risk of the train condition being altered by intruders or other influences during the up to 10-hour period between the brake continuity test and departure.

However, at about 08:30 hrs a trainer and two trainees undertook some familiarisation activities on the locomotive. This would normally have taken place at Roberts Road depot, in Doncaster, but had been relocated because there were fewer people in the sidings and maintaining COVID-19 social distancing there would be easier.

The trainer alerted the morning team leader to their presence by telephone, but did not state that his intention was to use the locomotive on train 6M31 for familiarisation. At the locomotive, the trainer turned on the battery isolation switch to allow the trainees to practise the locomotive preparation procedure. He closed the BPIC and MRPIC so that this procedure would not be affected by the wagons that were coupled to the locomotive.

Shortly afterwards, the driver arrived at the sidings and met the morning team leader who confirmed that the train had been prepared and handed over the train documentation. The trainer and trainees were still on the locomotive when the driver arrived at it. The driver released the three wagon handbrakes while the trainer quickly completed the familiarisation exercise. The trainer did not reopen the BPIC and MRPIC, nor did he advise the driver that he had closed them.

The driver started the locomotive’s engine and began charging the train air system. He then got out of the locomotive to check the wheel sanding hopper levels and the condition of the brake blocks, and so did not notice that the train air pipes had charged more quickly than normal as a result of the BPIC and MRPIC being closed. He also did not notice the subsequent brake overcharge rate because he was making tea during that time.

The train departed at 09:25 hrs with only the brakes on the locomotive operational. After passing Doncaster station and moving onto the line towards Wakefield, the driver applied the train brake to perform a running brake test as required by the Rule Book.

The running brake test did not alert the driver to the lack of wagon brakes because the driver did not check that he had achieved a reduction in speed during the test. The Rule Book states that a running brake test is to be undertaken to ‘be sure that the brake is operating effectively’ and ‘the speed of the train is being reduced’. Although the driver felt the effect of the locomotive brake applying, the speed of the train remained at 35 mph (56 km/h) and no speed reduction was obtained. Had the driver checked that he was achieving the required speed reduction, he would probably have been alerted to the lack of wagon brakes.

The driver then continued to drive as normal, encountering a series of green signals, and reaching a maximum speed of 50 mph (80 km/h). On the approach to Hare Park Junction, where the train was scheduled to take the diverging route towards Crofton West Junction, the driver observed a double yellow signal, shut-off power and started to apply the brakes. On recognising that the train speed was not reducing, the driver increased the brake application, and around the time he passed the next signal, which was yellow, he increased the brake demand to full service and shortly afterwards to emergency. This started to reduce the train speed slowly, but by the time it reached the signal protecting Hare Park Junction, it was still travelling at about 40 mph (64 km/h). Although the route was set for the train, the signal is approach-controlled with a delay of 45 seconds before clearing. The train reached it only 40 seconds after occupying the associated track circuit, and so the signal did not clear and the train passed it at danger. The driver was aware of it being red on his approach and saw that the route was correctly set, but was uncertain whether the signal had cleared by the time he passed it and did not make a GSM-R REC call or contact the signaller.

The train then continued past the next signal, which was yellow, and the subsequent protecting signal for Crofton West Junction, which was red. The train then trailed through the points, causing some damage to them, coming to a stand about 250 metres after Crofton West Junction. The train was scheduled to wait at the red signal until a passenger train had passed Crofton West Junction on the converging line from Pontefract. This passenger train was still about 3 km away at the time and was stopped by the signalling system before reaching the junction.

After the train came to a stop, the driver contacted the signaller to report the incident, and then reported it to GB Railfreight control.

4. Previous similar occurrence

RAIB report 05/2020 describes a similar incident when a London to Edinburgh sleeper train was unable to stop on the approach to Edinburgh Waverley station. This was caused by a BPIC between the locomotive and the coaches being inadvertently closed, thus leaving only the locomotive brakes under the control of the driver. The investigation identified learning points relating to the integrity of brake continuity tests and the effectiveness of the running brake test.