Near miss near Nottingham station, 1 January 2024

Published 24 April 2024

1. Important safety messages

This incident demonstrates:

- the importance of ensuring that a clear understanding of the situation and any intended actions is reached between those involved in operational incidents

- the importance of following correct safety critical communication protocols

- the importance of correctly carrying out the requirements of the Rule Book when dealing with reports of hot axle boxes on trains

- that using a mobile phone other than where this is permitted by the relevant operating rules carries a significant risk of distraction and could lead to a serious accident or incident

2. Summary of the incident

At around 09:30 hrs on 1 January 2024, a freight train carrying dangerous goods activated a hot axlebox detector (HABD) at Netherfield Junction, to the east of Nottingham station. The freight train was brought to a stand with signals by the signaller, responding to the alarm generated by the HABD. While the freight train driver was examining their train on the up line, a passenger train was allowed to depart from Nottingham station and approached the location of the freight train on the down line. As the passenger train approached, its driver observed that the driver of the freight train was in the passenger train’s path. The passenger train driver braked and sounded a warning using the horn. These actions gave the freight train driver enough time to move and to avoid being struck.

The passenger train driver subsequently brought their train to a stand and reported the incident to the signaller.

3. Cause of the incident

The incident occurred because the driver of the freight train and the signallers involved had not reached a clear understanding about how the freight train was to be examined for any defects in response to the HABD activation, and how this check was to be carried out in a safe manner. This resulted in the freight train driver being in an unsafe position as the passenger train approached.

The freight train involved, train 6M57, was operated by Colas Rail. It consisted of a class 70 locomotive and 30 loaded tanker wagons with a total train length of 571 metres. It was classified as a dangerous goods train as it was conveying petroleum products.

The passenger train involved was train 2S93, a Nottingham to Skegness service, operated by East Midlands Railway. This train was scheduled to depart from Nottingham at 09:55 hrs.

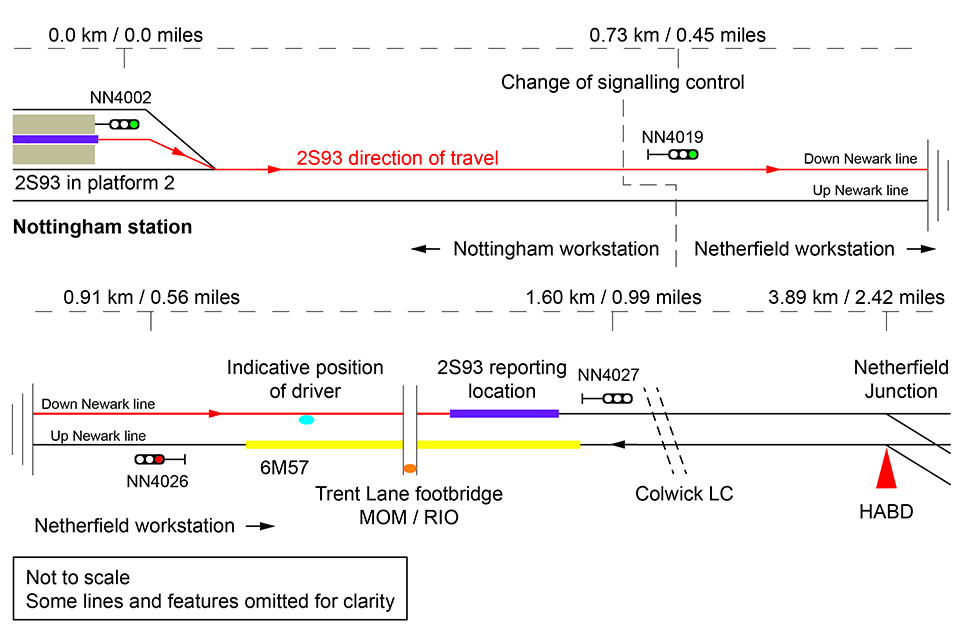

Netherfield Junction is located approximately 2.4 miles (3.8 km) from Nottingham station; trains heading towards Lincoln (via Newark) and Skegness (via Grantham) diverge here.

The Netherfield workstation is situated in Network Rail’s East Midlands Control Centre (EMCC). The signaller at this workstation controls the signalling around Netherfield Junction. The signal at which train 6M57 was stopped, NN4026, was the last signal under the control of the Netherfield workstation in the direction of travel towards Nottingham station.

Nottingham station workstation controls the next section of signalling, which the freight train was about to enter. It also controls movements in and out of Nottingham station towards the Netherfield workstation area. Both workstations are in close proximity within the EMCC. A signalling shift manager (SSM) supervises a number of signallers operating workstations within EMCC, including the Netherfield and Nottingham workstations.

Diagram showing location of stopped train 6M57, and the route taken by train 2S93 once it departed from Nottingham. Also shown are the approximate location of the change of control between workstations and the location of HABD. Distances shown are relative between areas of interest.

Also situated in the EMCC is an East Midlands incident controller (EMIC). They are responsible for dispatching a mobile operations manager (MOM) to respond to incidents. This may include asking the MOM to act as a rail incident officer (RIO) in an incident involving a train transporting dangerous goods. The EMIC is not situated with the signalling workstations but in a separate area of the building.

At 09:30 hrs, train 6M57 activated the HABD at Netherfield Junction. This sounded an alarm in the EMCC for the SSM and indicated the location of the defect on the train. The SSM requested the Netherfield signaller to bring the train to a stand at signal NN4026 on the Up Newark line. The SSM also informed the Netherfield and Nottingham signallers that no trains were to be signalled past train 6M57 on the adjacent Down Newark line. This led to train 2S93 being held in the platform at Nottingham station after its scheduled departure time of 09:55 hrs.

Once at a stand, the driver of train 6M57 spoke to the Netherfield signaller at 09:41 hrs using the train radio system. The signaller informed the driver of the HABD activation, and that the system had reported axle 110 on side 1 of the train as being the source of the alarm. Side 1 in this case was the left-hand side of the train in the direction of travel. This was adjacent to the cess (the part of the railway to the outside of the rails and within the boundary fence). The driver correctly repeated back the message. The signaller asked the driver if they required a line blockage, where other trains are stopped on adjacent lines. The driver responded that they would be remaining on the cess side of the train and that a line blockage would not be required.

A MOM was dispatched to the site by the EMIC and arrived at around 10:00 hrs. They were instructed to act as a RIO because train 6M57 was classed as a dangerous goods train. After arriving on site, the MOM and the driver of train 6M57 spoke with each other. The MOM at this point was on Trent Lane footbridge which passed over the line approximately halfway along the freight train. The driver, who was returning to the locomotive cab, reported that they had found no evidence of a hot axlebox.

The MOM informed the EMIC that the freight train driver had not found a fault and that it was safe for trains to pass on the adjacent line once the driver was back in their cab. The EMIC passed this information to the SSM who, in turn, informed the Nottingham and Netherfield signallers that trains could be allowed to pass train 6M57 on the adjacent line once the driver was back onboard their train.

At 10:05 hrs, the driver of train 6M57 called the Netherfield signaller from their locomotive’s cab, using the train radio. The Netherfield signaller informed the Nottingham signaller at this point that the driver was calling them. The driver of 6M57 informed the Netherfield signaller that they had checked axle 101 and had found no fault. The signaller correctly identified that the HABD alarm related to axle 110, and that the wrong axle had been checked by the driver. The signaller informed the driver that the correct axle would need to be examined. The driver did not request a line blockage for this second check, and the signaller did not ask the driver if they required one.

At around the same time as this conversation was taking place, 2S93 was authorised to depart from Nottingham station by the Nottingham signaller. By the time the second call between the driver of train 6M57 and the Netherfield signaller had ended at 10:06 hrs, train 2S93 was heading towards the location where train 6M57 was stood.

The driver of train 6M57 then left their cab to go back and check the correct axle. This time they decided to use the area between the Up Newark line, on which 6M57 was stood, and the Down Newark line. This area is known as the ‘six-foot’. While walking back to check the correct axle, the freight train driver used their mobile phone to contact their manager.

As train 2S93 approached the freight train at approximately 37 mph (60 km/h), the passenger train driver saw that the driver of train 6M57 was standing between the rails of the Down Newark line and directly in the path of their train. The freight train driver was using a mobile phone. The passenger train’s driver braked and used the train’s warning horn. This gave the freight train driver enough time to move and to get close enough to their own train to avoid being struck.

Following the incident, the freight driver continued to examine the train, and confirmed that the axle identified by the HABD was indeed defective. The wagon concerned was later removed from the train.

The driver of train 6M57 later reported that they had found using the cess side “hard going” during the first check due to the presence of foliage. For this reason, they decided to use the six-foot side instead for the second check.

The Rule Book GERT8000 Module TW5 issue 12 ‘Preparation and movement of trains: Defective or isolated vehicles and on-train equipment’ contains rules for the signallers and other railway staff relating to a HABD activation. These instruct signallers to stop any trains on the adjacent line to the affected train and, once the train which is the subject of the activation has been brought to a stand, the signaller must ask the driver if the adjacent line needs to stay blocked while the examination is carried out. This process was, however, only followed during the first call between the driver of train 6M57 and the Netherfield signaller. The Netherfield signaller was unaware that the driver of train 6M57 had decided to carry out the second check via the six-foot side instead of the cess.

GERT8000-TW5 also details the actions to be taken by a train driver when checking to see if an axlebox is overheating. If no evidence of overheating is found with the axlebox concerned, a driver must continue to check the other axleboxes on the vehicle concerned, and all axleboxes on the vehicles either side of the one concerned. During the first check the driver of train 6M57, who stated they had not dealt with a hot axlebox incident previously, examined the axle they erroneously believed had triggered the alarm and the axles adjacent to it. They did not, however, check the ones on the opposite side of the train before returning to their cab.

Rule Book module GERT8000-G1 Issue 9.1 ‘General safety responsibilities and personal track safety for non-track workers’ provides rules regarding using communication equipment. It makes it clear that an individual must be in a position of safety before using mobile communications equipment. Research has found that using a mobile telephone can result in a decrease in situational awareness, slower reaction times and a reduction in hazard perception.

The General Signalling Regulations, GERT8000-TS1 Issue 17, contain rules for the signallers dealing with incidents involving trains carrying dangerous goods. These state that a signaller must stop the passage of trains on all lines at the location, making sure they do not bring trains to a stand in the immediate area unless there is no damage to the wagon, tank, container, or flask. Although there was no damage to the wagons on train 6M57, train 2S93 was allowed to pass the location at which train 6M57 was stood before this had been directly confirmed with the driver.

4. Previous similar occurrences

RAIB has investigated several previous incidents where drivers have had near misses when examining trains as a result of not reaching a clear understanding with signallers about which lines were blocked or open to trains. These include:

- In March 2018 at Stafford (RAIB safety digest 03/2018), when a driver inspecting a defective train had a near miss with a train approaching at speed on an adjacent line. The driver and the signaller had not reached a clear understanding about which lines had been blocked before the inspection took place.

- In August 2016 at Kyle Beck (RAIB safety digest 07/2016), a driver had to lie down alongside their train to avoid being struck by a train on an adjacent line. The driver believed that train movements on the adjacent line were blocked while they were examining their train, but the line blockage had not yet been granted by the signaller when the driver went onto the track. This occurred due to a misunderstanding between the signaller and driver.