Near miss with staff at Clapham Junction, London, 17 January 2018

Published 6 March 2018

1. Important safety messages

This accident demonstrates the importance of:

- staff, who are responding to urgent faults, adopting systems of work which are safe and suitable for the task being carried out, and modifying that system of work when necessary to take account of any changes to the area in which the work needs to take place

- maintaining awareness of the risks involved when working on a live railway and of the limits of protection under the safe system of work that has been set up

2. Summary of the incident

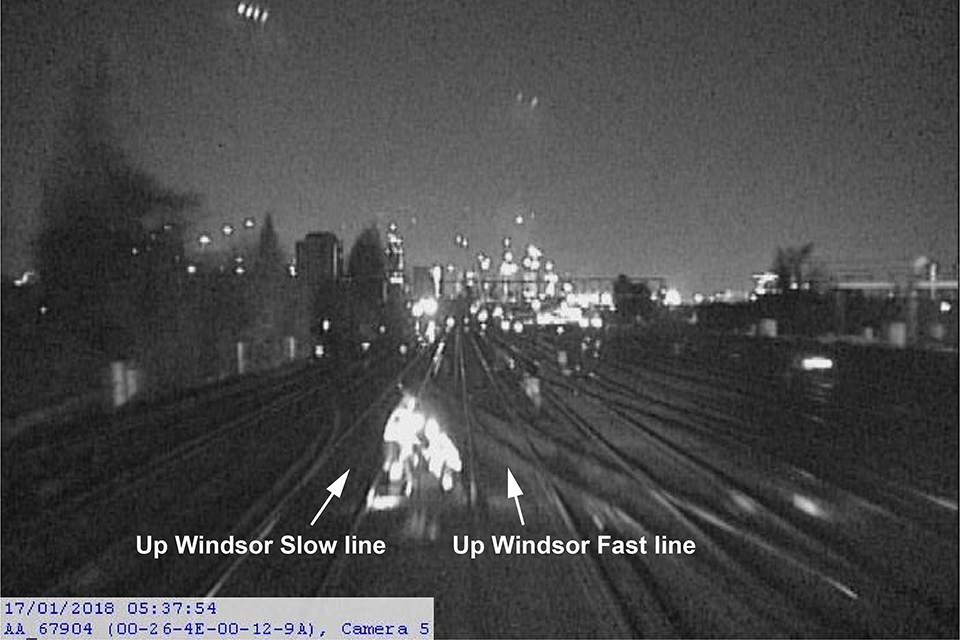

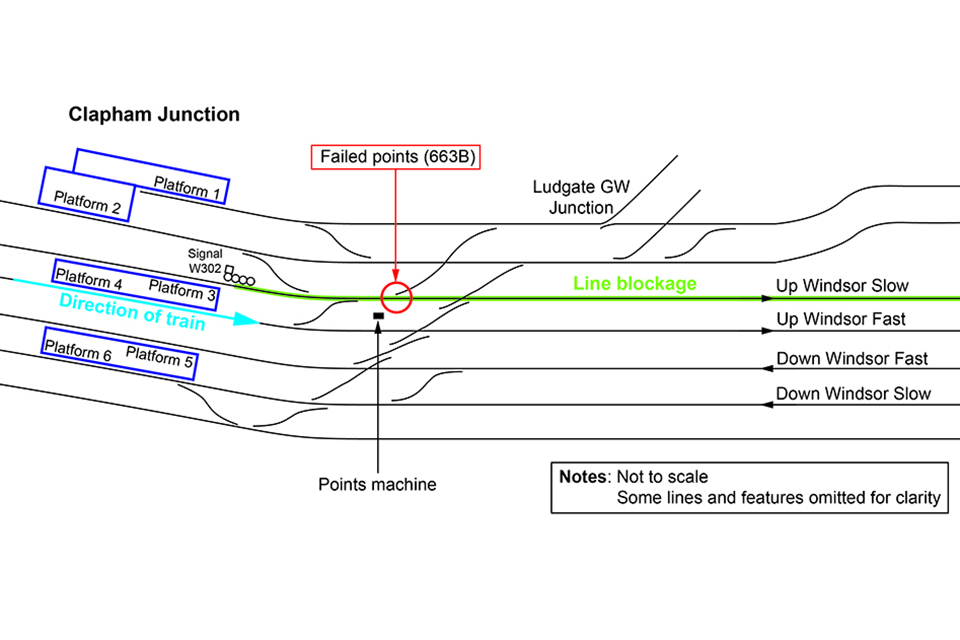

At about 05:51 hrs on Wednesday 17 January 2018, three signalling technicians were involved in a near miss with a train while they were working on a set of points near Clapham Junction station, south-west London. The technicians were diagnosing a fault on a machine that operates the points, which is situated in the space between two adjacent railway tracks – the Up Windsor Slow line and the Up Windsor Fast line. Although the Up Windsor Slow line had been blocked to carry out this work, the train passed on the Up Windsor Fast line, which was open to traffic.

The train involved was the 05:17 hrs South Western Railway empty coaching stock train from Wimbledon Park Sidings to London Waterloo. It was travelling at a speed of about 42 mph (68 km/h) at the time of the incident. The driver sounded the horn about five seconds before reaching the group of technicians, and then applied the emergency brake at almost the same time as he passed them. One of the group heard the approach of the train and shouted a warning to his colleagues. They started moving clear of the train about two seconds before it passed them.

Nobody was injured, but the three technicians and the train driver were badly shaken by the incident.

Image from the train’s forward facing closed-circuit television camera showing the position of the track workers (with their reflective clothing visible) just prior to the near miss (image courtesy of South Western Railway)

3. Cause of the incident

The incident occurred because the technicians were working in a location where they were not protected from moving trains. The system of work that they had set up was arranged so that the Up Windsor Slow line provided a position of safety for them, but this safe area did not extend to the space (known as the six-foot) between that line and the Up Windsor Fast line. Consequently, to work in that space would have required a change to the system of work to provide protection from train movements on the Up Windsor Fast line.

Track layout at Clapham Junction showing the line blockage, the failed points and the direction of the train

The fault with the set of points was caused by an engineering train (a tamper), which cut through some cables connected to the points machine during engineering work in the early hours of the morning. The engineering work involved a possession of the line, in which all lines are blocked to train movements. The three technicians involved in the incident had earlier been working in this possession on a night shift from 22:00 hrs to 07:00 hrs. When the fault was identified, they were dispatched to deal with it, but they arrived at Clapham Junction after the possession had finished and the lines were open again, so they had to set up a new safe system of work to protect themselves.

The senior technician in the group, who was acting as Controller of Site Safety (COSS) for this work, set up the system of work while standing on platform 3 at Clapham Junction station. He did this by telephoning the signaller and arranging that the Up Windsor Slow line would be blocked from Clapham Junction station to beyond the faulty set of points. Once this was done, the group then walked from the platform to the location of the work, using the Up Windsor Slow line as a safe route to reach the points.

Normally, work on the track is carried out under safe systems of work that are planned in advance. However, failures of equipment on the railway require a rapid response, and so special arrangements exist to cater for these situations. These arrangements allow the person in charge (ie the COSS) to decide how the safe system of work will be set up, whereas under normal circumstances these decisions are made by a dedicated planner. Nevertheless, the systems of protection that can be used under these arrangements remain the same.

All of the group were experienced on the railway and held a number of relevant competencies (including COSS). They were all aware that only the Up Windsor Slow line had been blocked, but their initial assumption was that the work would not involve straying outside the protection provided by that line. By the time it became clear that they would need to work on the points machine itself (ie between the blocked line and an open line), they had all become engaged in the task and lost awareness of the fact that the Up Windsor Fast line was still open. It is also possible that they had slipped back into a mindset of working in a possession, having recently worked in the possession in the same area earlier in the night.

There was some evidence to suggest that, before this incident, it was normal practice for signalling technicians from the Waterloo section to block only one line when working on points in similar circumstances, even when this meant working on the points machine (which is typically located between running lines). Witness evidence also suggested that operational pressures led to a reluctance to block multiple lines for this kind of work, in order to complete the work with the least possible disruption to the railway.

Following the incident, Network Rail issued a bulletin across its Wessex route reminding staff of the need for a suitable and valid safe system of work at all times, including a reassessment of the protection arrangements when the nature of the anticipated work changes.

4. Previous similar occurrences

In April 2017, RAIB published its report of a class investigation into accidents and near misses involving track workers outside possessions (RAIB report 07/2017). This report drew together the findings from several RAIB investigations involving track workers and highlighted the RAIB’s concerns for track worker safety. The RAIB identified several common causal factors relevant to the incident at Clapham Junction, including:

a. the COSS became preoccupied with the task and was no longer effectively monitoring or maintaining the system of work

b. inappropriate perception of the risks due to over-familiarity

c. circumstances had changed from the planned safe system of work

The report made two recommendations to Network Rail that are of particular relevance to this incident: one regarding the ability of those in charge of safety on the track to deal effectively with circumstances not encompassed by the planned safe system of work; the other regarding the non-technical skills of track workers including the risk perception abilities of staff who lead work on the track.

Since publication of its class investigation, the RAIB has published five safety digests concerning accidents or incidents involving track workers, where the decisions or actions of the track workers were causal to the incident. These were:

a. Ascot (RAIB safety digest 09/2017)

b. Great Chesterford (RAIB safety digest 12/2017)

c. Clapham, North Yorkshire (RAIB safety digest 16/2017)

d. Dutton Viaduct (RAIB safety digest 18/2017)

e. Raynes Park (RAIB safety digest 19/2017)

RAIB is also currently investigating a near miss with a team of track workers at Egmanton, Nottinghamshire, which occurred on 5 October 2017. That investigation will consider, among other factors, how the safe system of work was planned and implemented on site.

You can print this safety digest.