Runaway and derailment of a locomotive, Toton sidings, Nottinghamshire, 30 October 2016

Published 12 January 2017

1. Important safety messages

This incident demonstrates the importance of:

- drivers and shunters ensuring that a rail vehicle is secured, for example by scotches, before attempting to reconfigure its braking system

- drivers closely following, and seeking advice when unclear about, an operational procedure involving a safety critical system

- minimising the need for drivers to isolate safety critical systems (such as brakes)

- ensuring that the competence management system for drivers adequately covers processes that a driver might be called upon to perform only occasionally.

2. Summary of the accident

At 13:40 hrs, Class 70 locomotive number 70804 ran away while it was being prepared to be attached to another train. The locomotive had just arrived in Toton sidings at the rear of a train. The driver and the shunter, who were preparing to move the locomotive, were unable to stop it. It ran down a gradient out of the yard and onto a running line; the independent goods line. The locomotive ran for 6½ minutes and travelled 880 metres before it derailed at trap points at the end of the independent goods line.

The derailed train in Colas Rail yellow and orange livery. The wheels on one side of the train are all in the cess, and the wheels on the other side are in the four foot (courtesy of Network Rail)

3. Cause of the incident

The locomotive ran away because its brakes had been isolated, it was no longer attached to other vehicles and it had not been scotched.

The locomotive had been dead hauled (ie with its engine not running) to Toton and had just arrived there. Its parking brakes, which are normally applied by spring force and released by air pressure, had been isolated as part of the procedure for hauling it dead. The train in which the locomotive had been hauled had operated in ‘single piped’ mode. The term ‘single piped’ means that the train braking is operated from a single air pipe along the train. This pipe must both supply the air to operate the brakes, and signal when the brakes on a vehicle are to be applied (a pressure of 5 bar releases the brakes fully, lowering the pressure causes the brakes to apply).

Just prior to the incident, the driver, having dealt with the locomotive at the front of the train, started the engine on locomotive 70804. He then intended to reinstate the parking brakes. However, he was unsure of the correct steps to take and mistakenly operated the bogie isolation valves thereby isolating the service brakes on each bogie in turn. The two bogie brake isolation valves are positioned on the underframe, one above each bogie. They allow part of the compressed air system, in this case the brakes on a bogie, to be isolated. The locomotive manufacturer’s operating manual lists 21 such isolation valves in various parts of the air system; these are provided to isolate parts of it in case of faults (eg an air leak).

The driver did not secure the locomotive before commencing the operation. Because the locomotive had already been uncoupled from the train, he would have had to do this by scotching the wheels. Scotches were provided on the locomotive for this purpose.

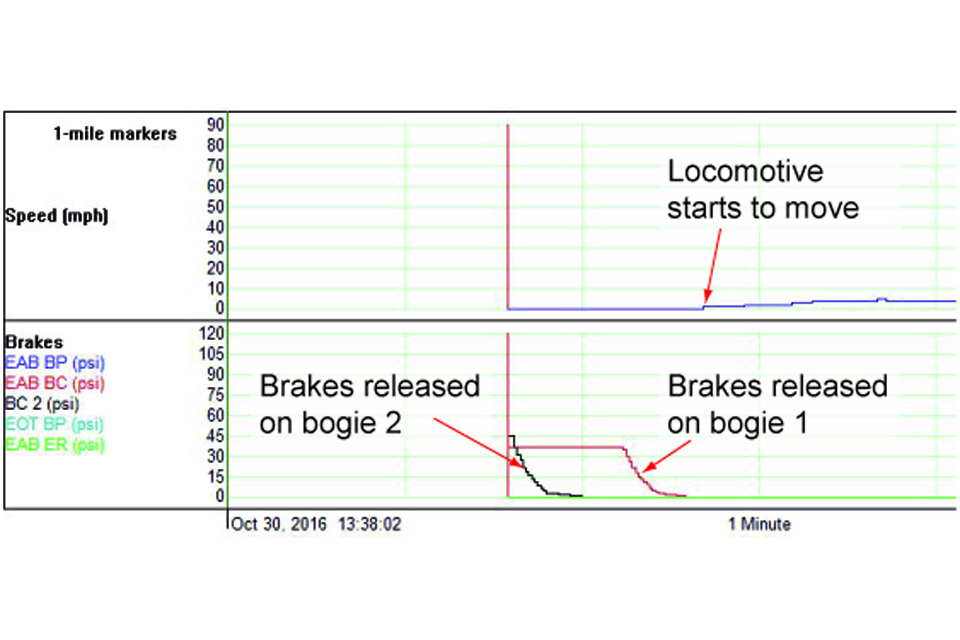

The locomotive’s data recorder shows that he isolated bogie 2 first, then bogie 1. The locomotive then ran away on the slight gradient.

Graph showing the brake pressure and locomotive speed as recorded by the locomotive’s data recorder. The points at which the brakes were released on the two bogies and the point at which the locomotive starts to move are indicated by red arrows.

The manufacturer’s operating manual for the Colas Rail class 70 locomotives includes a number of steps for manually isolating the parking brake when preparing a locomotive to be hauled dead in a single piped train. These include:

- Ensure that the locomotive is prevented from moving when its brakes are released (ie by scotching its wheels or coupling it to a train with brakes applied)

- Apply the parking brake and release the service brakes

- Release the parking brakes by pulling on the release handles on the brake units.

The parking brake units are situated on each side of each bogie and there are two such units on each bogie (four in total). The driver must get down onto the track to operate these handles.

View of the locomotive's bogie. The parking brake isolation handle at the bottom of the bogie is highlighted with a yellow circle. The bogie brake isolation valve is at the centre top of the bogie, highlighted with a yellow circle.

The manual also states that to reinstate the parking brakes, air pressure at 7 bar (ie main reservoir pressure) must be applied to the parking brake units (this is done using the parking brake control valve in cab 1), then the release handles on the bogies must be manually pushed back to their normal positions. The RAIB observed that a printed copy of this manual was present in cab 1 after the incident.

Colas Rail produced a ‘Class 70 Traction Digest’ on the isolation of parking brakes on class 70 locomotives. This, although very similar to the manual produced by the manufacturer, included the following additional steps:

- Operate the bogie brake isolation valve on each bogie to drain the air from the bogie brakes

- (after isolating the parking brakes) Open the bogie brake isolation valve to reapply the bogie brakes

- Attach a reminder to the parking brake handle in the cab.

Although it also included a warning against isolating the brakes on both bogies at the same time, the RAIB observes that these additional steps increase the risk of a runaway (if wrongly implemented). The isolation of service brakes on rail vehicles is normally only permitted when it is necessary to isolate a failure, or in case of emergency. Colas has stated that it added these steps to the procedure for isolating the parking brake so as to make it suitable for use in cases where the locomotive is to be prepared remotely from a train to which it is to be attached. It may not be safe to carry out this isolation at the site where the attachment is to take place due to site hazards (eg there may be a conductor rail present).

The process to reinstate the parking brake was the same as that described in the manufacturer’s manual.

It is possible that, when attempting to reinstate the parking brakes, the driver may have incorrectly applied the additional steps in the class 70 traction digest for isolating the parking brake.

The shunter who was assisting the driver saw that the locomotive was moving without the driver on board and, as it passed him, he climbed into the cab to attempt to stop it. He tried operating various controls but was unable to do so because all of its air brakes had been isolated. He then got off the locomotive.

The driver had worked for Colas Rail since 2006 and was trained to operate class 70 locomotives in 2014. As part of the Colas Rail competence management system for its drivers, he successfully underwent a driving skills assessment in September 2016 and had a refresher on the class 70 locomotive on 25 September 2016. However, he normally operated other types of locomotive and did not often drive class 70 locomotives.

4. Previous similar incidents

The need to ensure that trains are appropriately secured when working on their braking systems, including the use of wheel scotches, was covered in the RAIB Safety Digest on the runaway and derailment of a rail vehicle near Bury, GreaterManchester, on 22 March 2016.

A locomotive that had not been adequately secured ran away from Quorn station on the Great Central heritage railway on 14 May 2014 (RAIB report 04/2015). It had not been scotched securely and its parking brake was not applied. It ran away towards Loughborough station where it collided with stationary vehicles.

You can print this safety digest.