Direct Research Portfolio annual report 2020 to 2021

Published 15 March 2023

Introduction

The Nuclear Decommissioning Authority (NDA) is responsible for cleaning up the legacy from the UK’s pioneering post-war nuclear programme.

From the late 1940s onwards, the country’s smartest scientists and engineers led the world with ground-breaking nuclear discoveries. The result was a diverse range of experimental facilities and early nuclear power stations, designed initially for the UK’s defences but later to provide electricity for its citizens.

Their work spanned 17 locations across the UK and included:

- Dozens of prototype reactors

- 11 nuclear power stations

- Scores of research labs

- Fuel-manufacturing and enrichment facilities

- Spent fuel reprocessing plants

Many of the designs were unique, producing radioactive wastes and spent fuel that no-one had ever dealt with before. Structures, pipework, container vessels and land became contaminated and were mostly left for a future generation to clean up.

Many years later, NDA is dismantling this historical legacy, demolishing structures, and preparing sites for future uses. The mission will stretch for another 100-plus years and cost more than £100 billion.

Dealing with such a range of complexities and uncertainties requires fundamental science, innovative thinking, and novel engineering. Progress depends on clearly understanding the problems, finding solutions, and ensuring the cost for taxpayers remains acceptable. Research & Development (R&D) is therefore an essential part of decommissioning programme. The aim is to solve the challenging technical problems more effectively, more efficiently, more safely and, where possible, for less cost.

A total of approximately £85.5 million was spent on R&D during 2020 to 2021 by the NDA group.

The bulk of this forms part of the budget allocated to our Site Licence Companies and subsidiary organisations and is aimed at addressing specific on-site challenges identified during decommissioning activities. The work is carried out by SLCs, the subsidiaries and through contracts awarded to their supply chain.

Separately, NDA also retains a strategic portfolio to commission projects directly, particularly in areas with potential to have an impact across several sites, or to develop our overall strategy. This kind of research may help shape and develop our strategy, encourage early innovation, or maintain key technical skills.

About the DRP

The Direct Research Portfolio (DRP) is a key component of NDA’s R&D programme accounting for approximately £4 million of our annual investment. It represents an area of overall support for R&D across the group’s 17 sites and subsidiary organisations.

The DRP is made up of projects that:

- Help shape and underpin NDA’s overall Strategy for the UK

- Deliver innovation across multiple sites

- Develop vital technical expertise for the future

DRP projects are aligned against NDA’s four driving strategic themes:

- Integrated waste management

- Site decommissioning and remediation

- Spent fuel management

- Nuclear materials

DRP projects are commissioned through framework contracts that run for four years using a five-step process. The current contracts, awarded from 2020-2024, involve three frameworks and cover research into the following areas:

- University interactions

- Integrated waste management, site decommissioning and remediation

- Spent fuel and nuclear materials

Twelve successful consortia are involved, six of which are led by SMEs, comprising over 60 organisations ranging from UK universities and research bodies to global corporations and small businesses.

This report outlines several of the projects and key themes funded through the DRP during the financial year 2020 to 2021, for which the total investment was £4.2 million. Some projects are ongoing from earlier contracts, but all have potential for a significant impact across the group.

Further information on NDA’s R&D programme can be found in our 5-year R&D plan.

DRP spend

£4.2 million spent during 2020 to 2021

2020 to 2021 spending breakdown

| Framework Contract | 2020 to 2021 spend |

|---|---|

| University Interactions | £2.0 million |

| Integrated Waste Management & Site Decommissioning and Remediation | £0.5 million |

| Spent Fuel & Nuclear Materials | £1.7 million |

New DRP Projects Started in 2020 to 2021 by NDA R&D Driver

| NDA R&D Driver | Number of new projects (2020 to 2021) |

|---|---|

| Delivering Innovation | 6 |

| Informing Strategy | 26 |

| Maintaining Skills | 22 |

Note: Some DRP research projects have multiple drivers

University Interactions

University Interactions Framework Contractors

| Lead Organisation | Consortia |

|---|---|

| NNL | Frazer-Nash Consulting Ltd, Arup and National Physical Laboratory |

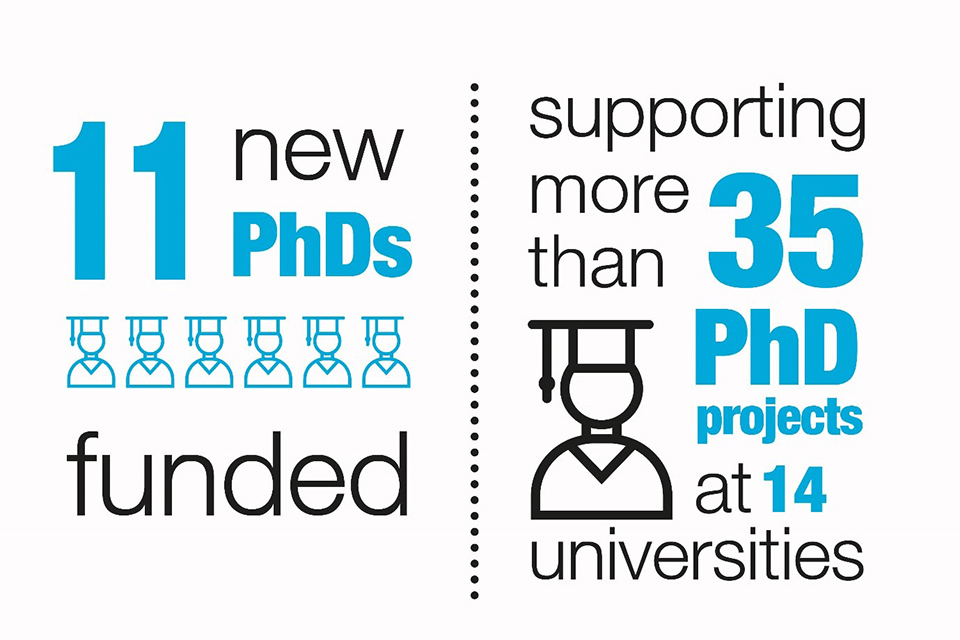

New PhDs Funded in 2020 to 2021

| PhD Title | University | R&D Driver |

|---|---|---|

| Eversion and Growing Robots: Pipe Navigation, Inspection and Characterisation | Queen Mary’s College, University of London | Maintaining Skills |

| Multiphysics Modelling of Laser Decontamination | University of Bristol | Maintaining Skills |

| Radionuclide speciation and Fate in Concrete Contaminated Land – Underpinning Options for In-Situ Disposal | University of Manchester | Maintaining Skills |

| Next Generation Muon Tomography | University of Glasgow | Maintaining Skills |

| Thermochemical modelling of radiation induced segregation in stainless steel clad for interim storage of spent advanced gas cooled reactor fuel pins | Coventry University | Maintaining Skills |

| Applying Machine Learning to Benchmarking Nuclear Decommissioning Project Performance | University of Warwick | Maintaining Skills |

| The Behaviour of Radioactive Aerosols in Wall-bounded Turbulent Flow | University of Bristol | Maintaining Skills |

| Disposal MOX: A Combined Study of Its Fabrication and Disposability | Lancaster University | Maintaining Skills |

| In-situ Gas Analysis in Interim Spent Fuel Containers | University of Manchester | Maintaining Skills |

| Understanding cement-superplasticiser interactions in PC, PC-BFS and PC-PFA encapsulants | University of Sheffield | Maintaining Skills |

| Developing comprehensive thermodynamic models for predicting the long-term aging process of encapsulated cement waste form in storage and geological disposal facilities | University of Bath | Maintaining Skills |

Case Study: Supporting our PhD Students during the Pandemic

Challenge: To avoid impacting NDA’s funded academic research and ensure our students were supported during the evolving global Coronavirus pandemic.

Solution: Work with the universities and research students to provide the offer of relevant time and funding to mitigate the impact of lockdown on the quality of PhD research.

Benefits: Ensuring the best possible quality of final research projects despite the limited access to facilities and resources during the nationwide lockdown

Status: Complete

R&D Driver: Maintaining skills

Research Organisations: Various universities

Continuous academic research is vital to understand and address the uniquely complex challenges across NDA’s 17 nuclear sites. NDA, therefore, invests in a range of university research programmes targeted directly at decommissioning and fundamental supporting topics and work closely with the Engineering and Physical Sciences Research Council (EPSRC) to support collaborative research programmes that align with industry requirements. A good level of support for the postgraduate-level researchers is essential to maintain the high-level skills needed for current decommissioning work and to foster the expertise needed for a mission that will continue for at least another 100 years.

Due to the global coronavirus pandemic which resulted in a national lockdown in March 2020, many of the funded PhD research projects underway were significantly disrupted by laboratory closures and a lack of resources being provided. This led to a delay in the expected progress of a large proportion of the current academic research. In order to support not only the relevant research but also the mental health and wellbeing of the students affected, NDA offered deadline extensions and extra funding to all of NDA sponsored researchers who had begun their research projects by March 2020, regardless of their year of study. 93% of the students applied for and received a time and/or funding extension to their project, with a total of >£263k extra funding being supplied. These extensions will minimise the impact of the virus-related lost research time and thus help to ensure the best quality research outcomes from the NDA-funded academic research portfolio, ultimately resulting in better value for the taxpayer. The students who took up the offer found the extension to be extremely useful in helping them complete their anticipated research.

Alana Mcnulty, NDA-sponsored PhD student at Manchester University, said,

As a result of the COVID-19 national lockdown, the laboratories I had access to were closed for over 5 months at a critical time during my PhD and were re-opened with limited access to adhere to COVID-19 rules and ensure social distancing. This had an obvious impact on my ability to carry out lab work that formed a key part of my research. Being granted an extension by NDA meant that I had time to complete any remaining lab work and subsequent data analysis that had been delayed and write it up before thesis submission. The additional time also meant that the stresses of finalising a PhD, compounded with the added delays due to Covid were significantly lessened.

Case Study: TRANSCEND - Ion Exchange

Challenge: To research new Ion Exchange materials for use in Sellafield’s SIXEP facility to remove radioactive substances from waste effluent streams

Solution: Collaborate with industry, universities and the Engineering and Physical Research Council to allow PhD students to carry out research in active areas of the laboratories

Benefits: Foster new technical specialists, with experience in hands-on active work, while also developing a greater understanding of current challenges and potential new technical solutions

Status: In progress

R&D Driver:Maintaining skills

Research Organisations: University of Birmingham

The TRANSCEND consortium (Transformative Science and Engineering for Nuclear Decommissioning) is the third joint initiative to focus on specific NDA technical priorities in the areas of radioactive waste, spent fuels, nuclear materials, and site remediation. The initiative brings together 11 universities and a range of industry experts allowing for close work relationships between UK academics and research students. One of the current projects running through TRANSCEND is based around research into new methods of decontaminating radioactive effluent streams.

The Site Ion Exchange Plant (SIXEP) is one of the prime means of protecting the public and the environment from radioactivity in aqueous liquid effluent discharges from the nuclear site Sellafield. Currently SIXEP uses a natural zeolite Clinoptilolite, which is an ion exchange (IX) material, to remove the radioactive isotopes of caesium and strontium from the waste effluent streams at the power plant. However, there is only a finite stock of Clinoptilolite available and as post operational clean out (POCO) occurs at the site the effluent streams may change, leading to incompatibility with the Clinoptilolite. Research into alternative IX media is therefore currently extremely important.

James Reed, a PhD student at the University of Birmingham, is investigating potential chemical modifications of various zeolites to attempt to increase their uptake of Cs and Sr to make them suitable alternatives to Clinoptilolite. Studies have shown that partial chemical modification of another known zeolite Mordenite can increase its selectivity for Cs and Sr. With EPSRC and NDA funding, and National Nuclear Laboratory’s (NNL) facilitation James was able to work in radioactive areas of laboratories and complete hands-on work that is not possible within the scope of a normal PhD research project. This allowed for further development of his practical skills, building high-level expertise for the future while also developing new solutions to technical challenges. Whilst working within the laboratories at NNL in Preston James has performed active tests assessing the IX performance under dynamic conditions using simulated SIXEP waste effluent.

James said:

I was fortunate to receive funding from NDA and NNL, which I secured through the Transcend Consortium, to spend six weeks conducting experiments within the radioactive laboratories at NNL, Preston. Working on a licenced nuclear site allowed me to see how my materials performed in more ‘lifelike’ conditions, by testing their ability to remediate radioactive solutions. In addition to obtaining valuable results for my research, I learned a lot about the importance of safety, procedure and meticulousness while working at this site. I strongly believe that this time enhanced my skillset as a chemist, and I was inspired by meeting people in the industry and understanding more about their roles. The results from this work suggest that some of the materials I have made have the potential to succeed the current, depleting supply of ion-exchange resin at Sellafield. These results are also being formulated for publication and will hopefully further the research in the area.

The work being carried out by James will ultimately influence the future techniques used for removing radioactive isotopes from the waste effluent streams at SIXEP- and potentially other nuclear facilities.

Integrated Waste Management & Site Decommissioning and Remediation

IMW&SDR Framework Contractors

Lead Organisation: DBD

Consortia:

- AECOM

- Amentum

- Westinghouse (WEC)

- United Kingdom Atomic Energy Authority (UKAEA)

- University of Sheffield including Nuclear AMRC (UoS)

Lead Organisation: Eden Nuclear and Environment Ltd.

Consortia:

- Cyclife EDF

- Gardiner & Theobald

- Golder Associates (UK) Ltd

- Hydrock Consultants Ltd

- Integrated Decision Management (IDM)

- University of Bristol and WSP UK Ltd

Lead Organisation: Galson Sciences Ltd.

Consortia:

- National Nuclear Laboratory

- Frazer-Nash Consulting Ltd

- Amphos 21

- Lucideon

- Mott MacDonald Ltd

- Resolve Robotics Ltd

- VTT Technical Research Centre of Finland

- Orano

- Veolia

- Universities of Bristol, Lancaster and Sheffield

Lead Organisation: Jacobs

Consortia:

- Andra

- CL:AIRE

- British Geographical Survey

- NPL

- AFRY

- Arup

- Brenk Systemplanung

- Costain

- Thornton Thomasetti

- Urenco

- Croft

- Cogentus

- Decision Analysis Services

- Longenecker and Associates

- MCM

- Imperial College London

- Universities of Birmingham, Bristol and Manchester

Lead Organisation: NSG Environmental Ltd.

Consortia:

- Abbott Risk Consulting

- KDC

- Quintessa Ltd

- RPS Consulting Services Ltd

- SOCOTEC UK Ltd

- The University of Sheffield including Nuclear AMRC (UoS) and Veolia Nuclear Solutions

- Lucideon

- Mirion Technologies

- STERIS

- The University of Manchester

Lead Organisation: Nuvia

Consortia:

- TÜV UK (TÜV NORD)

- CIEMAT

- Createc

- Cognition Land and Water

- Lucideon

- NucAdvisor

- Empresarios Agrupados

New IWM&SDR Projects Started in 2020 to 2021

Project Name: Strategic Aspects of Managing Contaminants of Emerging Concern

Lead Organisation: NSG Environment

R&D Driver:

- Maintaining skills

- Informing Strategy

Project Name: Assessments to Support Near-Surface Disposal Project - 2019 Inventory Update

Lead Organisation: Eden

R&D Driver:

- Informing Strategy

Project Name: Social value in Site Decommissioning - Scoping Assessment

Lead Organisation: Arup

R&D Driver:

- Informing Strategy

Project Name: Update to UK Radioactive Waste Inventory Website Supporting Documentation

Lead Organisation: NSG Environment

R&D Driver:

- Informing Strategy

Project Name: HAW Package Material Properties

Lead Organisation: Jacobs

R&D Driver:

- Maintaining Skills

Project Name: NDA Principle Membership of CL:AIRE

Lead Organisation: CL:AIRE Ltd

R&D Driver:

- Informing Strategy

Project Name: Stores, R&D Knowledge Management Systems

Lead Organisation: Jacobs

R&D Driver:

- Informing Strategy

- Delivering Innovation

Project Name: Development of a Specification for Basic Standards of Monitoring Equipment for Stores Operators

Lead Organisation: NSG Environment

R&D Driver:

- Maintaining skills

- Informing Strategy

Project Name: Development of a Tool for Modelling of Alkalinity Release from Concrete-based Demolition Material

Lead Organisation: Eden

R&D Driver:

- Maintaining skills

- Informing Strategy

- Delivering Innovation

Project Name: Demolition and development on nuclear sites: Protecting our protected species – Good Practice Guide

Lead Organisation: Galson Sciences

R&D Driver:

- Informing Strategy

Project Name: NSD - Preferred Options for the At Surface NSD Concept

Lead Organisation: Eden

R&D Driver:

- Informing Strategy

Project Name: Identifying Fume and Particulate Composition Produced by Laser Decontamination

Lead Organisation: Eden

R&D Driver:

- Delivering Innovation

Project Name: Identifying Fume and Particulate Composition Produced by Laser Decontamination

Lead Organisation: Galson Sciences

R&D Driver:

- Delivering Innovation

Project Name: GPG Dust Management Issue

Lead Organisation: Eden

R&D Driver:

- Informing Strategy

- Delivering Innovation

Project Name: Understanding the Non-Commercial Value of Materials and Assets derived from Demolition and Remediation

Lead Organisation: DBD

R&D Driver:

- Maintaining skills

- Informing Strategy

Case Study: Protecting our Protected Species

Challenge: Sifting through overwhelming volumes of generic guidance to identify best practice for protecting our protected species during nuclear site decommissioning is timely and can result in project delays and increased cost.

Solution: The development of good practice guidance for protecting protected species during nuclear decommissioning activities.

Benefits: Good practice is demonstrated in all decommissioning projects. Skills and confidence in protecting protected species during decommissioning is developed within NDA

Status: Complete

R&D Driver:

- Informing Strategy

- Maintaining skills

Research Organisations:

- Galson Sciences

- Mott MacDonald Ltd

- Prospect Law

Along with protecting people, protecting animals, ecosystems and the environment when undertaking decommissioning projects is of paramount importance to the successful delivery of NDA’s mission. To effectively protect wildlife living in, on, or near planned decommissioning locations, our staff must have a good understanding of ecological legislation and accepted best practice.

While the required level of knowledge will differ between roles, it is important that we all have a good baseline understanding of protected species, such as nesting birds, bats, and badgers, as well as knowing what to look out for to identify their presence before disturbing them.

The NDA commissioned research to pull together accepted best practice across multiple industries, and to create a nuclear specific good practice guide. This guide will enable our project teams to identify and protect protected species in decommissioning locations efficiently and effectively, reducing project overruns and any resulting increase in cost.

Galson Sciences, supported by their consortia members, were awarded the contract. The team completed the project in two phases.

Phase 1:

- Reviewing the protected species legislation, already available government and industry guidance on the subject matter, and species licensing specifically relevant to nuclear sites and decommissioning.

- Working closely with stakeholders from across the industry including NDA group and regulators to develop the scope of the good practice guide.

Phase 2:

- A detailed deep dive into the legislation, including legal case and mitigation studies that apply to specific challenges faced by the industry

- Compilation (and appraisal) of best practice, technologies (including emerging technologies and technology gaps that require further development) and techniques to legally and safely deter protected species from accessing or occupying building or land due to be remediated.

- Gathering advice on what is the best approach to take when (despite best efforts) protected species are found in (or on) a building or land after, or close to, the start of demolition.

- Gathering advice and guidance on the criteria for declaring buildings free of protected species prior to remediation/decommissioning activities.

The good practice guide is being brought up to date in line with the Environment Act 2021 and is expected to be published in Summer 2022. To improve information accessibility and dissemination a training package was produced which can now be used to train our workforce.

Case Study: Improving Stores Management

Challenge: R&D activities undertaken to improve the operation of waste package storage facilities is constantly undertaken across the NDA estate. The sharing of research outcomes is limited and predominantly limited to people networking.

Solution: A searchable R&D database or management system to create a common reference point across the NDA group where problems, requirements, previous and ongoing work can be catalogued.

Benefits:The searchable database will help avoid duplication of efforts and enable the dissemination of, and application of, best available technologies and techniques

Status:Approaching completion

R&D Driver:

- Informing Strategy

- Delivering Innovation

Research Organisations:

- Jacobs

- Arup

Waste storage is an essential component of the decommissioning lifecycle and provides a safe, secure environment for waste packages awaiting final disposal. As such, NDA owns and operates several active storage facilities across the NDA group.

It is important that waste stored within interim facilities remains compliant with future final waste disposal solutions. This requires controlling the storage environment (humidity, temperature, etc.) to prevent package degradation, completing visual monitoring to provide assurance of package integrity, and performing maintenance or re-packing activities when required, all while minimising unnecessary packaging movements. While stores operation varies between each storage facility, the research performed to underpin stores operation is important for multiple facilities.

The main aim of this project is to create a searchable knowledge management system for all industry where problems, requirements, previous and ongoing work can be catalogued and referenced to in future work. Some systems within the industry do parts of this scope but most data is stored in Electronic Document Record systems which are not accessible to everyone in working on NDA sites. Forums such as the Stores Operator Forum exist as a way of airing common interests and requirements however the new system will help extend the audience of the group, document and store common interests, and help Operating Companies to shed light on any growing problems and help to prioritise research.

The successful delivery of this project relies on excellent stakeholder communication to identify any systems currently used within both the NDA group and other industries, to review preferred options with end users, and to ensure operational acceptance upon the implementation of the final system.

The overall outcome of this work will help:

- improve access to key operational data,

- reduce duplication of efforts providing better public value for money,

- improve awareness of new technologies supporting the drive for innovation,

- underpin operational best practice to inform the development of future strategy and policy.

Once complete the knowledge management system will be utilised on all NDA sites.

Spent Fuel & Nuclear Materials

SF&NM Framework Contractors

Lead Organisation: DBD

Consortia:

- AECOM,

- Amentum,

- Westinghouse (WEC),

- United Kingdom Atomic Energy Authority (UKAEA)

- University of Sheffield including Nuclear AMRC (UoS)

Lead Organisation: Eden Nuclear and Environment Ltd.

Consortia:

- Integrated Decision Management (IDM),

- NSG-Environmental Ltd,

- Nuclear-21,

- TÜV UK (TÜV NORD)

- University of Bristol

Lead Organisation: Jacobs

Consortia:

- Andra,

- Pacific Northwest National Laboratory,

- British Geographical Survey,

- NPL,

- Arup,

- Brenk Systemplanung,

- Thornton Thomasetti,

- Urenco,

- Studsvik,

- Croft,

- StrataG,

- GRI Ltd,

- Decision Analysis Services,

- Longenecker and Associates,

- Thor Energy,

- Loughborough Materials,

- Integrity Corrosion Consulting,

- Gary Was Consulting,

- Nigel Donaldson Consulting,

- Imperial College London,

- Universities of Birmingham, Bristol, Cambridge, Manchester, Oxford and Sheffield

Lead Organisation: NNL

Consortia:

- Frazer-Nash Consultancy Ltd

- Galson Sciences Ltd

- GRI Ltd

Lead Organisation: Orano

Consortia:

- EDF Energy,

- Cavendish Nuclear,

- Lucideon

- Galson Sciences Ltd,

- University of Manchester,

- University of Sheffield

New SF&NM Projects Started in 2020 to 2021

Project Name: First step towards the development of a fuel drying model for AGR-Phase 1

Lead Organisation: Jacobs

R&D Driver:

- Informing Strategy

Project Name: In-active Trials of the Fabrication & Leach Testing of Simulated Plutonium Waste forms incorporating Neutron Poisons

Lead Organisation: Jacobs

R&D Driver:

- Maintaining skills

- Informing Strategy

Project Name: In-active Trials of the Fabrication & Leach Testing of Simulated Plutonium Waste forms incorporating Neutron Poisons.

Lead Organisation: NNL

R&D Driver:

- Maintaining skills

- Informing Strategy

Project Name: Further Development of RWM’s Immobilised Plutonium Disposal

Lead Organisation: Jacobs

R&D Driver:

- Informing Strategy

Project Name: Active electrochemical measurements to support long-term storage of AGR Fuel

Lead Organisation: NNL

R&D Driver:

- Maintaining skills

- Informing Strategy

Project Name: DOE-NDA Filling System Demonstrator Collaboration

Lead Organisation: NNL

Project Name: Developing a Disposal MOX Product and Process – Uranium

Active Pellet Trials

Lead Organisation: Orano

R&D Driver:

- Maintaining skills

- Informing Strategy

Project Name: Modelling the Generation and Subsequent Release of Hydrogen from Radiolytic Reactions between PuO2

Lead Organisation: NNL

R&D Driver:

- Maintaining skills

- Informing Strategy

Case Study: Empirical Work to Further Evaluate Alternative Techniques for Online Pond Water Monitoring

Challenge: To develop alternative monitoring technologies for AGR spent fuel storage ponds to monitor pond chemistry in-situ without the need for ex-situ lab capability

Solution: Undertake empirical tests of multiple emerging sensor technologies and determine their applicability for monitoring chlorides within spent fuel ponds

Benefits: Increasing the understanding of multiple varieties of sensor systems for in-situ monitoring of AGR spent fuel storage ponds

Status: Complete

R&D Driver:

- Delivering Innovation

Research Organisations: - Jacobs

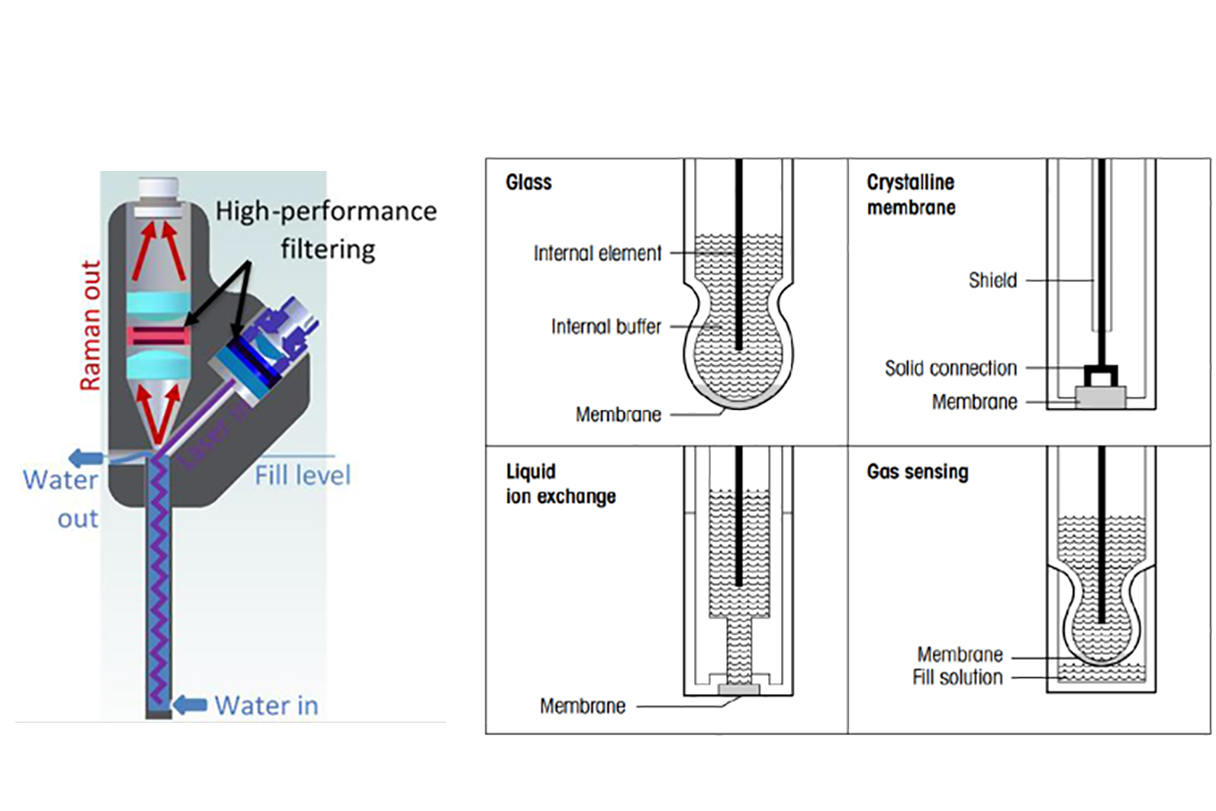

Currently AGR spent fuel is managed by an ‘open-cycle’ based on long-term wet storage in ponds pending disposal in a geological disposal facility (GDF). Pond conditions including the pH and chloride concentration ([Cl-]) levels need monitoring to reduce the potential of cladding corrosion, and consequently fuel leaks. At present the monitoring is done on site within analytical laboratories. However, the ponds will likely outdate the labs, so alternative monitoring systems will be needed. Research into in-situ environmental technologies to help support/replace the current ex-situ on site techniques is therefore becoming very important.

The aim of this project was to undertake empirical assessments of candidate sensors for in-situ monitoring. Through studies, workshops, and stakeholder feedback the two emerging technologies proposed were:

- A Raman based system for chloride detection

- Ion Selective Electrode (ISE)

Following functional surface testing, a design for a high-sensitivity Raman has been proposed, which could be developed into a prototype instrument to measure Raman detectable aqueous species. Also, a potential chloride-active resin (Triskem) with which to form Raman active bonds has been identified, which requires further work to assess the potential for its use alongside a Raman system as a reliable pond monitoring technology. The Raman system and associated resin will undergo further research and testing in order to create an appropriate pond monitoring method for use in the future.

Investigation into ISEs for measuring chloride was not able to achieve suitably low detection limits and the behaviour documented in a previous study used as a source paper was not reproducible with the available information. An assessment of the original published work was then carried out and findings showed uncertainties in the reliability of the data prompting a change in approach. If further work on this electrode system is pursued, the use of specialist subject matter experts has been highly recommended for the purposes of determination of suitable experimental protocols, and analysis of the relevant results. Raman technology has been identified as a more viable option than ISEs at this stage, highlighting the importance of R&D in both discounting unfeasible solutions as well as finding successful conclusions.

The results of this project will help influence future strategy into technologies for pond monitoring systems for the long-term wet storage of AGR spent fuel at multiple nuclear facilities across the UK.

Case Study: Developing a Disposal MOX Product and Process- Uranium Active Pellet Trials

Challenge: Can a Disposal MOX product for storage and disposal be optimised and what is the likely performance envelope of the production process?

Solution: Undertake experimental work to produce several uranium active pellets which can be characterised and tested

Benefits: Informing NDA on the properties of Disposal MOX pellets and allow for some optimisation of the pellet configuration to aid in future development of plutonium disposition options

Status: In Progress

R&D Driver:

- Informing Strategy

- Maintaining Skills

Research Organisation:

- Orano

- University of Sheffield

The safe and secure management of civil separated plutonium is an NDA and UK government priority.

Solutions to address this priority include the re-use of the separated plutonium as Mixed Oxide fuel (MOX) in a reactor and the manufacture of Disposal MOX- a plutonium immobilized waste form suitable for direct disposal in a Geological Disposal Facility (GDF). Disposal MOX is based on established MOX Fuel manufacturing technology, however research is needed to optimize the product for disposability and to establish the performance envelope of a Disposal MOX process.

The main aim of this project is therefore to inform NDA on what may be possible in terms of optimisation of a Disposal MOX product for storage and disposal and the likely performance of the relevant production process.

The project is taking place in two phases:

Phase 1- Literature review of industrial experience of manufacturing MOX and UO2 fuels focusing on specific issues including the maximum reliable dimensions of pellets and the impact on pellet quality when adding neutron poisons such as gadolinium (Gd).

Phase 2- Uranium Active trials based on an industrially relevant, proven MOX production process

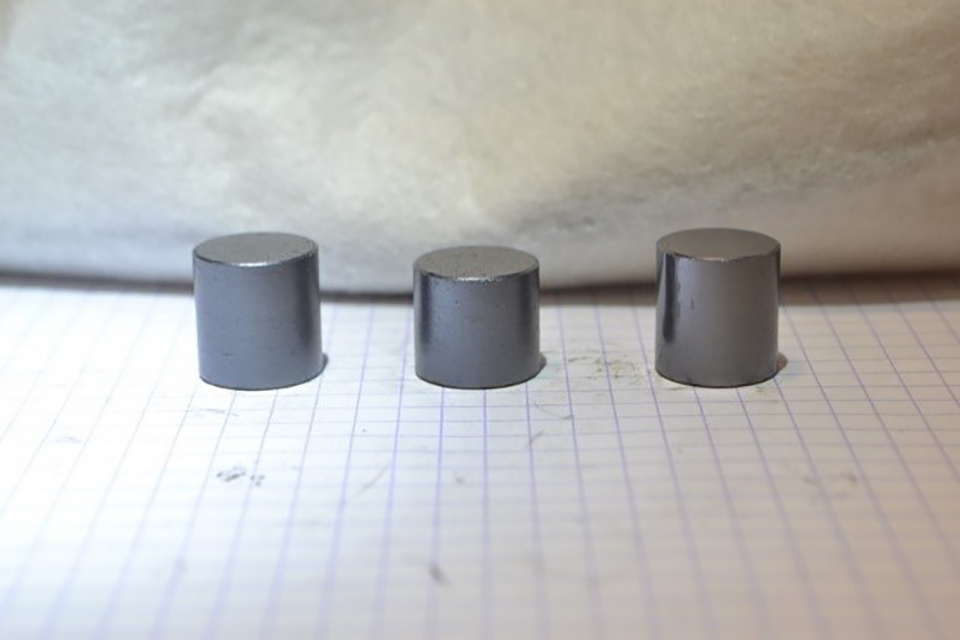

The Uranium Active Trials are being carried out at one of Orano’s facilities to:

1) Develop and validate MOX fabrication process improvements on an

industrial scale

2) Test and validate technological improvements for production,

maintenance, quality control and waste treatment

3) Test new MOX fuel fabrication processes with uranium

4) Qualify new uranium suppliers for strategic procurements

5) Carry out system performance tests prior to installation in the production plant

More in-depth analysis on the pellets including advanced characterisation of Gd-doped UO2 pellets is being carried out at The Immobilisation Science Laboratory in the University of Sheffield’s Department of Materials Science and Engineering. This involves evaluation of both pellet batch quality and distribution of neutron poison (Gd) within the UO2 matrix of the pellets.

Following from these tests it has been shown that pellets of ~15mm diameter, which are significantly larger than any currently available pellet, are possible and the method and conditions of manufacture are now known. This larger size allows for the avoidance of both interconnective porosity, and the likelihood of issues caused by cracks within the pellets, providing a promising lead for a potential Disposal MOX product and its relevant manufacture process.

In the future this work will be used to inform the next round of advice to the Department for Business, Energy and Industrial Strategy (BEIS), as well as providing insight to NDA surrounding SLC activities with regard to plutonium disposal.

Case Study: US-UK Collaboration - DOE-NDA Filling System Demonstrator Collaboration

Challenge: Hot-Isostatic Pressing (HIP) has been investigated by NDA as a potential option for disposition for the UK plutonium inventory, previous work in this area have identified critical technology elements which would be required for a future treatment process. Specifically design and demonstration of powder blending, transfer and filling systems, canister design, evacuation/sealing systems and overall process control.

Solution: Working with the US Department of Energy (DOE), NDA have contracted with NNL, GRI and NuVision Engineering to modify the DOE HIP rig to develop these critical technology elements and demonstrate the potential for HIP as an option for potential disposition

Benefits: This work will determine the technology readiness of HIP as a potential option for future disposition of the UK inventory. Working in collaboration with the DOE we are investigating the critical technology elements which could address both the US and UK requirements of HIP technology. Understanding of the technology elements will allow NDA to assess the potential for HIP as a potential option and assist in the technical underpinning of strategic information

Status: Ongoing

R&D Driver:

- Delivering Innovation

Research Organisations:

- NNL

- GRI

- NuVision Engineering

NDA is currently supporting the UK government in developing strategic options for managing the UK’s plutonium stockpile. This is a project of national importance and is a key strategic aim for NDA.

UK policy favours reuse of plutonium as Mixed Oxide (MOX) fuel, however, a final decision will depend on the commercial viability of this option. Indefinite storage has security and safety limitations and reuse options (MOX and fast reactor fuel) have significant technical and commercial challenges. Portions of the stockpile are also unsuitable for reuse and other plutonium-bearing wastes also require treatment.

NDA have identified the need to develop viable technology options for treating the UK’s plutonium stockpile as waste, which requires a designated treatment and disposal pathway. Hot-Isostatic Pressing (HIPing) has been selected as a preferred treatment technology. Current work has built upon previous work carried out by NNL on behalf of Sellafield Ltd in support of the immobilisation of a range of Plutonium containing residues. This was to investigate immobilisation routes which could be deployed on plutonium oxide stocks unsuitable or uneconomic for the manufacture of MOX fuel.

NDA has identified the critical technology elements of a treatment process for the UK plutonium inventory as- powder blending, transfer and filling systems, canister design, evacuation/sealing systems, and overall process contamination control. The technology leaders in these areas NVE/GRI and their overall objective is to develop and demonstrate technologies which will integrate unit operations so that they can be incorporated into a demonstration rig, to produce an optimally packed, evacuated and sealed canister, using nuclearisable technology.

The US Department of Energy (DOE) has also selected HIPing as a preferred treatment technology for treating calcine wastes from their Idaho Site, as stated in the Record of Decision (ROD). Under DOE grant funding, NuVision Engineering (NVE) are carrying out a demonstration of powder blending, transfer and filling systems for the Idaho Calcine wastes at their North Carolina facility in the USA.

Whilst the final wasteforms in the two applications and the scale of the processing are different between the two organisations’ needs, the fundamental processing and material handling issues are identical in terms of moving the substrate (calcined wastes or Pu residues) from its current location (binsets or Pu storage cans) into a HIP can for processing. Recent work conducted by NuVision Engineering (NVE) and GeoRoc International (GRI) in partnership with the U.K’s National Nuclear Laboratory (NNL) has demonstrated an initial prototype system for this transfer, but more work is needed to refine/modify the system to meet NDA requirements that no material is released during the transfer and sealing of the HIP canister.

During the first phase of this project GRI & NuVision developed a non-active simulant material for the filling trials which shares physical properties (particle size, SSA, powder characteristics and flowability) with the UK’s bulk plutonium inventory. This was then used to optimise the trial-rig for use across a range of environmental conditions. The next phase of the work will be non-active trials to demonstrate the effectiveness of both the treatment technology and rig.

Like the disposal MOX work the output of the HIP trials will be used to inform the next round of advice to the Department for Business, Energy and Industrial Strategy (BEIS). It will also provide NDA with insight into future activities regarding plutonium disposition.

Case Study: Post Storage Examination (PSE) After Fuel Receipt

Challenge: To inform NDA on the potential for water ingress which is associated with failed AGR pins during wet storage and to assess the potential for removing water from these pins during fuel drying.

Solution: Undertake experimental post irradiation examination of AGR fuel taken from storage ponds, and trialling AGR fuel drying techniques using failed fuel pins.

Benefits: Informing NDA on the condition of sensitised AGR fuel and the potential for water ingress in AGR fuel elements which may have failed during storage. It will inform NDA on the behaviour of this fuel during drying operations which will allow NDA to assess disposal characteristics

Status: Ongoing

R&D Driver:

- Informing Strategy

- Maintaining Skills

Research Organisations:

- NNL

NDA has identified disposal routes for oxide fuels as a priority due to the end of reprocessing in the UK, and the closure of the Thermal Oxide Reprocessing Plant (THORP) in 2018. With oxide fuel from Advanced Gas-cooled Reactors (AGRs) making up the majority of the spent fuel inventory, and oxide reprocessing coming to an end, any remaining AGR oxide fuel will need to be put into long-term storage pending a future decision to dispose to a GDF.

This priority requires a method for the safe and secure storage of spent AGR fuel for a long period prior to packaging for disposal. There is several decades’ experience of storing AGR spent fuel and there is high confidence in the pond storage approach that Sellafield Ltd is now implementing.

Future decisions are needed on whether to continue with the current storage arrangements, and when and how to prepare and package the fuel for disposal. These decisions will be influenced by factors such as the performance of fuel and storage facilities over the timescales until the GDF is available, and the disposal system requirements for fuel acceptance. The outcomes of this work will directly impact these decisions.

It is the responsibility of the relevant SLCs and subsidiaries to undertake the research supporting the disposability of spent fuels and the performance of the disposal system, and therefore this work is being carried out in co-ordination with Sellafield Ltd.

This work presents NDA with an ideal opportunity to:

- Access fuel with unique fuel characteristics – the opportunity to collect data from fuel that has experienced long term pond storage after failure.

- Leverage the financial benefits to NDA, since the significant costs of fuel recovery, transfer and preparation are already covered as part of the work agreed with Sellafield Ltd.

- Supplement future programmes - this work will feed into planned programmes of inactive trials and modelling are undertaken as part of NDA’s work of fuel drying.

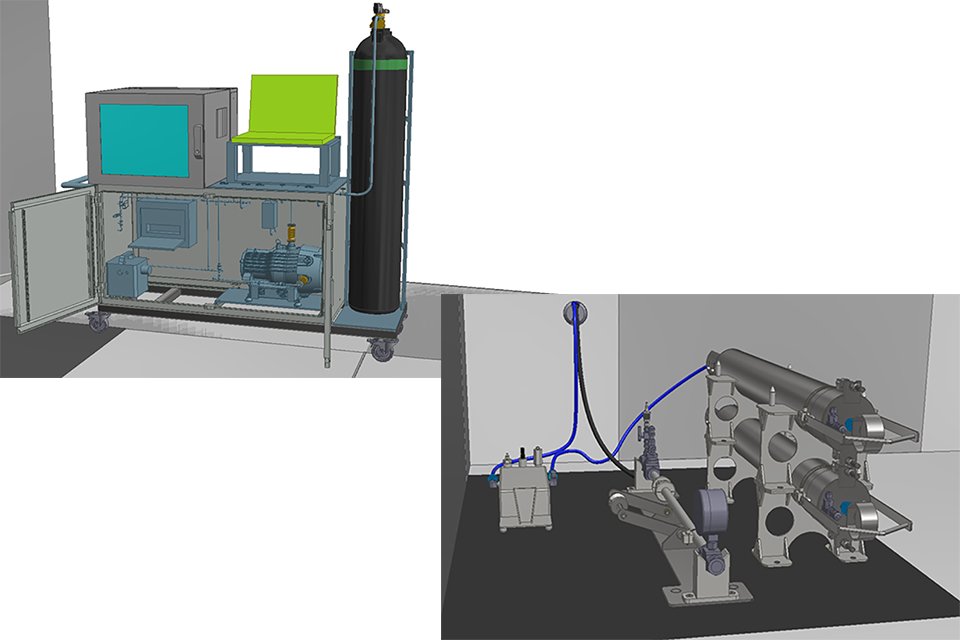

This is a multi-year programme of work which has involved the design and development of an AGR drying experimental rig. This rig has now been manufactured and is undergoing non-active commissioning and testing in NNL’s Workington facility. This testing will demonstrate the effectiveness of the drying rig and develop the procedures which will be used during the active drying of the AGR fuel pins. Once non-active testing has been completed the experimental rig is planned to be installed into the Active Handling Facility at Sellafield during the 2022/23 financial year and fuel drying trials will also be carried out.

Once dried the AGR pins will be analysed, to obtain data on the condition of the AGR fuel pins during storage, including sensitised pins which may have experienced failure of their cladding. This will provide an understanding of how these pins have behaved during wet-storage. This work will provide information on the amount of water which is retained in the AGR fuel pins after drying, include on intact and for potentially failed pins, which will underpin future work considering the drying and disposability of the AGR fuel inventory.