Sellafield’s most complex clean-up job reaches major milestone

Teams at Sellafield have successfully removed 70 tonnes of radioactive waste from one of the site’s most hazardous buildings.

Sellafield teams have successfully removed 70 tonnes of radioactive waste from the Magnox Swarf Storage Silo – one of the Sellafield’s site’s most hazardous legacy facilities – marking a significant step forward in the UK’s nuclear decommissioning mission.

Clearing waste from this legacy facility marks a significant step forward in one of our most challenging nuclear decommissioning tasks by placing it into interim long-term safe storage.

But success has presented a challenge, as is often the case in nuclear decommissioning.

And an innovative spin on an everyday gardening tool is helping overcome this.

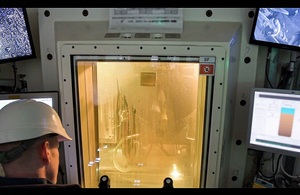

Sellafield's version of a garden rake - 1.4 tonne machine installed in MSSS.

Phil Reeve, head of legacy silos for Sellafield Ltd, explained:

As we’ve scooped waste out of compartment 10 in the silo, we’ve dug a 7-metre crater in the middle of it.

That creates a risk of the waste around the edges suddenly collapsing into it.

The answer is the Sellafield version of a garden rake. A 1.4 tonne machine which extends its stainless-steel arms outwards then pulls waste into the centre, smoothing it out.

We’ve always known this procedure was going to be necessary, said Phil.

The rake has been developed alongside the retrieval machine. So, it’s a big moment to see it successfully deployed in an active environment for the first time.

It allows us to crack on with confidence.

Congratulations to the teams involved, and our supply chain, for achieving this success.

Andrew Prince, a team leader at the Magnox Swarf Storage Silo, said:

Deploying the rake for the first time in Compartment 10 was a major milestone. It’s one of the most challenging areas on the Sellafield site, and the successful operation gives us real confidence in the wider retrievals programme.

This achievement reflects the dedication of a large team across Sellafield Ltd and our supply chain.

Waste retrieval from the silo began in 2022 following 2 decades of careful preparation.

The retrievals operation is particularly complex due to the building’s original design in the 1960s, which did not account for future waste removal.

A painstaking process was needed to retrofit an exit route. It involved assembling huge retrieval machines on top of the building’s vast waste compartments, called a Silo Emptying Plant (SEP) machine.

Currently, one machine is operational, with 2 more due to begin work soon. All retrieved material so far has come from compartment 10 in the silo.

Sellafield’s most complex clean-up job reaches major milestone