What is the Magnox Swarf Storage Silo?

The Magnox Swarf Storage Silo at Sellafield is one of 4 legacy pond and silo facilities on the Sellafield site.

What is it?

The Magnox Swarf Storage Silo (MSSS) is the most hazardous building on the Sellafield site, so the work of removing the waste and putting it into modern, safe containment packages is our top priority.

MSSS was built more than 50 years ago for the underwater storage of Magnox fuel cladding (or swarf) that was removed from used nuclear fuel rods so that fuel could be reprocessed.

The silo contains approximately 10,000m3 of historic waste and 60,000 items of Miscellaneous Beta Gamma Waste this all needs to be removed from the underwater compartments.

MSSS was built more than 60 years ago.

It received swarf from the First Generation Magnox Storage Pond and the Fuel Handling Plant, along with a range of other items of intermediate level waste.

The silo was originally built in the 1960s, with 3 further extensions built in the 1970s and 1980s as it gradually filled up.

In total there are 22 individual compartments within the silo - each compartment is large enough to hold the equivalent of 6 double-decker buses and is approximately 15 metres deep.

By 1972, compartments 1 to 6 were full and by 1991 the silo stopped routinely receiving waste when the swarf from reprocessing started going to the Magnox Encapsulation Plant on the Sellafield site.

This new plant stores the waste more safely by cementing it into steel drums.

The final batch of waste was tipped into the legacy silo in June 2000, at which point the facility was put under a regime of care and maintenance while preparations were made to get the waste out.

The Magnox Swarf Storage Silo: Making our most hazardous facility safer

Why are its contents so hazardous?

Magnox fuel cladding was mostly made of magnesium, a material that ignites and burns easily.

To keep the waste cool and away from oxygen to prevent a fire, it is stored underwater.

This causes a chemical process which generates hydrogen – so the hydrogen levels in the facility also need to be managed through ventilation.

Over time the radioactive content in the waste has transferred into the water it is being stored under. This has created a radioactive liquor, which in itself is a major hazard.

In the 1970s we identified that some radioactive liquor had leaked into the ground underneath the facility. The leak then sealed itself for several decades, but started again in 2019.

The liquor now leaking is far less radioactive than the liquor lost in the 1970s, but it’s still an issue we’re taking very seriously. There is no way of stopping the leak other than removing the waste first.

For over a decade we have been removing liquor from some parts of the facility so it can be treated elsewhere on the Sellafield site.

This allows us to replace the removed liquor with fresh water, therefore diluting the liquor and reducing its radioactive content.

We have more than halved the radiation levels in the liquor in some parts of the silo.

How are we going to get the waste out of the silo?

The facility was built with filling in mind, not emptying. The only way to get the waste out is through the same openings at the top of the 22 compartments where the waste went in in the first place.

This will be done with a machine which acts like a lucky grabber at a fairground, reaching down with a hydraulic grabber to lift the contents below into a skip inside the machine.

The machine is called the Silo Emptying Plant (SEP machine) and, even though we will eventually have 3 of them all working simultaneously, it’s still a job which is expected to take around 25 years.

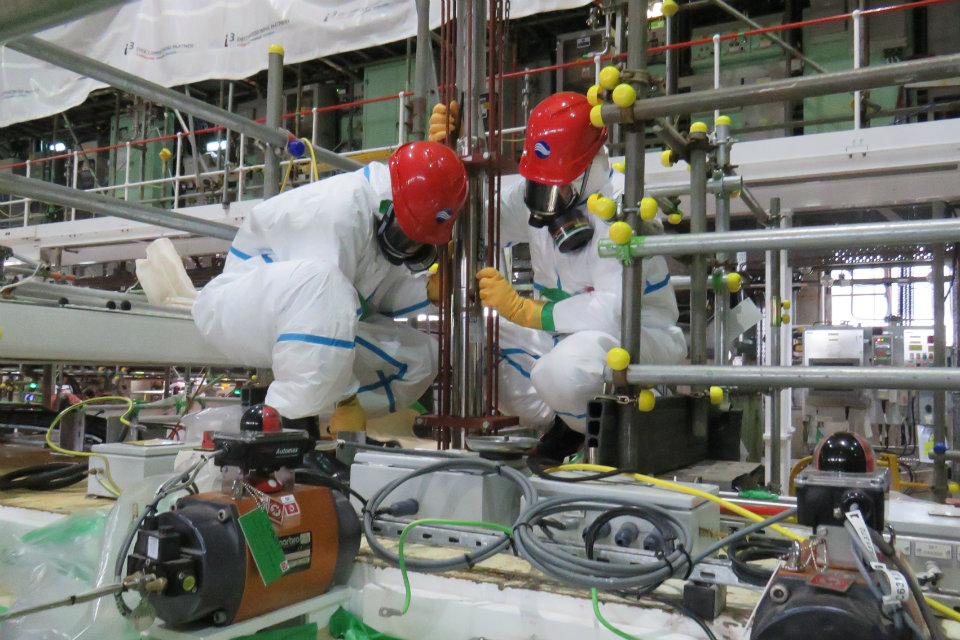

The SEP machines will move from compartment to compartment on rails, locking onto the opening below and providing all the shielding necessary to keep workers safe while they are lifting waste into their ‘bellies’.

The emptying of the silo will be done in the order that the silo was built - extension by extension with the oldest part of the silo being started first.

The waste levels will reduce in ‘waste size bites’ with each bite being a waste height reduction of approximately 5 metres with the corresponding cover water levels reduced to align with the new waste level.

The first SEP machine started getting waste out in April 2022 and we’ve also installed the second machine, which is now being commissioned.

The third machine has been manufactured and is being prepared for its installation into the facility.

Work begins on second silo emptying machine

These mammoth machines weigh in at 400 tonnes, are 13 metres long, 5.5 metres wide and standing 6.5 metres tall.

To then get the waste out, the skips of waste are then put into a shielded transfer ‘package’ which is attached to the SEP machine.

This 50-tonne containment device can then be lifted off the machine to transport the waste to a new interim storage facility called the Box Encapsulation Plant, which is nearing completion.

Enough transfer packages have been received from the manufacturer to start retrievals.

We need a minimum of 5 to get started and will eventually have a whole fleet of them.

The packages will also be used to transport contaminated retrievals equipment to a new state-of-the-art plant called the Silo Maintenance Facility (SMF).

It will be the place where all the equipment needed to run the retrievals operation will be maintained.

The Silo Maintenance Facility

Progress to date

-

increased batch size of liquor activity reduction (LAR) process from 1st extension compartments - 2011

-

seismic restraint tower built to strengthen the facility - bracing the building to the ground to offer extra support and sturdiness - 2012

-

electrics and systems overhauled - 2012

-

installed a plant and system to generate and distribute nitrogen to manage the risk of fire - 2018

-

lifted and lowered all of the original charge plugs at the top of the 22 compartments

-

Installed the SEP 1 gamma gate

-

Installed the SEP1 operator bulge (the operator bulge will house the control desk where the operators will operate the SEP machine)

-

moved SEP2 to silo compartment 6 - January 2020

-

moved SEP 2 from silo compartment 6 to silo compartment 10 - May 2021

-

SEP1 started retrieving waste from the silo - April 2022

-

2nd silo emptying machine was fully built inside the silo, with the final piece of equipment - the main control cubicle - being lifted into the silo and fixed into position - March 2023

-

70 tonnes of waste retrieved from the silo. A rake like tool has been developed to aid waste retrievals. This 1.4 tonne machine which extends its stainless-steel arms outwards then pulls into the centre of the compartment, enables the craters which have been created by the SEP Machines to be levelled, which stops the waste from collapsing down on itself - October 2025

Next steps

-

second SEP machine to start retrieving waste alongside the first SEP machine - 2025

-

new Box Encapsulation Plant opens to start receiving all waste from silo - 2027

-

third SEP machine to start retrieving waste alongside the first two - 2030

-

first silo extension will be half empty of waste by 2040

-

second and third silo extensions will be empty of waste by 2043

-

original silo building will be half empty by 2045

-

bulk waste removal to empty the silo (95% out) - predicted 2049/50

Further reading

Sellafield thinks outside the box

Sellafield tackles its biggest risk yet

A step forward for Sellafield’s most hazardous building

Sellafield unveils new plant to support clean-up

Sellafield Ltd confirms contract for waste storage boxes

What is the Silo Maintenance Facility at Sellafield?

Work begins on second emptying machine at Sellafield waste silo

SEP2 moves into position for retrievals

Sellafield silo installs second waste retrieval machine

Sellafield’s most complex clean-up job reaches major milestone $CTA

Updates to this page

-

Progress to date - update with information on new retrievals innovation

-

First published.