2. Steering

Mechanical condition, handlebar, forks and yokes and wheel alignment rules and inspection for motorcycle MOT tests.

2.1.1. Not in use

2.1.2. Not in use

2.1.3. Steering linkage condition

To inspect motorcycles with steering linkage:

-

Hold the front wheel firmly between your legs.

-

Rock the steering side to side.

-

Assess any free play in the linkage.

You must distinguish relative movement due to excessive wear from relative movement due to built-in clearance or spring loading of a joint.

The presence and effectiveness of some locking devices, such as locking fluid or ‘nyloc’ nuts, cannot be easily determined. If it is not certain that a locking device is missing or ineffective, you must give the benefit of the doubt.

Unsafe modifications include:

- welded repairs

- the use of excessive heat to highly stressed components (see Appendix A)

- modifications likely to affect the roadworthiness of the motorcycle

| Defect reference | Defect description | Category |

|---|---|---|

| (a)(i) | A steering linkage component with relative movement between components which should be fixed | Major |

| (a)(ii) | A steering linkage component with excessive movement between components or likely to become detached | Dangerous |

| (b)(i) | A steering ball joint with excessive wear or free play | Major |

| (b)(ii) | A steering ball joint worn to the extent there is a serious risk of detachment | Dangerous |

| (c)(i) | A steering linkage component fractured or deformed | Major |

| (c)(ii) | A steering linkage component fractured or deformed to the extent that steering is affected | Dangerous |

| (d) | Steering linkage locking device missing or ineffective | Major |

| (e) | Not in use | |

| (f)(i) | Steering linkage with an unsafe modification | Major |

| (f)(ii) | Steering linkage modified to the extent that steering is affected | Dangerous |

| (g)(i) | Steering ball joint dust cover damaged or deteriorated | Minor |

| (g)(ii) | Steering ball joint dust cover missing or no longer prevents the ingress of dirt etc. | Major |

2.1.4. Steering operation

To inspect a motorcycle’s steering operation:

-

With the wheels supporting the weight of the motorcycle, turn the steering from lock to lock.

-

Check that any adjustable steering damper is released before failing a motorcycle for excessively stiff steering.

You can conduct a road test to determine if the stability or control is adversely affected. You must let the motorcycle presenter know if the damper is released during the test.

| Defect reference | Defect description | Category |

|---|---|---|

| (a) | Steering linkage fouling any part of the motorcycle | Major |

| (b) | Handlebar fouling on the fuel tank or bodywork on full lock | Major |

| (c) | Restriction in the movement of the handlebars from lock to lock | Major |

| (d)(i) | A steering damper which is insecure or ineffective | Major |

| (d)(ii) | A steering damper which is in such a condition that the steering action is adversely affected | Dangerous |

| (e) | Any fairing or leg shield impeding steering operation | Major |

2.2.1. Handlebar condition

To inspect a motorcycle’s handlebar condition:

-

With the wheels supporting the weight of the motorcycle, grasp the handlebars by the grips.

-

Apply firm pressure to check for movement at the grips, clamps or any weakness of the handlebars or fork yokes.

Handlebars on some machines are rubber mounted. You might detect some movement when applying firm pressure to handlebars secured in this way.

| Defect reference | Defect description | Category |

|---|---|---|

| (a)(i) | Handlebar mounting insecure | Major |

| (a)(ii) | Handlebar mounting so insecure that steering is adversely affected | Dangerous |

| (b)(i) | Handlebar retaining device missing or loose | Major |

| (b)(ii) | Handlebar so insecure it is likely to become detached | Dangerous |

| (c)(i) | Handlebar fractured, excessively deformed or excessively corroded | Major |

| (c)(ii) | Handlebar fractured, deformed or corroded to the extent that steering is adversely affected or detachment likely | Dangerous |

| (d)(i) | Handlebar grip missing | Major |

| (d)(ii) | Handlebar grip insecure to handlebar | Dangerous |

2.2.2. Forks and yokes

To inspect a motorcycle’s forks and yokes:

-

Check that the lower steering head bearings are adjusted correctly and are in good condition by turning the handlebars from lock with the front wheel on the ground.

-

Check that the upper steering head bearings are adjusted correctly and are in good condition by turning the handlebars from lock with the front wheel raised clear of the ground.

-

Apply the front brake and push the handlebars forward to check the head bearings for excessive free play.

To inspect a lightweight motorcycle’s bearings for excessive play:

-

Raise the front wheel clear of the ground with an assistant.

-

Apply the front brake.

-

Lift the front of the front wheel. It may be necessary to support the centre of the motorcycle if it does not have a suitable stand.

If a motorcycle does not have a centre stand, you must use suitable equipment to raise the wheels clear of ground, one wheel at a time or both wheels at the same time. If necessary, use an assistant. Pulling a motorcycle over on its side-stand is not recommended.

Unsafe modifications include:

- welded repairs

- the use of excessive heat to highly stressed components (see Appendix A)

- modifications likely to affect the roadworthiness of the motorcycle

| Defect reference | Defect description | Category |

|---|---|---|

| (a) | Not in use | |

| (b) | Not in use | |

| (c) | Not in use | |

| (d)(i) | Forks or fork yoke fractured, insecure, excessively deformed or excessively corroded | Major |

| (d)(i) | Forks or fork yoke in such a condition that steering control is adversely affected | Dangerous |

| (e) | Forks or fork yoke with an unsafe modification | Major |

| (f)(i) | Steering head bearings excessively stiff, notchy, or with excessive wear or play affected | Major |

| (f)(ii) | Steering head bearings in such a condition that steering control is adversely affected | Dangerous |

You do not need to inspect the motorcycle’s wheel alignment if either the front or rear wheels have already been failed for buckling, eccentricity or damage.

A wheel clamp can be used, as long as it does not obstruct the straight edge or cord.

If the motorcycle’s wheels seem to be excessively misaligned, you can conduct a road test to assess the effect on the handling.

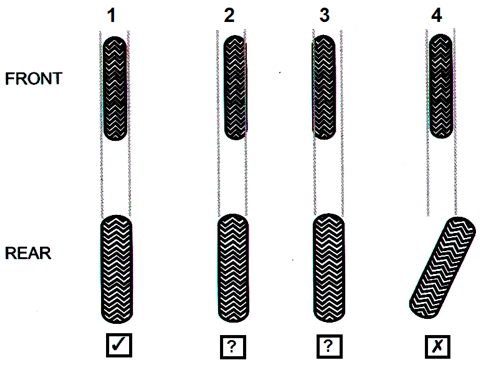

Some shaft driven motor bicycles and motor bicycles adapted for use with a sidecar may have a certain amount of parallel misalignment (see examples 2 and 3 in Diagram 1.).

Diagram 1. Examples of correct alignment (1), parallel misalignment (2-3) and misalignment (4)

To check a solo motorcycle’s wheel alignment:

-

Use a wheel clamp or an assistant to ensure that the front wheel is held upright and in line with the frame.

-

Place a straight edge or cord against the rear tyre parallel to it and as high off the ground as other parts will permit.

-

Estimate the gap (if any) between the straight edge or cord at the rear points where it’s opposite the front tyre.

-

Move the straight edge or cord to the other side of the motorcycle and repeat steps 2 and 3.

-

Sight along the front wheel and forks and assess any misalignment.

To check the wheel alignment on a motorcycle combination:

-

Set the steering in the straight ahead position, and place a straight edge or cord against the outer walls of the rear tyre.

-

Place a second straight edge or cord against the outer walls of the sidecar tyre and measure between the straight edges or cord at the front and rear of the combination.

-

Assess any toe-in or toe-out of motorcycle and sidecar wheels.

-

Check visually the vertical alignment of the motorcycle and sidecar.

It’s normal for motorcycle combinations to be set up in a way that is not perfectly vertically aligned.

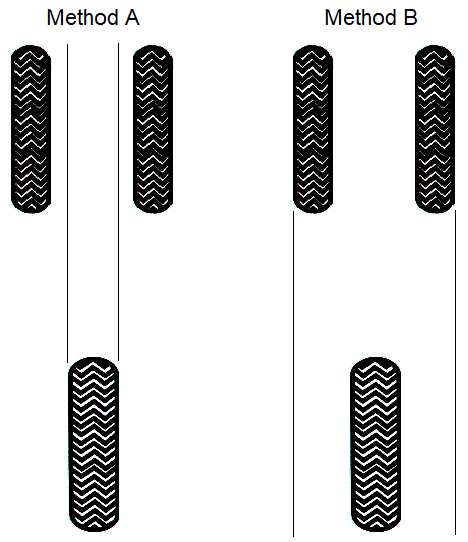

To check the wheel alignment on a three-wheeled solo motorcycle:

Method A

-

Use an assistant to ensure the front wheels are held upright and in line with the frame.

-

Place a straight edge or cord against both side of the rear tyre parallel to it and as high off the ground as other parts will permit.

-

Assess or measure the gap between each straight edge or cord and points on the front and rear edges of the front tyres.

Method B

-

Use an assistant to ensure the front wheels are held upright and in line with the frame.

-

Place a straight edge or cord against the outer edge of both front tyres parallel to each tyre and as high off the ground as other parts will permit.

-

Assess or measure the gap between each straight edge or cord and a point on the front and rear edge of the rear tyre.

Diagram 2. Examples of Method A and Method B

| Defect reference | Defect description | Category |

|---|---|---|

| (a) | Wheels of a solo motorcycle sufficiently misaligned to adversely affect the handling or steering | Major |

| (b) | Toe-out of the sidecar wheel relative to the motorcycle | Major |

| (c) | Excessive toe-in of the sidecar wheel relative to the motorcycle | Major |

| (d) | Excessive vertical misalignment between the motorcycle and the sidecar wheel which adversely affects the handling of the combination | Major |