Annual Review of Performance 2016/17

Published 4 October 2017

1. Our Business

Operating Sellafield

Sellafield has led the development of the UK’s nuclear industry, from the production of plutonium for the country’s nuclear deterrent programme through to the development of nuclear power.

We still play an important role by supporting:

- the production of ~20% of the country’s electricity supply by receiving and looking after used nuclear fuel

- national security by keeping our nuclear materials safe and secure.

Our challenge is to clean up the legacy of Sellafield’s early operations, including some of the most hazardous nuclear facilities in Europe. These legacy storage ponds and waste silos have large inventories of nuclear materials and do not meet modern standards. There are no readily available solutions for how we clean-up these buildings, but what we are learning can help others address their own environmental challenges.

Safety management is our top priority and the site operations are regulated and the site operations are regulated by both UK and international nuclear regulatory bodies. Risks are reviewed on a regular and frequent basis. The UK has a number of sites with risks classified as ‘intolerable’ risks.

We must:

- reduce risks posed by our highest nuclear hazards sooner

- spend more of the funding we receive on these priority activities and less on overhead costs

- complete our reprocessing mission and focus on ‘clean-up’

- deliver greater value to the Nuclear Decommissioning Authority, government and the UK taxpayer.

In 2016/17:

After years of planning and preparation we are removing fuel and sludge from the First Generation Magnox Storage Pond and the Pile Fuel Storage Pond. We have accessed the Pile Fuel Cladding Silo and also installed the first machine that will retrieve waste held in the Magnox Swarf Storage Silo.

We also launched our updated Corporate Strategy and Transformation Plan, setting out the direction of travel for our organisation and the Sellafield site.

Pile Fuel Storage Pond

2. A year in highlights

A year in highlights

Making progress

In the first full year as a subsidiary of the Nuclear Decommissioning Authority we have:

-

Made good progress in the clean-up of the country’s most hazardous nuclear buildings: * installed all 6 doors onto the side of the Pile Fuel Cladding Silo, a key step towards retrieving the waste held inside * transferred the first 500-litre drums of radioactive sludge from the Pile Fuel Storage Pond to our Waste Encapsulation Plant for treatment. The encapsulation plant was originally designed to support spent fuel reprocessing but has been adapted to support retrievals * installed a 350-toone machine to tackle one of the world’s most challenging nuclear clean-up jobs. The £100 million Silo Emptying Plant will scoop radioactive waste out of the Magnox Swarf Storage Silo.

-

Installed a self-climbing platform that will enable and support the safe demolition of a 61 metre redundant discharge chimney on site.

-

Moved closer to completing our reprocessing mission: * 433 tonnes of spent fuel reprocessed in Thorp against a target of 428 tonnes * 466 tonnes of spent fuel reprocessed in Magnox against a target of 457 tonnes.

-

Achieved the majority of our production and waste management targets, including: * 55 multi element bottles removed from Thorp pond * 1,000 drums of encapsulated waste sent to store against a target of 880 * 161 containers of high level waste vitrified against a target of 166 * 2,511 tonnes of metal recycled against a target of 1,900.

-

Launched our first corporate strategy as a subsidiary and a transformation programme which will see us: * accelerate the high hazard mission by 25% * reduce our costs by £1.4 billion by 2020 and a further £1-£1.4 billion by 2029 * be able to flex by £100 million in any financial year, by 2020.

-

Transferred the first flask of fuel from the First Generation Magnox Storage Pond to the Fuel Handling Plant.

-

Continued to invest in the next generation of nuclear workers at Sellafield through the recruitment of 46 graduates and 137 apprentices.

3. A letter from our Chairman

Tony Fountain, Chairman, Sellafield Ltd

In our first year as a wholly-owned subsidiary of the Nuclear Decommissioning Authority (NDA), we have transitioned from being a contractor and are shifting to a value-led delivery focus for the business.

We are naturally more aligned with our owner the NDA and through to government. We have a shared focus on safety, mission delivery and value for money.

There are very few businesses for which the consequences of its decisions and actions are of such national significance. Sellafield Ltd and the supply chain are working to deliver our nationally important mission.

That mission is changing. Our core task of reprocessing used nuclear fuel is almost done. The emphasis of our work on site is shifting to decommissioning and we must become more effective, more efficient and we must make every taxpayer pound count.

We will develop into a high-performing organisation, working collaboratively and innovatively to build capability. Improved performance will not only deliver better value for the taxpayer but open up much better opportunities for Sellafield Ltd and our communities.

Delivery in the year

It has been a successful year for Paul Foster CEO, the executive team he has built and the highly skilled workforce. They have delivered some impressive milestones, particularly in our legacy ponds and silos facilities and the Board is rightly proud of the team’s achievements.

Our social impact

The potential benefits of our transformation are far reaching. Our ambition is to create greater impact with the funding entrusted to Sellafield Ltd for mission delivery. We will do this by helping to create the right conditions in which the supply chain can diversify.

We will work with the NDA and Government to find ways to stimulate and encourage investments into our regional economies. We will use the technologies, skills and knowledge vital to delivering our mission as the platform for exporting expertise and services. This in turn will contribute to economic prosperity.

Leadership

Our non-executive Board membership has been refreshed with the appointment of John Baxter, Anne-Marie Choho and our NDA nominated nonexecutive director, Rob Higgins. Their combined experience and skills span the national and international nuclear industry and their commitment to our mission is already evident through their contribution to our strategy and performance.

Tim Chittenden completed his tenure as a non-executive director this year. He brought passionate support for skills, professionalism, diversity and education in the nuclear industry to the Board. I thank him for his 9 years of service to our organisation.

Paul Foster has strengthened his executive team, creating a balance between Sellafield experience and home-grown talent with expertise from the wider nuclear industry and beyond.

I believe that we have a strong and experienced Board and Executive, fully engaged with the business and able to transform our organisation.

Vision and plan in place

We have worked with our leadership team and the NDA to develop a target operating model for our enterprise, which sets out the characteristics of the high-performance organisation we will become. We have implemented a corporate centre as well as our delivery and transformation agendas. This vision for our enterprise is underpinned by our refreshed corporate strategy and new transformation plan, both of which were published at the end of the financial year.

Journey ahead

2017/18 will be another year of transformation for the business, during which the Board will continue to provide both challenge and support to the executive team.

We will continue to improve performance at Sellafield, while at the same time making progress on the commitments that we have made to the NDA and to government.

The near-term emphasis remains on completing reprocessing and reducing high hazards. We will now spend time thinking strategically about the best way to take on other elements of our mission.

Chairman’s highlights

- Safety - best Lost Time Accident performance on record

- Pile Fuel Cladding Silo - Installing the doors and removing a small section of the silo wall in preparation for the retrieval of the waste held inside

- People of skills - continuing our commitment to the future through apprenticeships and graduate schemes.

4. A letter from our Chief Executive Officer

Paul Foster, Chief Executive Officer, Sellafield Ltd

Our first full year as a subsidiary of the Nuclear Decommissioning Authority (NDA) has seen steady, sustained progress in safe, secure site stewardship, high hazard reduction and nuclear operations.

Safety performance is good statistically but we must remain vigilant as events still occur and we lead one of the highest hazard businesses in the world. Investigating the cause of these events and taking action has been a significant focus this year, and everybody has a role to play.

Safety – including security and environmental protection – is our overriding priority, why we start every meeting with a conversation about safety, and why safety is everyone’s responsibility.

From planning to progress

We have delivered significant progress in all our work, including:

- installed the first of the retrieval machines for removing waste from the Magnox Swarf Storage Silo

- removed 51 tonnes of nuclear fuel from the First Generation Magnox Storage Pond, having started fuel exports from this legacy facility for the first ever time in April 2016

- fitted all the doors onto the side of the Pile Fuel Cladding Silo and removed a section of wall as a monolith, giving us access to retrieve waste from inside the silo

- removed the first drums of sludge from the Pile Fuel Storage Pond, an achievement we reached in the First Generation Magnox Storage Pond at the end of the previous financial year

- delivered reprocessing targets in line with planned throughput to allow completion of workload ahead of scheduled end dates

- received materials as part of the NDA’s consolidation programme, a national priority.

Changing mission

Our production plants performed well this year and we are on target to complete the end of our reprocessing mission as scheduled. Post 2020 our focus will be entirely on hazard reduction and the clean-up of the site. This is one of the biggest environmental challenges of our generation and will require new ways of working.

Transforming our business

We launched our refreshed strategy and new transformation plan at the end of the year, pulling together the strategic direction for our organisation, the drivers for change, and the significant commitments that we have made to the NDA and government.

We are focused on reducing our business costs to create more value and flexibility in how we deliver our mission. We are looking at how to use our resources to focus entirely on environmental remediation and delivering our four value streams: retrievals, remediation, spent fuel management and special nuclear materials.

In this first year as an operator we have:

- delivered sound financial performance, ending the year within 1 per cent of our budget, and achieving our efficiency targets

- achieved efficiencies, saving £181.6 million against our baseline plan

- addressed performance in project management with the launch of a procurement which will bring in programme and project partners

- streamlined and rebalanced our governance and assurance arrangements.

Transforming our organisation and the way we work with our supply chain will help our communities to build greater resilience, demonstrating the longer-term future of our nuclear capability to attract inward investment and economic growth.

Our ambition is to create greater social capital, to play our part in growing our local economies in partnership with our stakeholders.

To achieve this, we need stronger collaboration with our supply chain and our stakeholders in 2017/18.

CEO highlights

- Aerial drones - were used, for the first time, in the separation area of site to inspect the condition of the First Generation Reprocessing stack

- Global returns - the ongoing returns of highly active waste to Japan and Switzerland

- Robots - A supply chain partner, Forth Engineering, has developed robots to help us complete radiological surveys.

5. How we run our business

Our fundamental purpose is to keep Sellafield safe and secure, cleaning up the site to a defined end state.

We work in value streams, focusing on what we are really here to do, prioritising what we do, and how we do it to maximise value. We currently have four value streams:

- retrievals

- remediation

- spent fuel management

- special nuclear materials.

Together with the skills and experience of our supply chain partners, we are delivering environmental clean-up, constructing new nuclear waste facilities, and keeping Sellafield safe and secure.

Our operating model

We are a wholly-owned subsidiary of the Nuclear Decommissioning Authority (NDA), which is part of the Department for Business, Energy and Industrial Strategy.

As a publicly-owned organisation our work is taxpayer-funded and we are committed to reducing the cost of our work and increasing the value generated by it. Funding is provided year-on-year and can’t be held over to future financial years.

We are regulated by the Office for Nuclear Regulation and the Environment Agency.

Our social impact

We want to enhance the social impact of our funding by helping to create the right conditions in which the supply chain can diversify and, in turn, revitalise communities.

5.1 What we do

Value Streams

Retrievals - We are retrieving nuclear waste, fuel and sludge that is stored inside our legacy ponds and silos.

Remediation - Beyond the legacy ponds and silos, we have hundreds of nuclear and non-nuclear facilities at Sellafield that need to be cleaned up and demolished.

Spent nuclear fuel management - We currently reprocess spent nuclear fuel. That means taking fuel that has been used inside a nuclear power station and extracting the individual components of uranium, plutonium and waste. In future we will store this fuel instead of reprocessing it.

Special nuclear materials - We have the facilities and expertise to provide safe, secure and appropriate storage to manage special nuclear materials.

Site Management

Nuclear waste management - We are the only organisation in the UK with the expertise, experience and facilities to safely manage all three forms of nuclear waste: high level, intermediate level and low level waste. The new buildings we are constructing at Sellafield will further strengthen our waste management capability.

Infrastructure - Our day-to-day operations at Sellafield rely on the availability of a range of services, from an onsite laundry to a comprehensive rail network that criss-crosses the site. We also pay for steam, power and water for the site and for the services of two security services: the Civil Nuclear Constabulary and the Guard Force.

Ageing assets - We make appropriate decisions about the level of investment we make in some of our older facilities. Our combination of supply chain support and in-house engineering capability means that we can keep facilities operating safely for as long as we need them.

Professional services - We rely on the same functional support that any organisation requires, from stakeholder engagement and human resources to financial management and information technology.

5.2 How we do it

Safety and security

Keeping Sellafield safe and secure is our priority and governs the operational decisions that we make every day. One of the ways that we can make Sellafield safer is by removing the nuclear risks and hazards posed by our oldest facilities, the legacy ponds and silos.

Skills mix

Sellafield demands a mix of direct employment and supply chain capability, working together as a team of more than 11,000 nuclear professionals.

Innovation

Innovation at Sellafield spans the spectrum of bespoke technology to fit-for-purpose solutions. Our supply chain partners are developing solutions for us that can then be exported to other challenges. We in turn research and invest in areas with the potential to add greatest value to our mission.

Project delivery

We have a responsibility to deliver new projects at Sellafield that will support our clean-up mission and site operations. We must do this safely, securely, to the agreed specification, on schedule, within budget and with due regard to the environment.

Collaboration

We aim to strengthen relationships with the NDA, regulators, stakeholders and supply chain, recognising that we can achieve more together than we can alone.

Governance

We make strategic decisions about our business and operations within an agreed governance framework. Our work is carried out in accordance with the appropriate regulatory authorisations and permissions.

6. Retrievals

6.1 Pile Fuel Cladding Silo

Dating back to 1952, the Pile Fuel Cladding Silo is the oldest intermediate level waste store at Sellafield and contains cladding waste removed from fuel used in the Windscale reactor. In 1957 it also started to take waste from the Calder Hall reactors. It received waste until 1968.

The structure is 21m high and internally subdivided into 6 waste compartments.

Pile Fuel Cladding Silo

Progress in 2016/17

- In September 2016 we started to remove the deflector plates that sat on the top of each section of the silo and directed waste into the compartments.

- In November 2016 we completed the installation of six access doors onto the side of the silo.

- In April 2017 we cut the first hole into the side of the silo, removing a section of the side of the building as a single slab or monolith, creating the first of six access points for the retrievals equipment that will reach in and grab the waste.

Collaboration

Our teams are collaborating with colleagues from:

- Bechtel Cavendish Nuclear Solutions

- Babcock Marine Technology

- James Fisher Nuclear

- Shepley Engineers Limited.

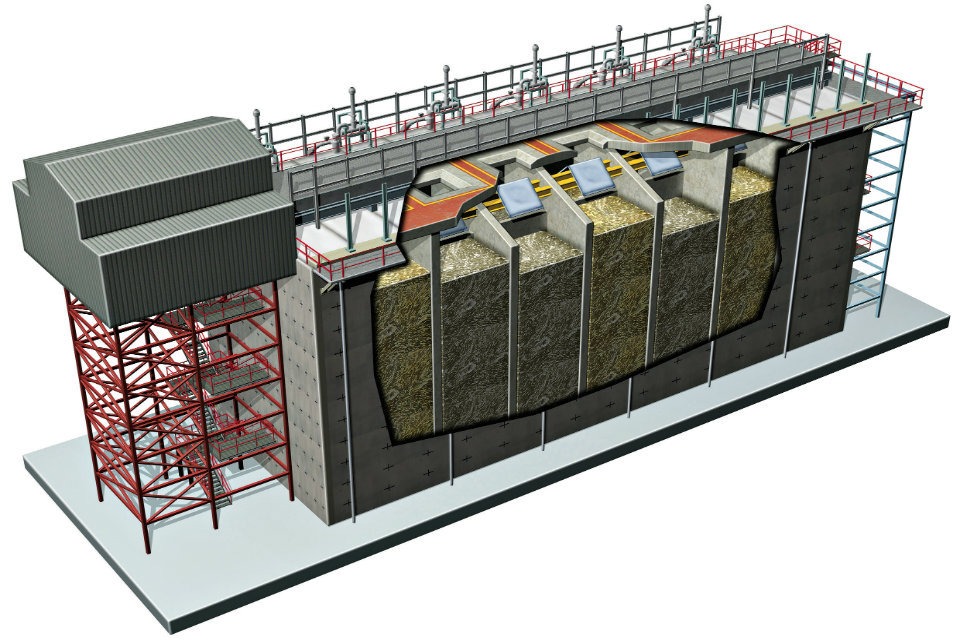

6.2 Pile Fuel Storage Pond

This is the oldest storage pond on the Sellafield site (it was built etween 1948 and 1952) and was used to store used nuclear fuel from the Windscale Reactors and later from Calder Hall. It also had the facilities to remove the cladding from the outside of the fuel rods before the fuel was sent to another building for reprocessing.

The pond itself is open air and at seven metres deep it is the largest single open air nuclear storage pond in the world. It received fuel until the mid-1970s.

Today the facility includes new buildings; a local sludge treatment plant and a drum filling plant – used to receive and export radioactive sludge.

Pile Fuel Storage Pond

Progress in 2016/17

- In December 2016, after around six years of consolidating radioactive sludge in the corral area of the pond, we started to export the sludge for treatment on site. We expect the bulk of the sludge to be removed by 2022.

Collaboration

Our teams are collaborating with colleagues from:

- Nexus

- CNSL

- Cavendish

- Hertel

- Amec Foster Wheeler

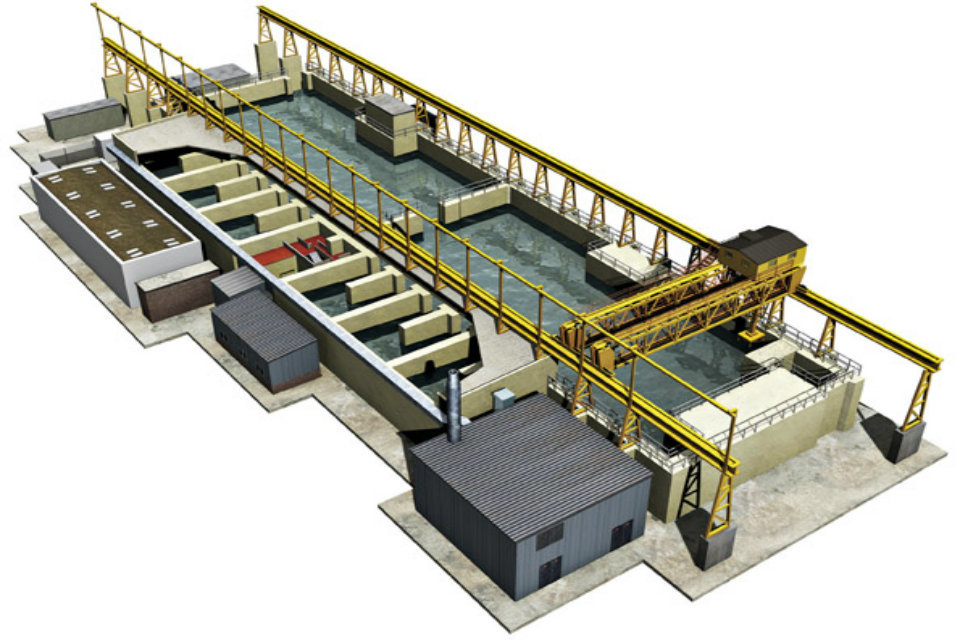

6.3 Magnox Swarf Storage Silo

The Magnox Swarf Storage Silo started operating in 1964 and was used to provide underwater storage for Magnox Swarf generated from the reprocessing of used Magnox fuel, and for a variety of other intermediate level Miscellaneous Beta-Gamma Waste.

The original silo was full by 1972 so three silo extensions were built between the early 1970s and mid-1980s. There are now 22 compartments in total, each large enough to hold six double decker buses.

The facility stopped receiving bulk waste in 1991, with smaller waste receipts continuing until 2000.

Magnox Swarf Storage Silo

Progress in 2016/17

- in November 2016 assembly of the first waste retrieval machine was complete.

Collaboration

Our teams are collaborating with colleagues from:

- NES Ansaldo

- i3 consortium (comprising Hertel, Amec Foster Wheeler and Shepley Engineers Limited).

6.4 First Generation Magnox Storage Pond

Constructed in the 1950s, the First Generation Magnox Storage Pond started operations in 1962. It received used nuclear fuel from Magnox reactors, stored and cooled the fuel in the pond.

It operated for 26 years, storing and processing approximately 27,000-tons of fuel (nearly 2.5 million fuel rods).

Progress in 2016/17

- in April 2016 we started to export fuel and sludge from the pond.

- in February 2017 we completed isolations on the pond’s redundant effluent sludge pipework system.

Collaboration

Our teams are collaborating with colleagues from:

- ACTtiv (comprising Atkins, Carillion and Jacobs)

- Shepley Engineers Limited

- PPS Electrical

- James Fisher Nuclear.

7. Cleaning-up the site

Once buildings are no longer operational they go through a process called decommissioning, which includes decontamination and demolition. There are hundreds of buildings that need to be decommissioned over the lifetime of the Sellafield site. Some of the achievements of our remediation teams dramatically change the site’s skyline, while others take us one step closer to demolishing redundant nuclear facilities.

7.1 Progress in 2016/17

Removing redundant stack

The challenge of demolishing a chimney that doesn’t meet modern safety standards, on top of a nuclear facility, adjacent to other high-consequence nuclear facilities, without impacting on their operations and without the ability to use explosives is a tough one.

Yet that is exactly the challenge we face in demolishing the chimney stack on top of one of our earliest facilities – the First Generation Reprocessing Plant. The 61 metre chimney sits atop the 61 metre plant and because the stack wasn’t built to modern safety standards, it needs to be removed.

However, the earliest facilities on the Sellafield site were built quickly to deliver their essential mission for the country, and without decommissioning in mind. This means that we had to find an inventive, safe solution, to the challenge of demolition.

The answer is a combination of specialist technology, industrial tools and hard graft. The specialist technology in question is a self-climbing platform – a bespoke piece of kit designed to ascend the stack allowing teams access to carefully deconstruct it from the top.

The platform will descend incrementally, allowing for demolition of both the concrete wind shield and the internal stainless steel flue liner. The platform has been designed especially for the tapered chimney stack, and is a first for the Sellafield site.

However, the technology has been used successfully on the Battersea Power Station chimneys, which are being replaced as part of a huge regeneration project.

A scaled-down replica of our chimney stack was built at the Delta International facility in Oldham to test the platform and the climbing methodology.

In addition to the self-climbing platform, a new industrial lift and roof bridge structure was built to allow access to the base of the chimney. These will be used for the removal of waste materials once demolition gets under way.

The tower will be “eaten” by hydraulic jaws attached to a circular working rig at the top of the chimney. As the rubble cannot be allowed to fall to the ground or inside the stack, it will be transported down the lift in small containers – a meticulous and time consuming task.

In 2016/17 the self-climbing platform was fitted to the chimney and it started its ascent.

First Generation Reprocessing Plant stack

Collaboration generates savings

When faced with the challenge of removing some redundant gloveboxes that were classed as plutonium-contaminated materials due to their routine exposure to the material during operation, the experience and knowledge of two teams was better than one.

The retrievals team charged with removing the gloveboxes collaborated with waste management teams who are the experts in dealing with plutonium-contaminated materials.

Together they created a simplified way to put the items into crates that could then be safely stored in one of our engineered waste stores, pending final disposal. The simplifications that the team came up with, including the removal of an unnecessary layer of containment on the packages, have created savings in excess of £1 million.

Radiography lifts the lid on the contents of waste containers

Managing the waste we create is an integral part of what we do at Sellafield on a day-to-day basis. To do this successfully, it is important that we know exactly what waste we have.

We have a stock of more than 250 crates of plutonium contaminated material that dates back to the earliest operations at Sellafield and there is very little information available about their contents.

In partnership with site radiography, the remediation team is using advanced radiography equipment – more commonly found in the health care sector – to X-ray and confirm the contents of the crates. This provides essential characterisation information to ensure we invest in the right future treatment options.

8. Looking after spent fuel

Spent Fuel Management at Sellafield includes the reprocessing of spent Magnox nuclear fuel from stations across the UK and also the reprocessing of spent oxide fuel from overseas customers.

Reprocessing takes used fuel which has been removed from a nuclear reactor to recover the reusable materials. After about four years in a reactor the fuel becomes less efficient. Reprocessing allows 97% of reusable material to be recovered.

Spent fuel management also includes the storage of Advanced Gas-cooled Reactor (AGR) fuel, a service that we will continue to provide in Thorp when the facility completes its reprocessing mission in 2018.

We will complete our mission in Magnox reprocessing plant in 2020.

Spent Fuel Management at Sellafield

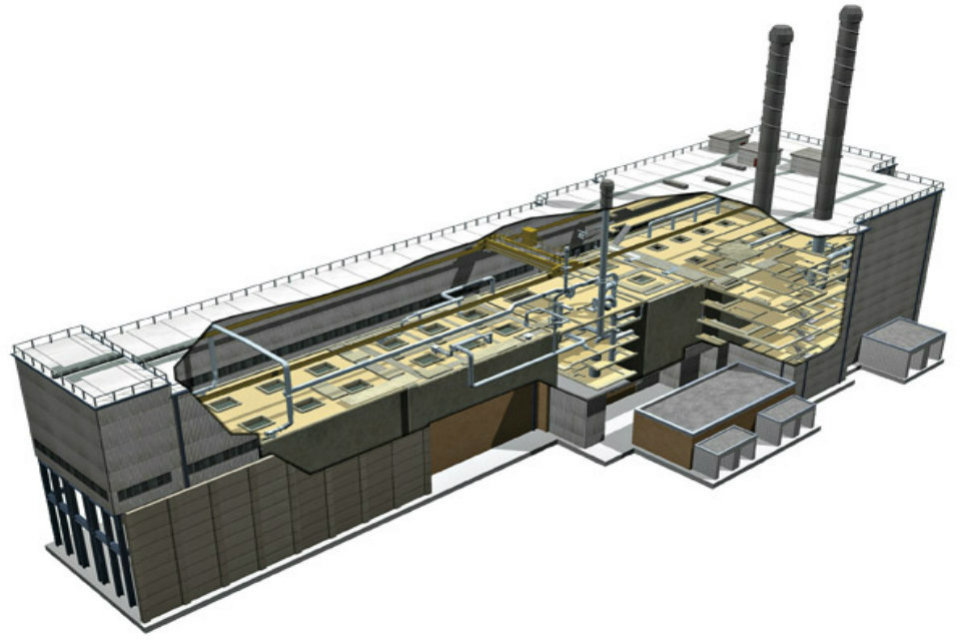

8.1 Thorp

Thorp – or the Thermal Oxide Reprocessing Plant – combines all of the facilities needed to reprocess spent oxide fuel under one roof. It reprocesses both UK and foreign spent fuel.

Thorp’s operations are divided into three main areas:

- fuel receipt and storage

- head end plant operations where spent fuel is chopped up and dissolved in nitric acid

- chemical separation where uranium, plutonium and waste products are separated out.

Our strategy

In order to complete our mission in Thorp and continue to add value to the nuclear industry, we will:

- maintain safe operation of all facilities

- reprocess all contracted overseas oxide fuel reprocess the contracted amount of AGR fuel

- reprocess sufficient AGR fuel to allow continued receipt of fuel from the AGR stations

- provide long term safe storage of UK-derived uranium and return of overseas uranium to customers

- provide long term safe storage of AGR fuel within Thorp’s receipt and storage facility

- 433 tonnes of spent fuel reprocessed in Thorp against a target of 428 tonnes

- 55 multi-element bottles removed from Thorp pond, making room for the storage of AGR fuel

- replaced the 10-tonne nitric acid recovery boiler vessel – a key piece of equipment that supports our evaporative capacity.

8.2 Magnox Reprocessing

The Magnox Reprocessing plant reprocesses spent nuclear fuel from Magnox nuclear power stations across the country – including our own former power station, Calder Hall.

The reprocessing plant is the only one of its kind in the UK. As such it has a vital role in supporting risk and hazard reduction operations across the Nuclear Decommissioning Authority’s estate by reprocessing fuel which is being retrieved from the fleet of Magnox power stations now being decommissioned.

Our strategy

In order to complete our mission in the Magnox reprocessing plant we will:

- maintain continued safe storage of fuel, products and radioactive material

- maintain safe operation of all facilities • receive, store and reprocess Magnox fuel

- decommission the plant.

Progress in 2016/17

- We reprocessed 466 tonnes of spent fuel in Magnox against a target of 457 tonnes.

- We worked with James Fisher Nuclear to install a replacement remote arm that is used to recover fuel, debris and blockages in the building.

9. Operating the site

Sellafield is home to thousands of buildings and thousands f people. Operating the site 24 hours a day, every day of the year means that we have to provide many of the same services and provide the same infrastructure that you would expect to see in a small town.

9.1 Site management

Logistics

We have established a receipt and distribution centre away from Sellafield in order to co-ordinate deliveries to the site and reduce the number of heavy goods vehicles using the public road network close to the site.

Utilities

We manage and maintain our own network of utilities and services, from power and water to waste.

Services

Our diverse network of services, such as catering, emergency services, refuse and laundry are essential to the 24/7 operation of Sellafield.

Transport

Thousands of people work on the Sellafield site. Keeping them and the site moving relies on our road, rail, transport, and traffic management.

Emergency preparedness

Our emergency response teams and workforce practice emergency procedures every week.

Security

We employ the services of two security forces at Sellafield, the Civil Nuclear Constabulary and the Guard Force, to protect the site, our employees and our nuclear materials.

9.2 Radioactive waste management

We reduce waste volumes arising as part of our current activities and historic operations and ensure the waste is stored safely, minimising the risk to the public and environment.

Our strategy

Sellafield is the only UK nuclear site that has the facilities, experience and expertise to safely manage all three levels of radioactive waste: low, intermediate and high.

Low level waste is compacted and sent for disposal at the national Low Level Waste Repository.

Some intermediate level waste is mixed with a grout material in engineered stainless steel drums to form a solid, stable form suitable for long-term storage and disposal.

High level waste is dried to a powder, mixed with glass and heated to form a molten mixture that is then poured into stainless steel containers and allowed to solidify. The vitrified waste is then placed into a specially engineered Vitrified Product Store pending final disposal in the UK or returned to its country of origin.

9.3 Progress in 2016/17

New waste building takes shape

The plant which will treat some of our most hazardous nuclear waste now has a heart. The project team working on the Box Encapsulation Plant has taken delivery of and installed the two main effluent system vessels vital to treating waste. The two vessels were manufactured by Bendalls of Carlisle and lifted into the building using a 10-tonne construction crane. When complete, the building will give us the capability to treat nuclear waste recovered from the Magnox Swarf Storage Silo. It will immobilise the waste and prepare it for long-term storage.

Reusing our plants

Our Waste Encapsulation Plant was originally designed to support reprocessing work. The team in the plant believed they could also play a major role in accelerating the retrievals mission. This year the plant received and encapsulated radioactive sludge that had been retrieved from the Pile Fuel Storage Pond. The end of reprocessing is no longer the end of the useful lives of our plants, it is merely a transition from one important mission to another.

New interim waste store

We have more than 200 Zeolite skips that need to be removed from the First Generation Magnox Storage Pond. Zeolite is a material that was used in skips to extract the caesium from the pond water.

Our original plan was to take the skips out of the pond still full of water, transfer them to a new facility – the Box Encapsulation Plant – drain them of water and then grout them inside a box, at which point they would be suitable for storage ahead of final disposal in a geological disposal facility. However, the Box Encapsulation Plant won’t be available for several years.

Meanwhile, the Berkeley nuclear site has developed an alternative approach to intermediate level waste; interim storage in boxes that not only provided containment, but also radiological protection. Following in its footsteps, our new plan for the zeolite skips is to lift them out of the pond full of water, place them directly into specially manufactured self-shielded boxes and then store those boxes in an interim waste store.

The shielding provided by the storage box means it can be stored in a relatively simple (and therefore quick to build) building like the one constructed at Berkeley, rather than a heavily shielded structure.

High level waste returns continued

We continued to work with International Nuclear Services and its subsidiary Pacific Nuclear Transport Limited to repatriate vitrified high level waste to its country of origin. Returning this waste to overseas customers fulfils contractual obligations and also UK government policy, which states that the waste from reprocessing contracts signed since 1976 should be returned to the country that benefited from the reprocessed fuel.

This year the Vitrified Residue Returns programme saw us consign our sixth shipment to Japan and our second, and final, shipment to Switzerland.

New ventilation stack gets to work

This year we switched on a new ventilation system, meaning that work could get under way to remove a 61 metre stack that sits on top of the First Generation Reprocessing Plant. The new ventilation system includes a three-storey building, two and a half miles of stainless steel duct and pipe bridges and a new 122-metre-tall chimney.

10. Safety and Security

Within the Sellafield nuclear licensed site we have teams of people working at height, in radiological areas, on construction projects, and on demolition projects. They are working 24/7 and cheek-by-jowl with teams operating nuclear reprocessing and waste plants. Other teams are moving nuclear materials around the site on our complex road and rail network. All of this happens on a footprint that covers just 2 square miles.

Keeping our workforce, supply chain partners, facilities and the environment safe is our priority

10.1 Safety

Keeping our workforce, supply chain partners, facilities and the environment safe is our priority.

It is a relentless pursuit that requires the focus and attention of everyone involved at Sellafield, every day.

As a large organisation with employees working on a large industrial site and in offices in Cumbria and Warrington, one of our measures of safety performance is conventional safety statistics.

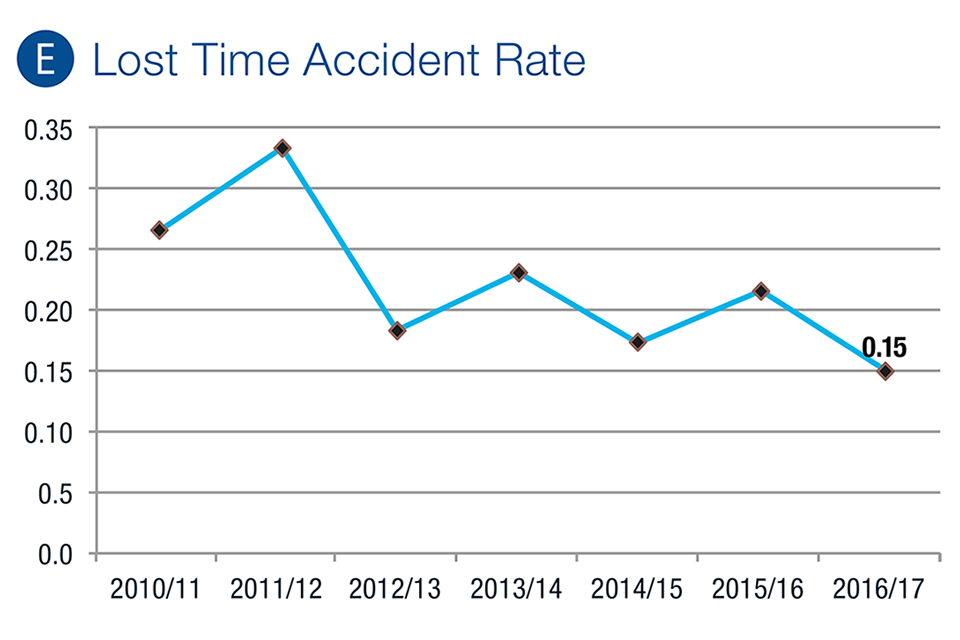

We also measure our safety performance in terms of nuclear, environmental and radiological safety. One of the ways that we look at conventional safety is through lost time accidents, which is the amount of time that any employee is absent as a result of a safety event. In 2016/17 our greater than one day lost time accident performance was our best ever rate, but this is still not good enough.

We have undertaken a safety peer review of our performance through the UK Nuclear Operators Safety Directors’ Forum that focused on identifying any organisational factors that might be impacting our safety performance. We will also be benchmarking our performance and safety arrangements against those with world-class safety performance.

10.2 Security

Keeping our site, our people and our community safe depends also on security and resilience.

Physical and cyber security, business continuity and emergency preparedness all help us manage risk, enhance our response capability and, of course, meet our legal and regulatory obligations.

We operate in an increasingly challenging security environment, and our approach is focused, ambitious and integrated. At the heart of this is our security culture, supported by appropriate assurance and professional development; this underpins our various achievements in the past financial year, including:

- the close out of 138 recommendations within the Sellafield resilience programme

- the completion of our new outer perimeter boundary

- the introduction of emergency management warehousing and logistics, providing easy access to essential equipment in the unlikely event of an emergency

- the construction of our new emergency response facility got underway

- the introduction of additional cyber response and detection capability, meaning we can detect and prevent cyber-related attacks on our business.

10.3 Safety performance in 2016/17

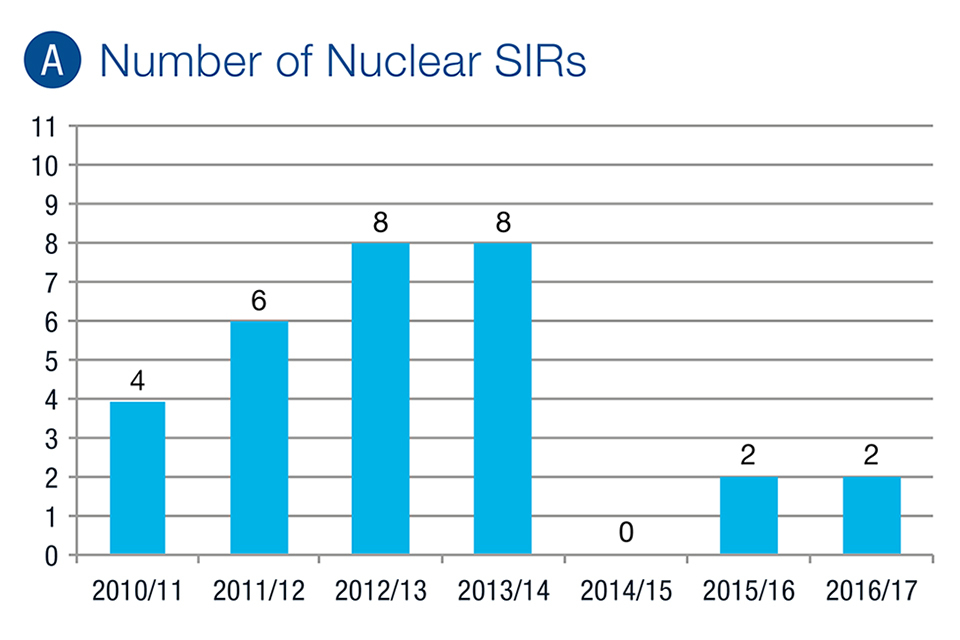

A - Number of Nuclear SIRs

Number of Nuclear SIRs

Note: This metric represents the number of nuclear incident reports categorised as significant under our sentencing scheme. There were two nuclear SIRs recorded this year. One involved the fall of a non-irradiated fuel assembly (see INES Level 1 event below). The other involved a non-irradiated fuel assembly being suspended during lifting operations.

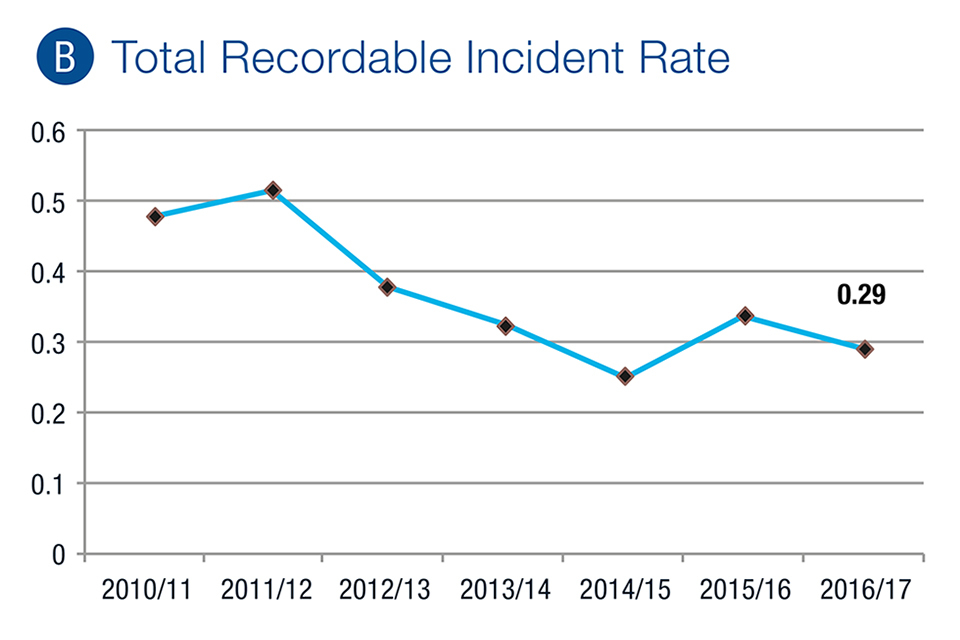

B - Total Recordable Incident Rate

Total Recordable Incident Rate

Note: This records the rate of all recordable injuries including medical treatments, lost time accidents, and RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) reportable injuries.

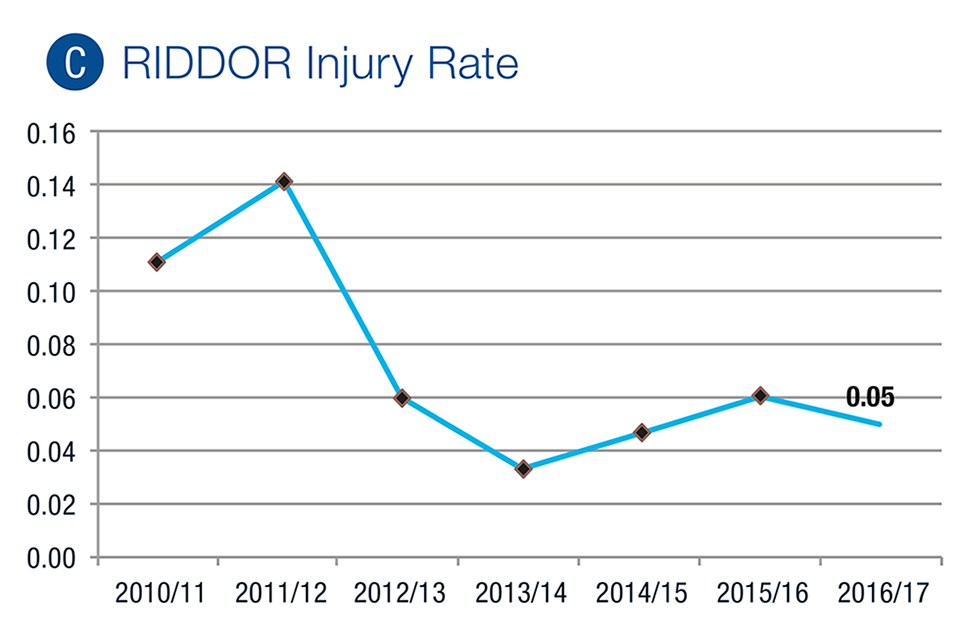

C - RIDDOR Injury Rate

RIDDOR Injury Rate

Note: This metric records the rate of RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) injures which result in employees being away from work from more than seven days, and Specified Injuries.

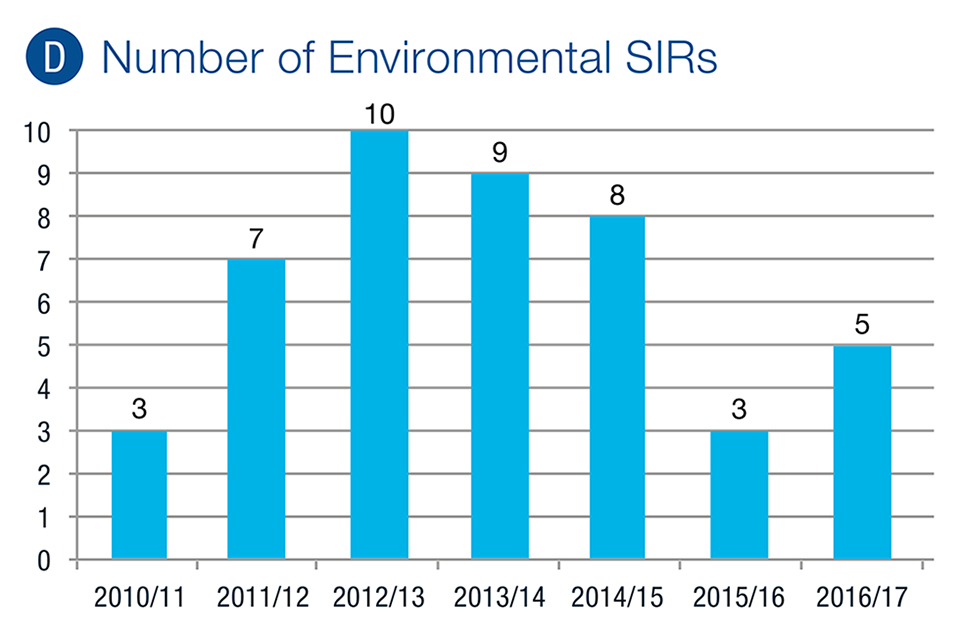

D - Number of Environmental SIRs

Number of Environmental SIRs

Note: This metric represents the number of environmental incident reports categorised as significant under our sentencing scheme.

The 5 recorded were:

- diesel powered compressor omitted from register

- a chemical used for decontamination purposes was not included in our non-radiological discharge conformance paperwork

- a small amount of nonradioactive grout washings entered a surface water drain listed within Sellafield Ltd’s non radiological environmental permit for the discharge of storm water only

- a small volume of post-analysis chemical samples were disposed of via Sellafield’s surface water drainage system

- a small release of treated effluent has entered the site’s drainage network and subsequently the river Ehen, from one of the site’s settlement tanks.

Details on these can be found on our incident reports page

E - Lost Time Accident Rate

Lost Time Accident Rate

Note: This metric records accidents which result in individuals being away from work for more than one day.

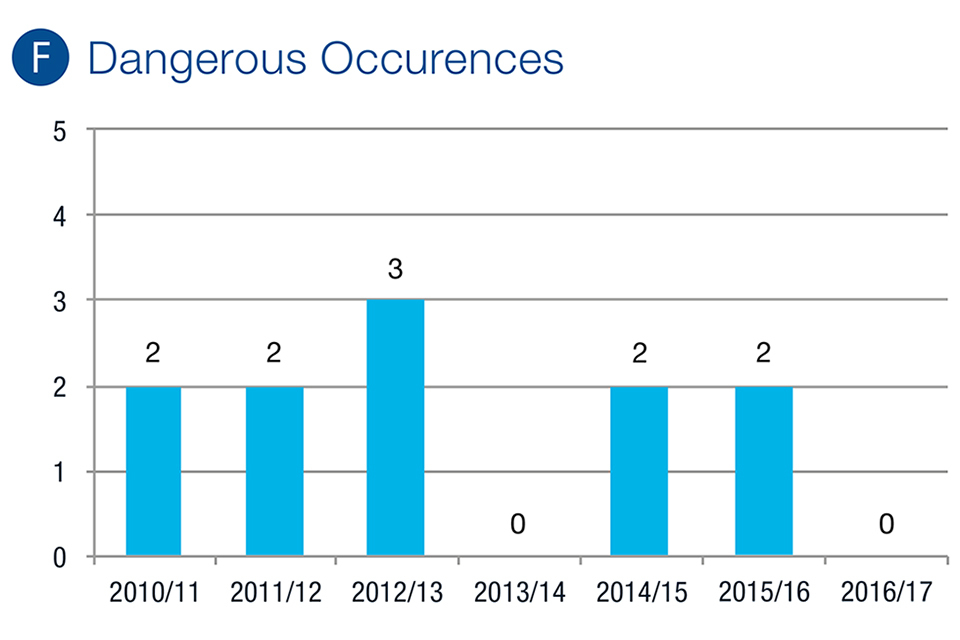

F - Dangerous Occurences

Dangerous Occurences

Note: This metric records the number of RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) Dangerous Occurrences.

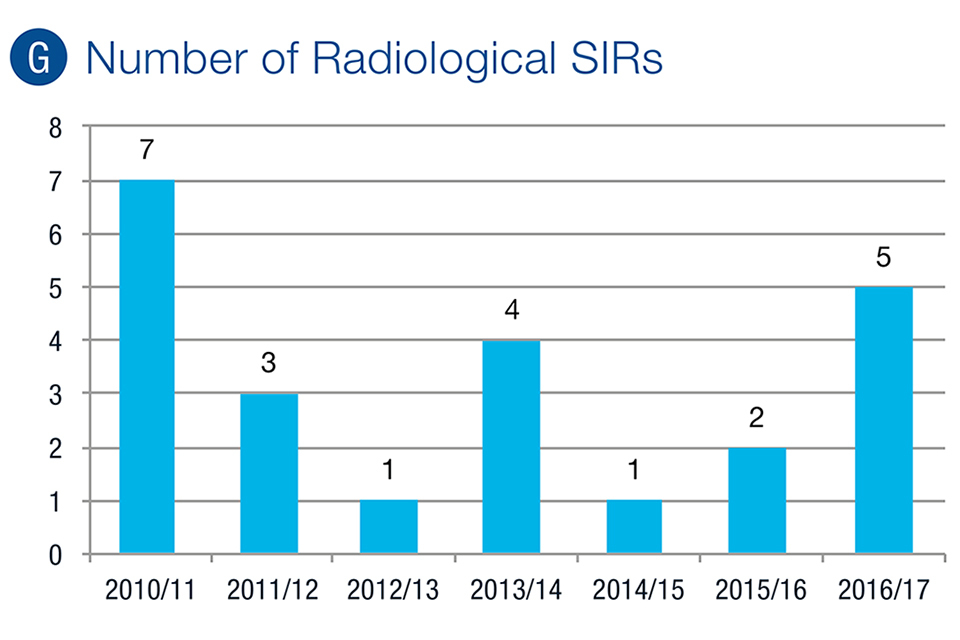

G - Number of Radiological SIRs

Number of Radiological SIRs

Note: This metric represents the number of radiological incident reports categorised as significant under our sentencing scheme. There were five recorded this year. Three of these were INES Level 2 events (reported below).

The remaining two SIRS were:

- during routine operations in a waste metals recycling facility, a small area of contamination, measuring roughly 2mm in diameter, was found on the floor. There was no contamination of personnel or material

- whilst carrying out routine work in our analytical laboratories, a bottle containing uranium and nitric acid was knocked over causing a small spillage onto the work bench and the floor. As a result there was a small area of contamination. There was no harm to the employees and no radiological or environmental consequences. Details on these can be found on our incident reports page.

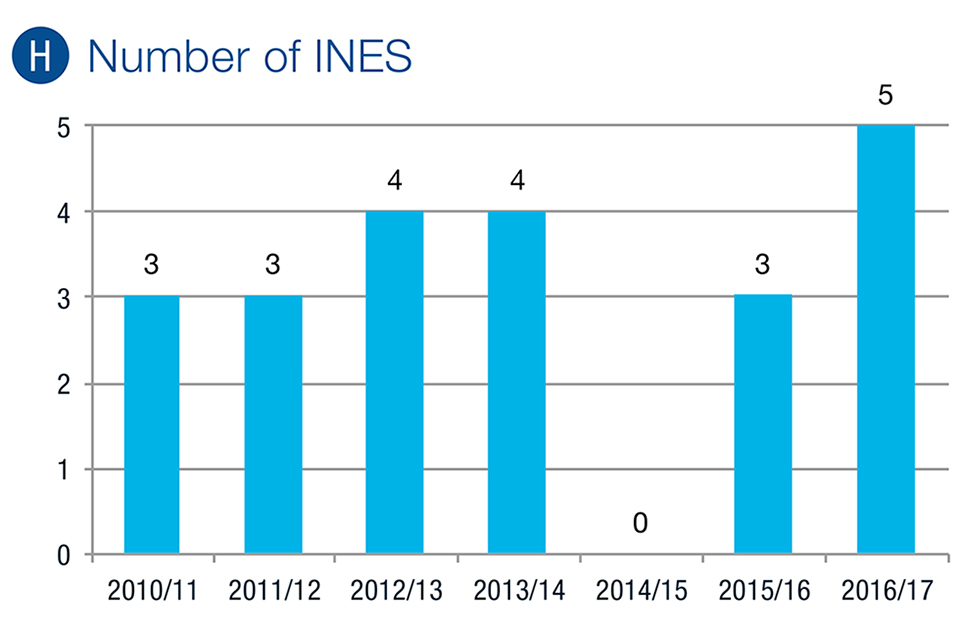

H - INES Events

Number of INES

The International Nuclear and Radiological Event Scale (INES) is a rapid alert system used for consistent communication of events across the nuclear industry. These are categorised between Level 1, which is anomaly, to Level 7 which represents a major accident.

In 2016/7 we had three INES events rated Level 2 and two events rated as Level 1.

Level 1 event, May 2016 – fall of non-radiated fuel assembly. While lowering a non-irradiated fuel assembly, it became detached from its lifting adaptor and fell less than 1m into its storage canister. There was no harm to employees and no radiological or environmental consequences.

Level 2 event, August 2016 – Triggering of personal alarm during digital imaging. Two operators were carrying out digital imaging of legacy crates, using X-ray equipment to identify the contents, when their electronic personal dosimeters alarmed during screening operations. The incident took place in a redundant reprocessing facility.

Neither of the operators received a significant radiation exposure and there was no release of radiation to the environment. This was assessed as a Level 2 rating because of degraded defence-in-depth operation arrangements.

A management investigation concluded that radiation measured on the electronic personal dosimeter was due to the X-ray generator, rather than from ambient radiation levels in the cell, or originating from the crates in storage.

Level 2 event, January 2017 – Personal contamination event. One of our employees was contaminated during highly active sampling operations in the Magnox Reprocessing Plant.

The employee became aware of this contamination during routine monitoring, when leaving the plant. They reported for health physics investigations and subsequently attended the site surgery where the contamination was removed through chemical washing.

It has been assessed that the external dose to the hand the individual received was greater than the annual dose limit detailed within the Ionising Radiation Regulations.

As a result of the investigation, changes have been made to improve the process. In addition, we have carried out observations of the task and are confident that the individuals carrying out the process are suitably qualified and experienced.

Level 1 event, February 2017 –Electrical fault in calibration centre. During the routine calibration of monitoring equipment in the Health Physics Instrument Calibration Centre an electrical fault occurred which caused the system to stop working. This caused a radioactive source to be exposed inside a shielded cell and elevated levels of radiation were detected, while the shield door was open, triggering an alarm.

Trained operators closed the system down, and the source was lowered back into a shielded enclosure. No-one was in the area where the elevated levels were detected, and there were no safety implications.

Level 2 event, February 2017 – Personal wound contamination. While carrying out routine work in a glove box wearing protective clothing including latex gloves, an employee felt a pain in their hand and immediately called our health physics team for assistance.

The individual attended the site surgery where the wound was monitored and dressed. A follow up monitoring assessment a few weeks after the initial injury identified a small point of contamination which required further medical intervention to remove the contamination.

A provisional dose estimate indicates that the dose received is greater than the statutory annual dose limits. An investigation is under way.

11. Skills mix

Our mission at Sellafield is a magnet for people in all disciplines who want to be part of nationally-important work. For those people who thrive on facing challenges and pioneering new solutions, we offer all that, and more.

Growing our own talent

Growing our own talent

We are committed to continuing to grow our own talent.Our graduate and apprentice schemes provide a pipeline of new talent and the numbers speak for themselves. We welcomed 137 apprentices and 46 graduates into our organisation in 2016/17 and the next cohort are in training. We have also widened our range of opportunities for apprenticeships beyond the traditional engineering disciplines to include business management and health physics.

We are proud of our apprenticeship programmes and the attitude, work ethic and skills of the young people who take up the opportunity every year.

A workforce fit for the future

A long-term view of resource needs

Our support to training doesn’t stop at providing employment for the next generation of nuclear workers. We believe in making long-term strategic investments that will provide young people in our communities with access to state-of-the-art training facilities, raising their aspirations, meeting our long-term resource needs and helping to address the long-term skills shortage beyond our own needs.

This year we have seen work get under way on the new National College for Nuclear with ground breaking at the northern hub at Westlakes College and the southern hub at Bridgwater and Taunton College. We are proud to stand with our industry partner EDF Energy to help make this flagship college a reality.

We also opened the doors on the new Project Academy for Sellafield; a collaboration between ourselves and the University of Cumbria. The range of training and education developed for the academy is available to all individuals andcompanies. The academy is for the benefit of the whole region and will help develop skills across all areas of project management from entry to executive level.

At secondary school level we were delighted to celebrate the achievements of West Lakes Academy who received an ‘Outstanding’ rating from OFSTED. We collaborated with the NDA and the University of Central Lancashire to establish the academy which opened its doors in September 2008.

Reskilling and redeployment

The reality of coming to the end of our reprocessing mission at Sellafield means that there are roles across the business that we will no longer need. We are not waiting until the Thorp and Magnox plants stop reprocessing in 2018 and 2020, we are addressing the issue now. Already, 28 people from operations have moved into new roles to support the commissioning of the new Box Encapsulation Plant and Box Encapsulation Plant and Product Store/Direct Import Facility buildings. This is part of a larger group of employees redeployed in 2016/17.

Following an expression of interest in opportunities in the project management profession, the first cohort of employees are due to start their training at the Project Academy in September 2017.

Equality, diversity and inclusion

Providing meaningful and rewarding employment and career opportunities has always been at the heart of our talent management. This year we also looked at the kind of organisation that we want to be.

We are a large organisation with a challenging and complex mission, which will require contribution from all our people. We will expect the best from them. They should expect the best from us.

We are developing a working environment in our organisation in which we:

- are recognised as an inclusive employer

- treat our skilled and diverse workforce with respect and integrity

- recognise and value the contribution ade by everyone, irrespective of age, gender, or other personal characteristics.

As we change our business and ways of working, we rely on the contribution, performance and innovation of our leaders and workforce to deliver that transformational change.

We will lead and engage our teams effectively to make sure people feel comfortable to be themselves at work, with equality of opportunity for all, free from any form of discriminatory behaviour or process. In this way we will maximise our effectiveness, deliver our mission and create a positive and successful future.

A workforce fit for the future

Over the past 12 months we’ve made changes to terms and conditions for new starters with the business which bring us in line with other comparable companies. This put us in a better place for the future by reducing the cost of staffing in the medium to longer term.

We are also in the process of changing our grading structure so that our employees have the opportunity to be rewarded for the work they do in a fairer and more equitable way.

12. Innovation

Cleaning up our nuclear facilities and making sure that our ageing plants and equipment continue to be available to safely complete our work requires a balance of cutting-edge technology and fit-for-purpose innovations. It also demands a mix of in-house capability, supply chain expertise and collaboration between the two.

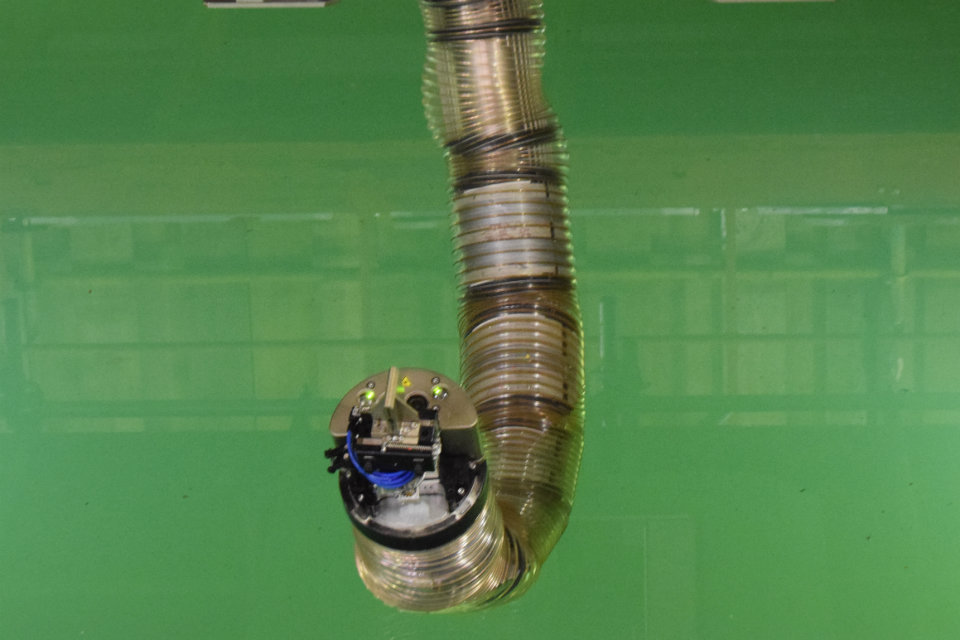

A snake-like robot arm

Here are some of our major innovative approaches deployed in 2016/17.

Innovation Centre

Nestled in our engineering workshop at Sellafield, a new innovation centre is giving our teams the space to develop new approaches and freedom from our standard processes during prototyping and development. State-of-the-art design tools, software and prototyping machinery such as 3D printers, 3D scanners and electronic circuit prototyping machines sit alongside conventional tools and equipment.

Suck it and see

An innovative use of a household storage solution has been put to work at Sellafield to help deal with the storage of asbestos soft waste. Items like protective clothing worn in asbestos risk areas are packaged for disposal in 200-litre drums and traditional methods meant that those drums could hold only three bags, with each bag holding four suits. In comparison, vacuum packages can hold 40 suits, and three of these packages can fit inside the drum. This approach has increased the storage by a factor of 10.

National Nuclear Laboratory collaboration

We share a history, knowledge and expertise with the National Nuclear Laboratory. The fact that our facilities on the Sellafield site are physically integrated means that our futures are inextricably linked – this has been recognised in a long-term collaboration agreement. Together we will either develop new technologies or source them from external suppliers in order to accelerate our clean-up mission using cost-effective and innovative research.

Sonic boom

This year we used sonar mapping to reveal what is in one of the most challenging and congested areas of the First Generation Magnox Storage Pond. The tangle of material in an area of the pond meant that it was inaccessible by remotely operated vehicles. Now we have been able to replace prediction with precision, thanks to the sonar mapping work of our Barrow-based supplier, Fortis Remote Technology. Their sonic probes fire millions of pulses which shape incredibly detailed 3D images in a ‘point cloud’, which produces pictures of the complex conditions of legacy wastes. The team can use this information to plan how to empty and decommission this area of the pond far more effectively.

Laser sampling

There was a time when the idea of a robot wielding a laser was the stuff of sci-fi, but these days we are equipping our robots with laser technology, speeding up the sampling of materials, while reducing radiation doses to our employees. Developed through the Innovate UK project by Viridian Consultants, the process sees an infrared laser being used to remove samples from a contaminated surface, which can then be collected for testing. The laser light is delivered to the sampling head through a 20-metre-long fibre optic cable and the sample is collected via a vacuum line. It can be used manually or attached to a remotely operated vehicle known as the WallRover.

Laser snake

A snake-like robot arm has been added to our decommissioning tool kit. The arm is capable of spanning gaps of up to 4.5 metres unsupported, making it ideal for working in confined and hazardous spaces. The snake is driven by wire ropes and can be used for laser cutting, inspection, fastening and cleaning operations. The project, funded by the NDA and the Department for Business, Energy and Industrial Strategy and delivered by OC Robotics Ltd and the Welding Institute Ltd, has been successfully tested in our First Generation Reprocessing Plant.

13. Project Delivery

Our clean-up mission at Sellafield requires new buildings that can hold waste, sludge or fuel, or that can process nuclear waste into stable forms for storage and, ultimately, disposal. We will also need replacement infrastructure as we need to operate the nuclear site for many decades to come. We must do this with due regard to the environment.

We need new assets to be available on time, to be fit-for-purpose and to be delivered with nuclear safety, security and value for money as our key considerations.

The key building blocks of our project delivery improvements include:

- upskilling of our employees through the Project Academy for Sellafield

- establishing the intelligent client team

- engaging programme and project partners

- removing waste from our design processes

- removing waste from construction logistics

- creating state-of-the-art project tools and systems.

13.1 Highlights in 2016/17 included:

Programme and Project Partners

We started the process of engaging long-term supply chain programme and project partners. We will work together in a project environment where both our organisation and our partners can grow and develop our skills and improve our collective project delivery performance. Our partners will provide project management and controls, engineering design, construction and inactive commissioning delivery capability.

Project Academy for Sellafield

We have opened the doors to a new Project Academy for Sellafield, creating a centre of excellence for the development of project delivery skills. It will allow us to create the capability to deliver projects by providing people with education, training and professional qualifications.

Intelligent client

We are using the Infrastructure and Projects Authority’s ‘Improving Infrastructure Delivery: Project Initiation Routemap’ as the best practice guidance reference point to assess, design and develop our intelligent client capability.

Skills

Our investment in the future of project management has continued with:

- 38 project management apprentices spread across 4 cohort years

- 43 project management graduates either in or recently finished their training

- 69 project managers successfully completing their professional accreditation at Registered Project Professional level, with another 30 in progress. This is more than any other UK company.

13.2 Project delivery 2016/17

Sellafield Product and Residue Store Retreatment Plant

A new facility that will provide safe and secure storage for nuclear materials. Progress this year included:

- meeting the requirements of the concept design review point

- awarding a contract with the Design Service Alliance to deliver the preliminary design

- starting enabling works on the site of the new plant, including: – drilling 13 boreholes (9 of which went right down into bedrock) and digging 6 silt trenches. The data from this work will inform the final structural design – designing the relocation of a substation that sits on the construction site

- awarding a contract with Graham Engineering Ltd to develop ‘100 year packages’ that will be used to store materials in the new building.

Replacement Analytical Project

A project to provide us with a new analytical capability, replacing a 60-year-old facility. Progress this year included:

- completing the studies stage of the project, concluding with a decision to modify the existing National Nuclear Laboratory’s Central Laboratory on site to provide our future analytical capabilities.

Evaporator D

A new highly active liquid evaporator that will extend our existing evaporative capability. Progress this year included:

- we started inactive commissioning of the facility and demonstrated that the throughput performance of the evaporator will meet the demands of reprocessing and Post Operational Clean Out work.

Box Encapsulation Plant

A new facility that will handle and treat intermediate level nuclear waste. Progress this year included:

- completing 70% of the detailed design

- successfully completing the functional acceptance test of the building’s mast manipulator

- establishing a project office, providing co-location for our team and our supply chain partner, epC.

Box Encapsulation Plant Product Store Direct Import Facility

A new facility that will provide medium term storage for intermediate level nuclear waste. Progress this year included:

- competing the detailed design phase of the project

- completing civil works that supported the steel superstructure build

- starting the superstructure steelwork installation.

Interim Storage Facility

A new facility which will store self shielded containers of intermediate level nuclear waste. Progress this year included:

- progressing directly to detailed design phase by using a Magnox Ltd reference design for an above ground intermediate level waste store

- taking the project from 26% complete to 70% complete

- achieving £4.3 million of savings.

SIXEP Contingency Plant

A new facility that will replace the effluent treatment function of the existing Site Ion Exchange Plant by 2024. Progress this year included:

- completing the preliminary design on schedule.

Silos Maintenance Facility

A new facility that will provide the capability to store, decontaminate, maintain and change over retrieval equipment and tool/waste packages used in retrieval of waste from the Magnox Swarf Storage Silo. Progress this year included:

- completing the bulk civil construction

- installing a commercial, off-the-shelf construction crane

- installing a permanent sub-station providing main power to the facility.

Sellafield Security Enhancements

A series of interdependent security enhancements. Progress this year included:

- installing hostile vehicle mitigation measures

- completing the site perimeter intruder detection system upgrade

- started physical works on the new Main Site Command Facility.

14. Collaboration

The Sellafield mission is too big and complex for us to achieve on our own. We need the expertise, skills and technology of our supply chain partners, the authorisations and permissions of our regulators and the support of our community.

One of our stakeholders are local, regional and national media.

14.1 Supply chain

In order to deepen our collaboration with our supply chain partners we are starting to work differently. We are entering into longer-term relationships, working in shared spaces and on shared goals. We are also raising our expectations of our supply chain partners so that we can achieve a greater social impact from the money spent on the Sellafield mission.

Long-term relationships

We have awarded some long-term contracts across our main areas of delivery, creating the opportunity to deepen our relationships with suppliers, to work collaboratively and to accelerate the rate at which we get work done on the site.

These collaborative alliances and frameworks include:

- Decommissioning Delivery Partnership: a 10-year commercial framework agreement with six lot Delivery Partners, each made up of a consortium of suppliers that we can call upon as required to support decommissioning tasks and projects.

- Design Services Alliance: a 15-year commercial framework agreement to provide specialist design, engineering and safety case assessment services.

- Infrastructure Services Alliance:a 10-year commercial framework to provide a range of essential infrastructure asset services to the Sellafield site, including steam generation, water supply and electricity generation.

- Programme and Project Partners: We have started the procurement process to bring together four partners to collaborate with one another and with us to deliver the portfolio of major projects at Sellafield over the next 20 years.

We will use the expertise of these partners to help improve the outcomes of major projects, to help develop our delivery capabilities, and to bring about site-wide project delivery improvements.

There will be four partners, each appointed to carry out a specific role. These are:

- integration partner

- design and engineering partner

- civils construction partner

- process construction partner.

In the context of this arrangement, we will have two different roles: first and foremost as Intelligent Client; and secondly as delivery partner – the fifth partner.

Maximising our social impact

We work with more than 600 suppliers every year. In 2016/17 we spent more than £1 billion with these suppliers. Collaboration therefore must stretch beyond the boundaries of the nuclear site so that we work together to achieve the greatest benefit for the community and economy.

This year we introduced social impact into more of our procurements, setting an expectation of our supply chain partners and then a contractual mechanism which can be used to monitor delivery. We are focusing on those procurements that have the potential to deliver additional value to the local area. This is not a one-size-fits- all approach as we need to weight procurements appropriately to deliver the outcomes we need for our mission and transformation programme.

Regulators

A collaborative group – known as the G6 – was formed in 2014 and brought together representatives from the key decision makers for our mission.

Each organisation maintains its independent roles and responsibilities in relation to work at Sellafield, but we also work together to identify ways of safely and securely accelerating hazard and risk reduction at Sellafield.

Together we are removing barriers, applying fit-for-purpose solutions, saving money and accelerating delivery.

15. Stakeholder engagement

We engage with our many stakeholder groups in a variety of formal and informal settings. These range from employee engagement sessions and meetings with local and regional and national authorities to ongoing dialogue with our regulators and suppliers.

We are committed to ongoing stakeholder engagement. As active members of the communities in which we operate, we want to play our part in strengthening and diversifying our local economies.

Although we tailor our communication to make it appropriate for our broad range of stakeholders, it is always based on openness and transparency.

15.1 Our stakeholders

The nature of our work means that a broad range of stakeholders are interested in and can influence what we do at Sellafield. These stakeholders include:

- employees and their union representatives

- regulators

- national and international nuclear operators

- supply chain

- local, regional and national authorities

- local and regional communities

- local, regional and national media

- the independant scrutiny group, the West Cumbria Sites Stakeholder Group

- non-governmental organisations

- academia

- trade organisations.

We are the legal entity responsible for Sellafield, which is owned by the NDA

15.2 Stakeholder engagement in 2016/17

The value of stakeholder engagement is the strength of the relationships we create and the difference that we can make together. Like any successful long-term relationship, ours rely on openness, trust and require time and commitment. Here is a snapshot of our engagement in 2016/17:

Employees

As well as routine team engagement, across the organisation we hosted:

- 12 monthly team4action discussion and cascade meetings

- 54 executive roadshow events

- 41 executive-led round table discussions

- 3 all-hands briefings

- 8 employee forums chaired by our Chief Executive Officer; and

- we answered 497 questions via our online ‘Ask the Exec’ intranet function, gaining valuable feedback from all of these to shape onward engagement.

Site visits

We welcomed 1,923 visitors through our site gates during the year. They came from Europe, Asia and Australasia to see the progress we are making, to learn from the work we are doing or to familiarise themselves with the site.

West Cumbria Sites Stakeholder Group

We attended 4 main committee meetings and more than 20 sub-committee meetings throughout the year to give an update on our work and to answer any questions from the committee or members of the public. This group provided responses to relevant consultations, including the NDA’s strategy and business plan.

Local and regional authorities

We meet regularly with representatives from local parish councils, Copeland Borough Council, Allerdale Borough Council, Warrington Council and Cumbria County Council. In 2016/17 we took part in more than 40 discussions with these groups.

15.3 Achievements

Sharing our expertise

In February 2017 our strategy and technical director, Rebecca Weston, was invited to talk to the House of Lords science and technology select committee. During the two-hour session she answered questions on the future of nuclear policy, gave her view of what a sector deal for the nuclear industry might look like, and offered her thoughts on what the future of Euratom might be in a post-brexit world.

Engagement with our Chief Executive Officer

We set up an employee engagement forum last year to complement the existing range of engagement opportunities. A group of employees meets up with Paul Foster every six weeks to discuss a broad range of topics such as company performance, changes, and issues and bring views and feedback from colleagues in their different areas of the business. The rules of engagement are very informal – employees bring to the group topics they’d like to discuss, and share experiences and our CEO seeks out opinions on changes, current and potential, in the company.

Collaborative approach

We continue to work as part of G6; a group that brings together the six key organisations involved in the Sellafield mission and facilitates a co-ordinated approach to complex issues on the site, where input may be required from a broad range of decision makers.

The approach is not only delivering progress on the site, but is attracting international recognition as the way to collaborate to achieve risk and hazard reduction.

16. Governance

We are a company licensed under the Nuclear Installations Act 1965 and holder of the nuclear site licence for the Sellafield site. We are the legal entity responsible for Sellafield, which is owned by the NDA.

We are responsible for ensuring that our activities are carried out:

- safely, securely, reliably and predictably with due regard to the environment

- to the satisfaction of the NDA

- in the long-term interests of our organisation, our employees, the local community and our supply chain.

Our Board and Executive

Our Board and Executive Our Board sets our strategic aims and provides the leadership to put them into effect. It delegates authority to the Chief Executive Officer or to Board Committees but is still accountable to the NDA for those decisions. The Board includes non-executive directors who provide independent oversight and challenge.

Accountability for the day-to-day management of our business is held by the Chief Executive Officer, supported by the executive team. The Executive oversees the implementation and delivery of short to medium-term strategic decisions for the business.

16.1 The Board

Chair

Tony Fountain took up the role of Chair for Sellafield Ltd on 1 April 2016 as part of the new management arrangements which saw Sellafield Ltd become a wholly owned subsidiary of the NDA. Tony brings 30-years of industry experience, having held key roles within BP and more recently having spent a highly successful period leading Reliance Industries’ refining and marketing business in India. Tony also brings valuable knowledge of the nuclear industry, having been CEO of the NDA from 2009 to 2011.

Non-executive Directors

-

Nigel Smith a highly-experienced senior executive with deep technology and industrial sector expertise, he has previously worked in HM Treasury as Permanent Secretary, Board Member and Chief Executive of the Office of Government Commerce. Prior to HM Treasury he was Chief Executive Officer of a number of International FTSE and global industrial businesses. He is also a Non-Executive Director of Sepura Plc and Obillex Ltd

-

Dr Dolores Byrne OBE is a Chartered Engineer and has served as a Vice-President and Trustee of the Institution of Engineering and Technology and is currently Chair of the IET Impact Engineering Fundraising Campaign. She is also a Non-Executive Director at Rail Safety and Standards Board. She has held senior executive positions in private and public sector engineering and technical services organisations in the defence and aerospace and security sectors

-

Rob Higgins is the Shareholder nominated non-executive director for Sellafield Ltd. He is also the Nuclear Decommissioning Authority’s business services director. He is a chartered civil engineer and a solicitor. Rob was legal director of Atkins and before qualifying as a solicitor worked for 12 years as a civil engineer in infrastructure construction

-

Anne-Marie Choho started her career with AREVA in France 29 years ago. After 3 years as a research and development engineer, she held several engineering positions in France in nuclear fuel reprocessing, nuclear waste treatment, and mixed oxide fuel fabrication projects. In December 2016, Anne-Marie was appointed Deputy CEO of the SETEC Group, an engineering and project company operating in the transportation, urban infrastructure, water, energy and environment field

-

John Baxter CBE has worked in the energy industry for over 40 years covering nuclear, electricity and latterly oil and gas. He trained as a Royal Navy Engineer Officer serving at sea on nuclear submarines, worked for the United Kingdom Atomic Energy Authority where he was involved in all aspects of the nuclear industry, including running the Dounreay and Windscale nuclear sites and AWE, was a UKAEA Board member and also a Director of Nirex Ltd; he was then head of engineering for the UK electricity utility, Powergen plc, followed by a similar role at BP plc.

Chief Executive Officer

Paul Foster joined the company in 2000 having spent most of his early career in the steel industry. He’s previously held senior roles within the business including chief operating officer, decommissioning director and infrastructure director.

Paul is responsible for leading, managing and developing all activities across our business, including directing our executive in delivering our strategic objectives.

Programme and Finance Director

Jon Seddon has over 30 years’ experience in finance leadership roles, change and profit turnaround with complex national and international industries in both the private and public sectors.

Jon is responsible for the Enterprise Portfolio Office and Independent Assurance Group, internal audit, the finance organisation, corporate planning, Nuclear Shared Business Services and the Information Services organisation.

16.2 The Executive

General Counsel and Company Secretary

Andrew Carr is a specialist nuclear regulatory lawyer with significant experience of managing legal issues at a national and international level throughout the nuclear fuel cycle.

Andrew’s responsibilities include leading the provision of specialist legal advice and insurance support to the business, supporting the Board with corporate governance and compliance and being the executive lead for Hinton House in Warrington.

Supply Chain Director

Martin Chown has a strong background in responsible procurement, both in the public and private sector. His experience stems from roles within the Cabinet Office and Balfour Beatty. He has also held senior roles with GSK (GlaxoSmithKline), Toyota and Varity Perkins.

Martin is responsible for the implementation of the supply chain strategy which ensures the safe, reliable and predictable operation of the business against the operations, corporate and baseline plans.

Projects Director

Steve Livingstone is an MBA graduate from the University of Manchester’s business school. He is responsible for the delivery of multi million pound projects. He has extensive experience in all aspects of major project delivery having worked in the oil and gas industry, as Project Director at Heathrow Airport on the successfully delivered Terminal 2: The Queen’s Terminal and as Delivery Director for Hinckley Point C.

Transformation Director

Angela Seeney worked previously in the Oil and Gas Authority as Director of Technical, Decommissioning, Supply Chain and Data. Before that she spent 28 years with Shell in a variety of roles, driving business transformation yielding multi-billion pound returns on investment. A consistent focus in her work has been developing performance and prospects for employees as well as partners and the organisation.

Human Resources Director

Colin Reed has over 30 years’ experience working in mainly Human Resources for a range of large companies, including shipbuilding, engineering, support services and energy. He spent a period with British Energy and then EDF energy. His experience includes shipbuilding, engineering, support services and energy including a period with British Energy and then EDF Energy.

Colin’s responsibilities focus on the leadership role along with the HR and training functions required to support the business.

Waste Retrieval Director

John Oliver has more than 30 years’ experience in the energy sector, where he has delivered a diverse range of major projects around the world. Most recently he led a major programme to expand one of the world’s largest oil and gas fields, in Kazakhstan.

John is responsible for leading the business across legacy ponds and silos in order to safely deliver the targets in our operating plan.

Chief Operating Officer

Steve Bostock has over 26 years’ experience in complex, high-hazard chemical waste processing facilities, from project conception through steady-state operations. He has domestic and international experience in nuclear energy, chemical manufacturing and environmental remediation industries.

Steve is responsible for reprocessing, waste management, remediation and vitrification as well as site infrastructure.

Security and Resilience Director

Mark Neate has considerable experience in the multi-national arena, including strategic work dealing with security, political, legal, policing and economic issues in high-threat environments.

Mark is responsible for security and resilience, which also incorporates emergency management and information security.

Technical Director

Rebecca Weston has wide experience across the business and has held leadership positions in Operations, Technical and Commercial.

Rebecca is responsible for the technical strategies for Sellafield Ltd and the science, technical and engineering solutions and standards across the business, ensuring the business makes and creates optimum technology choices and develops the science, technical and engineering skills and capabilities needed now and for the future.

Environment, Health, Safety and Quality Director

Euan Hutton has held a number of roles with the business, including programme manager in Environment, Health, Safety and Quality (EHS&Q) and then later deputy director of EHS&Q and head of EHS&Q decommissioning respectively.

Euan is responsible for leading and developing all EHS&Q activities across the business, enabling the company to deliver nuclear safety, conventional safety, environmental, safeguards, occupational hygiene, radiological protection and quality activities in accordance with all legislative, regulatory and company policy requirements.

Chief Engineer

Steve Cockayne has held a variety of lead roles within the company, including engineering and operations within the high-level waste plants and Thorp.

Steve is responsible for leading the enterprise plant engineering department, which delivers plant engineering strategies for the site, in addition he provides an asset management and site maintenance strategy assisting in providing informed asset funding allocations.

Corporate Director

Andy Smith has 20 years’ experience in the Nuclear industry having joined BNFL in 1997 as an engineering graduate from Imperial College, London. He started his career in engineering and manufacturing roles at Sellafield before moving on to fulfill a number of senior roles across the company at various UK sites. Andy joined the Sellafield Executive team as Site Integration Officer in 2013, taking up his current post as Corporate Director in October 2016.

Head of Development and Community Relations

Jamie Reed joined Sellafield Ltd as the Head of Development and Community Relations in 2017 after spending twelve years as the Member of Parliament for Copeland.