The First-Generation Reprocessing Plant

The First-Generation Reprocessing Plant is one of the oldest buildings at Sellafield, dating back to the military origins of the site.

Far right - The First Generation Reprocessing Plant on the Sellafield site.

We’re keeping this ageing facility safe and secure as we clean it up in preparation for decommissioning and demolition.

The challenge

Sellafield has been at the forefront of pioneering nuclear technologies for almost 80 years.

The site opened in 1947 with a single mission; to produce plutonium for Britain’s nuclear deterrent.

In 5 short years, thousands of engineers, architects and construction workers designed and built a fully operational nuclear facility known as Windscale.

This included Britain’s first nuclear reactors; the Windscale Piles, as well as the Pile Fuel Storage Pond, the Pile Fuel Cladding Silo, and the First-Generation Reprocessing Plant.

These legacy buildings remain at Sellafield to this day and represent some of the most difficult and hazardous decommissioning challenges on the site.

Originally known as the Primary Separation Plant, the First-Generation Reprocessing Plant was commissioned in 1952 and performed the first stage of reprocessing for uranium fuel rods used in the Windscale Pile reactors.

The building is 61 metres tall and made up of 6 processing cells. It also originally housed a huge 61 metre tall ventilation stack on its roof.

Used fuel would be transferred from the reactors to the Pile Fuel Storage Pond for cooling and processing, then on to the First-Generation Reprocessing Plant to undergo a ‘butex’ chemical separation process to remove the plutonium.

Early reprocessing technology used a gravity-fed system to transfer dissolved fuel between vessels, meaning the building needed to be considerably taller than more modern reprocessing plants that used pumps.

The plant was operational until 1964 and processed over 5,229 tonnes of fuel.

Following the Windscale fire and closure of the Windscale Piles in 1957, it continued to receive fuel from other reactor UK reactors.

Today it represents a unique decommissioning challenge for which there is no blueprint. The ageing plant is situated in one of the oldest and most congested parts of the site making conventional clean-up and demolition techniques difficult or impossible.

The solution

The solution is to keep the plant safe and secure while we prepare it for decommissioning.

Removal of the stack from the top of the building was a key priority, as it posed a seismic risk to other nuclear buildings nearby.

The stack at reduced height

We also have to balance working on this plant with other priority decommissioning projects on the Sellafield site.

Until we fully decommission the building we need to continually monitor and maintain it to keep it safe.

| Benefits: | To reduce risk and hazard and safely prepare for decommissioning. |

| Status: | Currently partially decommissioned. |

Progress so far

We’ve already partially decommissioned the plant, including the major milestone of removing the stack from the top of the building.

This was complicated as other neighbouring plants had become reliant on the stack for their ventilation as the site had grown over the decades.

Before we could remove it, we had to build a completely new ventilation system – the 120 metre tall Separation Area Ventilation Stack (SAV), which was commissioned in 2016.

The Separation Area Ventilation Stack

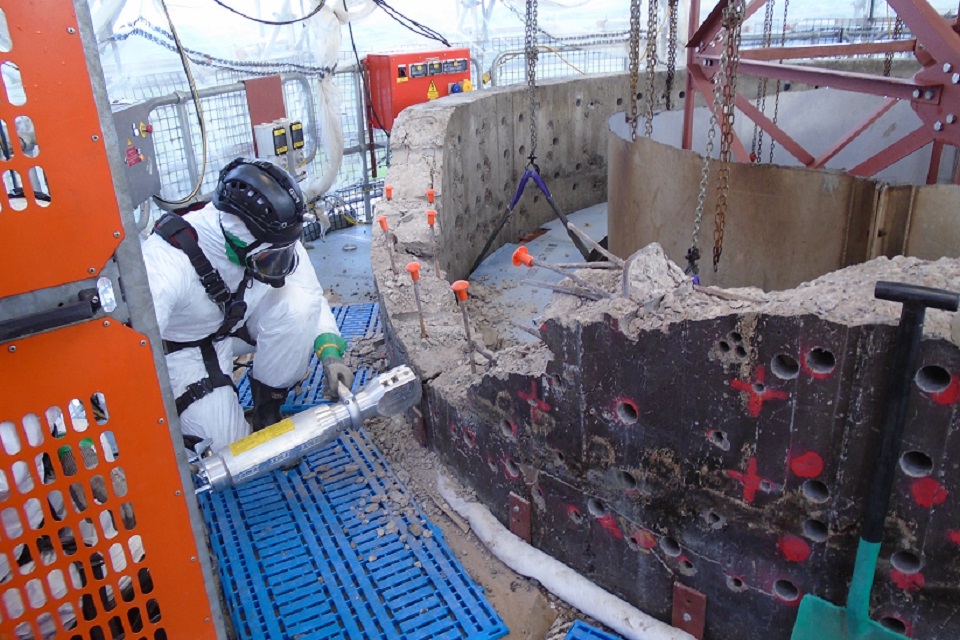

It then took nearly 2 years to reduce and cap the old stack from 61 metre to 0.5 metre, requiring the removal of 300 tonnes of concrete and 50 tonnes of steel.

The stack was successfully removed in 2019, marking a major milestone in reducing the hazard.

FGRP ventilation stack demolition

Now we’re cleaning up the rest of the plant to get it ready for full decommissioning and eventual demolition.

Examples include stabilising steel structures with aerated grout to make it easier to cut and remove it in the future, and using sugar solution to help fix contamination to surfaces and reduce potential airborne hazards

We’ve also removed a dissolver vessel using diamond wire cutting techniques and successfully demonstrated the use of a laser snake robotic cutting tool in the plant, the first of its kind on a UK nuclear site.