Promethean: nanoparticle products go into full-scale production

Nottingham University spin-out builds on €10 million multi-partner EU project to enter global market in novel inks, paints and coatings.

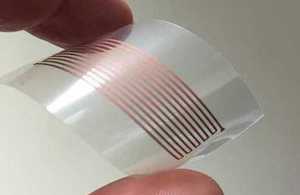

Finger tips holding a flexible, clear plastic printed with a copper-based nanoparticle conductor

Scaling up: a nanoparticle adventure

Scaling up: a nanoparticles adventure

A Nottingham-based nanomaterials business is launching straight into global markets with commercial-scale production of a range of inorganic nanoparticle products, including conductive inks.

Promethean Particles Ltd, spun out from Nottingham University in 2008 and supported by EU innovation funding, is targeting specialist markets with its proprietary inks, paints and coatings.

They include printed electronics, adsorbent materials and other applications where nanoparticles can be used to modify conductivity, hardness, optical, mechanical or fire-retardant properties, even in plastic or composite systems.

A step change for the industry

Operating from a new, full-scale nanomaterial production facility, Promethean will first be manufacturing batches of a metal organic framework material, a metal oxide and a metallic nanomaterial. These products will be available for purchase through its website.

Chief executive officer Laurie Geldenhuys said:

This is a step-change for the UK nanomaterials industry.

This plant is the culmination of a collaborative effort with consortium partners both in the UK and the wider European economic area, highlighting the importance of maintaining strong ties to the EU technical community.

Promethean's production plant can produce 1,000 tonnes of material annually.

The company succeeded in developing a low-cost, continuous flow process for producing nanoparticle materials after joining a consortium that was awarded €10 million under the EU Framework 7 funding programme for a project called SHYMAN.

There were 4 employees at the start of the project in 2010 and that number has grown to 10, with further expansion planned over the coming months.

SHYMAN helped to take Promethean’s proprietary technology from pilot-scale to a plant capable of producing more than 1,000 tonnes annually.

Pipeline of customers

Partners included Solvay (Belgium), PPG (France), Repsol (Spain) and FIAT (Italy) as well as universities from Ireland, Spain, the Czech Republic and Poland, all world leaders in their field.

This consortium of materials developers, modellers, analytical specialists, formulators and end-users covered the complete value chain, also helping to develop a pipeline of future customers for Promethean.

The project also raised Promethean’s profile and helped to generate business leads through market-specific events, trade shows and scientific conferences.

Updates to this page

-

First published.