Review of the Year 2021/22 - Creating a clean and safe environment for future generations

Published 22 September 2022

1. Foreword from the chair

Tony Meggs, Chair, Sellafield Ltd

We must deliver value for our public funding

The board is acutely aware that the money invested in our work every year comes from the public purse, and of the need to demonstrate value in return for the investment which could otherwise be diverted to other public services.

Historically, the value of our work at Sellafield was measured in kilowatt hours of electricity produced, or the commercial price of reprocessed fuel.

Now it is measured in our ability to place nuclear waste into containers that are safe for the long-term, to remove intolerable risks to our environment, and to nurture the diverse skills our nuclear community needs.

It is also measured in our ability to increasingly deliver our work with greater certainty of schedule and cost, particularly in our major construction projects.

The complexity of our work and the nature of our unique radiological challenges makes that difficult, but the board and I are pleased with the progress made this year.

Safety is our overriding priority at Sellafield. The site’s performance in nuclear safety was good this year, with strong performance noted in environmental safety and radiological safety. However, there was a decline in conventional safety performance.

The board fully supports the executive and leadership teams’ focus on improving this area of safety performance.

A further challenge for the business in 2022/23 is to improve our operational performance, as defined by targets set with the Nuclear Decommissioning Authority. Performance this year was mixed with some key targets missed.

I am pleased to see in this report that the value of our work at Sellafield also continues to be felt beyond Sellafield, in our supply chain and in our communities.

Seventy-five years ago, Sellafield helped to create the nation’s nuclear deterrent.

Today, we’re using our unrivalled knowledge of nuclear to create a clean and safe environment for future generations.

2. Foreword from the Chief Executive Officer

Martin Chown, Chief Executive Officer

We exist to create a clean and safe environment for future generations

The need for nuclear power as part of a secure, sustainable low-carbon energy mix for the UK has never been clearer. Our role, more vital than ever, is to demonstrate that nuclear waste can be safely managed, and the legacy of the UK’s first generation of nuclear power can be safely and efficiently decommissioned.

In 2021/22 we have taken consistent steps towards creating a clean and safe environment for future generations.

Since the turn of the financial year those steps have turned into leaps.

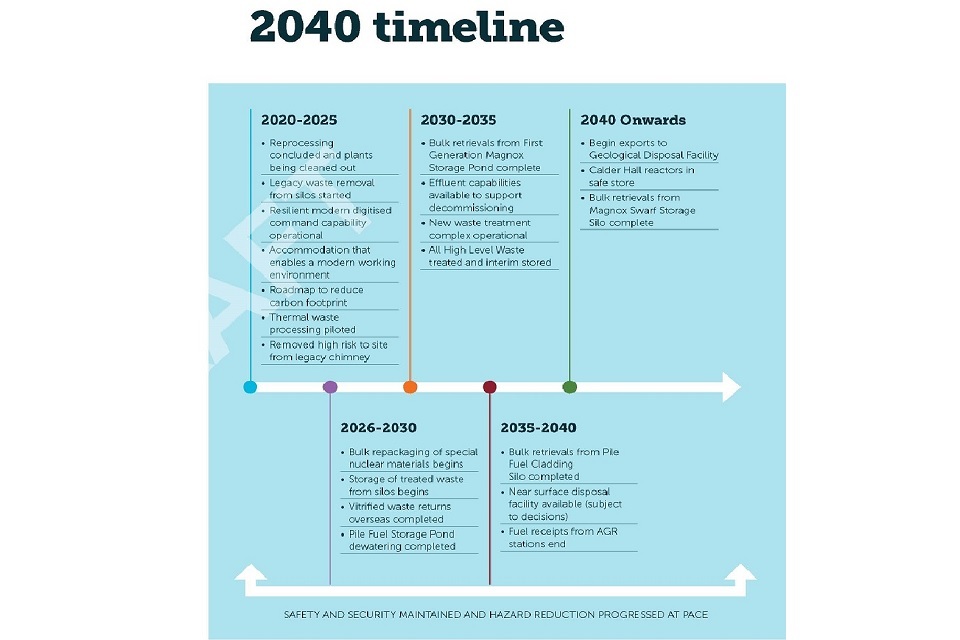

Reprocessing, an activity that has defined our work and value since the site started operations in the 1950s, is now complete. We are retrieving radiated waste from legacy waste silos that date back to the same period.

As a result of these activities, we have one of the largest portfolios of national infrastructure projects which are changing the Sellafield skyline.

Decommissioning means economic growth, not decline. Thousands of supply chain partners from hundreds of companies of all sizes are helping us and in turn, exporting to the global decommissioning market.

We are creating jobs not unemployment. Hundreds of apprentices and graduates have joined us in the last twelve months, joining the thousands that came before them.

Making Sellafield Ltd a great place to work, and a consistently diverse and inclusive employer, remained a priority for us this year and will continue to be an area of focus for me and my executive.

The social and economic benefits of our work and the social impact investments we are making with our community partners have the potential to create generational change.

This report shows the value of our work at Sellafield, delivered on behalf of our owner, the Nuclear Decommissioning Authority.

I am proud of what we have delivered at Sellafield. What we will do in the next 2 years will shape the next 20 and I am excited about the opportunity this offers us.

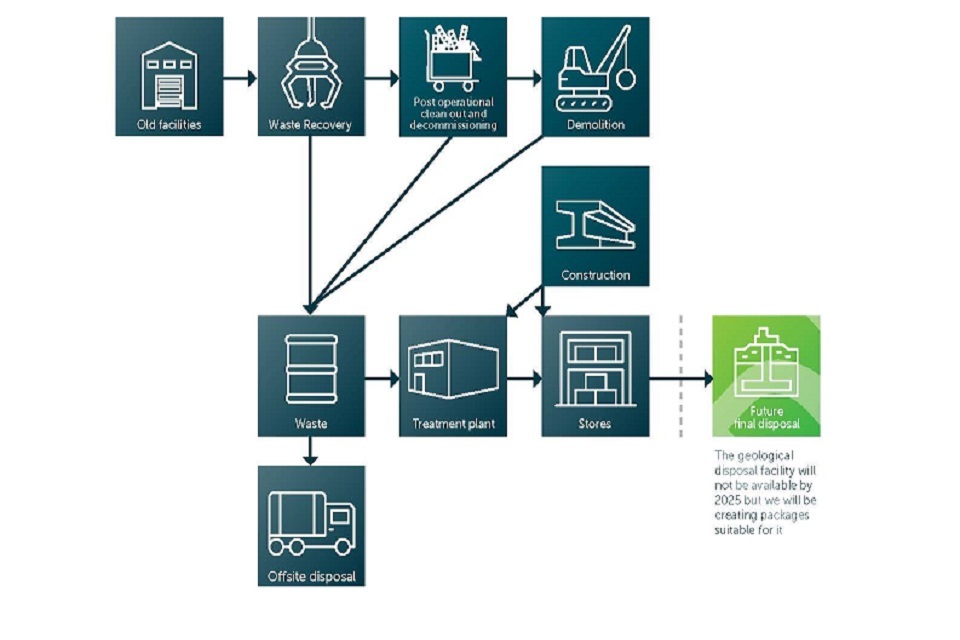

3. The next 3 to 5 years at Sellafield

Sellafield will change over the next 3 to 5 years. We are currently investing in one of the largest portfolios of complex major projects in the country, creating the facilities we need for the next stage of our purpose.

Our retrievals programmes are transitioning into a regular drumbeat of large-scale operational activities, establishing the process of recovering, treating and packaging waste.

Similarly, we will move from small scale repackaging in our special nuclear materials facilities into a long-term production process.

The next 3 - 5 years at Sellafield

By 2025 we will:

- make Sellafield a great place to work by living and breathing our manifesto behaviours

- demonstrate our nuclear professionalism by our visible pride in our operational environment

- work in an agile and adaptive way using digital technology

- create shared confidence in our programme and major project delivery

- have much greater understanding of the value and cost of our operations

- recognise and share expertise across the NDA group

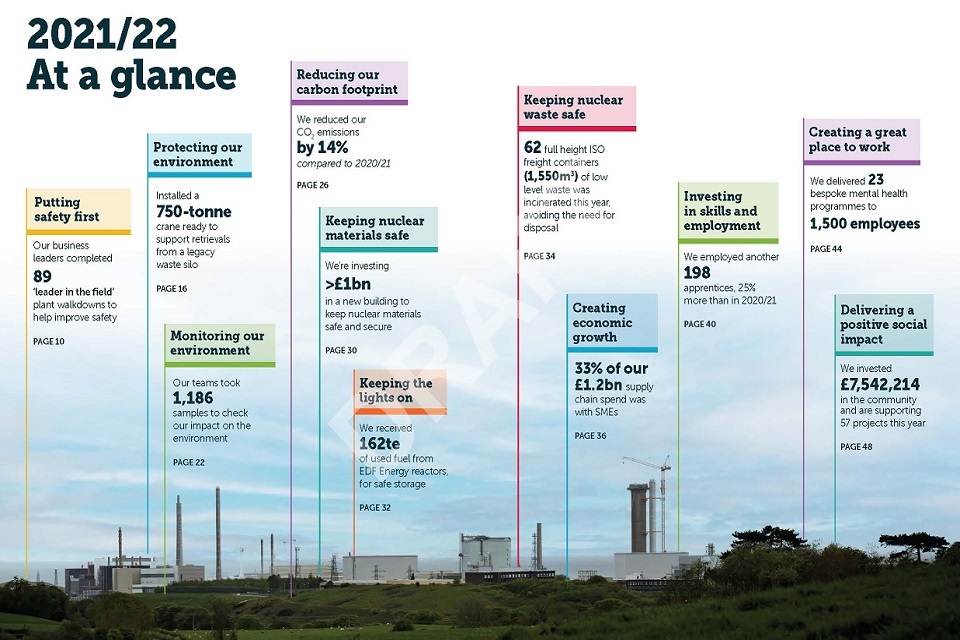

2021/22 at a glance update

A challenging year

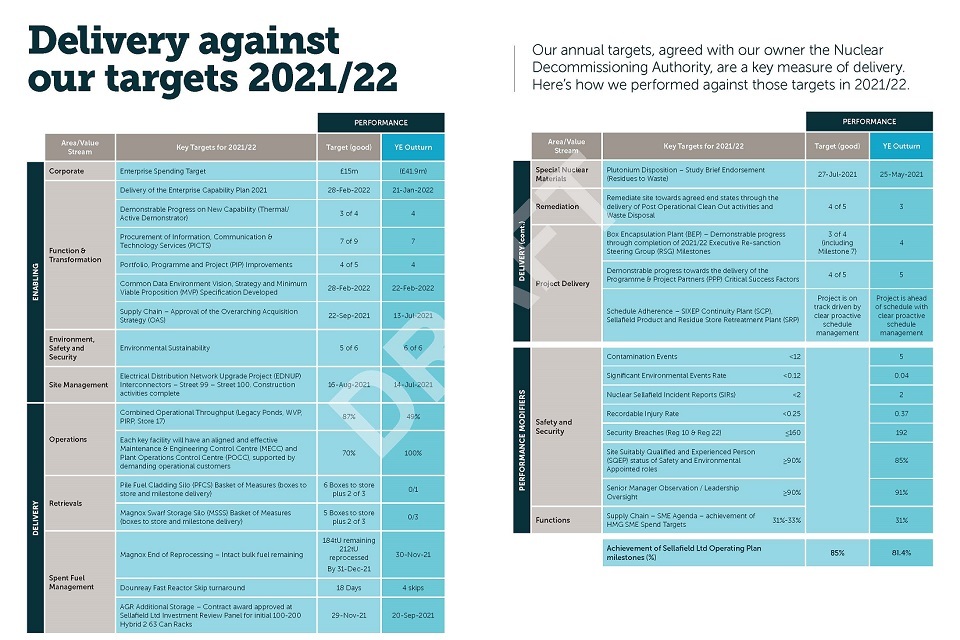

One of the ways that we measure progress in any financial year is our performance against specific delivery targets that are agreed with the Nuclear Decommissioning Authority.

The targets for 2021/22 are shown on the following sections.

This was another challenging year for our operations at Sellafield.

Our CEO Martin Chown said:

I’m proud of the way we are continuing to progress our important work across the whole organisation.

Maintaining our consistent operations has often been difficult, as shown by the missed combined operational throughput target. This is down to several factors that are particularly affecting retrievals from our legacy storage ponds and production in our vitrification plant. Improvement plans are already underway to help us do better in maintaining our operational throughput in 2022/23.

We did not start waste retrievals from the two legacy silos before the end of the financial year. It’s disappointing, but it reflects the complex nature of starting this work for the first time. The key thing is to start when it is safe and ready to do so.

I appreciate the efforts of the teams involved; we ended the financial year very nearly ready, and I am pleased to say that we retrieved the first flask of waste from the Magnox Swarf Storage Silo at the start of the 2022/23 financial year.

We can also celebrate our excellent performance in delivering our environmental sustainability targets. We’ve had success in progressing the work on our major projects alongside our supply chain partners and we also achieved the 2 individual throughput targets in special nuclear materials.

Overall, we have made important progress in the last 12 months in creating a clean and safe environment for future generations. We have performed with passion, pride and pace and embraced the other themes in our manifesto in the way we all work with each other.

Performance against agreed safety targets is covered in more detail further down this document

4. Delivering against our targets

Here’s how we performed against those targets in 2021/22.

Our annual targets, agreed with our owner the Nuclear Decommissioning Authority, are a key measure of delivery. Here’s how we performed against those targets in 2021/22.

Delivery against our targets 2021/22

5. Putting safety first

We are committed to safety, and keeping our workforce, supply chain partners, local communities, facilities, and environment safe.

Nuclear safety is our overriding priority at Sellafield because of the potential significant consequences from a nuclear safety event. However we focus on all aspects of safety as they are interconnected.

That means we focus on nuclear safety, environmental safety, radiological safety, and conventional safety. Our performance against each of these categories is covered in the tables on the following pages.

Performance against the nuclear safety performance indicator was good over the year. On radiological and environmental safety, there was strong performance during 2021/22 in both areas and a low level of events against company targets.

Performance against our conventional safety targets deteriorated when compared to 2020/21. Our accident- related safety metrics exceeded the corporate targets. The majority of these accidents resulted from things like slips, trips and falls associated with routine work, rather than large high-risk tasks.

In line with our aim for all people working at Sellafield to go home safely every day, we are focused on improving our conventional and nuclear safety performance.

We measure our safety performance against industry best practice at a national and international level, aided through our membership of the World Association of Nuclear Operators (WANO), and through various Key Performance Indicators.

We have a safety performance improvement process to identify gaps, analyse for (and prioritise) resolution and close the gaps. This approach aligns the behaviours inherent to a learning organisation and a healthy nuclear safety culture.

The programme comprises 3 work streams:

- Corrective action programme

Risk-based approach to progressing condition reports, for the reporting, screening (sentencing), investigating and correcting of issues.

- Trending programme

Routine trending and analysis of condition report data in order to identify underlying weaknesses and prioritise opportunities to close gaps, make improvements, and establish sustainable solutions for the business.

- Operating experience programme

Learning from internal and external issues is shared and used to prevent or minimise similar causes occurring and avoid making similar mistakes.

Improving safety

One of the ways we can improve safety at Sellafield is through taking a fresh look at the work being undertaken.

That can be done by leaders from elsewhere in the business and by bringing in external experts from the wider nuclear industry.

In 2021/22 we had…

10 interactions with WANO - including visits to the Pile Fuel Cladding Silo and our high level waste plants

89 leader in the field’ observations where members of the leadership complete safety walkdowns of different areas of the Sellafield site.

We use these metrics and others to scrutinise our performance, identify areas for improvement and put plans in place to close gaps to achieving excellence (all metrics correct at the time of publication).

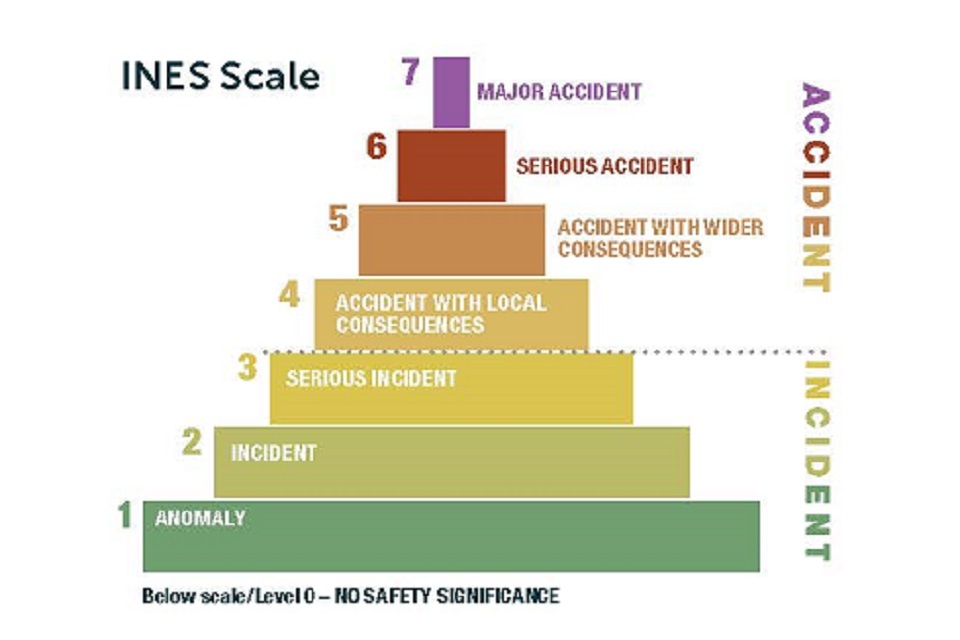

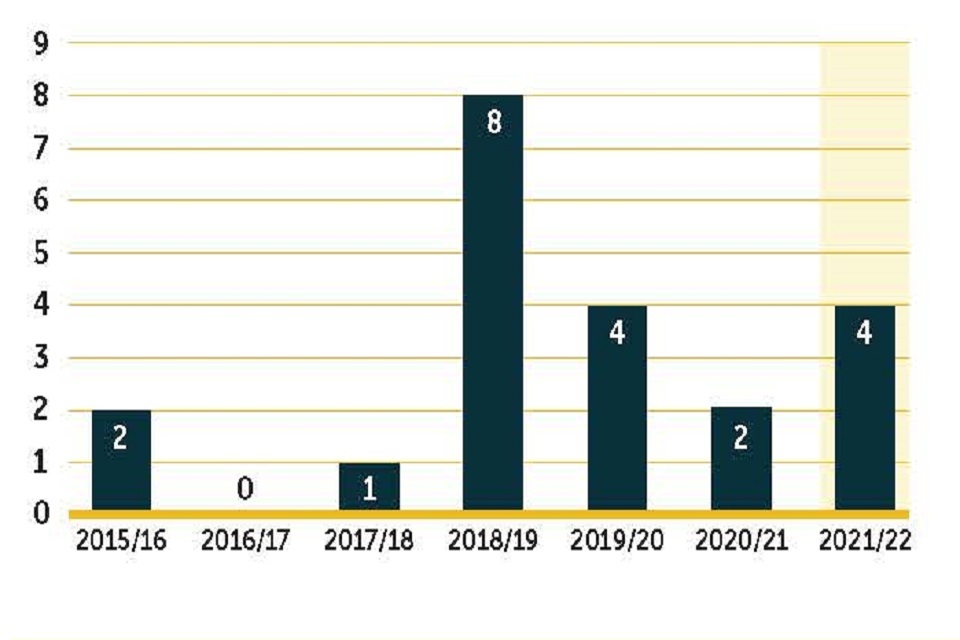

INES Events

The International Nuclear and Radiological Event Scale (INES) is a rapid alert system used for consistent communication of events across the nuclear industry.

These are categorised between Level 1, which is an anomaly, to Level 7 which represents a major accident.

See INES scale.

There were 2 INES events in 2021/22.

INES Scale

INES Events

Small fire in building

A small fire in a building associated with the Magnox Reprocessing Plant at Sellafield was quickly extinguished by the Sellafield Fire and Rescue Service.

The building occupants were alerted to the fire – which was associated with plastic scaffolding boards within the area – via the building fire alarm and they evacuated the facility in line with emergency instructions.

Once the fire was extinguished the fire crew confirmed that there was no further risk, and a facility team then carried out a controlled shutdown of equipment in the building.

The follow-up investigation identified a number of operational improvements. These have now been implemented and recovery work carried out including repairs to electrical cables.

There were no injuries and no nuclear, radiological or environmental safety issues. Sellafield Ltd has liaised with the Office for Nuclear Regulation regarding the event.

Sellafield Ltd rated this event as an INES (International Nuclear and Radiological Event Scale) Level 1 (minor problems with safety components with significant defence in depth remaining)

Potential gap in criticality

During inspection of the criticality detection system in the Magnox Reprocessing plant at Sellafield, a number of detectors were identified as not fit for purpose.

A review of the system was immediately initiated and a programme of work completed to address the issue which included repositioning a number of detectors.

There was no risk to our workforce or the community, and we have engaged with our regulators.

Sellafield Ltd rated this event as an INES (International Nuclear and Radiological Event Scale) Level 1 (minor problems with safety components with significant defence in depth remaining).

Sellafield Incident Reports

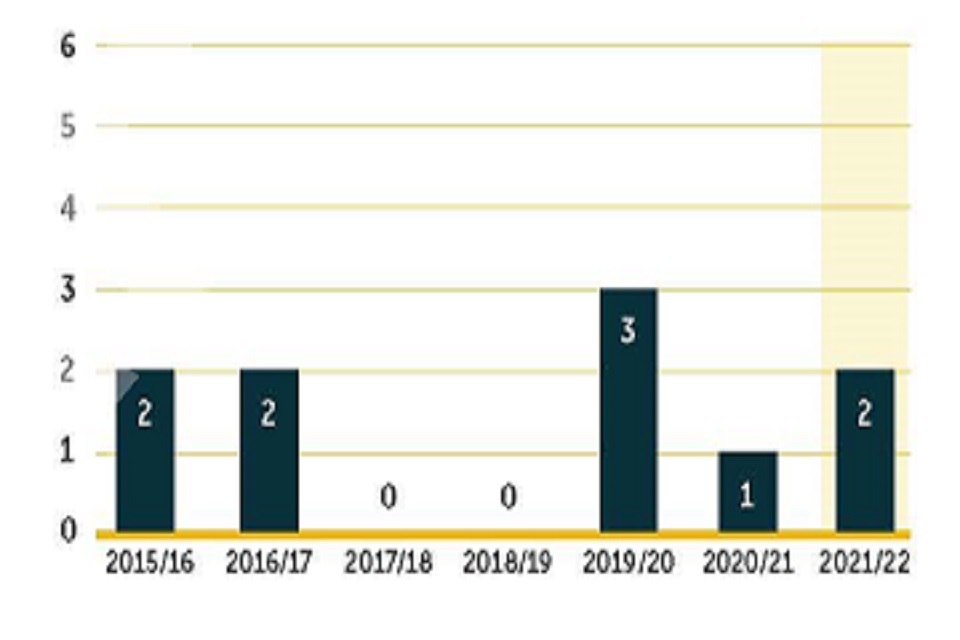

Nuclear SIRs

This metric represents the number of Nuclear Site Incident Reports (SIRs) which are nuclear events categorised as significant under our sentencing scheme.

There were 2 recorded during 2021/22.

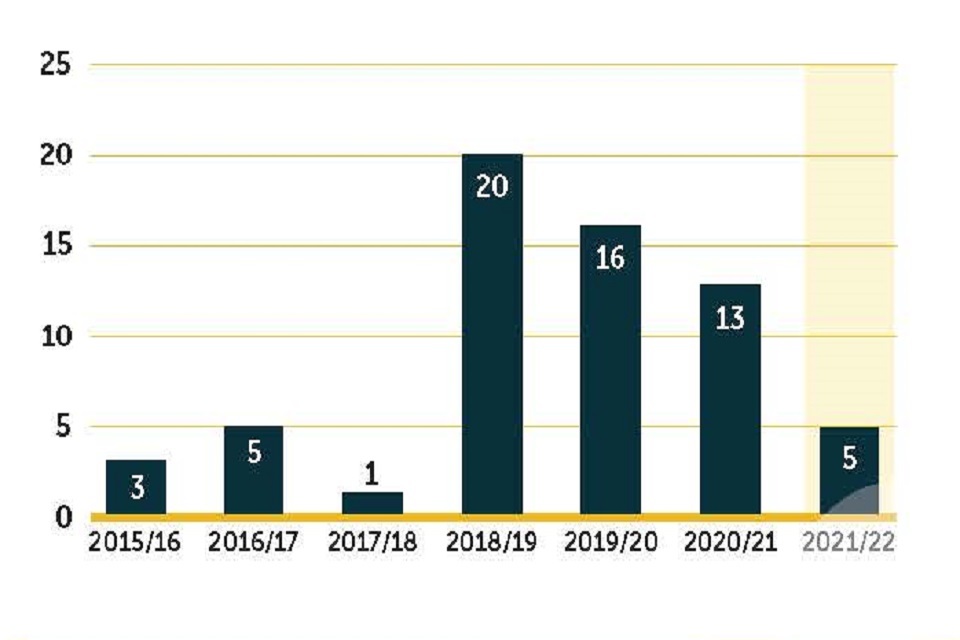

Nuclear SIRs graph

Potential gap in criticality emergency plan

For details, see INES section.

Telephone system impact

A new telephone system used at Sellafield experienced operating difficulties resulting in an intermittent impact to the system.

Impacts across the Sellafield site were not uniform, however the pager system and computer-based communications remained unaffected. In the Magnox Reprocessing Facility both the telephone system and analogue telephone land lines were lost, and precautionary measures were put in place.

An inquiry was carried out and the work to upgrade the telephone system has been completed.

There was no safety consequence and no requirement to use emergency arrangements.

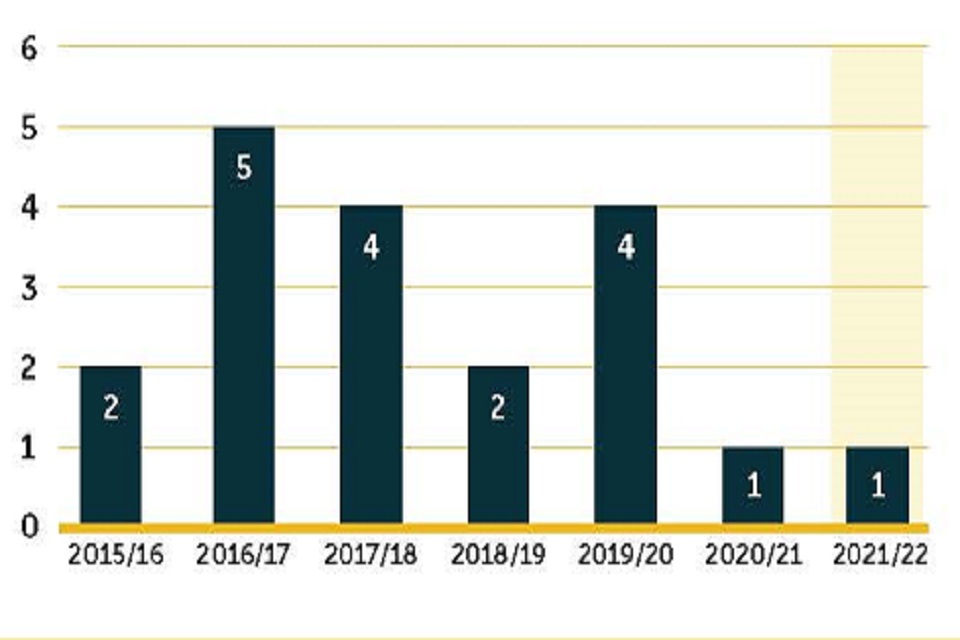

Radiological SIRs

This metric represents the number of Radiological Site Incident Reports (SIRs) radiological events categorised as significant under our sentencing scheme.

There was one recorded during 2021/22.

Radiological SIRs graphs

Holes in ductwork

Sellafield Ltd has been carrying out improvement work on the ventilation systems associated with an ageing facility on the Sellafield site.

As part of the improvement work, small holes were identified in ductwork outside the facility.

An assessment concluded that activity may have been released local to the duct. This is essentially historic in nature and was uncovered in a long-running programme of inspection and repair.

We have put in place some additional defence measures including enhanced monitoring systems in the area, and produced an improvement schedule that includes further repairs and additional containment provision.

There has been no harm to people and plant operations are unaffected.

Our regulators have been regularly updated on the duct and are fully aware of the current situation.

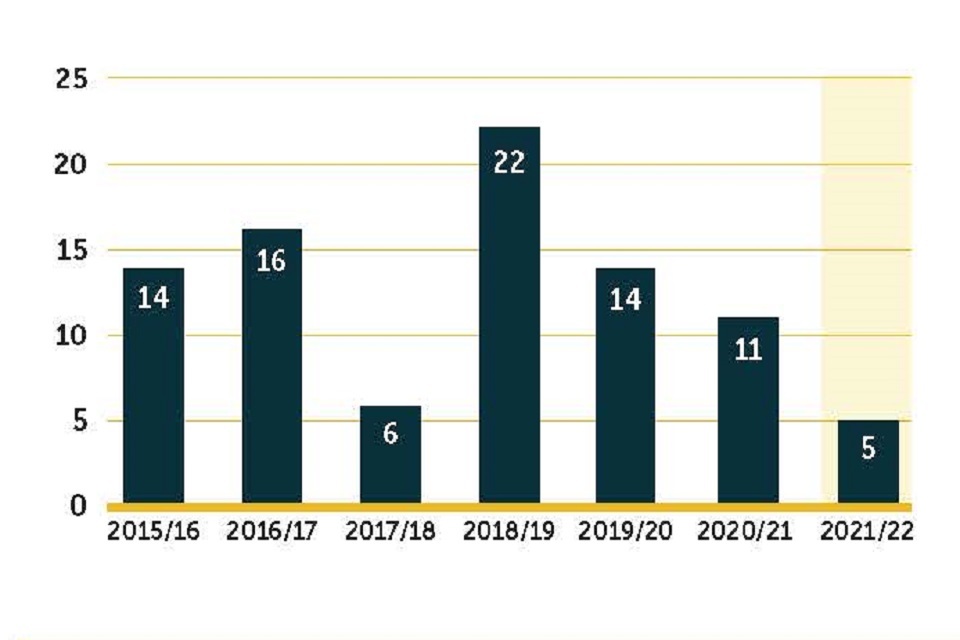

Recordable personal (skin) contamination events

This metric provides the number of personal (skin) contamination events and was adjusted to take account of all skin contamination events and not just the ones recorded at surgery.

We continue to work with workforce radiological protection working groups to prevent further contamination events.

The radiological improvement governance group is taking learning and best practice from across Sellafield, to share and deliver improved performance.

During 2021/22 all doses to employees remained as low as reasonably practicable and none of the personal contamination events resulted in internal dose to employees.

Recordable personal (skin) contamination events graph

Environmental SIRs

This metric represents the number of environmental Site Incident Report (SIR) events categorised as significant under our sentencing scheme and includes non-compliances of the environmental permit.

We promote a culture where environmental issues are reported openly across our business so that learning can be shared.

Raising SIRs aligns closely with notifications made to the Environment Agency and includes events where there is actual or potential for non-compliance with our environmental permits.

We have seen a decrease in the number of environmental SIRs in 2021/22 compared to the previous financial year.

None of the events in either financial year resulted in significant damage to the environment.

Examples of environmental SIRs included: asbestos contaminated water, and elevated radiation levels at a filter change.

Environmental SIRs graph

Lost Time Accident Rate

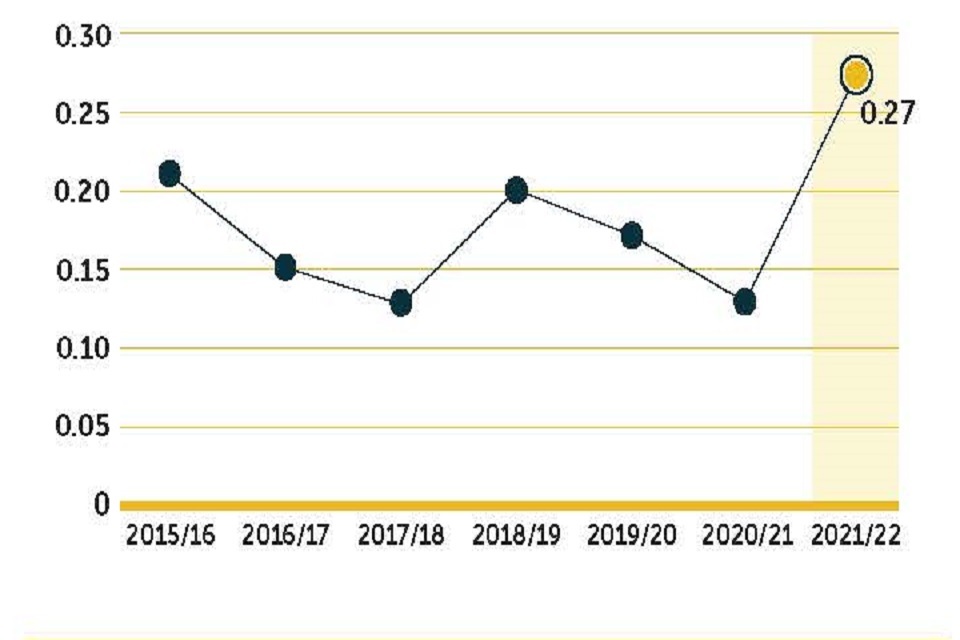

This metric records the 12 month rolling average rate of lost time accidents (accidents resulting in more than one day from work) per 200,00 hours worked.

Our Lost Time Accident rate has increased in 2021/22 to 0.27. The majority of accidents were as a result of slips, trips, falls and manual handling. We remain focused on reducing the number of Lost Time Accidents.

Lost Time Accident Rate graph

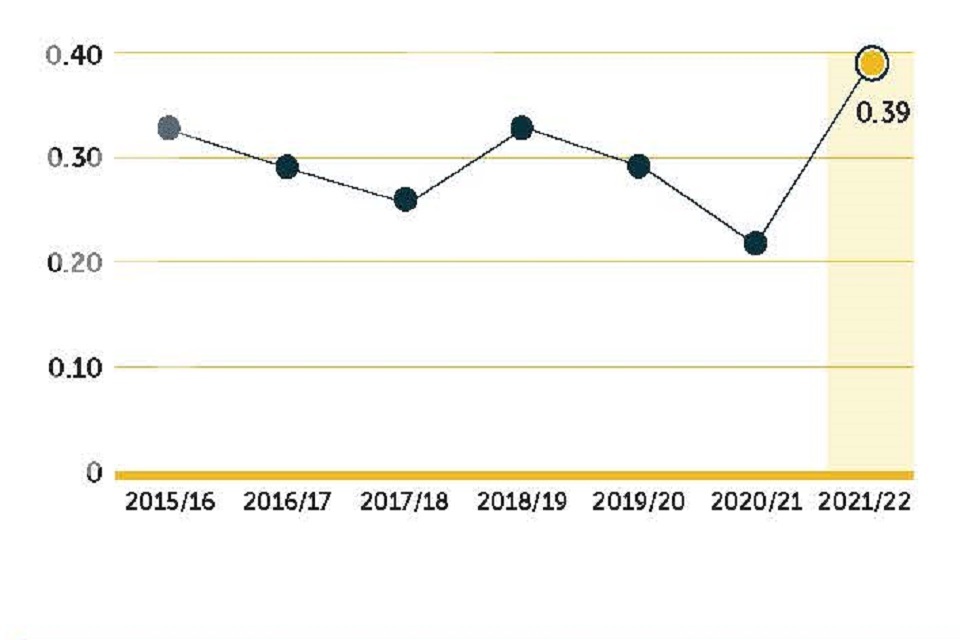

Total Recordable Incident rate

This records the 12 month rolling average rate of all total recordable incidents (accidents resulting in lost time or medical treatment) per 200,000 hours worked.

Total Recordable Incident rate graph

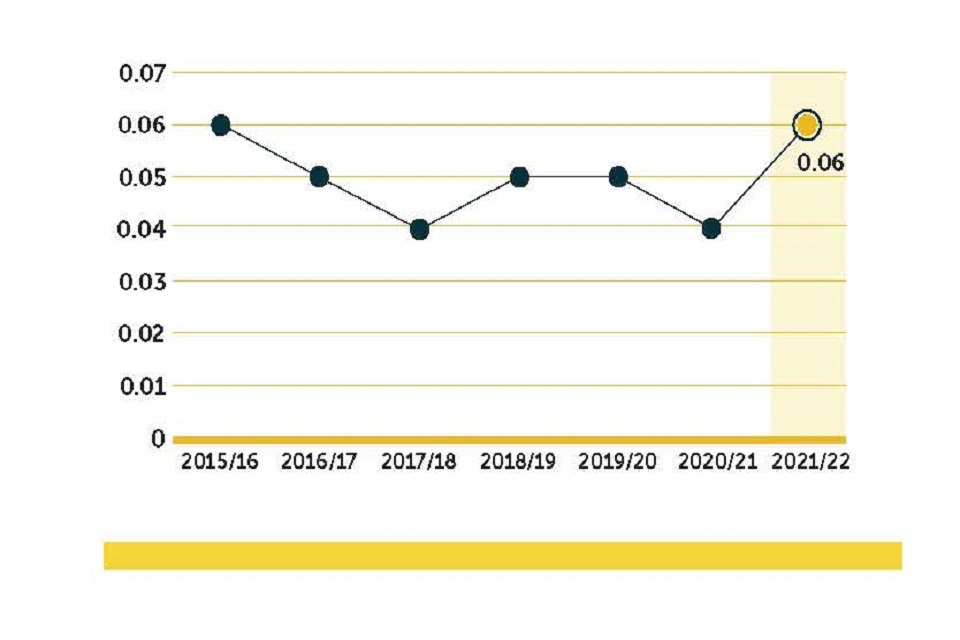

RIDDOR Injury rate

This metric records the rate of RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) injuries which result in employees being away from work for more than seven days, and specified injuries such as broken bones.

The figure shown is the 12-month rolling average rate of RIDDOR events per 100,000 hours worked.

RIDDOR injury rate graph

Dangerous Occurrences

This metric records the number of RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) dangerous occurrences. These included small fires and a failure of a crane hoist.

These events are investigated to learn lessons and implement actions to prevent reoccurrences.

Dangerous Occurrences graph

6. Protecting our environment

Our work at Sellafield will take us more than a century to complete, but we make progress every day, week, month, and year.

The work we deliver is set out in our Operating Plan which is informed by the near-term objectives set out in our Enterprise Strategy. Our Enterprise Strategy is, in turn, informed by and aligned to the Nuclear Decommissioning Authority’s Strategy.

The single biggest contribution that we can make to the protection of the environment is removing the risks and hazards associated with our oldest facilities, the legacy ponds and silos, and cleaning up the Sellafield site on behalf of the Nuclear Decommissioning Authority.

These are some of our highlights from 2021/22.

We continued work on construction delivery, including installation of a 750-tonne crane next to the Box Encapsulation Plant, ready to undertake retrievals from the Magnox Swarf Storage Silo.

Installation of a 750-tonne crane next to the Box Encapsulation Plant,

We made progress towards the end of reprocessing operations in the Magnox plant.

Magnox Plant on the Sellafield site

Successfully completed a test run to move 3m3 boxes of nuclear waste into the new Box Encapsulation Plant Product Store Direct Import Facility.

This is an important step in demonstrating the route that will be used for waste retrieved from the legacy silos.

3m3 boxes of nuclear waste

In the Magnox Swarf Storage Silo we made progress with the installation of the second Silo Emptying Plant and moved the first machine into position ready to start retrieving the waste held inside the silo.

Installation of the second Silo Emptying Plant

We removed the Windscale Pile 1 chimney diffuser, removing the seismic risk associated with the chimney at Sellafield, and changing the site skyline.

The Windscale Pile 1 on the Sellafield site

We moved the 175-tonne waste retrieval module which will be used to get nuclear waste out of the Pile Fuel Cladding Silo for the first time.

The Pile Fuel Cladding Silo superstructure moves into place

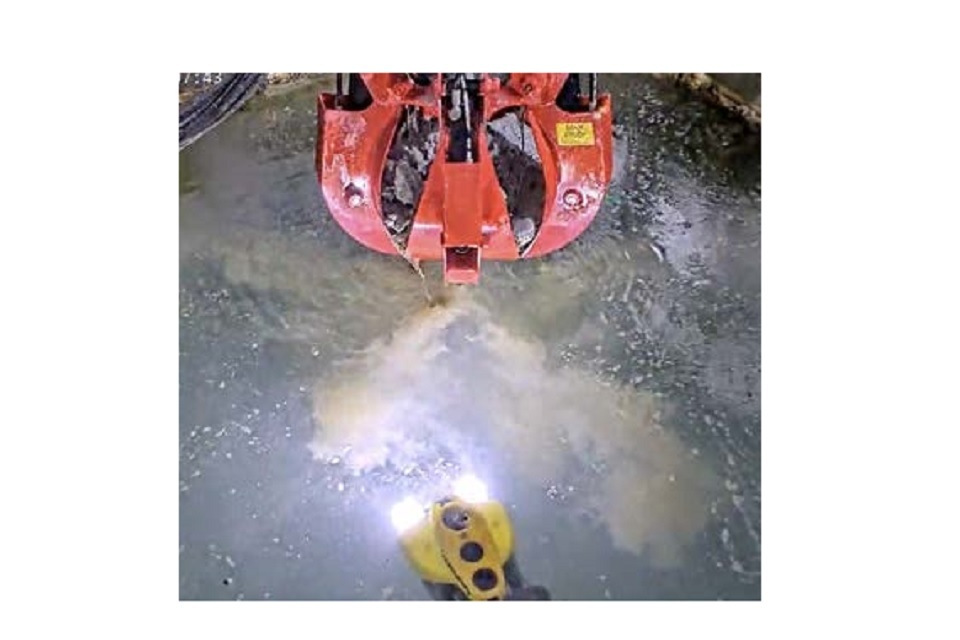

We started to retrieve solid waste from an old building at Sellafield, the Redundant Settling Tank.

Retrieving solid waste

We took delivery of the first ready-to-use self-shielded box to Sellafield, ready to store nuclear waste from the legacy ponds in the new Interim Storage Facility.

Ready-to-use self-shielded box

Working with colleagues from Nuclear Transport Services, and in line with our commitment to return nuclear waste to its country of origin, we successfully repatriated intermediate-level waste to Australia.

Nuclear Transport Services,

We confirmed that all of the containers that hold vitrified high level nuclear waste destined to be returned to their country of origin have been filled, cleaned, weighed and checked (a process known as pre-attribution).

High Level Waste containers

We have invested in the technology and solutions we’ll need tomorrow, including £78 million in research and development and £1.3 million towards the creation of an Industrial Solutions Hub in Copeland.

We also opened a purpose-built, off-site, Engineering and Maintenance facility and the first Robotics and Artificial Intelligence hub in Whitehaven.

We worked with our supply chain partners Createc and Boston Dynamics to trial Spot the Dog in Calder Hall.

The robot will be able to help us clean up Sellafield by accessing radiological areas that people cannot easily enter safely.

Spot the robotic dog

We took delivery of 2 new hybrid trains, replacing older and less environmentally friendly engines, part of our plan to replace solely diesel locomotives with smaller all electric 40-tonne versions.

All electric 40-tonne locomotive

For more on our work to reduce our carbon footprint, see chapter 8.

We brought our own COVID-19 Test and Trace facility – the first non-NHS facility to be opened during the pandemic – to a close. Its last day of operations was 31 March 2021.

We brought our own Covid-19 Test and Trace facility

7. Monitoring our environment

Over the last few years there’s been a global change in how we think about everything we do, and we’ve developed a common understanding – we must look after our planet for future generations.

The single biggest contribution we will make to our environment is removing the risks from our oldest buildings at Sellafield. Removing the waste held inside and storing it in purpose-built containers that will keep it safe for the long term

In completing that work, we will continue to discharge radiation into the environment, with the type and quantity set by discharge permits granted to us by the Environment Agency.

To assure ourselves and our stakeholders that we continue to make a minimal impact on our environment, we carry out an extensive environmental monitoring programme, the results of which are made available on our website.

That programme in 2021/22 included:

Monitoring and sampling

With the support of our supply chain partners, we carried out 1,186 sampling and monitoring programmes.

-

529 x terrestrial monitoring

-

212 x marine monitoring

-

208 x specifically to support retrievals from one of our legacy storage ponds, the First Generation Magnox Storage Pond

-

13 x investigatory monitoring

-

156 x specifically for our installation (non-rad) permit

-

68 x specifically for the Calder Landfill Extension Segregated Area

The samples collected were sent for laboratory analysis and provided more than 7,000 results.

Beach monitoring

121 hectares of beach close to the Sellafield site were monitored using specialist equipment. That’s the equivalent of monitoring Wembley football pitch 27 times.

Beach monitoring next to the Sellafield site

Beneath the ground

Our teams routinely monitor water in purpose-built boreholes across the site.

In 2021/22:

-

174 borehole locations monitored

-

708 samples taken

Beneath the ground Our teams routinely monitor water in purpose-built boreholes across the site.

Day-to-day air monitoring

Each nuclear facility has its own ventilation system and associated alarm system that would identify increased levels of radioactivity in the air within those buildings.

Across the site we also have:

-

5 high volume air samplers to support our statutory monitoring programme

-

4 air samplers specifically supporting retrievals from one of our legacy storage ponds, the First Generation Magnox Storage Pond retrievals

A network of 34 real-time radioactivity in air monitors that can detect an increase in radiation in the air at our site perimeter fence

Decades of environmental monitoring - Case study

Jim Desmond, Sellafield Ltd

Hello

I’m Jim Desmond and I have worked in environmental monitoring throughout my career at Sellafield.

I joined Sellafield in 1986 working in the analytical labs, based in one of the original Ministry of Supply buildings on site, which are no longer here.

Three months after I started, Chernobyl happened. Our lab was a focal point for the northwest of England for monitoring the fall out. It was an exceptionally busy time.

I joined the environmental capability team in 2002 and I’ve been there ever since.

Our work as a team is about ensuring environmental compliance and standards, and environmental monitoring and assessment on and off site.

We carry out environmental monitoring all the time to ensure we comply with our permits.

Our team is involved in producing an annual report to show the results from our environmental monitoring programmes.

The data is used to assess the impact of current and past operations at Sellafield and provides reassurance that this impact is significantly below internationally agreed levels.

I am proud to be part of a team that contributes to minimising our environmental impact and of our current environmental programme which is underpinned by rigorous Best Available Techniques (BAT) assessments.

I retire this year and I look forward to more travel after the last few years and sorting my local environment (garden) out – I might be busy!

Beyond Sellafield

As part of our Social Impact, Multiplied programme we’re investing in projects designed to protect and enhance the environment in our communities.

The projects deliver immediate environmental benefit and education programmes to help engage future generations in environmental protection.

Seabins

Seabins collect rubbish, debris and oils in Whitehaven Harbour.

- we funded 5 Seabins for Whitehaven Harbour

- up to 36,500kg of waste was captured by the 5 bins on 2021/22

- 658 young people attended marine life awareness sessions designed around the Seabins

Seabins

People on the Keekle

The project aims to improve habitats on the lower River Keekle by stabilising riverbanks, reducing erosion and giving advice on livestock management.

- our £229,000 of funding leveraged a further investment of £20,500 from Cumbria County Council, Cumbria Wildlife Trust and community donations

- volunteers provided 654 hours of support in 2021

- 4.8 hectares of Japanese knotweed/Himalayan balsam have been treated and/or cleared

- 50 metres of gravels have been raked to improve fish spawning habitat for trout and salmon

- 350 willow pegs/stakes have been hammered into the riverbanks, helping to prevent further bank erosion

- 6 fish surveys have been completed

- 25 metres of riverbank stabilisation has taken place, including the translocation of 21 freshwater mussels

- in 2021, 450 people attended 15 community events, including family bat walks and river dipping

- 330 young people attended Forest School sessions including groups of students with special educational needs

People on the Keekle

8. Reducing our carbon footprint

Our heritage of carbon free technologies has, however, created a large carbon legacy.

Tackling climate change, while pursuing our overriding priority of safe, secure, sustainable site stewardship, is implicit within our purpose and will provide the single largest challenge for us in the decades to come.

Through continuous improvement in our policies, procedures and workplace practices, we will deliver reductions in our carbon footprint that will enable us to contribute, alongside other public and private sector organisations, in supporting our national climate change goals. Good progress towards these goals was made in 2021/22

Since 1956, UK nuclear power has saved 2.3 billion tonnes of carbon emissions, the equivalent of all the UK’s emissions from 2015 to 2020.

- 14% reduction in total gross CO2 emissions compared to the previous year

- 17km of steam pipework across the site has been inspected and work done to reduce leakage

- we reduced our fleet of vehicles by 19

- a pilot project of steam pipe insulation

Carbon footprint scope

New buildings, new approach to carbon - Case study

Historically, we have used steam mains as the primary heat source in our buildings. A new and innovative approach to heating, ventilation, and air conditioning system design based on direct exchange heat pumps will lead to a substantially reduced carbon footprint.

The change will achieve up to a 90% reduction of the heating requirement when compared to steam.

The planned Box Encapsulation Plant Product Store 2 at Sellafield will incorporate this new system, rather than steam in its design. Further measures to reduce energy consumption in the nuclear waste store will include head recovery air handling units and reduced flow rates.

Over the operational lifetime of the store these measures are estimated to provide a total emission saving of approximately 20,000 tonnes CO2.

An estimated ~20,000 tonnes of CO2 would be saved

New hybrid locomotives

We introduced them to replace 2 diesel engines in our internal fleet of trains

Achieving carbon net zero

We have developed a Carbon Management Plan which articulates our ambition and a high-level roadmap of how we will play our part in supporting Carbon Net Zero 2050.

-

200 streetlights on site have been converted to LED (approx. 40% of total street lighting)

-

31 vehicles were changed over to Ultra Low Emission Vehicles

-

52 tower lights on site are now solar, with diesel tower lights only used for essential site security work

52 Tower lights on site are now solar, with diesel tower lights only used for essential site security work

9. Special Nuclear Materials

75 years ago, we helped to create the nation’s deterrent. Today, we’re using our unrivalled knowledge of nuclear to create a clean and safe environment for future generations.

At every step in between, our people have decoded the mysteries of the nuclear atom.

In 2021/22 we continued to safely look after the country’s stockpile of special nuclear materials.

We also partnered with leading academic institutions to deliver academic research in nuclear materials and continued to make progress in the construction of a modern treatment and storage facility.

Sellafield Product and Residue Repackaging Store

This new retreatment plant will treat and re-package all nuclear material into new 100 year packages to be transferred, safely and securely into the Sellafield Product and Residue Store through a connecting transfer corridor.

The building will:

- retreat and/or repackage those packages into 100-year packages

- transfer the new 100-year packages containing special nuclear material to the Sellafield Product & Residue Store

- enable all special nuclear material to remain safe and secure in this store – into the next century and beyond

- safely receive all special nuclear material packages from their current storage locations

Did you know?

- the height of the building is the equivalent of approximately seven stacked double-decker buses

- the building is thought to weigh the same as the Burj Khalifa building in Dubai: 100,000 tonnes

- The volume of the building has the equivalent volume of 46 Olympic-size swimming pools

Actinide research - case study

This year we increased our direct engagement with national and international research organisations.

That included:

- co-authoring 6 papers in themes ranging from modelling of hydrogen deflagrations in nuclear material packages, through to calculations on aged nuclear materials

- engaging with a PhD student at the University of Birmingham. Their work secured them a prestigious scholarship

- agreed a PhD with the University of Liverpool and an internationally renowned researcher at JRC

- provided £10,000 of funding to studies at the University of Glasgow

- committed to a £60,000 investment in the University of Bristol. The funding helped the team to secure a grant application for glovebox equipment

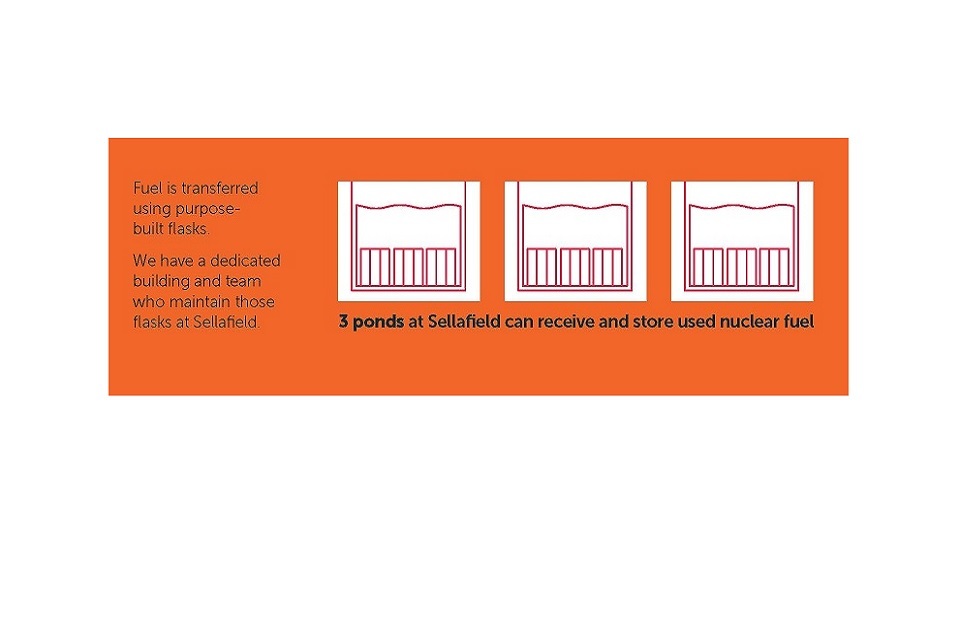

10. Keeping the lights on

Advanced Gas-cooled Reactor Operating Plan

Through the delivery of our spent fuel reprocessing work, we have created a significant used fuel capability, including the skills and experience of our teams and a fleet of nuclear buildings.

By repurposing those buildings to provide long term storage for nuclear fuel from working Advanced Gas-cooled Reactor stations across the country, we’re maximising the value from these nuclear assets.

We’re also helping to keep the lights on across the UK by providing a safe route for the used fuel once it has been removed from the reactors.

- 4 operating Advanced Gas-cooled reactors

- ~5,000 tonnes of fuel from those stations will be stored at Sellafield

- ~2,300 tonnes of that fuel is already here

- ~160 tonnes of fuel from those stations will be stored at Sellafield

Fuel journey

- Mined uranium is enriched

- fuel manufactured

- fuel used in reactors for ~ 5 years

- spent fuel transported to Sellafield

- fuel stored under water at Sellafield

Fuel is transferred using purpose built flasks. We have a dedicated building and team who maintain those flasks at Sellafield.

We provide long-term storage for nuclear fuel from working Advanced Gas-cooled Reactor stations across the country

We provide long-term storage for nuclear fuel from working Advanced Gas-cooled Reactor stations across the country.

3 ponds at Sellafield can receive and store used nuclear fuel

11. Keeping nuclear waste safe

Our work inevitably generates nuclear waste. We have the capability to safely treat and store all types of nuclear waste

High level waste comes from the separation of plutonium and uranium during reprocessing, and it can’t be reused or recycled. This waste is evaporated to reduce its volume before it is mixed with glass to form a solid, stable substance which is kept safely in our purpose-built store.

A large amount of our intermediate level waste is made up of the cladding from the outside of used nuclear fuel rods.

It also includes radioactive sludge that has built up in the bottom of our legacy storage ponds. Intermediate level waste is mixed with grout in drums and stored in engineered stores on the site.

The biggest volume of the waste that we generate at Sellafield is low level waste. It includes things like single use PVC suits that have been used as personal protective equipment.

We also look after low level nuclear waste generated by hospitals and universities. Where we can, we remove the radioactivity from this waste meaning it can be treated as a nonradioactive waste.

Where we can’t do that, the waste is compacted to reduce its volume then sent to the Low Level Waste Repository for disposal.

Keeping nuclear waste safe - In 2021/22....

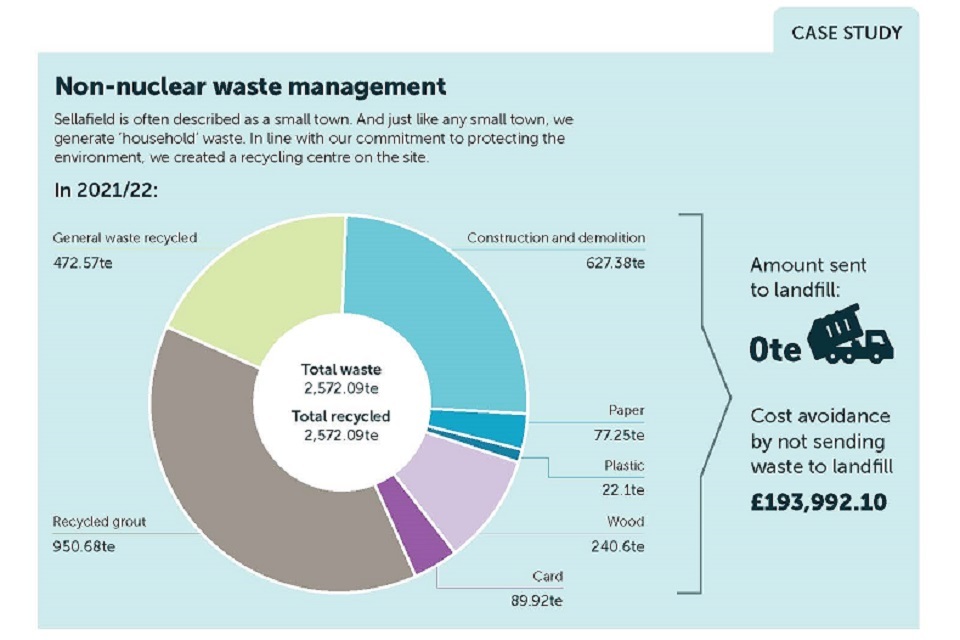

Non-nuclear waste management

12. Creating economic growth

Delivering our work at Sellafield relies not only on the skills and expertise of our own teams, but also on those of our supply chain partners.

Businesses of all sizes, from small to medium sized enterprises to global market leaders, bring value to Sellafield. Supply chain colleagues work with us on the site and in our offices.

They also work on our purpose in their own factories and facilities, developing solutions that will help us today and the global decommissioning market tomorrow.

Sustainable Sellafield

Sustainability is an integral part of everything we do, and we rely on internal and external stakeholders aligning with this principle.

We are committed and dedicated to ensuring our contribution to protection of the environment, and to collaborating with our local communities to understand their needs and their priorities.

It is promising that together with our colleagues, and our senior management commitment, we are seeing our supply chain aiming to work closer with us and contribute to the greater good.

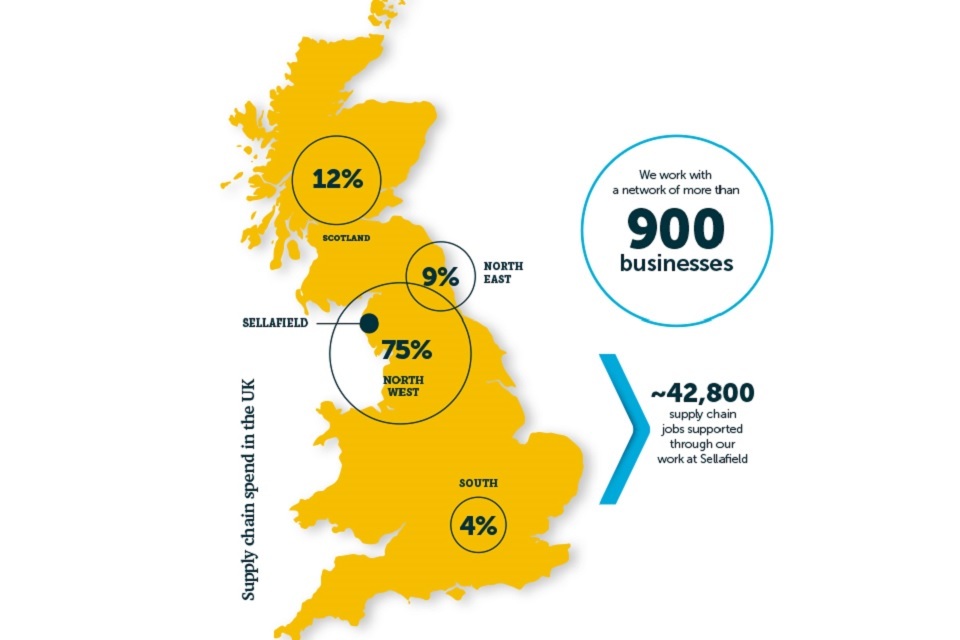

- £1.32 billion supply chain spend

- In 2021/22 34.3% (£416 million) of that was spent with SMEs

- 50 tenders each worth >£100,000 awarded

- 20 LINC challenges issued targeted towards SMEs

- £125 million direct SME spend

- £291 million indirect SME spend

Creating economic growth map

Breaking the commercial mould

Sellafield is home to one of the most complex portfolios of construction projects in the world, stretching over many decades. Our performance in delivering such projects to schedule and cost is something that we are actively working to improve.

One of the improvements we have made is developing an industry leading new approach to how we deliver projects with the supply chain – the Programme and Project Partners.

Who are the programme and project partners?

-

KBR - integration partner

-

Jacobs - design and engineering partner

-

Morgan Sindall Construction Infrastructure - Civil construction management partner

-

Doosan - Process construction management partner

-

Sellafield Ltd - Works collaboratively with the other partners

Programme and Project partners logos and description

What is PPP delivering diagram

Breaking the commercial mould diagram

-

the partners achieved a significant ‘first’ for the nuclear industry, setting a Major Project Baseline for the Sellafield Product and Residue Store Repackaging Plant.

-

on the Sellafield Product and Residue Store Repackaging Plant and SIXEP Continuity Plant, the team used 5,082 tonnes of steel and 46,700m3 of concrete.

-

the team has also banked 2,200 hours in their social impact timebank. These hours will be used to volunteer in support of social impact community projects.

13. Investing in skills and employment

Achieving our purpose of creating a clean and safe environment for future generations will rely on us having a fully engaged workforce that includes the right people, in the right roles, at the right time, behaving in the manner set out in our manifesto, helping everyone to perform at their best.

As such, we continue to operate as a major employer in our communities. This year we have continued our commitment to training the next generation of nuclear experts through our extensive apprenticeship and graduate programmes.

As these pages show, our investment in skills and in providing meaningful employment means that we are actively engaged at all levels of education and training.

One of the top 100 large apprentice employers in the UK according to the Department for Education.

My name is Charlotte and I’m a craft apprentice at Sellafield Ltd - case study

Charlotte a craft apprentice at Sellafield Ltd

I started my apprenticeship in September 2020, where I was able to get a mixture of mechanical and electrical work, before specialising in Electrical and Instrumentation.

I have just started working on the Sellafield site, having previously been based off site at the Gen2 facility near Workington, where I work in the Pile Fuel Storage Pond.

Its early days, but the work I have been involved in so far includes isolations and re- energising systems. I really enjoy the practical work now that I am on site, especially given that the COVID pandemic meant that the apprenticeship experience wasn’t what we all expected.

I haven’t had a typical entry into the apprenticeship scheme. Upon leaving university in 2014, I worked in the dental sector, including as a nurse and technician. Still unsure of where I wanted my career to progress, I tried something new and completed an electrical installations course before starting on the apprenticeship. My Dad was previously an electrical engineer, so it helped to know that I could get his advice on the role.

What I enjoy most about my job is the people. The apprentices often get together as a group to go out for meals and socialise outside of work, which has helped create a sense of community on the scheme.

I am the only woman in my team on site, but everyone has been really welcoming since I started and there is a strong network between all the women on the apprenticeship team. This has really helped with my apprehension in being a slightly older apprentice!

I am keeping my options open for future plans in my career, though the HNC or HND route is something I may look to explore. At the moment I am enjoying starting in the new team and finding my feet in this role.

Investing in skills and employment

Do you know that we work with all stages of education

WELL Project - case study

The Western Excellence in Learning and Leadership (WELL) Project is an ambitious programme of targeted investments and interventions to improve educational outcomes in the region, particularly for the most disadvantaged.

We initially invested £1.7 million in 2019 along with the Nuclear Decommissioning Authority and the project was co- created with Cumbria County Council and local schools.

In 2021 the project was granted additional funding of almost £4 million over the next 3 years.

118 schools in West Cumbria are actively involved in the project and the independent board has representatives from ourselves, the Nuclear Decommissioning Authority, Cumbria County Council, Department for Education, Cumbria LEP and school leaders from each phase.

Every school benefits from a universal offer of grant funding to implement evidence informed interventions, access to coordinated CPD activities, access to accredited training and access to the support provided through the Education Endowment Foundation research school network.

Additionally, the 23 schools that include 60% of disadvantaged pupils in West Cumbria are receiving more targeted support and higher levels of grant funding.

14. Creating a great place to work

Almost 11,000 employees and a further 4,000 supply chain colleagues worked on delivering our purpose at Sellafield in 2021/22.

Creating an environment where each and every person working for us or with us can bring their whole selves to work, and where they feel respected and included, is the right thing to do.

We know that diversity of thinking and inclusivity in decision making will allow us to explore every opportunity to deliver our work in the safest, most efficient, and innovative way possible.

We also know that creating a great place to work isn’t something that we can do solely at a corporate level, which is why we are also celebrating here the interventions and passionate commitment of our employee networks,

Delivering mental health training and supporting our employees as they drive change

Learning from external experts

Learning from external experts - case study

Former Chief Crown Prosecutor for the North West of England, Nazir Afzal OBE, is committed to employee led support networks and the value that they bring.

He has worked with our employee networks on how they can develop and evolve, and how Sellafield Ltd can truly become an inclusive workplace.

Nazir Afzal, Former Chief Crown Prosecutor

Building a better understanding of the make up of our teams today

Reverse mentoring our leaders

Last year our Executive was reverse mentored by members of the Black, Asian, and Minority Ethnic employee network. This year we rolled out reverse mentoring to another 30 senior managers (see case study)

Reverse mentoring our leaders - case study

This year we have extended our successful reverse mentoring scheme to more employees and leaders.

Reverse mentoring keeps the benefit of transferring experiences and knowledge, but the focus is independent of grade, rank or position.

Jack and Joanna share their highlights from their mentoring relationship.

I’m Jack Pike, a health physics and safety assistant team leader based on Sellafield site. While I’ve mentored Jo, I’ve moved from ‘oh this is a manager who I’ve got to be strait- laced and overly professional around’ to ‘while I acknowledge Jo is a senior manager, I can be professional, and relaxed and have conversations as I would with anyone else, while still getting what would benefit us both.

I’ve gained information about leadership training, which has helped make me into a better manager.

Joanna Petrie-Rout, head of leadership development, is based in one of our off-site offices.

I have had a fantastic experience through reverse mentoring because of the open relationship Jack and I have developed.

He has been so patient in answering all of my questions. By shadowing him doing his job I’ve seen the challenges that face future team leaders on site. This will help me develop a version of our Leadership Academy that will support them.

Jack - reverse mentoring leaders

Joanna, a reverse mentor

Providing a base level understanding of diversity and inclusion

15. Delivering a positive social impact

For us, social impact is about making a positive difference. It’s about having a positive effect on our local communities and our local economies.

It’s something we’ve done forever. But we knew we could do it better. So, we created a new approach. Social Impact, multiplied. While still providing support in times of immediate and urgent need, Social Impact, multiplied represents a significant shift that will make a difference.

That difference will be felt for generations to come.

Our ambition

To generate as much positive social impact as possible from the £2 billion we spend on our work every year, including the £1.2 billion we spend with our supply chain.

To help us achieve that ambition we:

-

deliver projects that deliver immediate benefit and longer-term projects designed to target the root cause of issues that people in our local communities are facing.

-

create an expectation in our supply chain – by embedding social impact in all supply chain contracts valued valued at more than £3 million.

-

deliver through collaboration – with our owners, the Nuclear Decommissioning Authority, with our local authorities and communities, and with community groups.

-

invest where there is evidence of a need – so that we can measure the difference that we are making

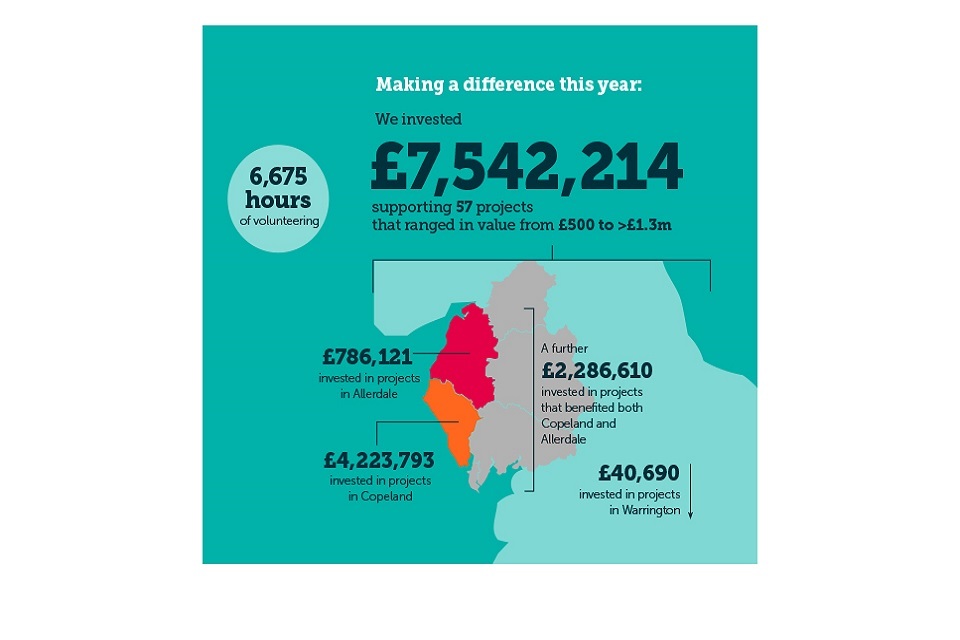

delivering a positive social impact map

Mental health investments

This year we launched the West Cumbria Mental Health Partnership, part of £1.8 million investment in low level mental health services as part of the wider Transforming West Cumbria programme, led by Cumbria Community Foundation.

Through the programme we funded two strategic partners. Groundwork North East & Cumbria for adult low level mental health, aiming to support 2,000 beneficiaries over 3 years; Cumbria Youth Alliance for youth low level mental health, aiming to support 1,250 beneficiaries over 3 years.

Together we run a Recovery College and two Citizens Advice Bureas Copeland and Allerdale provide financial advice to anyone who is struggling.

14 funded delivery partners, some of which support multiple initiatives.

The other partners are:

- GHealthy Hopes

- Always Another Way

- Mind in Furness

- Mental Health North West

- iCan Health & Fitness

- Spiral

- CADAS

- Happy Mums

- Blue Jam

- Every Life Matters

To find out more visit www.wcmhp.org.uk.

Pride in our place

Often our social impact projects seek to deliver transformational change that inevitably will take a number of years to deliver a measurable impact – things like improving educational attainment, for example.

Other projects have more of an immediate impact in our communities. They help to create pride in where we live. They bring local businesses together to work on a common goal.

This year, that included the refurbishment of 2 lighthouses at Whitehaven Harbour.

- project took 40 weeks

- 12 businesses involved (of which 10 including the main contractor were based when 10 miles of the lighthouses)

- £219,000 invested by us (matched with ~£75,000 of support in kind including volunteering hours)

The Bus Station

A £5.7 million project delivered in partnership with the Nuclear Decommissioning Authority, Britain’s Energy Coast, and Copeland Borough Council.

We transformed a derelict former bus station into a hub for creative and digital start up businesses. It is also home to the first Barclays Eagle Lab outside of a major conurbation.

In its first full year, the Bus Station is already making a difference: