Future Research and Development Requirements 2021

Published 28 June 2021

1. Purpose

The purpose of this document is to:

- clearly articulate the medium to long term science and technology research needs requiring R&D investment aligned to the Sellafield mission

- provide the company with the information it needs to make informed decisions on work prioritisation

- encourage opportunities for dialogue and involvement in R&D from academia, the supply chain and stakeholders

- ensure efficient use of resources. There is an opportunity to maximise the use of available funding routes such as the Research Councils UK and Innovate UK

2. Executive Summary

Covering 6 square kilometres, Sellafield is home to more than 200 nuclear facilities and the largest inventory of untreated nuclear waste in the world, with a diverse portfolio covering the management of special nuclear material, spent fuel management, reprocessing, decommissioning and waste management.

As a company, Sellafield Ltd is preparing for the end of reprocessing and delivering its mission as efficiently as possible while providing value for money.

The future for the Sellafield site is to:

- continue hazard reduction programme of legacy facilities

- manage the closure and decommissioning of the current spent fuel reprocessing plants and associated facilities

- continue the waste management operations together with the implementation of new ones

- environmental remediation

- safe storage of waste forms pending final disposal

Government policy and the Nuclear Decommissioning Authority (NDA) strategy defines the mission for Sellafield Ltd which is to remediate the Sellafield site to an agreed End State.

Sellafield Ltd has recently published its Enterprise Strategy which is driven by its purpose and manifesto and outlines the type of organisation it wants to be whilst setting out the 2020 to 2025 objectives.

Sellafield Ltd is required to define a ‘technical baseline’ setting out all of the processes and technologies used or planned to be used to deliver the mission.

These processes and technologies need to be sufficiently underpinned by research and development (R&D) and as the mission evolves, it is essential that the science and technology areas requiring R&D investment are aligned to the changing needs of the business. The use of innovative approaches and technologies is a key part of the Enterprise Strategy.

A project was undertaken in 2017/18 to identify key areas where R&D needs to be focussed in the medium to longer term, to ensure that the mission continues to be underpinned and to manage future risks.

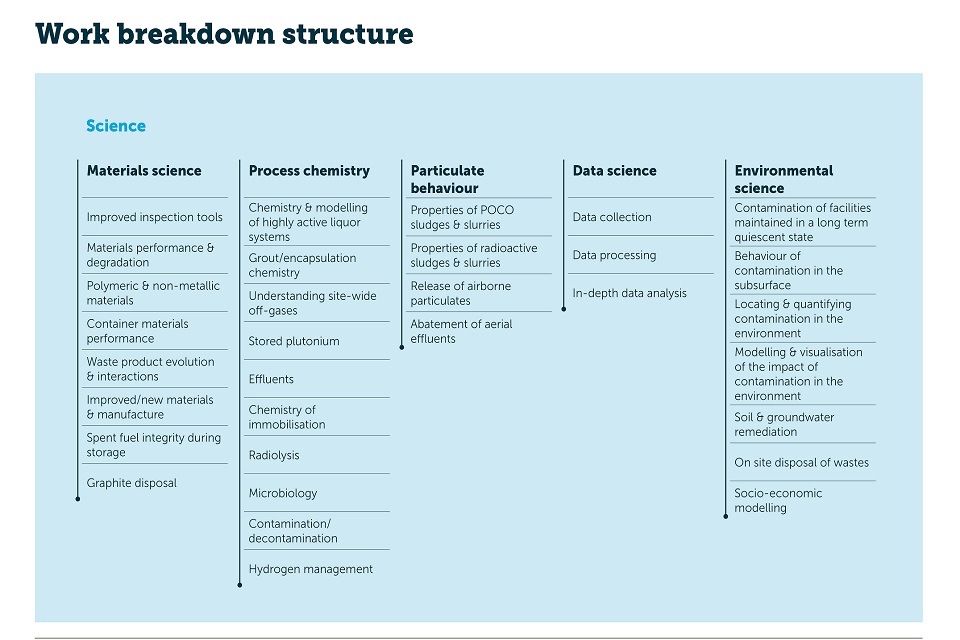

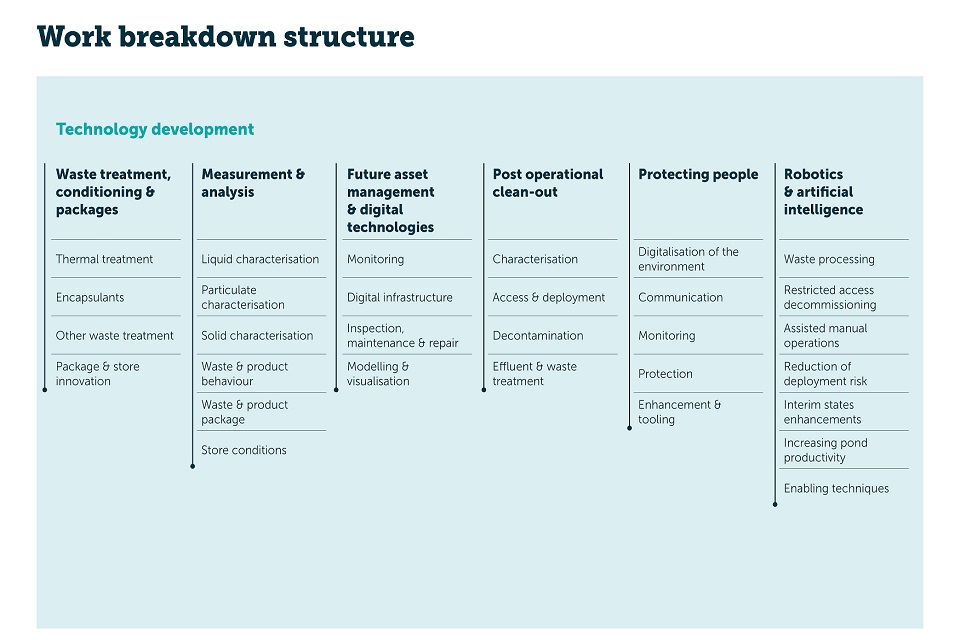

Five science and 6 technology themes were identified and these now form the work breakdown structure which drives the R&D programmes.

In 2020/21, a review of the research needs was undertaken, with the high level updated details presented in this document. It does not cover the shorter term challenges that the business is facing i.e. where direct technical support to projects and programmes is needed.

Critical to success is integration and coordination of the various R&D programmes that are delivering science and technologies and therefore programmes are managed by research teams with end user input.

Key to delivery of the work to address these needs is the supply chain, academia and the potential for collaboration with funding opportunities from other organisations such as Research Councils UK, these are presented and explained in this document.

This is the second publication of this document and it is underpinned by science and technology research needs sheets that have been articulated in a consistent manner, these are stored centrally within the Sellafield Ltd management system and can be obtained by contacting the technical community at Sellafield Ltd.

To find out more contact: technical.innovation@sellafieldsites.com

3. Content

Background

Sets the scene for this document covering the mission at Sellafield and alignment with Sellafield Ltd value streams.

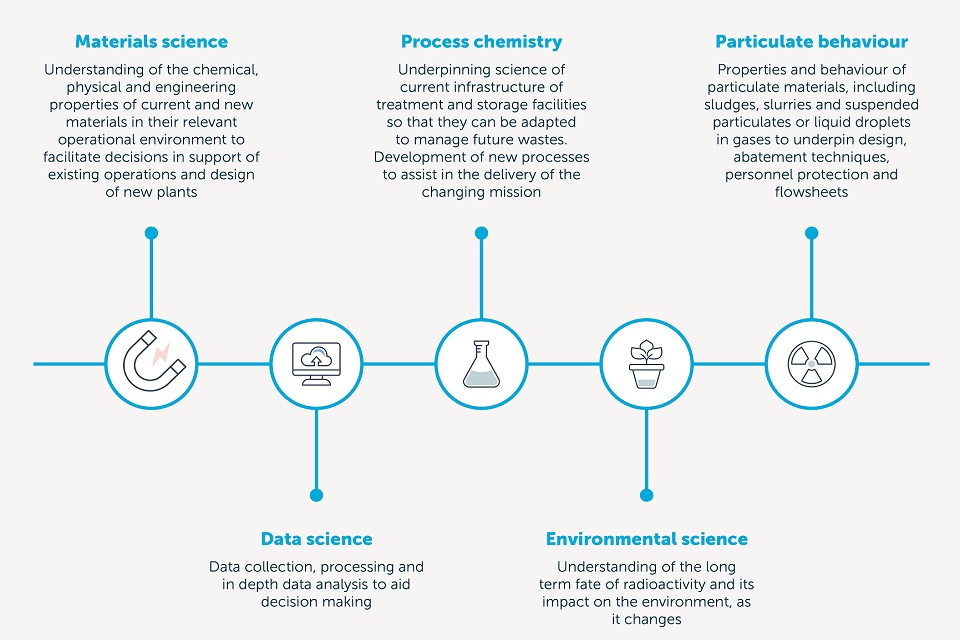

Science

The 5 scientific areas for focus and investment to underpin current and future operational processes.

Technology

Areas of the business where new and emerging technologies can be used to reduce costs and accelerate schedules during the safe clean-up of the Sellafield site.

Delivery

How our R&D is delivered, interfaces and stakeholder management, funding opportunities and enabling functions.

Work breakdown structure

Abbreviations, acronyms and references

4. Background

The mission at Sellafield

Sellafield is the largest UK nuclear site with a unique and diverse range of complex challenges arising from more than 60 years of varied nuclear operations.

As a company, Sellafield Ltd is faced with the challenge of preparing for the end of reprocessing and delivering its decommissioning mission as efficiently as possible whilst providing value for money.

The focus of the organisation is now changing from operational reprocessing to waste management, storage and environmental remediation.

Thorp reprocessing was completed in 2018 and Magnox reprocessing is expected to be completed in 2021, post operational clean-out (POCO) of facilities will commence and in parallel with this, is the continuing hazard reduction programme to remove waste from legacy ponds and silos on the site.

Sellafield Ltd’s purpose is to create a clean and safe environment for future generations. This purpose links directly to the Enterprise Strategy which has 3 strategic focus areas:

Safe, secure sustainable, site stewardship

A continuing visible commitment to safety and security and responsibility as the steward of one of the largest and more hazardous sites in the world.

Progress at pace

A commitment to delivering the purpose whilst recognising that significant progress has been made on some major projects. With an increased prominence of waste treatment, management and storage as a core activity.

Lifetime value for money

Wider than a financial context this includes unlocking the potential of people, driving innovative solutions as well as minimising liabilities for future generations.

5. Why scientific underpinning and technology development?

Sellafield is the largest UK nuclear site undergoing decommissioning with a diverse range of complex technical challenges.

This is an expensive process, lasting more than 100 years, with the current estimate calculated to be in the region of £97 billion (undiscounted) [2] to cover the decommissioning of facilities, managing and disposing of all waste and the remediation of land.

This figure is based on assumptions, decisions and technologies that are currently available and scientific research provides the necessary underpinning of this baseline.

6. Technical baseline

In order to deliver its mission to safely and securely remediate the Sellafield site, the company is required to ensure that all processes and technologies used or planned to be used are sufficiently underpinned by R&D - this is known as the technical baseline.

It’s captured in the technical baseline and underpinning research and development (TBuRD) document and is reviewed on an annual cycle.

7. Underpinning of processes

One of the cornerstones of Sellafield Ltd’s business is a reliance on scientific underpinning of its processes. Sellafield Ltd has been at the forefront of science and technology since the beginning of the ‘nuclear age’.

These decades of activities have yielded an enormous volume of scientific information on which Sellafield Ltd bases its processes. The importance of this underpinning is embodied in the Office for Nuclear Regulation’s (ONRs) Safety Assessment Principles for Nuclear Facilities [3]:

The safety case and its assessment should include a comprehensive examination of relevant scientific and technical issues taking account of precedent when available.

The relevant science applicable to operations is captured in either Sellafield Ltd’s internal management systems or published in scientific literature and the Sellafield Ltd value streams have technical programmes that focus on the shorter term needs and risks associated with their operations.

There are however, areas where Sellafield Ltd needs to develop more detailed scientific understanding of processes particularly where more knowledge and understanding is required or where the mission is changing.

8. Technology development

As the mission evolves there is an opportunity to adopt modern techniques and invest in innovative technologies to meet the challenges of the future mission.

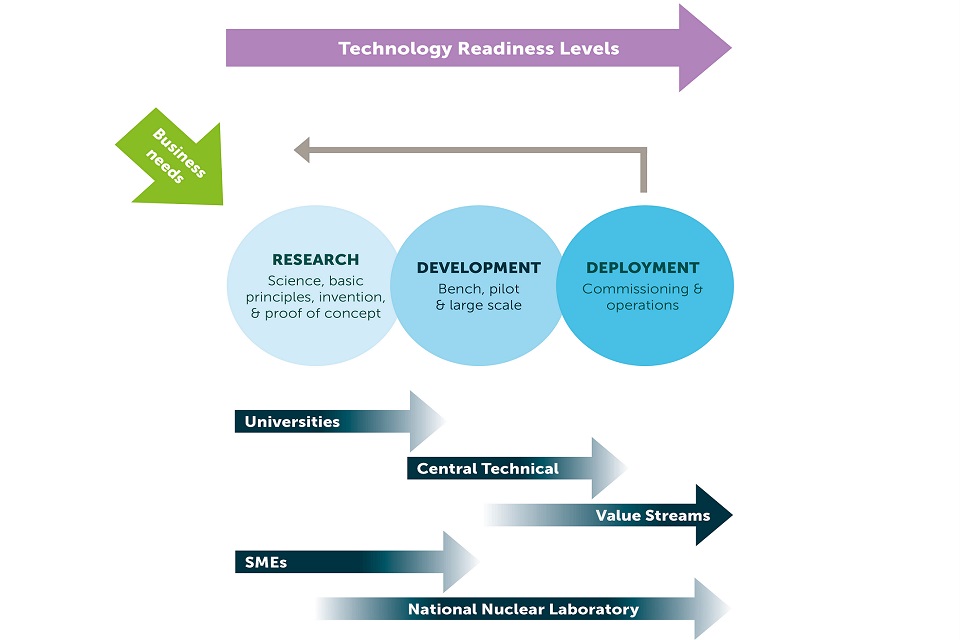

There are areas where new and emerging technologies can be progressed through the technology readiness levels (TRL) scale to a point where they can be integrated into the business by the value streams.

9. R&D programmes

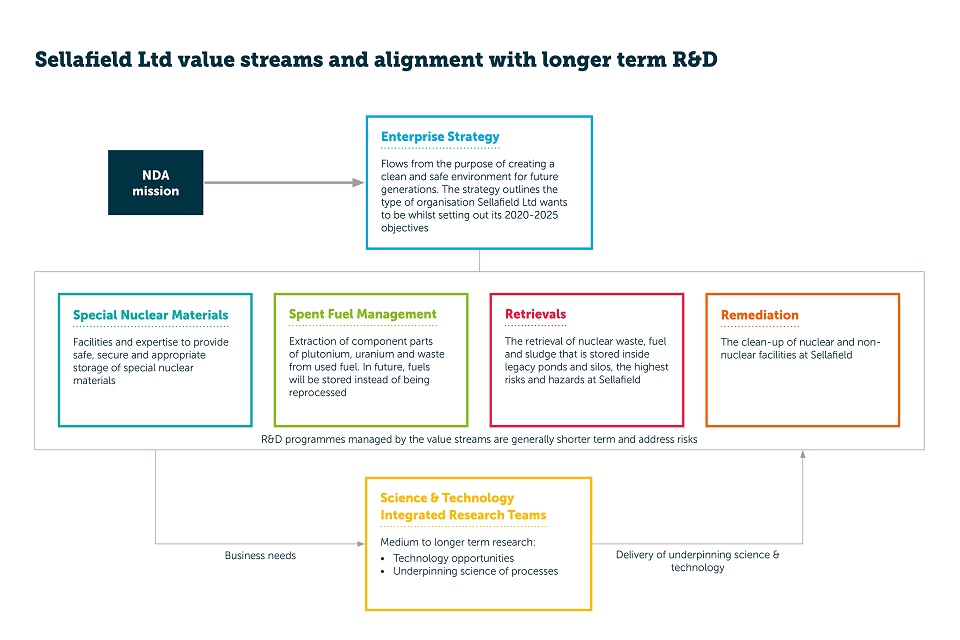

The Sellafield Ltd value streams table below illustrates the Sellafield Ltd value streams, stemming from the Enterprise Strategy which is part of the overall NDA mission. Each value stream manages R&D programmes to address shorter term needs and risks.

To complement these programmes, the Central Technical function of Sellafield Ltd manages the R&D programmes required to deliver underpinning science of processes and new innovative technologies aligned to the longer term needs of the business.

This research and development forms the subject matter of this document ‘Sellafield Ltd future research and development requirements’.

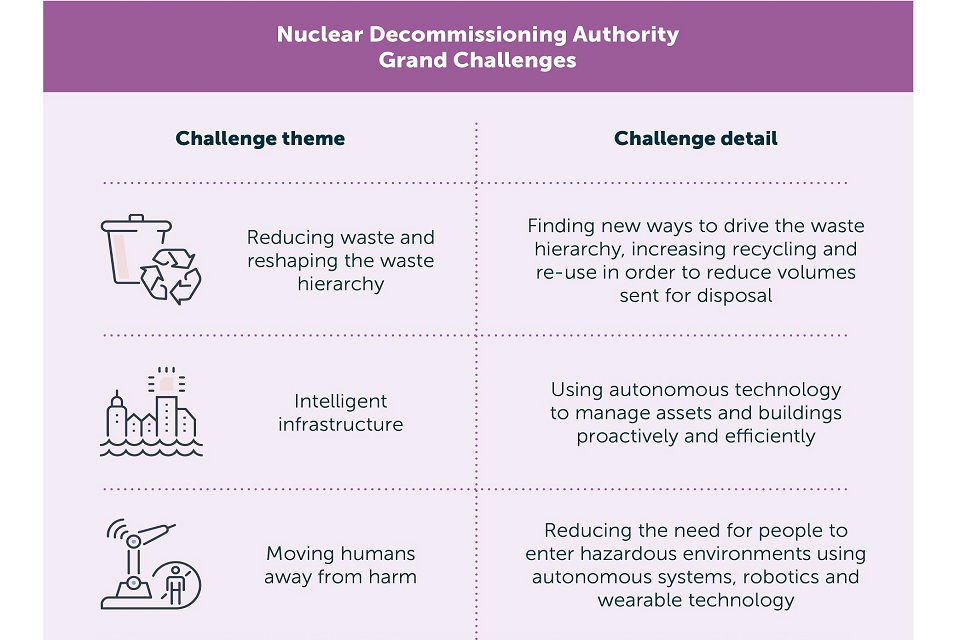

This table illustrates the NDA Grand Challenges, aspects of which the R&D programmes are addressing

10. Science

Analysis of scientific needs

The Sellafield mission is technically complex and requires programmes of underpinning science to support it. Whilst ongoing programmes are aligned to the current mission, it is critical that the needs of the changing mission are periodically reviewed to ensure that resources are invested in the areas of most importance to the business.

As Sellafield is undergoing transformation this further supports the need for a high level review of the R&D requirements of the business.

In 2017/18 a review was carried out with input from both senior technical managers and specialist technical leads from across the business which identified 5 key science themes that cut across the value streams.

A detailed exploration of each of the themes was then undertaken to develop the topic areas in the work breakdown structure (featured in this document) and to clearly articulate the research needs.

In the 2020/21 review the 5 science themes remained unchanged but there were a number of areas that required updates:

-

a revised work breakdown structure for the data science theme

-

streamlining and simplification of some of the research topics within the themes

A summary describing the subject matter of each of the science themes is presented in this section.

Underpinning science themes

Materials science

A wide range of materials are used on the Sellafield site, often for unique and challenging applications.

These materials are typically used in equipment for highly radioactive processes, providing reliable shielding and containment of hazardous solids, liquids and gases.

A common feature of these operating environments is the requirement to maintain performance under beta, gamma, alpha and/or neutron irradiation.

Depending on the application, the materials can also be required to perform in environments which are demanding in other respects, including high temperatures, pressures, acidity and abrasion.

The unique challenges of industrial operations in a nuclear environment make replacement of installed equipment extremely difficult and so materials are often expected to have long service lifetimes, sometimes for several decades and occasionally for more than a century.

For example, waste containers are being held in storage prior to geological disposal.

A further consequence of the nuclear environment is that access for monitoring or inspection can be difficult. It is therefore important that material properties in the relevant environment are well understood, so that performance throughout the operating life can be confidently predicted.

Nevertheless, there is still a requirement to monitor the materials performance of key equipment using remotely deployed instrumentation.

A fundamental understanding of the chemical, physical and engineering properties of materials in their relevant operational environment, backed up with appropriate monitoring and inspection, therefore allows appropriate decisions in support of existing operations and design of new plants.

The materials used on the Sellafield site include:

- steels and other ferrous and non-ferrous alloys used in a range of applications, including spent fuel cladding, process vessels and pipework, shielded cell liners, waste containers and process equipment

- spent fuel as metals, oxides or other compounds

- polymers used in, for example, seals and hoses

- glass, ceramics and cement grouts as encapsulating or immobilising matrices for radioactive waste

- concretes and other construction materials

- electronic components in control, monitoring and inspection systems

Research on novel materials which may have the potential for future uses or to replace existing materials is also required.

Key areas for scientific underpinning

Improved inspection tools

There is a need to understand plant conditions and have confidence that life limiting degradation will be detectable before failure and therefore underpin long term storage and operation. Information is required to underpin strategy and operations and meet regulatory requirements.

Material performance and degradation

Underpinning science of metallic, cement-based, polymeric materials and fuels performance in both current and future applications such as ageing plant structures, new build plants and storage containers. In particular an improved understanding of degradation mechanisms such as corrosion and radiation damage.

Polymeric and non-metallic materials

Degradation mechanisms and long term performance, impact of material changes on performance, in-situ inspection of polymers, assessment of new materials and technologies, management of ageing plant through use of modern repair technology.

Container materials performance

There is a range of package configurations on the Sellafield site such as vitrified waste containers, boxes, special nuclear material containers and drums containing encapsulated waste.

There is a requirement to predict container performance over 100 years or more with respect to the store environment during service, including for example, the integrity of welds and lifting and closure mechanisms. This requires novel in-situ inspection capability.

Waste product evolution and interactions

- Understanding of waste evolution mechanisms including interactions with immobilisation matrices.

Improved/new materials and manufacture

- Assessment of novel materials and manufacturing processes so that advantage can be taken of features that may improve performance, for example in high radiation environments.

Spent fuel integrity during storage

- Condition and degradation in both wet and dry storage of fuel and cladding including short term nuclide release, environmental conditions (such as temperature over time) and condition monitoring.

Graphite disposal

- Effective method to manage the graphite waste stream in terms of storage and disposal. This requires a good scientific understanding of the key challenges of the various graphite waste forms and the identification of the optimum treatment, storage and disposal methods.

Process chemistry

Reprocessing is the separation of uranium, plutonium and fission products from spent nuclear fuel. The fission products are managed via a series of waste and effluent treatment processes to produce waste streams and authorised discharges.

In 2018 reprocessing operations on Thorp were completed and Magnox fuel reprocessing is expected to conclude in 2021.

These operations were supported for many years by an infrastructure of treatment facilities such as the Enhanced Actinide Removal Plant, the Site Ion Exchange Effluent Plant, waste encapsulation plants and the Waste Vitrification Plant to manage and process the waste streams.

As the site moves from reprocessing, some of these plants will be decommissioned and others may be used to process wastes from the clean out of redundant facilities.

In addition, since there is no longer a requirement to reprocess fuel, an alternative approach is to store spent fuel in purpose built facilities prior to a future decision on final disposal.

There are more than 100 tonnes of plutonium dioxide that need to be consolidated at Sellafield in a safe, secure environment with planned storage for more than 100 years prior to reuse or disposal. This drives the need for minimum repackaging prior to plutonium disposition being fully implemented.

The underpinning science behind these activities needs to be understood so that:

-

control of operational processes can be maintained at all times by understanding the acceptable process parameters, the consequences of deviation from them and by monitoring them on plant.

-

plant efficiency can be improved, for instance by increasing plant throughput, maximising separation factors in effluent treatment processes, increasing waste loadings in encapsulation processes to reduce the number of waste packages requiring storage or to improve product quality.

-

existing processes can be adapted to accept changing feeds, for example to deal with changing effluent composition.

-

new processes can be developed to assist in the delivery of the changing mission, including for example, alternative reagents for POCO of redundant plant.

This understanding will also be incorporated into models to aid in predicting the performance of existing processes and the design of new ones.

Key areas for scientific underpinning

Chemistry and modelling of highly active liquor systems

Defining the operating envelope of existing highly active liquor systems for handling POCO liquors.

Grout/encapsulation chemistry

Supports the re-purposing of existing processes and the development of novel systems, including novel mixing technologies, immobilisation of new wastes by existing processes (primarily in drum mixing), higher waste loadings and new encapsulant formulations.

Understanding of site-wide off-gases

Off-gas treatment and abatement for volatiles and reactive gases, aerial production mechanisms for new and existing operations, understanding potential mechanisms for unexpected reactions leading to aerial discharges (including organics).

This topic area has related subject matter with other areas of process chemistry and with particulate behaviour.

Stored plutonium

For a range of solid plutonium chemical types and physical forms; an understanding of surface speciation and chemistry, bulk behaviour evolution, chloride contaminated plutonium in heat treatment process and storage, developing new characterisation techniques where required.

Effluents

Improved understanding of the composition and behaviour of effluents during retrieval, POCO and remediation. Optimisation of abatement processes to process changing feeds and reduce site discharges.

Chemistry of immobilisation

Development of immobilisation processes in matrices such as glass or ceramic for a range of feeds such as higher activity wastes to support current and future operations. Definition of the operating envelopes, behaviour in long term storage and abatement of process volatiles.

Radiolysis

Radiolysis of a range of materials including water and organics in contact with radiogenic surfaces (e.g. POCO slurries, plutonium dioxide, spent fuel, exotics, cementitious phases or metals) leading to gas generation and potential degradation of the surface.

Microbiology

Understanding the impact of microbes on a number of process plants and stores leading to, for example, corrosion, blockages or fouling of infrastructure.

Contamination and decontamination

Improved understanding of contaminants including chemical composition, concentration and binding mechanisms for the development of tailored or improved decontamination technologies that could remove contamination through a targeted approach whilst minimising wastes.

Hydrogen management

A greater understanding of ignition and ignition sources, deflagration energies in real systems and geometries, hydrogen safe POCO states for process plants with residual inventory and potential accumulation of hydrogen in non-vented environments.

There is a need to understand the evolving chemistry within plutonium packages to underpin long term storage (Image courtesy of the National Nuclear Laboratory)

Particulate behaviour

A large proportion of the radioactive sludge at Sellafield is a by-product from the storage of nuclear fuel and other debris found in historic ponds and silos on the site.

However, there is also a significant inventory of other material generated as a result of effluent treatment processes e.g. spent ion exchange media, precipitated flocculent masses and insoluble solids arising as a result of evaporator concentration and fuel dissolution.

To enable safe retrieval, processing and packaging of these materials for long term storage and disposal it is important to understand their composition and behaviour throughout the lifecycle of their formation, evolution, transport and disposition.

This science theme also covers the properties and behaviour of particulate materials in the form of sludge, slurries, organics and other residues that may be left in vessels and pipes at the end of operations.

There is a need to understand the sources of these, their physical and chemical characteristics as well as their behaviour so that treatment options can be explored.

Suspended solid particulates or liquid droplets in gasses can be generated in a number of ways including high pressure water jetting of radioactive surfaces, as a result of retrieval activities from open air ponds, and size reduction techniques.

These source terms will become increasingly significant during decommissioning operations. There is a requirement to reduce uncertainty and to fill knowledge gaps in radioactive airborne particulate generation and evolution behaviour.

This will underpin design of future plants, abatement techniques, aerial effluent flowsheets, area classifications and personnel protection needs.

Plutonium dioxide is stored at Sellafield as dry powder and is also recognised as a particulate material, this area of research is captured in process chemistry.

Key areas for scientific underpinning

Properties of POCO sludges and slurries

Understanding the sources and behaviours of residual solids that exist as mixtures, potential benefits of separating components and effects of additives/cleaning agents on behaviour.

Some of these solids may be mobilised and some may require further treatment.

Properties of radioactive sludges and slurries

Bulk uranium corrosion product sludges, colloid formation, predicting and monitoring gas production (including hydrogen), settling behaviour and the effect of solid surfaces on radiolysis of sludges and in-situ measurement.

Release of airborne particles

Understanding of liquid aerosol generation from processes such as high-pressure water jetting, splashing and bubble bursts and solid particulate generation and disposition generated, for example, as result of cutting and grinding operations.

Abatement of aerial effluents

Effectiveness of abatement techniques such as filters and scrubbers as a function of particle size, distribution and air velocity.

Data Science

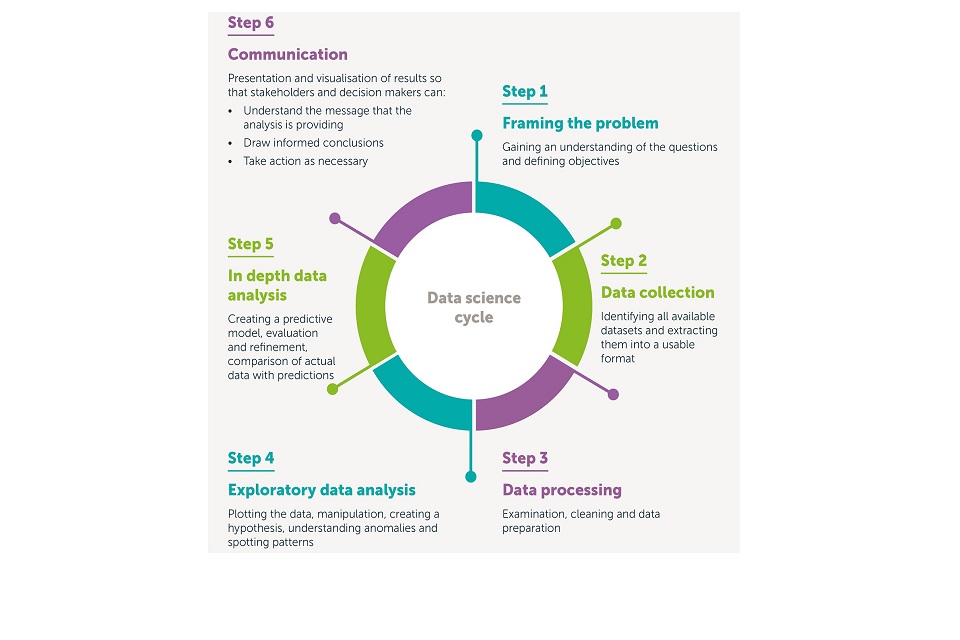

Data science is a multidisciplinary approach to extracting actionable insights from large and ever increasing volumes of data collected and created by an organisation.

For many years data have been generated at Sellafield for a variety of purposes in a number of different ways such as measurement by instruments, plant records, reports and by modelling or simulation.

As the site moves forward to clean up and decommission numerous facilities, remediate land, treat wastes and store products over extended periods, there is an opportunity to use data science to make use of these and new data to support the business decisions required to undertake these activities.

For example, predicting the condition of a building and developing an optimised maintenance strategy, creating an optimised POCO or decommissioning plan for a facility or predicting the impact of radioactivity in the environment.

Data science not only offers machine learning opportunities to extract more knowledge from existing data, adopting smart technologies that can integrate communication between machines, computers and people (the ‘internet of things’) will lead to an enormous increase in the volume and complexity of data that can be processed with increasing speed.

Data science covers a range of activities - the data science cycle, from exploring what questions need to be answered to the communication of results

Key areas for scientific underpinning

Data collection

New technologies are required to collect and securely transmit data. This could be through the use of in-situ sensors for example, and is a research need being addressed by the measurement and analysis technology theme.

Additionally, techniques are required to improve the quality of both new and existing data.

Data processing

Improvements in image processing or video analytics and techniques for combining different sources of data.

Novel forms of data and image processing that make it possible to analyse and translate analogue information into a useable, searchable and structured format.

In depth data analysis

Machine learning including interpretable models, uncertainty quantification, Bayesian belief networks and methods for integrating and optimising each stage of the data science cycle.

Increasingly this analysis will be automated and R&D is required to ensure methods are safe and secure and that they are trusted within the business.

Environmental science

During an evolving decommissioning programme over many decades, particular attention will be paid to the remediation of ageing structures and land quality management. In particular, the separation area on the site includes a number of legacy plants associated with Magnox reprocessing and associated waste management.

The site therefore operates a programme of groundwater monitoring and will carry out appropriate remediation as part of the clean-up programme.

There is an improving scientific understanding of the behaviour of radioactivity in the environment that has been developed to support current operations at Sellafield, however the coming years will see a change in focus to environmental remediation.

Understanding of the long term fate of radioactivity in the environment and its potential impact on a changing natural and man-made environment is required to aid decision making for remediation.

Key areas for scientific underpinning

Contamination in facilities maintained in a long term quiescent state

The current strategy is to take buildings through decommissioning and demolition, but some may need to be maintained in a quiescent state and will require asset care programmes (see future asset management and digital technologies technology theme).

Behaviour of contamination in the subsurface

Understanding of the geology, hydrology, hydrogeology and chemistry of the Sellafield site subsurface.

Understanding the chemical and biochemical processes in a range of materials such as concrete, soils, underground pipes and near surface hydrogeological environments.

Evolution of the Sellafield site through climate change scenarios and the impact on contaminant distribution. Improved assessment models.

Locating and quantifying contamination in the environment

In-situ or in-field groundwater monitoring technologies, laboratory techniques for environmental samples, in-situ measurements from higher activity zones and ex-situ for characterisation of ground and subsurface. Changes in distribution over time.

Modelling and visualisation of the impact of contamination in the environment

Development of predictive modelling to understand the fate and impact of radionuclides in the environment in the long term that will increase the confidence of stakeholders.

Soil and groundwater remediation

Development of methods for the removal and packaging of intermediate level waste, alpha contaminated soils and trench wastes. Methods for fixing contamination in source zones and limiting migration in plumes. Contingency planning.

On site disposal of wastes

Mechanisms for the mobilisation and transport of key radioactive and nonradioactive species from managed disposal of wastes on the site or from buried structures which may be left in-situ. Opportunities for the re-use of materials such as those used in construction.

Socio-economic modelling

Social value of the site and its associated infrastructure to the linked community. This knowledge can be used to address remedial end points, influence land use and redevelopment plans.

11. Technology

Identification of technology development opportunities

In 2017/18 a review was undertaken with technical leaders from the value streams. This was an iterative process focussing on the process steps needed to achieve the clean-up of the Sellafield site, including characterisation, POCO, dismantling, waste treatment and storage.

Six key themes emerged where opportunities for employment of innovative technologies, tools and techniques, to reduce costs, improve safety and reduce timescales were identified.

As with underpinning science, a work breakdown structure was developed for the 6 technology themes, presented on pages 29-30 and the research needs identified.

In the interim period between the 2017/18 and 2020/21 reviews the 6 science themes required further definition and evolution with a number of changes including:

- combination of condition monitoring and inspection and novel analytical techniques to form measurement and analysis.

- formation of protecting people and future asset management and digital technologies.

- the decommissioning theme was removed because the subject matter is covered in other parts of the work breakdown structure.

Each of the areas identified for R&D investment is discussed in this section.

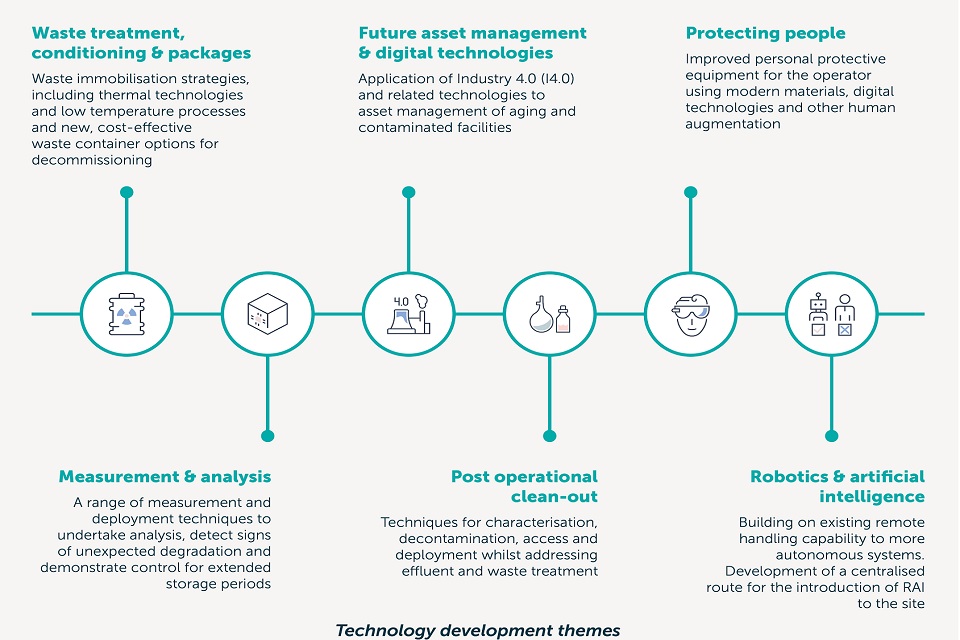

Technology development themes

Assessment of technical maturity

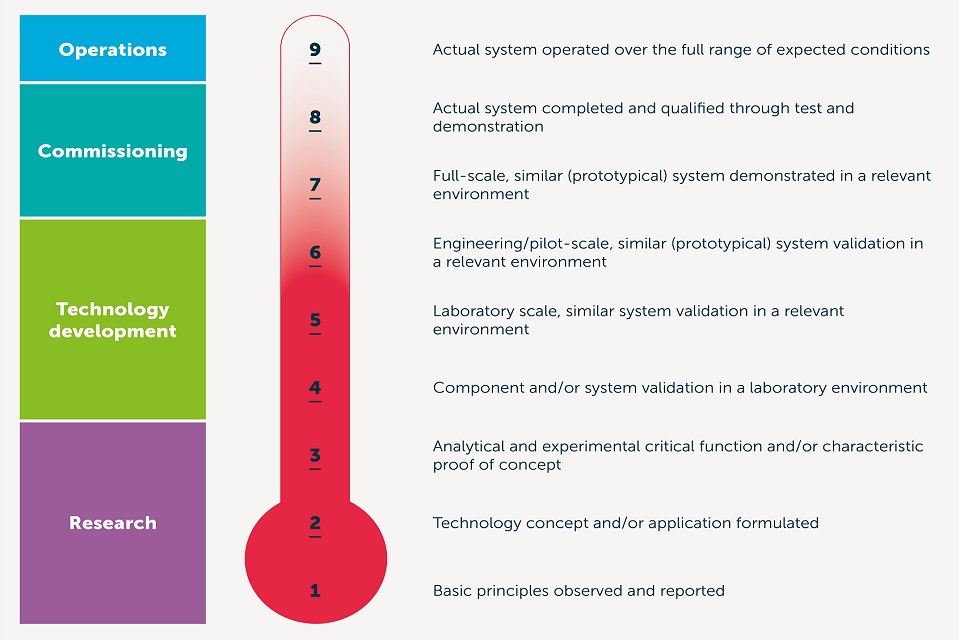

Technology Readiness Levels (TRL) provide an indication of readiness of a technology to be applied for a specific purpose and are used to monitor technology readiness on projects.

Sellafield Ltd has adopted the TRL scale that is used widely across the NDA estate [4].

Development programmes addressing the research needs aim to bring forward technologies through the TRL scale from fundamental research and early development, lab and pilot scale through to active demonstration.

Assessment of technical maturity

Waste treatment, conditioning and packages

There is a requirement for radioactive waste producers to convert waste into a passive and safe form as soon as reasonably practicable. For intermediate level wastes this has usually been achieved by encapsulation in a cement based matrix.

Ordinary Portland Cement (OPC) based encapsulants offer many advantages such as robust products with well understood properties at a reasonable cost and continue to be the baseline technology for a number of waste streams.

However, developments in cement powder supply in response to a range of sustainability challenges present a threat to the long term availability of current materials.

Furthermore, OPCs have a number of disadvantages and are unlikely to be the optimal solution for all future waste immobilisation requirements.

Consequently, R&D is essential to deliver credible alternatives for encapsulation of all higher activity wastes.

There are various insertion points for alternative treatment technologies into the technical baseline, depending on the retrievals timescale of each waste stream, and these generally fall between 2022 and 2040.

To underpin decisions on waste immobilisation strategies over this timescale, research is required on a range of options which have potential benefits over OPC based processes, including:

- thermal technologies

- alternative low temperature processes, including geopolymers, polymers and novel inorganic cements

Waste containers used for disposal of waste are expensive, with current projections suggesting that over the lifetime of the Sellafield mission up to £4 billion will be spent on waste containers alone.

There is therefore an opportunity to benefit from new manufacturing techniques in order to reduce the baseline costs. An R&D programme is required to provide an improved range of cost-effective waste container options that have been designed to facilitate decommissioning.

An example of a container used on the Sellafield site to store nuclear waste

Opportunities for technology development

Thermal treatment

Application of novel thermal processes to treat a range of higher activity wastes. Understanding issues such as feed envelopes and off-gas treatment.

Storage of wastes ready for later vitrification and long-term evolution of products (the underpinning science research needs for these technologies can be found in process chemistry).

Encapsulants

Research is required on optimised mixing/deployment methods at a representative scale to plant in order to develop an acceptable formulation and satisfactory product (the underpinning science research for these technologies can be found in both the materials and process chemistry themes).

Other waste treatment

Treatment or pre-treatment of wastes that are incompatible with current treatment options.

Package and store innovation

Feasible alternative container and package design, flexible adaptable designs, alternative disposal concepts, entombment media and product marking/identification.

Measurement and analysis

As the Sellafield mission evolves there will be a fundamental change in the analytical demand on the central services function resulting in a switch from analysis of routine process samples to a greater proportion of characterisation of material that is more heterogeneous in nature, requiring one off analysis or multiple analyses.

Analysis and characterisation of material on the Sellafield site is labour intensive, expensive and time consuming. Therefore, there is significant potential benefit to be gained through improvement of how analytical information is generated.

There is a driver to increase the efficiency of POCO and decommissioning decision making through the implementation of real/near time in-situ data capture analysis for liquids, gases, particulates and solids.

Increased understanding of analytical requirements at source, will aid decision making on treatment options and sentencing to maximise correct application of the waste hierarchy.

It’s also probable that a slightly different capability will be needed, with additional emphasis on non-radiological characterisation.

For many years both vitrified and encapsulated waste products have been stored on the Sellafield site and over the next decade, retrievals from legacy ponds and silos will generate many more.

As Sellafield evolves into a waste management and remediation site, the range of package configurations is also expected to increase and a programme of inspection of key properties of them will ensure safe storage.

With many thousands of packages located in engineered stores, it would be impractical to extract and inspect all packages, therefore in-situ measurements will be required.

To address the site wide challenge of package and stores inspection there is a need to provide a range of measurement and deployment techniques to demonstrate control, take appropriate mitigating action where required and reduce dose to workers who currently provide an ad-hoc measurement capability.

There is an additional driver to aggregate the many condition monitoring and inspection measurement techniques and deployment requirements to increase benefit and improve efficiency across Sellafield.

Portable XRF analyser on metal billets (Courtesy of Niton UK)

Opportunities for technology development

Liquid, gas, particulate and solids characterisation

Tools and techniques for the analysis of isotopes such as tritium, strontium-90, alpha and beta contaminated liquids, hazardous compounds such as asbestos and gases such as hydrogen and helium.

Waste and product behaviour

Inspection or measurement tools and techniques to enable the detection of signs of unexpected degradation including in-situ technologies requiring robotic or automated deployment in dark store environments where traditional communication channels or power sources are absent.

Store conditions

For existing stores, a better understanding of how store environments can change under a range of likely scenarios for different waste packages, to increase predictability and thus help infer waste behaviour.

Tools for monitoring to provide an early indication of deviation from the predicted environment, e.g. temperature, humidity and chloride.

Understanding long term optimum storage conditions for a range of products to provide information that could be used to influence new store design and build and to improve existing stores.

Future asset management and digital technologies

In the context of Sellafield, assets can be defined as buildings and facilities including their fabric, plant and equipment and services.

Sellafield Ltd would like to use state-of-the art asset management tools and techniques, broadly termed as Industry 4.0, to transform asset management within its nuclear facilities, so that it is more predictive.

Industry 4.0 involves the evolution of industrial practices to embrace smart technologies which can integrate communication between machines, computers and people in order to support increased automation of these practices.

Adopting this approach would enable Sellafield Ltd to optimise whole life maintenance costs, improve performance of assets, productivity and safety through enhanced maintenance delivery across the enterprise.

This will increase stakeholder confidence and enable a more balanced view of the environmental impact of the facility and its operations.

The historic approach for Sellafield is to use:

- existing instrumentation and visual inspection to ensure the building is operating within its designed parameters

- a programme of scheduled maintenance to ensure the facilities remain in good working order and state of repair

Sellafield Ltd would like to modernise this approach by developing more fit-for-purpose maintenance programmes.

This can be achieved through the development of intelligent technologies that can monitor the asset to accurately predict conditions and supporting digital infrastructure.

Rawwater’s molten metal manipulation (M3), a crack repair system that can be used to provide high integrity seals in ponds, vessels and pipes

Opportunities for technology development

Monitoring

Development of a suite of smart sensor technologies, enabling features that support long life and integration of sensors into new or existing facilities.

Digital infrastructure

Systems that enable timely and secure data transfer, improve data collection, storage and accessibility, improve data transfer to operators or maintainers for enhanced decision making and facilitate traceability of packages or containers.

Autonomous inspection, maintenance and repair

Tools and techniques that can be used to inspect structures such as pond walls, waste containers, pipes and civil structure and that can undertake maintenance or repair activities.

Modelling and visualisation

Development of visualisation technologies to provide a virtual representation of the physical environment that can use real time data to aid decision making, provide training or simulation of an environment.

Post operational clean-out (POCO)

The normal approach to POCO is the characterisation and reduction of the chemotoxic and radiological inventory using existing chemicals, tools and processes that are readily available or deployable in the facility.

However high dose rates, operational liquids and residues remaining in-situ and complex geometry mean that this is an expensive and time consuming task.

With the completion of reprocessing operations on Thorp, there is an opportunity to use the highly complex facility as a test bed for new tools and techniques with learning used to define the strategy for the rest of the site.

An example of technology under development for POCO is gamma-optical video imaging (GOVI), a handheld camera that can be deployed through 6” ports. It provides real time visualisation and the location of gamma activity and could simplify the glovebox POCO process (Images courtesy of Loughborough University)

Opportunities for technology development

Characterisation of the system

Tools and techniques to establish location, quantity and form of the material to identify appropriate treatment processes. Methods to determine how material is fixed to a range of surfaces and the effectiveness of cleaning.

Access and deployment into the system

For information gathering (physical/visible, radiological and chemotoxic), deployment of reagents, chemicals and monitoring probes using new and existing penetrations and pipework, application of commercial off-the-shelf equipment.

Decontamination

Identification of a range of reagents and decontamination techniques, and their effectiveness, to remove solids, sludges and strongly bound activity.

Processes to maintain ventilation and containment during POCO operations.

Effluent and waste treatment

Processes for treating contaminated effluents, computer modelling of effluents to understand their compatibility with site treatment plants and optimise their use.

Protecting people

As operations come to an end on the Sellafield site, the focus will be on decommissioning and clean-up and a wide range of capabilities are needed in order to make these activities safer, more predictable and more efficient.

The long term vision is to displace much of the planned human high hazard activities by using robotics (see robotics and artificial intelligence technology theme) and by improving the protection of people for remaining activities using modern materials for personal protective equipment (PPE), digital technologies and human augmentation such as exoskeletons.

The current methods for protecting the operator are more than 60 years old and primarily involve the use of air-fed suits, PVC suits, gloves and respirators, occasional semi-remote tooling, film badges and lead aprons.

These tools were designed for operational management of nuclear facilities rather than decommissioning tasks.

Coupled with this, environments are often unstructured, complex and not easily amenable to robotics and remote technologies.

Operators can only work for short periods of time in high hazard environments with challenges such as heat stress, fatigue, sweat build up and reduced dexterity and mobility.

Opportunities for technology development

Digitalisation of the environment

Hardware, software and networks to improve planning pre human entry and during tasks. Use of 3D imaging and dose maps for decision making.

Communication

Techniques for real time transfer of information to the operator and supervisor as the environment changes and the task progresses.

Monitoring

Techniques for real time transfer of information to the supervisor on operator health.

Protection

Modern approaches to PPE to protect the operator from conventional and radiological hazards. PPE that will provide greater dexterity and flexibility and provide comfortable working conditions. Optimisation of activities.

Enhancement and tooling

Development of tools such as exoskeletons and an improved understanding of how human nature affects safety and safety performance.

Robotics and artificial intelligence

Microelectronics, data processing and robotic technologies, including autonomously operated systems have undergone rapid development over recent times, and will continue to do so as the world adopts this modern lifestyle.

It has been driven by productivity and safety benefits across a range of industrial sectors, including agricultural, warehouse distribution centres, food and transport and by mass consumer markets in mobile phone, video gaming and the internet sectors.

The government, academia and some industries have recognised that robotics are game changers in the way we live and work in our environment today.

Increased utilisation of robotic technology has the potential to significantly increase productivity of UK industry with resulting growth in the UK economy. This has provided national and international funding opportunities.

With the end of reprocessing approaching and as Sellafield Ltd prepares for a programme of decommissioning there is an opportunity to take advantage of this funding to broaden its use of robotics and artificial intelligence (RAI), by building upon existing remote handling capability which uses techniques such as teleoperations, to increase safety, productivity and reduce financial risk.

The benefits gained from increased use of RAI

Improved safety

Moving the operative away from the hazardous part of the task. Reducing both radiological incidents (e.g. worker contamination) and conventional accidents (e.g. falls).

Increased productivity

Reducing the time associated with decommissioning tasks resulting in cost and schedule improvements.

Job enrichment

Removing dull and repetitive tasks allowing workers to carry out more value adding tasks.

Reduced uncertainty in the nuclear provision

Development of RAI technologies against opportunities should have the additional benefit of reducing the cost uncertainties associated with the required technologies.

Economic growth

Development of technologies that UK companies can sell either directly or through the provision of services to the wider UK and international nuclear decommissioning markets as well as other sectors (e.g. oil and gas).

Robotics and artificial intelligence

Opportunities for technology development

Waste processing

Autonomous size reduction capability and 24 hours per day, 7 days per week sort and segregation with robotically enhanced waste packing to increase productivity, reduce waste packages and stores.

Restricted access decommissioning

Robotic capability for high hazard environments such as high radiation, for example remote devices for small tasks and fully autonomous glove box operations.

Assisted manual operations

Robotically enhanced operatives using wearable technology, robotic assistants to carry out the hazardous part of the task and technologies that can enable an operator to reach the workface quickly, for example robotic scaffolding.

Reduction of deployment risk

Standardised equipment with a single set of spare parts that can be configured in a short space of time. Modular systems that can be adapted to suit, task by task.

Interim states enhancements

Robotic techniques for autonomous management of facilities in a long term phase known as ‘dry and dark’ or stores that can maintain their own systems and manage nuclear waste without operator intervention over the life-time of the stores.

Increasing pond productivity

Techniques that can operate in low visibility to retrieve material from a pond such as heavy items without disturbing visibility or residual sludge. Tether-less underwater systems for inspection in areas that are difficult to access.

Enabling technologies

Complete characterisation coverage of facilities, virtual reality and autonomous sampling.

12. Delivery

R&D programmes and projects financially supporting technology development and underpinning science at Sellafield are supported by both Sellafield Ltd and by a broad range of organisations, external to Sellafield Ltd, including the National Nuclear Laboratory (NNL), NDA, small to medium enterprises (SMEs) and the academic sector.

Sellafield Ltd has a long history of collaboration with NNL and in January 2017 a unique agreement was formalised between the 2 companies who pledged to work together to deliver value for the UK taxpayer.

As the site drives forward its decommissioning programme which spans 100 years, it is in the public interest for the companies to work more closely together to ensure hazard reduction on the Sellafield site is delivered as safely and efficiently as possible by utilising innovative solutions.

Critical to the success rate for the delivery of R&D is integration and coordination of programmes to maximise efficiency, identify gaps and opportunities and deliver value for money.

This section describes the resources available to manage and deliver coordinated R&D programmes through research teams drawn from the technical expertise, strengths and experience available in the technical community.

By clearly articulating the science and technology areas requiring investment, aligned to the needs of the business, this document aims to encourage opportunities for dialogue and involvement in R&D from academia, the supply chain and stakeholders.

Integrated research teams

The Science Integrated Research Team (sIRT) manages the underpinning science programme with an NNL coordinator for each individual topic area.

Activities tend to be at the lower end of the TRL scale and therefore naturally fall within the academic environment and the scope of innovative companies.

Each technology topic is managed by an IRT which provides a multi-disciplinary approach with input from the end user.

An IRT:

- understands challenges and coordinates R&D

- delivers R&D which provides value across the enterprise

- is a space for more speculative longer term, high value R&D

- helps the value streams engage with the wider external R&D community

- finds technology in the supply chain that can be of use to the value streams and helps them to demonstrate the value of this technology

This approach draws on the technical expertise, strengths and experience from a variety of sources to provide a coordinated and well-balanced team to deliver an optimised programme.

Techniques that progress through the TRL scale successfully are demonstrated in a suitable active environment at Sellafield with the expectation that delivery teams on plant will assess final suitability and undertake selection.

Integrated research teams

13. Delivery enablers

Interfaces and stakeholder engagement

There are a number of existing groups that are relevant to the research requirements for Sellafield, for example the Nuclear Waste and Decommissioning Research Forum and its various working groups, which promotes a common understanding and collaboration between relevant bodies across the UK about respective R&D requirements.

Sellafield Ltd actively engages with these groups.

Within the organisation, the following groups have recently been created which reflect the increasing appetite for the use of robotics on the site and which are engaged with to identify RAI R&D opportunities.

These are:

-

Central Robotics and Artificial Intelligence - a group aiming to support and manage consistent deployment of RAI technologies across the site through engagement with the value streams and enterprise organisations.

-

Remote Handling Equipment Programme which manages the deployment and utilisation of equipment such as remotely operated vehicles and unmanned aerial vehicles.

Funding opportunities

Funding for R&D is available from multiple sources for example:

- Sellafield Ltd

- National Nuclear Laboratory

- NDA Direct Research Portfolio

- RCUK such as the Engineering and Physical Sciences Research Council (EPSRC)

- Innovate UK

Sellafield Ltd has been involved in coordinated research programmes involving multiple universities that have attracted funding from, for example, other parts of the nuclear industry and the EPSRC.

These include:

-

Growing skills for Reliable, Economic Energy from Nuclear (GREEN)

-

Transformative Science and Engineering for Nuclear Decommissioning (TRANSCEND)

-

Centre for Innovative Nuclear Decommissioning (CINDe)

Improving the clarity and timing of research needs leads to improved focus, better use of grant funding and can open up opportunities for co-funded research.

Additional enabling functions

This document identifies the future research requirements for technology development and underpinning science that will be addressed over a period of c.a. 4 years.

There are a number of supporting functions and systems in place to identify the requirements and their R&D programmes.

Science and technology needs sheets

These contain the detail for each topic on the work breakdown structure featured in this document.

They are live documents to allow the value streams to flexibly influence the medium to long term research programmes and are reviewed periodically to ensure that the plan remains focussed and any emerging needs are captured.

The science and technology needs sheets are stored centrally within the Sellafield management system and they can be obtained by contacting: technical.innovation@sellafieldsites.com

Task sheets are prepared in response to the research needs.

Technical baseline

It is a site licence requirement to demonstrate visibility and transparency of the technical baseline to the NDA and a number of key pieces of information are required including R&D tables which detail plans to resolve technical issues.

The software system used for this also captures the detailed R&D tasks that are generated from the research needs.

Knowledge, skills and experience

These play a vital role in the efficient delivery of R&D. As part of the transformation process Sellafield Ltd has a project in place to ensure that resources and capabilities are in place to respond to the changing site requirements and a further initiative is addressing the site wide information and knowledge management requirement.

Horizon scanning

Central Technical manages a horizon scanning initiative which seeks to gain early insight into new science and technologies that could have very substantial benefits to the Sellafield mission.

This extends to trends in new areas such as digital, automation and new materials. Further information can be obtained from: horizon.scanning@sellafieldsites.com

Engineering and design

Research teams actively engage with the engineering and design capability in the development of technologies.

Future work

Further work is being undertaken on other subject matter including social sciences, environmental sustainability and manufacturing technology, which may be included as part of the next review.

14. Work breakdown structure

Science

Technology development

15. Abbreviations, acronyms and references

| CINDe | Centre for Innovative Nuclear Decommissioning |

| COTS | Commercial off-the-shelf |

| EARP | Enhanced Actinides Removal Plant |

| EPSRC | Engineering and Physical Sciences Research Council |

| GREEN | Growing skills for Reliable, Economic Energy from Nuclear |

| IRT | Integrated Research Team |

| NDA | Nuclear Decommissioning Authority |

| NNL | National Nuclear Laboratory |

| NWDRF | Nuclear Waste and Decommissioning Research Forum |

| ONR | Office for Nuclear Regulation |

| OPC | Ordinary Portland Cement |

| PPE | Personal Protective Equipment |

| POCO | Post Operational Clean-Out |

| RAI | Robotics and Artificial Intelligence |

| RCUK | Research Councils UK |

| ROV | Remotely Operated Vehicle |

| SIXEP | Site Ion Exchange Effluent Plant |

| SME | Small to Medium Enterprise |

| TBuRD | Technical Baseline and underpinning Research and Development |

| TRANSCEND | Transformative Science and Engineering for Nuclear Decommissioning |

| TRL | Technology Readiness Level |

| UAV | Unmanned Aerial Vehicle |

| WVP | Waste Vitrification Plant |

References

- Sellafield Ltd Enterprise Strategy, 10th November 2020

- The cost of cleaning up britains nuclear legacy

- Office for Nuclear Regulation, Safety Assessment Principles for Nuclear Facilities, 2014 Edition, Revision 0

- Technical baseline and underpinning R& D requirements V8