Annual Research and Development Review 2020/21

Published 10 November 2021

1. Annual Research and Development Review 2020/21

This report presents:

- research and development (R&D) managed by Sellafield Ltd value streams driven by the needs of the business

- Longer term R&D focused on opportunities for innovative technologies, tools and techniques to reduce costs, improve safety and reduce timescales

- Collaborative R&D with a wide range of supply chain companies, organisations and universities

- Some of the specialist staff from the research community working in and with Sellafield Ltd’s technical teams

Katherine Eilbeck, head of research and development, Sellafield Ltd

I am justifiably proud of our programme of world class R&D which continues to grow and deliver results.

This report is being published in the shadow of the preparations for the next 26th COP summit and it is timely to reflect on the impact that this work has on helping demonstrate that nuclear energy is sustainable through accelerating, de-risking and reducing the cost of Sellafield Ltd’s programme of decommissioning and waste management activities.

2. Foreword

Rebecca Weston, Chief Operating Officer, Sellafield Ltd

Each year we publish this document - our review of work being done by the research and development teams at Sellafield Ltd. It might sound obvious but science is the key to us successfully creating a clean and safe environment for future generations.

The Sellafield site is filled with unique challenges. It is our scientists who, working closely with colleagues in the wider business, our supply chain partners and academia, are creating the solutions to those challenges.

Our remit is wide and fascinating and this report captures just a taste of what we do.

As we begin to empty our ponds and silos and focus on delivering the infrastructure we’ll need in the decades to come to safely deal with and store that waste, we move into an exciting new era for Sellafield Ltd, which will have R&D at its forefront.

This report gives a sample of the work we do and introduces you to the people who do it.

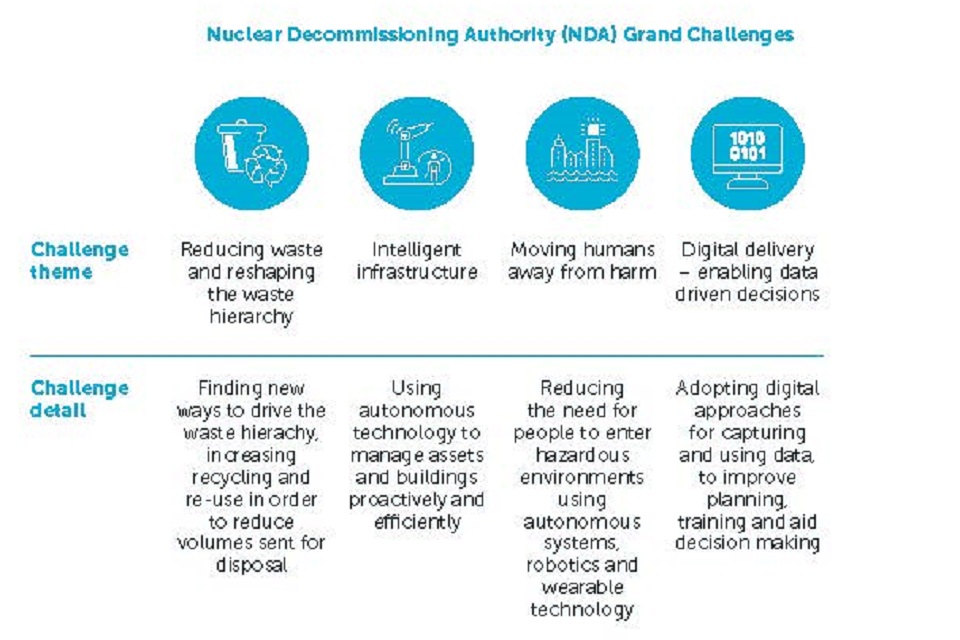

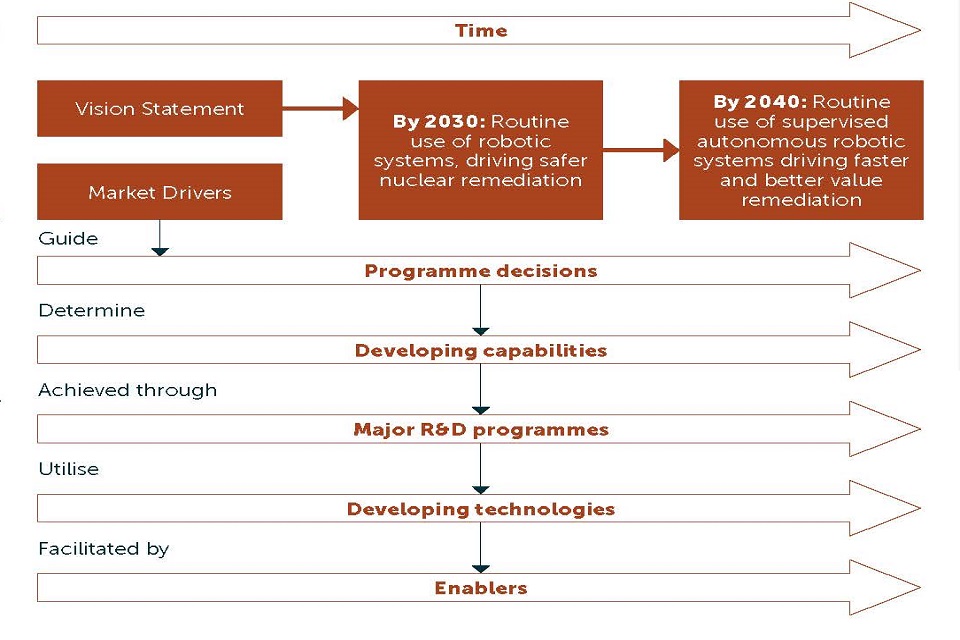

Nuclear Decommissioning Authority (NDA) Grand Challenges

To find out more contact: technical.innovation@sellafieldsites.com

For more information about the Nuclear Decommissioning Authority (NDA) Grand Challenges visit: NDA Grand Challenges.

3. Introduction

Welcome to this year’s annual research and development review featuring a cross section of research and development (R&D) activities.

It has been an extraordinary year as we have learned to work with the pandemic and ensuing lockdowns and we have included a great article on how we supported the response to this challenge in this report.

During lockdown we got used to new ways of working, which resulted in some of us reflecting on our current R&D programmes and reaching out for new ideas.

A highlight for me has been speaking to an artificial intelligence (Al) company in Silicon Valley called RealityAI about a collaborative project initiated by the Lloyds Register Foundation safety accelerator to use contact microphones on ducts to listen and identify defects using AI.

I’m excited by this work and look forward to the results.

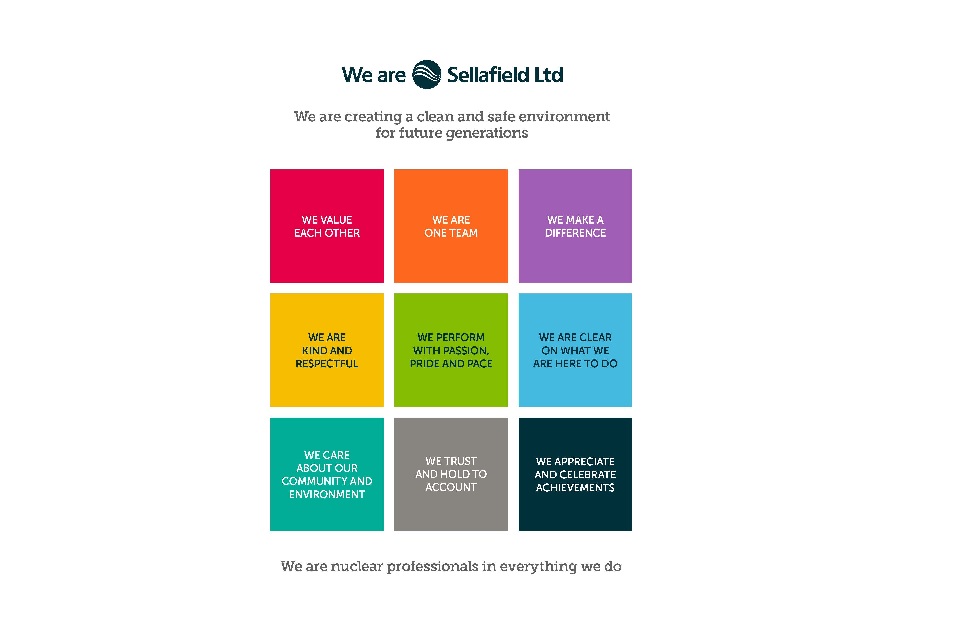

During the year Our Manifesto was launched. It describes the company we want to be – a Sellafield of which we can all be proud. It explains why we’re here, and the importance of what we do. Particularly it describes 9 behaviours we all expect to see from everyone working on our mission.

I hope that when you read this document and interact, work for us or with us, that these behaviours are demonstrated. We value working with the supply chain and endeavour to work as one team.

R&D is about making a difference to help us create a clean and safe environment for future generations. This approach means that we work with a wide range of supply chain companies, organisations and universities.

There are more than 50 involved in the delivery of the projects presented in this report. The National Nuclear Laboratory (NNL) is a key partner, facilitating our link with academia as well as delivering impactful research.

The report presents examples of key R&D managed centrally and by the 4 Sellafield value streams with their research areas captured at the beginning of each section.

Throughout the report, we have featured those involved in R&D and the real passion they have for what they do.

I believe the articles in here demonstrate the behaviours articulated in Our Manifesto; I hope you can see all the behaviours particularly the level of trust and respect we have that has enabled us to continue to deliver during the pandemic.

Please contact us if you see an opportunity for collaboration and/or coordination of research, development, or technology transfer in our challenge areas.

Warm regards

Andrew Cooney Technical Manager, Sellafield Enterprise R&D

4. Enterprise Technical

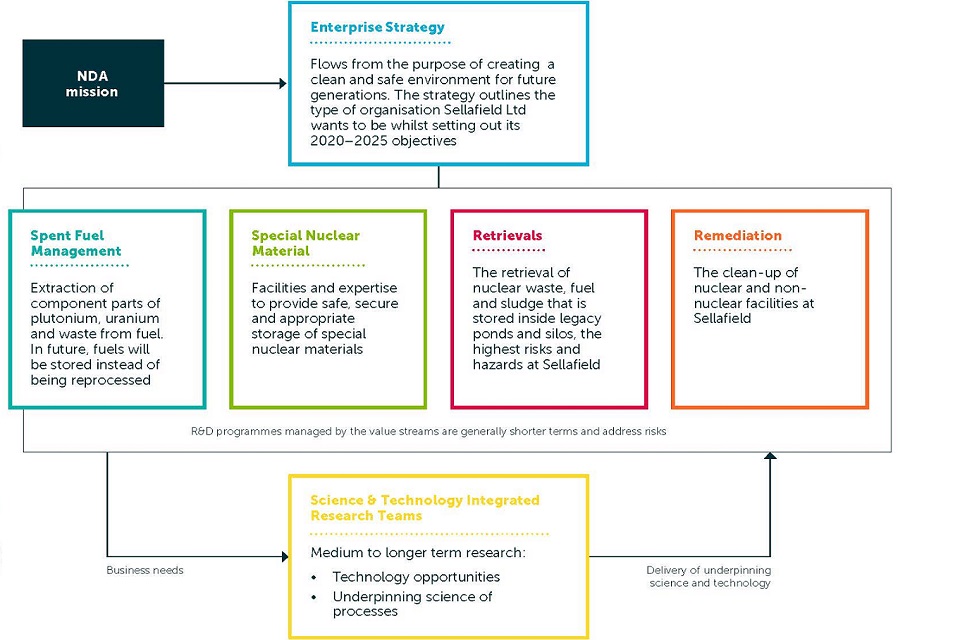

Our enterprise technical team has a wide-ranging remit. Its main responsibility is to oversee and manage the R&D programmes that address the medium to long-term needs of the business.

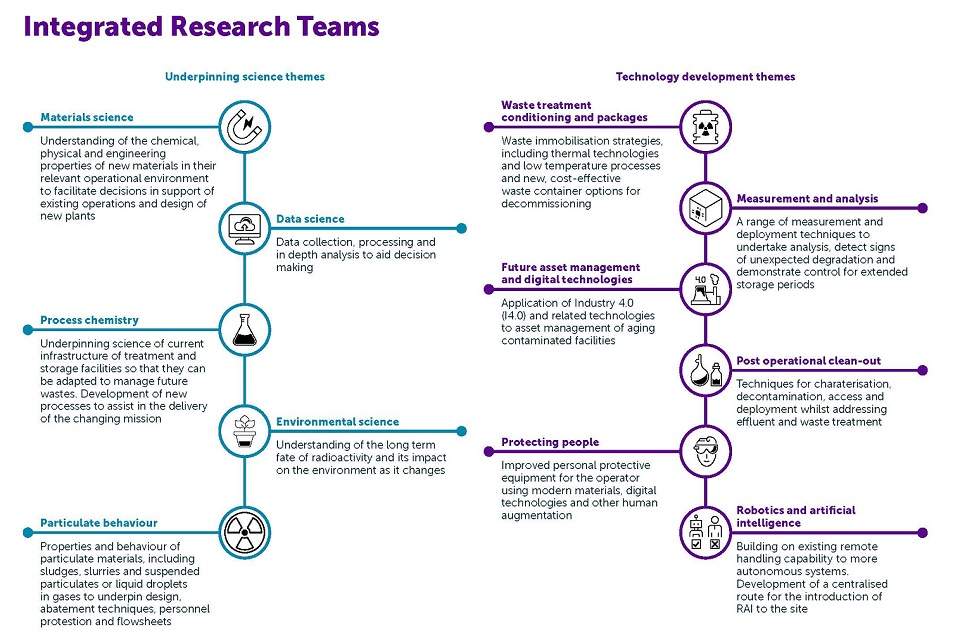

Within the R&D programmes, the key science and technology themes, which identify opportunities for the development of innovative technologies, tools and techniques, leading to lower costs, improved safety and reduced timescales, are managed by Integrated Research Teams (IRTs).

Our enterprise technical team is also responsible for representing Sellafield Ltd on numerous university engagement programmes and for ensuring their co-ordination across the business.

In addition, it manages the Game Changers programme and the horizon scanning capability which is featured later in this chapter.

The R&D programme is focused on:

- science, including sub-themes on materials, process chemistry, particulates, data and environment

- waste treatment, conditioning and packages

- Condition Monitoring and Inspection (CM&I)

- in-situ measurement and analysis

- Post Operational Clean Out (POCO)

- protecting people

- Robotics and Artificial Intelligence (RAI)

- future asset management and digital technologies

5. Integrated Research Teams

The role of the enterprise technical function is to ensure transformational solutions are delivered into the various value streams, within a range of R&D topics.

This process is supported by a number of Integrated Research Teams (IRTs) which work in collaboration with the end-user to identify appropriate technologies to address the challenges of decommissioning.

The role of the IRT is to:

- understand challenges and co-ordinate R&D efforts

- deliver R&D which provides value across the enterprise

- nurture a space for more speculative longer-term, high value R&D

- help the value streams engage with the wider external R&D community

- identify technology within the supply chain that can be of use to the value streams, helping to demonstrate its tangible value

The IRTs focus on the science and technology themes, which can be found further down this report in the IRT diagram. These themes are the key areas where R&D needs to be undertaken, in the medium to longer term, to support the fundamental delivery of Sellafield Ltd’s mission and to manage any potential future risks.

These themes are described in more detail in our ‘Future research and development requirements 2021’ report.

The longer-term R&D programmes, managed by the IRTs, complement the shorter-term programmes, which will be delivered by the value streams, as illustrated below:

6. Enabling innovation

Given the nature of our business, it is prudent to explore the best technologies that are available to address its particular challenges, demonstrating risks are as low as reasonably practicable (ALARP) and funding is being used appropriately.

This is achieved by enabling innovation which determines the challenges that are being faced, identifies the innovation solutions available and ultimately, actions the technology to deliver tangible impact within projects, while linking internal innovation needs with external innovators.

Instrumental in setting challenges are the IRTs, who listen to the business to gather and review priorities from value streams, linking to horizon scanning activities and identifying subject matter experts to deliver within medium-term timescales.

The Game Changers programme is a fundamental part of this enabling innovation process, as it works seamlessly with the KTN Innovation Exchange programme to share technology from other sectors.

In addition, innovation is encouraged through competitions launched by Innovate UK, which is the funding programme for UK Research & Innovation (UKRI).

This has previously included ‘Protecting the Nuclear Decommissioning Operator’, ‘Integrated Innovation for Nuclear Decommissioning’ and ‘Sort and Segregate Nuclear Waste’.

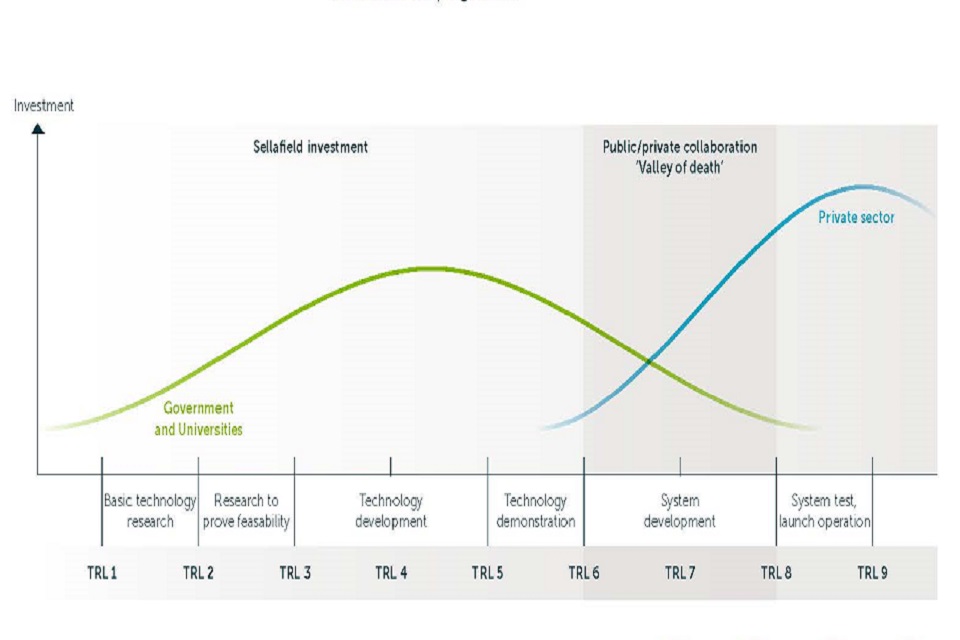

In order to gauge the relevance of innovation beyond the proof of concept stage, Technology Readiness Levels (TRLs), are applied to measure the various stages of maturity, from one to nine, from basic research, to feasibility study, to fully tested operational systems.

Technology Readiness Levels (TRLs)

The Game Changers programme tends to nurture projects rated between TRL 2 to TRL 6, before bespoke approaches are implemented to advance the technology to TRL 8 or TRL 9, in readiness for deployment on projects.

Bridging the gap between TRL 6 and TRL 8/9 is a well-established barrier to the adoption of new technology and is known in innovation circles as the ‘valley of death’.

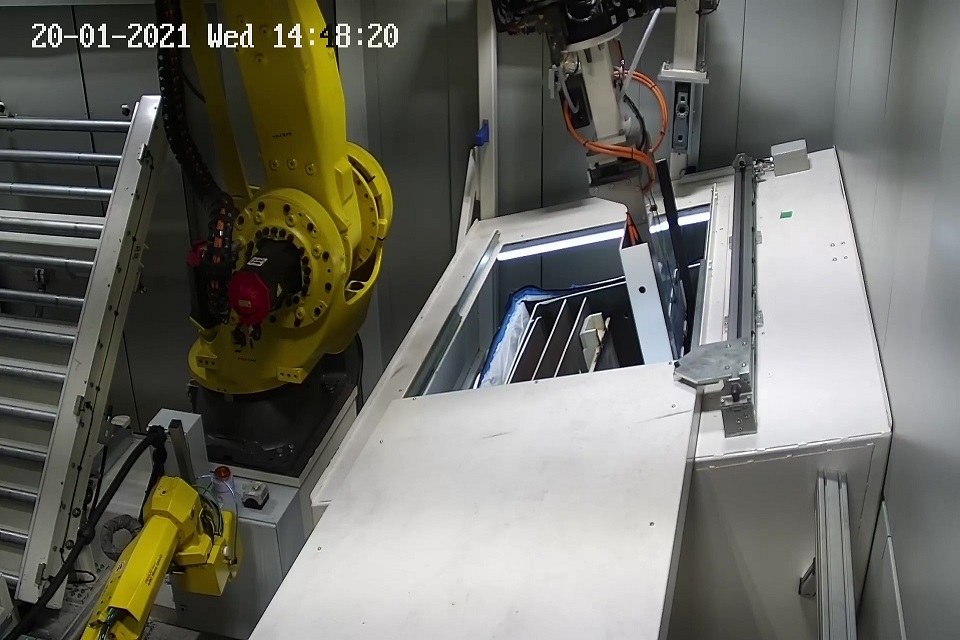

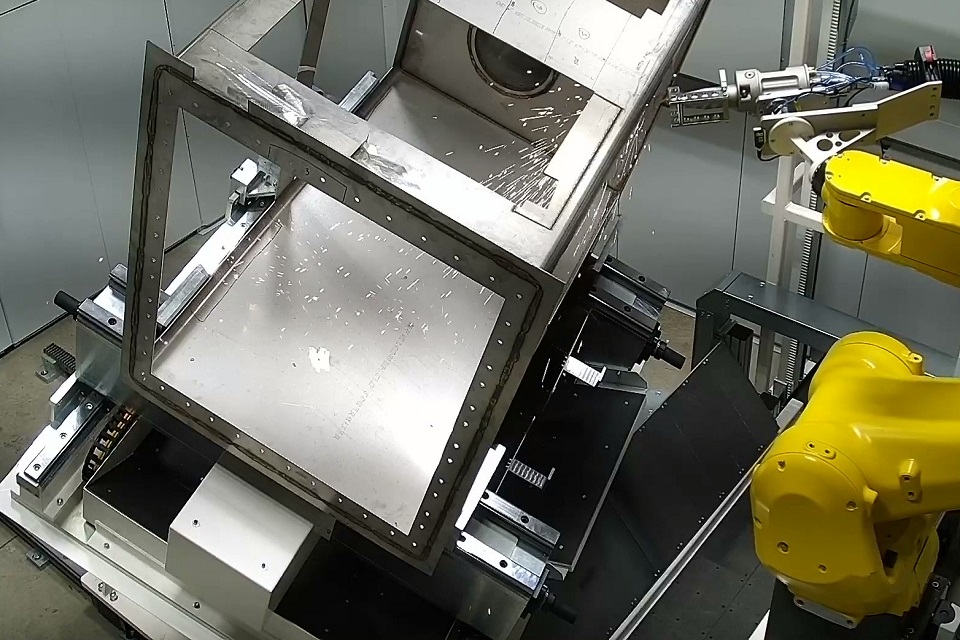

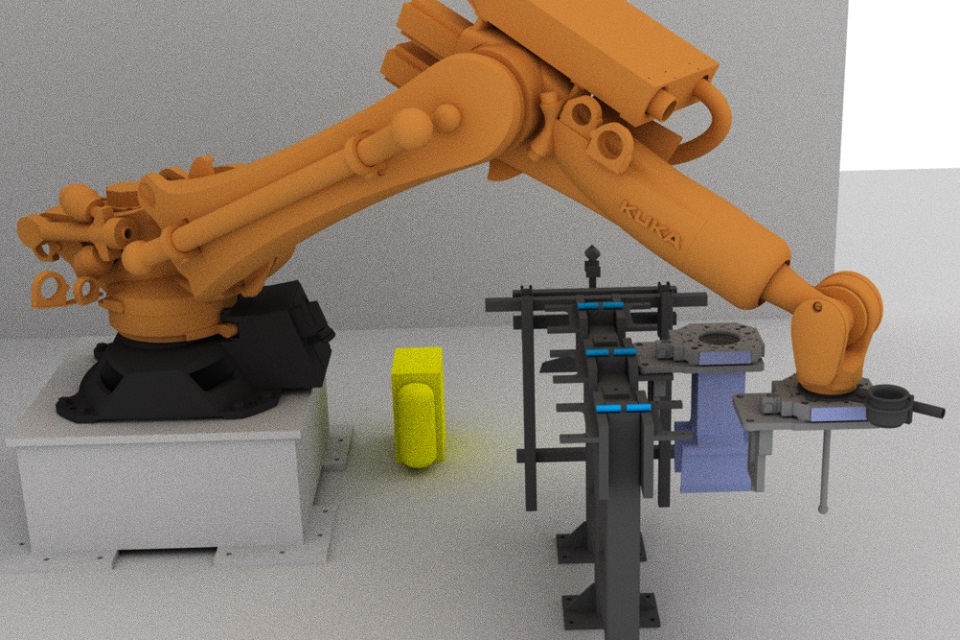

To overcome this barrier, we have developed facilities to enable at scale demonstration of technology both inactively, at the new RAICo One robotics facility, the Industrial Hub at Leconfield, Cleator Moor and the training and equipment development rig at the National Nuclear Laboratory, Workington and actively, via the Remediation Active Demonstration programme.

These facilities will go some way towards realising the steady stream of innovation needed to improve the way programmes are delivered and challenges are resolved.

7. Why science?

Science is about acquiring knowledge and testing hypotheses. We use this critical knowledge to inform and underpin our business decisions.

In many cases, these scientific endeavours lead to innovative ideas and the inception of new technologies. For generations, our scientific community has developed world-leading processes from nuclear reactors to nuclear fuel recycling.

In the coming decades, the role of our scientists will be to support the safe decommissioning and long-term storage of many types of nuclear inventory which has been generated during the past 6 decades.

The Sellafield scientist will provide the evidence to cement confidence in the decisions that are made that demonstrate that the nuclear fuel cycle is complete, thereby allowing future generations to benefit from new nuclear power generation.

Most of our scientific work is commissioned through UK academic institutions where we engage with around 40 universities. It commissions research fellows, postdoctoral research associates and PhD researchers to undertake a broad range of activities.

Not only do its academic interests produce high quality research but they also serve to develop advocates for its business, across many scientific disciplines, which enable support, challenge and peer review for its work, methods and approaches.

Perhaps the most important benefit of this work is the development of highly trained people who will become the scientists of the future, within Sellafield Ltd and across its supply chain.

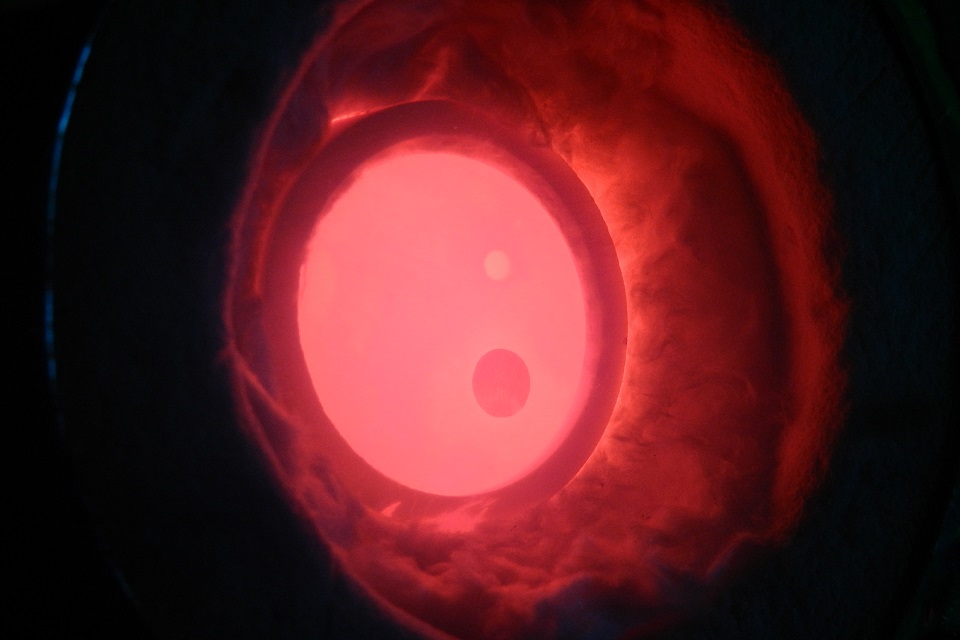

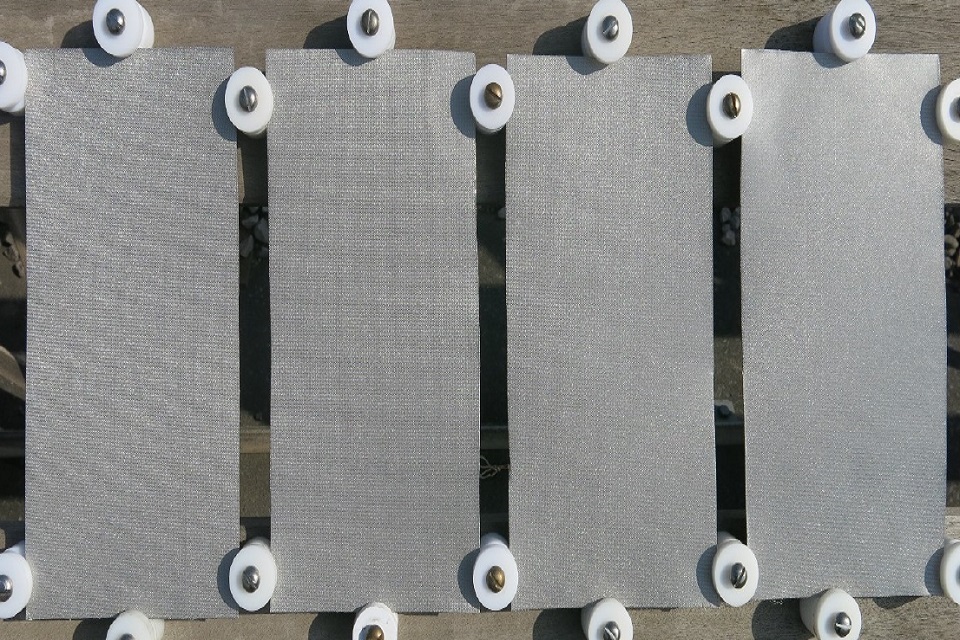

Optical image of Special Nuclear Material can

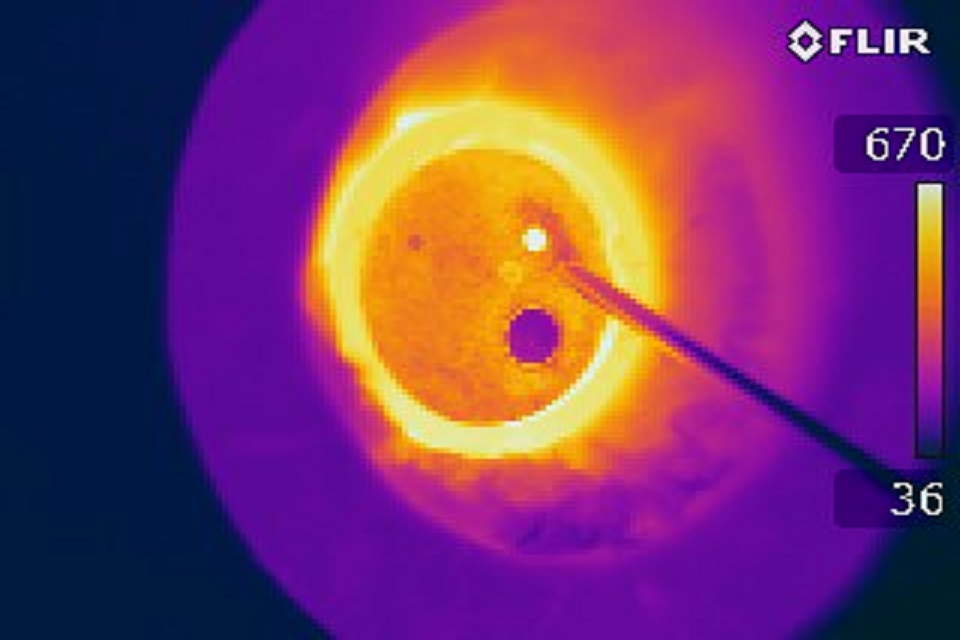

Phosphor thermometry of special nuclear material can

Phosphor thermometry of special nuclear material can

7.1 Our scientists

Spotlight: Materials science – Uranium and reactive metals

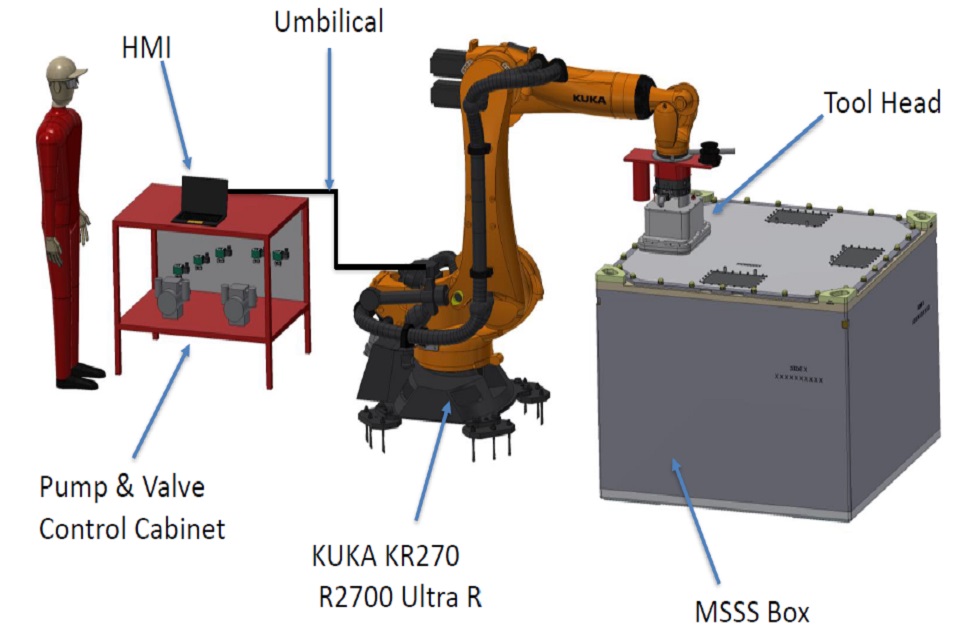

Over the next few decades, Sellafield Ltd will recover many tonnes of Magnox swarf (the waste cladding material that was removed from used Magnox nuclear fuel) from the ageing Magnox Swarf Storage Silo (MSSS) and will place it into highly engineered storage containers for interim store on the Sellafield site.

There has to be a degree of confidence that the physical processes and evolutionary chemistry of these and indeed many other types of waste forms are understood, so that their behaviour within the storage system can be predicted for decades to come.

As such, there is an assurance that problems are not being stored up for future generations.

Anna Adamska, Uranium and reactive metals science lead at Sellafield Ltd

Uranium and reactive metals science lead at Sellafield Ltd and visiting research fellow at the University of Bristol. Anna is our in-house specialist in uranium surface science and corrosion, filling in the gaps to help colleagues better predict how uranium and other reactive metals might behave and ensure they have access to cutting edge research in the field to support decision making.

After finishing a sandwich PhD at the Charles University in Prague, Czech Republic and the AGH University of Science and Technology in Krakow, Poland, Anna joined the Interface Analysis Centre at the University of Bristol as a Marie Curie Fellow investigating uranium alloy corrosion.

It was during this postdoctoral research that she started working with our Centres of Expertise and it led to her being handpicked by John Jowsey, the former technical lead of uranium and reactive metals, to take over his role.

Anna leads the Uranium Containing Waste Technical Group, co-ordinating experts from Sellafield Ltd, NNL and academia to undertake specialist reviews of reports, design and modelling parameters.

This oversight provides extra confidence that Sellafield is accessing the best scientific knowledge available to tackle its unique challenges.

Collaborating closely with university researchers helps Anna to better understand the gaps in current research and where further investigation is still needed to get the full picture of uranium corrosion behaviour.

Working with PhD students helps me to still learn new things and challenge my way of thinking. I don’t want someone to agree with me all the time – that’s not the point.

7.2 Our scientists

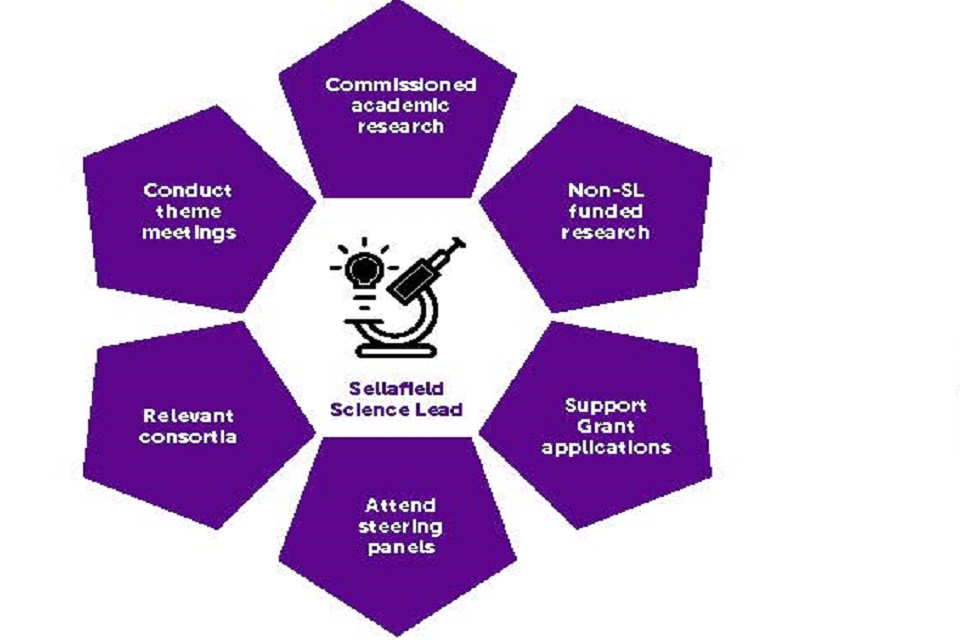

Our team of scientists are at the heart of the organisation.

They are its controlling mind; leading the scientific investigations that underpin our mission.

They understand and interpret business needs and uncertainties, build external capabilities to support its strategic objectives, commission scientific work, interpret outcomes and advise operational colleagues and decisionmakers, based on credible current findings and evidence.

The team works closely with academic institutions to facilitate and maximise the development of capability to meet our requirements.

The science leads’ role is a blend of direct-funded research, supporting grant applications, taking part in industrial steering groups and taking an active role in universities as visiting staff.

Steve Hepworth - Senior scientist, Sellafield Ltd

Steve took on the challenge of being senior scientist in 2020, following previous roles in both R&D and technical standards and assurance.

As senior scientist, he is responsible for identifying and implementing mechanisms to support our science leads, and ensuring we maintain a supply of highly trained scientists into the future.

Steve’s role includes brokering links between Sellafield Ltd and external research organisations, including UK universities, overseas institutions and funding bodies, to assist with scientific knowledge development and peer review.

This includes having access to nuclear related Centres-for-Doctoral Training (CDTs) such as GREEN (Growing Skills for Reliable Economic Energy from Nuclear) CDT, and for developing and maintaining capability across academia.

In addition, Steve is involved with various consortia, such as TRANSCEND (Transformative Science and Engineering for Nuclear Decommissioning), and the NNL’s CINDe (Centre for Innovative Nuclear Decommissioning) and is also responsible for supporting academic research grants and associated steering groups.

Steve is keen to continue strengthening links with the academic community and plans to involve broader expertise across Sellafield Ltd from academic interactions.

Scientific research is essential to Sellafield Ltd. By challenging norms, acquiring information and in developing understanding, we can inform the crucial decision-making of the future. Scientific research builds confidence in the choices we make as a business.

It leads to innovative ways to deliver our goals and, throughout the process, trains and equips new talent with the skills and knowledge the nuclear industry requires.

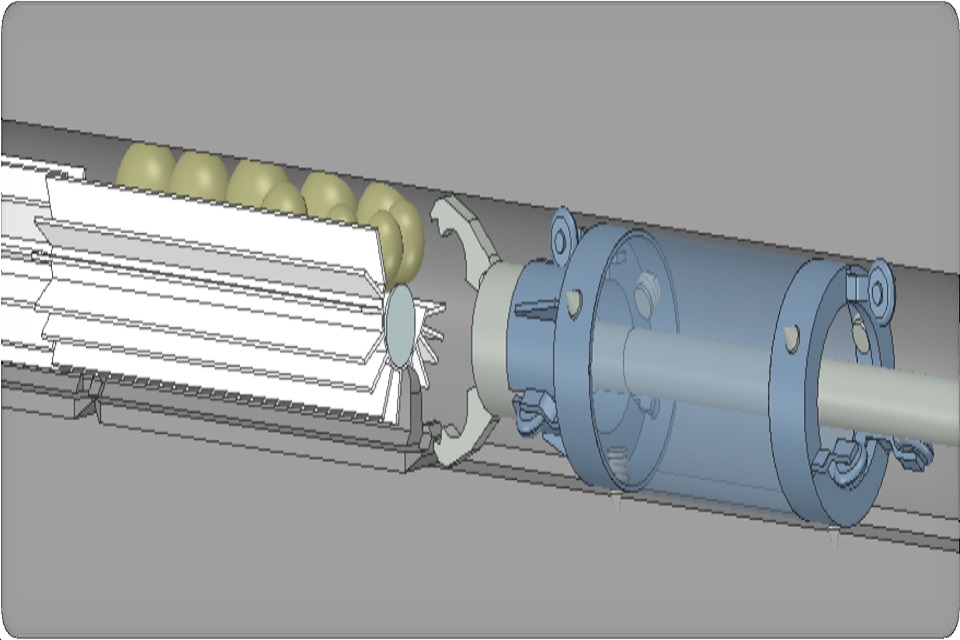

7.3 Smart sensors

Until now, the only way to monitor the temperature and pressure within the cans containing active material was to approach in-situ using an endoscope or ex-situ, using visual-only methods.

Traditional sensors have proven to be unsatisfactory, constantly using battery power, regularly sleeping, waking and measuring when often there is nothing of interest to measure. This typically limits battery lifetime to a few years.

Recognising the need to develop a long term solution to address the problem of monitoring high-radiation storage, Sensor Driven has developed unique microchip sensors that can extend battery lifetime to decades, using minuscule amounts of energy directly from transducer signals or from leakage currents, to wake up the measuring electronics and take a reading.

This innovative solution attaches to the bottom of the storage can and communicates wirelessly to a receiver.

A live demonstration of the prototype sensor and associated software was successfully held in April 2021, which confirmed that the system was working as expected, recording the temperature and pressure of product cans and relaying changes to plant operators. Radiation tolerance was also confirmed prior to the demonstration.

This 8 month project for the Special Nuclear Material value stream and enterprise technical teams was delivered both on time and in budget via the Game Changers programme, which engaged the use of 2 SMEs (small and medium sized enterprises.)

The prototype is capable of a 30-year lifetime with a 1mSv/h tolerance for 20 years at 70°C.

Fitted cap

Sensor Driven microchip sensor

Project

Long lasting radiation tolerant sensors

Benefits

Monitoring cans is currently complex, time consuming and requires removal of the can from the store. This sensor will greatly reduce the need for operator intervention, thereby reducing dose.

The ability to produce and apply the sensors would enable the condition of all cans to be monitored in real time.

Current Status

A second phase of work has been commissioned for 2021/22 that will refine and improve the communications route from the sensors and will develop them further.

Delivery Partners

Sensor Driven, supported by Collender Ltd, National Nuclear Laboratory, Game Changers

Contact Details

Simon Malone and Paul Mort via technical.innovation@sellafieldsites.com

7.4 Encapsulating the future

An extensive development programme was conducted from the mid 1980s to 1990s to identify suitable immobilisation media and techniques for Intermediate Level Wastes (ILWs).

The success of this programme led to the construction of the 4 current encapsulation plants on the Sellafield site.

Ordinary Portland Cement (OPC) based grouts were the encapsulants chosen as they are versatile, cost effective, easy to apply and stable over the required timeframe.

Whilst these plants and products have been highly successful, there is an opportunity to develop alternative encapsulants that will reduce cost, environmental impact and provide improved performance.

The simplest way to reduce costs and environmental impact is to reduce package numbers, which leads to a reduction in raw materials, encapsulation plants, stores, transports and geology space needed.

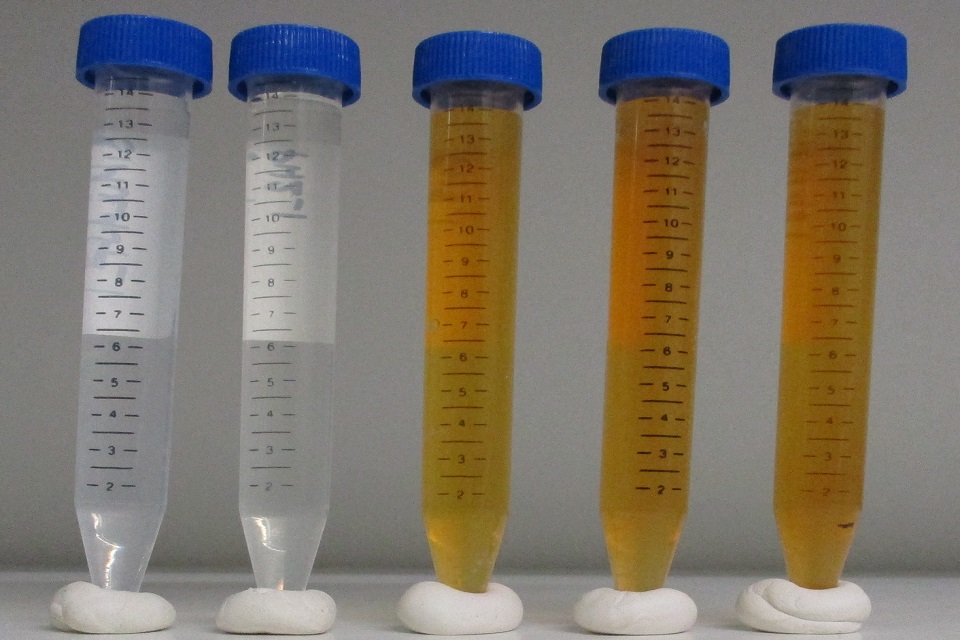

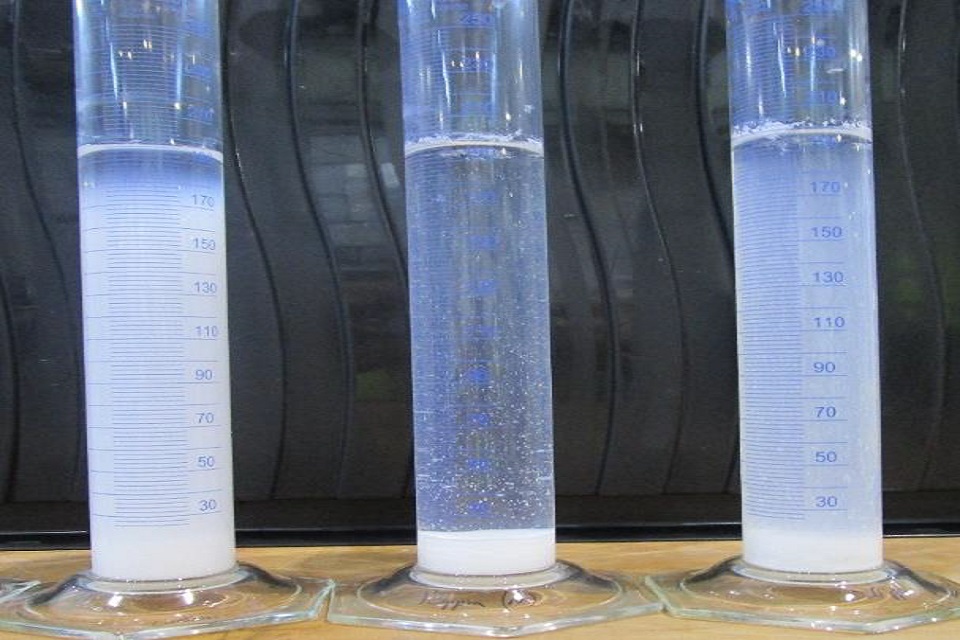

Hundreds of small-scale trials have been conducted and statistical analysis undertaken to identify formulation envelopes of these four cement systems.

The most promising formulations are now being taken forward and applied to non-radioactive waste simulants and scaled up.

Early scaling trials using ion exchange material and Magnox sludge simulant are already indicating improvements in mixing rheology and the ability to access other application methods that would facilitate higher waste loadings than could be achieved using traditional methods and OPC based encapsulants.

Trials to increase application to full scale are ongoing and, if successful, provide encapsulation options that could reduce package numbers for some waste streams by over 50%.

Package numbers can be reduced by utilising cement systems with a lower processing viscosity to make it easier to incorporate a higher waste loading and better encapsulate complex and large items.

The encapsulant IRT was launched to bring together national experts from Sellafield Ltd, National Nuclear Laboratory (NNL), University of Sheffield and TÜV SÜD Nuclear Technologies to identify wastes of interest and select promising cement systems.

Structured workshops and desktop reviews were undertaken to identify the potential encapsulants and wastes.

The encapsulants identified were geopolymers, calcium sulfoaluminate, high alumina cements and magnesium phosphate cements.

Hundreds of small-scale trials have been conducted and statistical analysis undertaken to identify formulation envelopes of these 4 cement systems.

The most promising formulations are now being taken forward and applied to non-radioactive waste simulants and scaled up.

Early scaling trials using ion exchange material and Magnox sludge simulant are already indicating improvements in mixing rheology and the ability to access other application methods that would facilitate higher waste loadings than could be achieved using traditional methods and OPC based encapsulants.

Trials to increase application to full scale are ongoing and, if successful, provide encapsulation options that could reduce package numbers for some waste streams by over 50%.

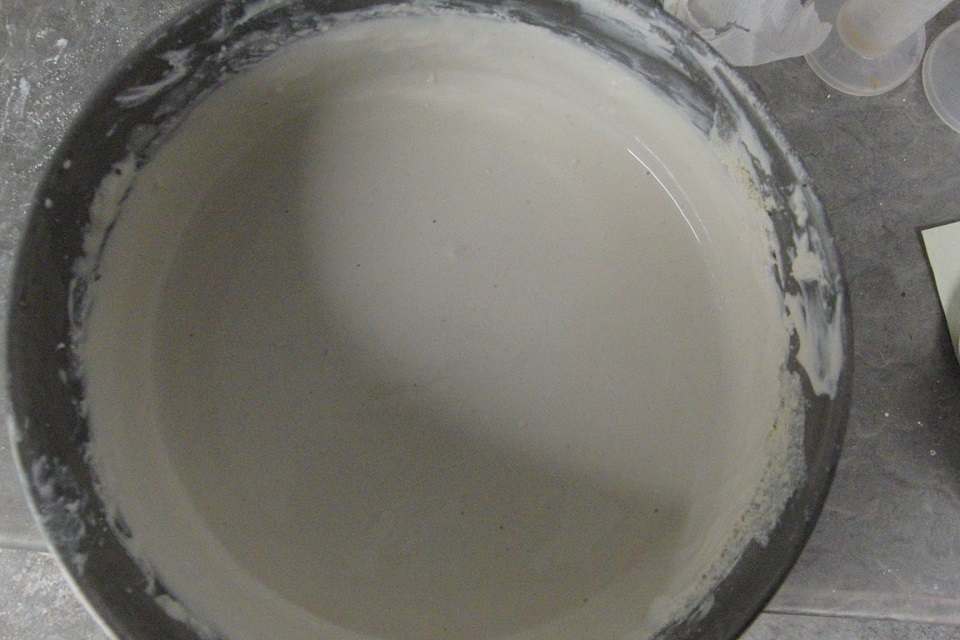

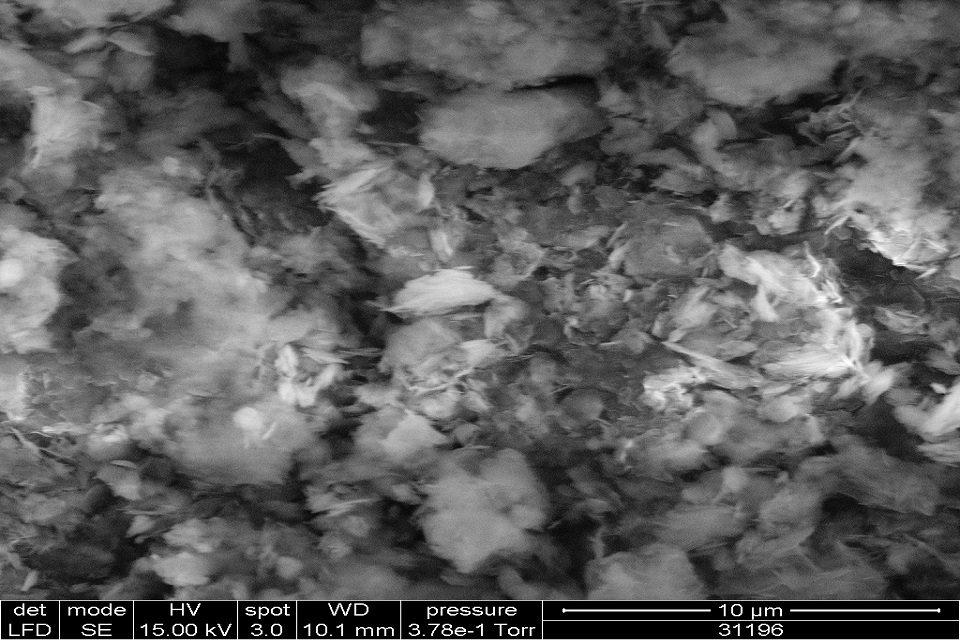

Magnox sludge simulant in geopolymer

Magnox sludge simulant in cement

Project

Development of improved encapsulant treatment options

Benefits

Novel encapsulants with low processing viscosities and greater tolerance to problematic chemical species offer benefits over traditional OPC based encapsulants by reducing potential package numbers.

Any reduction in package numbers reduces raw materials used, plants, stores, transport and Geological Disposal Facility (GDF) requirements and helps contribute to reduce our carbon footprint and contribute to the net zero CO2 targets.

Additionally, the novel encapsulants being investigated are viewed as “low CO2” alternatives to OPC based cements.

Current Status

Small scale formulation development of a number of alternative encapsulants have been concluded and statistical modelling undertaken. Proposed formulations are being taken forwards for waste compatibility assessment and scaling trials.

Delivery Partners

National Nuclear Laboratory, TÜV SÜD Nuclear Technologies and University of Sheffield

Contact Details

Sean Morgan technical.innovation@sellafieldsites.com

7.5 Pandemic support to the local community

This project challenged our normal ways of working and enabled us to consider actual rather than expected requirements.

For example, the usual standards for face visors include everything from welding to chemical and bacterial resistance but being able to use a visor for welding is not a requirement for a hospital ward, so challenging the actual ‘need’ vs the ‘must have this stamp’ and understanding the difference was a key technical requirement to getting the right products to the right places in the right time.

Our colleagues were keen to share their expertise and resources once it was apparent the pandemic had resulted in a national shortage of Personal Protective Equipment (PPE) and peripheral supplies.

Responding quickly to the situation, various teams were assigned to support local and national groups to help address the crisis to ensure enough suitable PPE and peripheral critical supplies were sourced, approved and delivered to areas where there were shortages.

The teams were established as a Technical Acceptance Group (TAG) with input from PPE specialists, Project Management, Innovation, Product Development and Supply Chain Management from Sellafield Ltd.

The TAG, which included representatives from BAE, was able to provide a similar response in South Lakes and Lancashire.

They worked alongside the heads of the Clinical Commissioning Group, Community and Acute Care Group and Social Care Services across Cumbria, Cumbria County Council response groups and the Highways Agency stores and transport.

The TAG members were instrumental in rounding up and approving supplies from our spares, supply chain partners and local hero volunteers who manufactured items such as visors.

In addition, Sellafield Ltd provided funding of over £270k for gowns and peripheral supplies, which were manufactured by a number of key suppliers.

This was only possible due to the technical abilities of our employees and the expertise and relationships within the supply chain, combined with the input on requirements from health experts.

This enabled decisions, development, acceptance and delivery of new/alternative products to be made in record time, allowing us to very quickly move from crisis to business-as-usual.

7.6 Horizon scanning

It’s no surprise that we are looking to technology to provide the solutions to address the diverse range of challenges, being faced now and in the future.

As such, the ability to see which technologies are emerging and are being deployed successfully elsewhere is critical to ensure that we are able to select and capitalise on the best solutions available.

In addition, the long-term nature of our ambitious mission requires us to understand, appreciate and adapt to the trends and drivers of change that are shaping the external environment.

Awareness of surfacing technologies will ensure that our strategies will be futureproofed and will be resilient to the wider scope of potential change.

The emerging technology team is tasked with identifying those tools and mechanisms that will allow us to undertake this horizon scanning in a systematic and robust manner.

Work to date has included:

Developing and piloting a strategic foresight methodology to explore multiple plausible future scenarios.

The pilot explored the topic of Artificial Intelligence (AI) and facilitated a more holistic conversation amongst a range of stakeholders about the wider social, economic and political drivers of change in this area and how they could combine in different ways to influence the future of the technology at Sellafield Ltd.

The resulting scenarios will be used by the Robotics & Artificial Intelligence (RAI) Programme to help us form its long-term vision for this particular technology.

- deploying technology databases, such as the Cogentus IdeaCatalog, into the business to give us instant visibility of thousands of technologies from multiple industries.

This reduces the risk of us developing costly bespoke solutions when suitable technologies could already exist.

Multiple technologies have been identified through IdeaCatalog and subsequently have been deployed to deliver tangible benefits.

- the creation of the “Sellafield Drop Box” as a facility for colleagues in the NDA or its supply chain to make the business aware of any interesting technologies.

So far, dozens of technologies have been suggested through the Drop Box, some of which were selected to explore further, while others were highlighted across the network to increase awareness of their impact.

With systematic horizon scanning methods in place, Sellafield Ltd is able to ensure that the best available technology and information is identified, developed and applied to support its mission.

In addition, the long-term nature of our ambitious mission requires us to understand, appreciate and adapt to the trends and drivers of change that are shaping the external environment.

7.7 Our ‘Dragon’s Den’ competition

Now in its 3rd year, the Dragons’ Den-style competition has successfully enabled ideas generated by our employees to drive innovation across the business.

Each year, this initiative is intended to encourage creative thinking around specific themes, which are then judged by business leaders. The winners are given time and funding to develop and implement their ideas.

This year, all employees were invited to focus on improving the working environment, delivering our mission and dealing more effectively with waste. The winners were announced in June 2020.

Winner - Ian Teasdale with Anti-Neutrino Ground Environment Logging System (ANGELS)

Anti-Neutrino Ground Environment Logging System (ANGELS)

Ian’s idea was to borrow technology from the world of particle physics to facilitate the monitoring of radioactivity when it is well shielded by concrete or is buried underground.

This can be done remotely without the need for expensive intrusive investigation or risk to workers.

The detector system depends on the properties of the ghostly anti-neutrino particle. It is deployed in a self-contained physics laboratory on the back of a lorry and has been developed by Liverpool University.

Ian is working with them to prove the concept when managing nuclear waste after the idea won support in both Dragons’ Den and the Game Changers programme.

Winner - Gavin Morgan with uniform reuse

This initiative was to reuse or recycle our corporate clothing at the end of its lifecycle to support our waste strategy and sustainability goals.

Gavin engaged with stakeholders across the business to ensure sustainability was considered at various stages of life with a placeholder to ensure that our next PPE contract incorporates sustainability principles when purchasing for the next tender.

Through discussions with facilities management and OneAIM, Gavin found our general day-to-day use aligned to sustainability principles, including use and washing.

Winners: Dan Braund and Jennie Stein with Deskspace AI app

Daniel Braund

Jennie Stein - Deskspace AI app

Jennie’s idea was to use an app to allow individuals to book hotdesks and resources, while Dan suggested using AI to optimally suggest and book resources (desks, days in the office etc) for users based on their interactions in Microsoft Outlook.

Dan and Jennie are working together to incorporate their submissions into the agile working programme in the future.

7.8 Game Changers

Now in its 6th year, Game Changers continues to go from strength to strength, providing a platform for exceptional innovation to solve the challenges of decommissioning at Sellafield and the wider Nuclear Decommissioning Authority (NDA) estate.

Managed by FIS360 Ltd and National Nuclear Laboratory (NNL), the process is being helped by the newly formed challenge statement steering group, which works across the NDA to identify and prioritise projects suitable for Game Changers, as well as raising awareness of the programme across the nuclear sector.

In addition, the Game Changers Innovation Forum was launched to support the scaling and commercialisation of technology and to help develop relationships between project partners and key stakeholders, including Tier 2 companies, operators, site licence companies, investors and collaborating partners.

Another partner, Dounreay Site Restoration Ltd (DSRL), also joined forces with Sellafield Ltd to search for innovative solutions to their shared challenges.

In 2020/21, there were 5 calls for innovation which attracted 60 applications for feasibility studies:

- detection of organics in pipes and vessels (in partnership with DSRL)

- removal of contaminated concrete (in partnership with DSRL)

- ground condition monitoring

- characterisation of landfill and disposal areas

- standardised robotics control architecture

A number of projects were subsequently awarded “proof of concept” funding which is granted after the feasibility stage, when the technology has been demonstrated or a prototype produced:

- Flexible Interchangeable Reconfigurable Mechanical Arm (FIRMArm) for POCO, with FIRMA Engineering Ltd

- developed by Resolve Robotics Ltd, CellRail is a versatile and modular robotic system that deploys tools and sensors at any position and orientation within hazardous environments

- Modular Tube Deployment System (MTDS) for working at height, with Remote Maintenance Systems Ltd

- energy resolved X-ray for detecting residual liquor and sludges for POCO, with Unitive Design and Analysis. This included successful non-active trials of their prototype device

- exploration of Raman, Laser Induced Breakdown Spectroscopy and hyperspectral imaging to determine whether they can be used to analyse soil samples and detect contaminants for POCO, with the University of Strathclyde

- mobile cost effective active neutron detection for CM&I, with Arktis Radiation Detectors UK Ltd

- fast detection and measurement of waterborne tritium, a collaboration between Hybrid Instruments and Lancaster University

In addition, Game Changers has continued to support projects to fully develop the technology including:

- Sensor Driven which developed a fully-functioning prototype of a remote sensor system to help us monitor the condition of product container cans in long-term storage

- Createc Robotics Ltd and UK Atomic Energy Authority (UKAEA) demonstrated their potential solutions for standardised robotics control architectures for enabling the use of modular robotics systems and allowing all robotics integrators to quickly develop robotic solutions through the reuse of previous designs

A challenge sprint of robotic tasks was broadcast live to stakeholders from Sellafield Ltd, NNL and invited independent robotics experts.

Robotic payload deployment system from Resolve Robotics

Hyperspectral imaging for soil sample analysis

FIRMArm product from FIRMA Engineering (Patent App. No. GB2101716.5)

Simon Malone - IRT lead for measurement and analysis, Sellafield Ltd

As IRT lead, Dr Simon Malone has a wide remit. His main responsibility is for overseeing a portfolio of diverse and wide-ranging research projects, such as in-situ measurements, hydrogen detection, and all aspects of CM&I across the value streams

In addition, Simon manages a number of partners and monitors the risks and plans for the research projects. He also scopes out new work with internal customers, maintains links with SMEs, universities and university spinouts whilst horizon scanning for new developments.

Simon has a strong academic background. He studied Applied Chemistry in Bristol, followed by an MSc in Analytical Chemistry and a PhD in Raman spectroscopy at the University of East Anglia. From there, he worked under Professor Sarah Heath as a Postdoctoral Research Associate (PDRA) at both York and Manchester University, researching crystallography of inorganic compounds, particularly those citrate complexes of aluminium and iron.

His next move took him into the polymer industry, where he spent 10 years at Innovia Films in Wigton, as a senior spectroscopist responsible for infrared spectroscopy, Time of-Flight Secondary Ion Mass Spectroscopy (ToF-SIMS), material testing as well as numerous classical analytical techniques.

Much of the role was developing and validating new measurement methods, reverse engineering and responding to customer complaints.

A member of the Royal Society of Chemistry, Simon joined Sellafield Ltd in 2015 and his significant background in both research and industry means that he is well-suited to this role as he understands the issues associated with developing innovative ideas and deploying them in an industrial context.

I want to use my academic and private sector experience to bring a different point of view to the industry, whilst keeping a sense of pace to deliver new and targeted R&D.

Sean Morgan, Encapsulant IRT lead, Sellafield Ltd

During his 20-year career, Dr Sean Morgan has developed significant expertise in all forms of waste treatment and is responsible for the identification and development of new encapsulants, to ensure that the waste is immobilised and rendered passively safe.

A Fellow of the Institute of Materials, Minerals & Mining, Sean holds several other roles, including lead for the Flammable Gas Centre of Expertise, ensuring a consistent approach is applied for flammable gas assessments.

Responsible for overseeing the hydrogen working party, Sean is also the University of Sheffield contact, the industrial supervisor for a number of PhDs and is joint chair of the intermediate level waste (ILW) Package Development group.

With a degree in Materials Engineering and a PhD in glass production for fibre optic devices, Sean joined BNFL in 1997 as part of the high temperature processes group, which included 18 months in the US, managing laboratory and pilot scale research on the Hanford vitrification project.

On returning to the UK, he spent 2 years at Inutec, assessing cementitious wasteforms and developing new waste packaging methods, before moving to Sellafield Ltd in 2010. Since then, Sean has gained a broad range of experience across SIXEP and SNM before moving into enterprise technical.

Thanks to a lot of effort, the alternative encapsulants that he is now developing are showing strong promise and he is on the cusp of doing large scale trials to verify that higher waste loadings are achievable, are more resistant to leaching and have improved fluidity.

This work includes the first novel encapsulant to get RWM assessment for Sellafield Ltd in 30 years.

Communication is a key aspect of any innovation project to ensure that its benefits and value are properly understood.

8. Spent Fuel Management

The Spent Fuel Management (SFM) value stream is responsible for the safe, secure and cost effective lifecycle management of spent nuclear fuel and associated waste, including:

- completing Magnox reprocessing as soon as practicable whilst creating contingencies for any remnant fuel

- the receipt and long-term storage of Advanced Gas-cooled Reactor (AGR) fuels which enables continued electricity generation and efficient reactor defueling, as well as the consolidation of spent fuel from Dounreay and the Ministry of Defence

- the evaporation and vitrification of high level waste and long-term storage prior to disposal along with completing the return of vitrified product to overseas reprocessing customers

- provision of effluent treatment and encapsulation capabilities to enable treatment of reprocessing effluent, enable high hazard risk reduction and treatment of future remediation effluent

- implement arrangements to transition facilities into ‘Post Operational Clean Out’ phase in a timely manner to enable effective lifecycle asset and waste management

8.1 Dounreay fuel consolidation

Irradiated nuclear fuels that are currently stored at Dounreay need to be consolidated at Sellafield to enable Dounreay to reach its interim end state by 2032.

From 1960 to 1994, Dounreay Site Restoration Ltd (DSRL) operated 2 fast breeder research reactors, the Dounreay Fast Breeder Reactor and the Prototype Fast Breeder Reactor.

In this period, these innovative programmes produced a wide range of irradiated experimental fuels including uranium oxide, mixed oxide, metallic uranic and carbide fuel of varying sizes.

Fast breeder fuel, often referred to as ‘exotic fuel’ is different to Magnox or Advanced Gas Reactor fuel, as it is irradiated to much greater levels in the reactor, subjected to higher operating temperatures and can have much higher enrichment.

Working collaboratively with DSRL, we are undertaking research to develop plans for interim storage to address this issue. This multi-year programme will require bespoke solutions to be identified due to the range of fuel types at Dounreay, which involves:

- assessing the irradiated fuels inventory at DSRL and the requirements for its inspection

- developing and licencing multiple types of transport packages to transport the fuel from Dounreay to the Sellafield site

- assessing and delivering various storage solutions at Sellafield, such as pond storage or novel dry cask storage systems

- investigating the interim storage behaviour of fast breeder fuel and developing the safety cases for interim storage

A detailed assessment of part of the fuel inventory has been completed through a collaborative project with Sellafield Ltd, NNL and DSRL to investigate the compatibility of the fuel with existing Self-Shielded Boxes (SSBs).

This research demonstrated that part of the irradiated fuel inventory could be stored safely in SSBs for up to 50 years, eliminating the need for a separate bespoke storage solution for this fuel type.

Camera footage within Dounreay Fast Reactor showing breeder elements and damage to top plate (© DSRL)

Project

Spent fuel consolidation programme

Benefits

This research programme will provide safe storage of the Dounreay irradiated fuel at Sellafield, pending the development of a lifecycle management solution including potential conditioning prior to storage in a GDF.

Current Status

This collaborative programme, involving DSRL and a range of supply chain partners, is ongoing with storage plans being developed for each fuel type.

Delivery Partners

Atkins, Dounreay Site Restoration Ltd (DSRL), National Nuclear Laboratory, Nuclear Advanced Manufacturing Research Centre (Nuclear AMRC), Magnox Ltd

Contact Details

Hannah Paterson technical.innovation@sellafieldsites.com

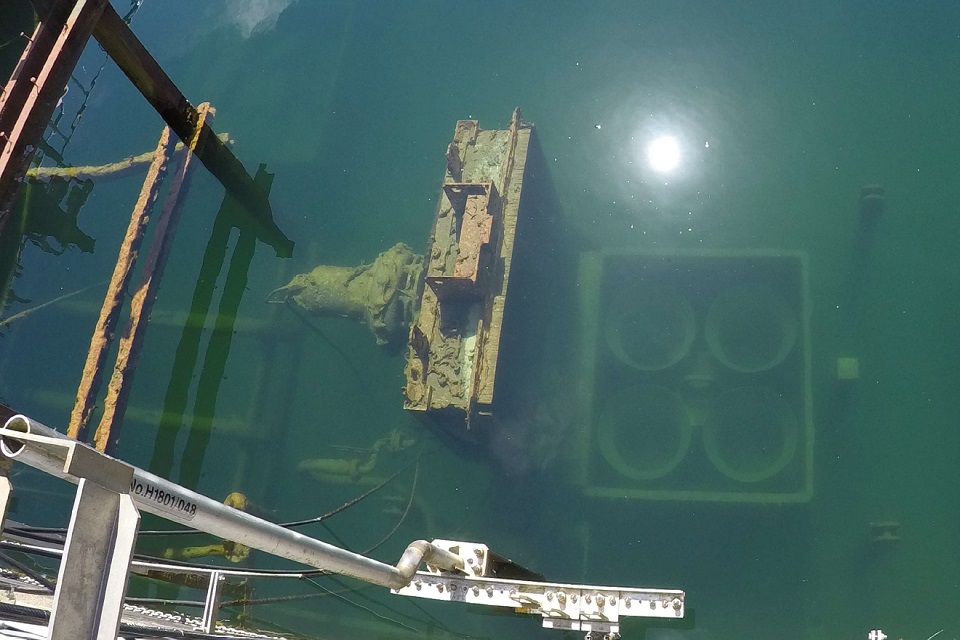

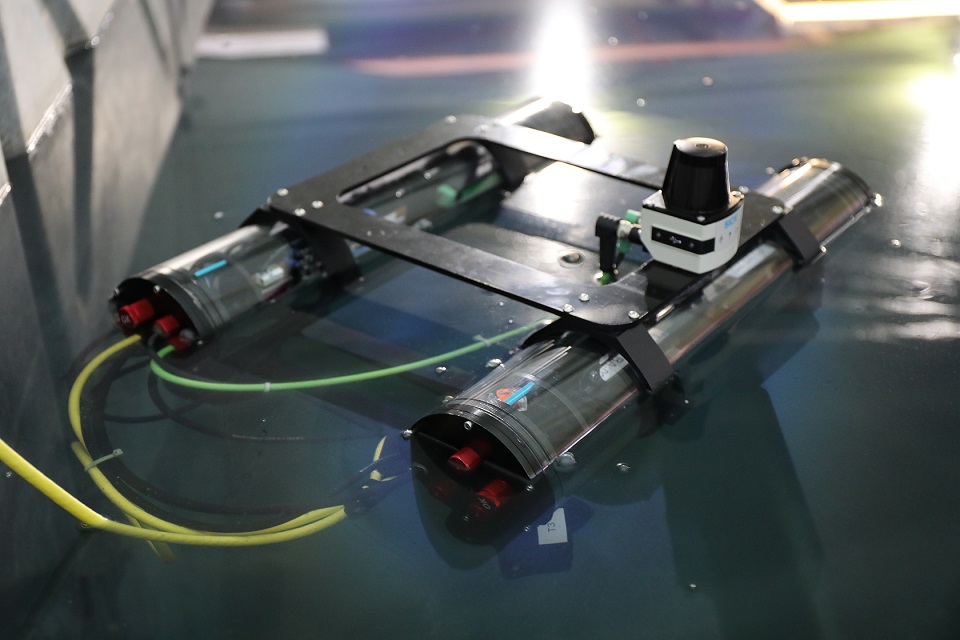

8.2 ROV inspection of vaults

The Vitrified Product Store (VPS), which houses the immobilised highly active waste generated from the reprocessing of spent nuclear fuel, has been at operation in Sellafield since 1990.

Ensuring it remains structurally sound is critical to ensure the safe management of the stainless steel containers of vitrified waste until they can be transferred to a Geological Disposal Facility (GDF).

As the Sellafield site transitions from reprocessing to decommissioning, the VPS will also store waste generated from the POCO of facilities that treat highly active waste.

Provision had been made within the Sellafield plan to build a replacement store to ensure the continued safe storage of the vitrified waste prior to the availability of the GDF.

Deciding when the replacement facility may be needed required a long-term assessment of the integrity of the facility.

Thanks to the collaborative relationship with NNL, a solution was identified which allowed the remote inspection of the tanks and vessels within the VPS.

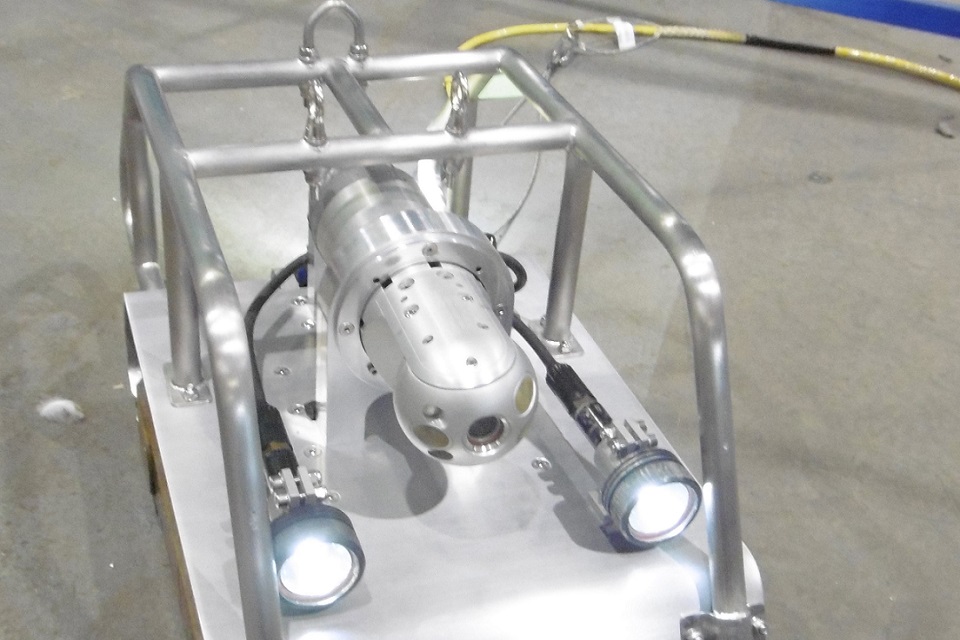

Their shared expertise was used to develop a Remotely Operated Vehicle (ROV) that is capable of operating in a high-radiation environment to capture high-definition images of the inside of the store, which were used to determine the condition of the asset.

The system was deployed by lowering it approximately 30m through an air duct to gain access to the floor of the vault, allowing visual inspection of critical structural components that haven’t been seen since construction and inactive commissioning.

A multi-disciplinary team of corrosion and materials scientists, modellers and structural experts reviewed the data gathered from the ROV inspection, together with analysis of corrosion coupons and data from plant monitoring systems and operational models to show that the store is in excellent condition.

This novel remote inspection method has allowed work to design and build a replacement store to be deferred, enabling resources to be focused on other high priority hazard reduction activities.

ROV for visual inspection of store.

Project

Vitrified product store asset management programme

Benefits

Deployment of the ROV has provided high quality images of critical structural components and environmental data (temperature and dose rate), allowing the condition of the VPS to be assessed to inform future management of the store.

This has enabled the life of the store to be extended.

Current Status

The asset condition of the store has been confirmed, allowing investment to design and build a replacement to be deferred.

Ongoing work to optimise management of the store will be supported by future inspections with the expectation that a replacement store can be avoided entirely.

Delivery Partners

National Nuclear Laboratory

Contact Details

Fiona Wright and Matthew Haigh

8.3 Effluent treatment transition

How effluent is treated at Sellafield is undergoing fundamental changes as the site transitions from reprocessing to remediation.

For 30 years, the effluent treatment process for the site has been unchanged, dominated by the reprocessing activities in Magnox and Thermal Oxide Reprocessing Plant (Thorp).

With the end of reprocessing in sight, there is now a complete change to the amount, nature and variability of waste effluent.

Research has been undertaken to focus on adapting the Enhanced Actinides Removal Plant (EARP) to accept alternative waste streams from donor plants.

EARP currently receives iron-bearing acidic effluent and coprecipitates activity through neutralisation with hydroxide, resulting in cleaned effluent for discharge to sea and an ILW slurry for encapsulation.

Laboratory and rig-based experimentation is being used to investigate whether the chemistry of the EARP system can be adapted to accept other waste streams, such as decontamination agents and to understand its potential operating capacity.

Modelling tools have also been developed and validated against the test results to assess scenarios, predict potential operational difficulties and the impact on discharges to the sea.

Although this work is ongoing, advice has already been issued to potential donor plants to specify how much organic decontamination reagent can be used and sent to EARP.

The treatment of other waste streams at EARP will be phased alongside the end of Magnox reprocessing. This will require a small amount of iron to be added to the EARP feed to replicate some of the Magnox effluent and to ensure that the EARP process will be effective, while producing a quarter of the ILW waste for ongoing safe storage and disposal.

In the future, further information will be generated to underpin the acceptance of other waste streams which could allow for effluents from the Highly Active Liquor (HAL) programme to be accepted, enabling a step-change reduction in costs and facilities required.

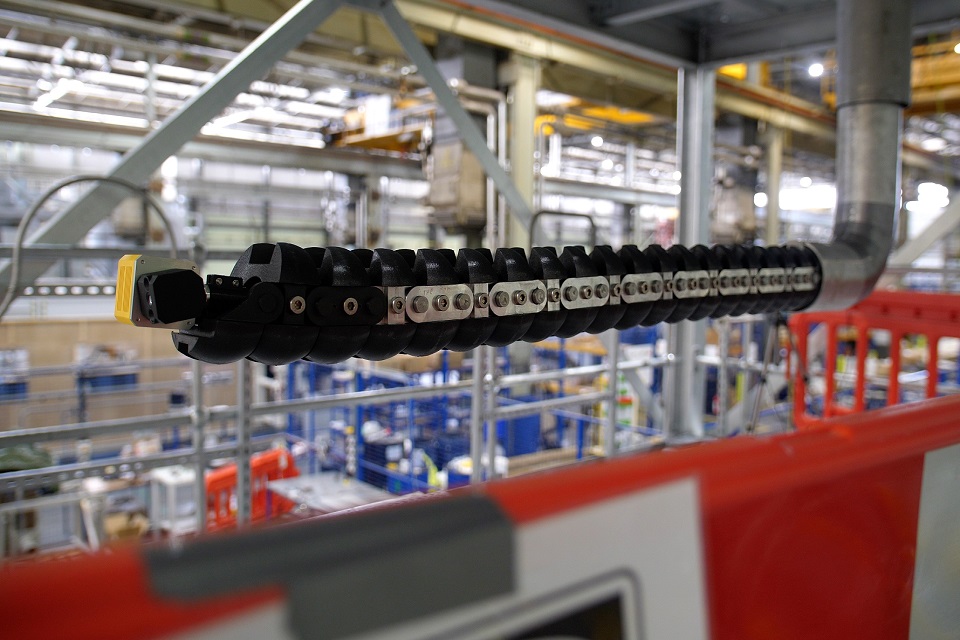

EARP rig in National Nuclear Lab's Workington Rig Hall facility

Floc with 0.2g/L iron with increasing pH left to right

Project

Enhanced Actinides Removal Plant (EARP) operating plan

Benefits

This work enables us to continue effluent treatment as the site transitions from reprocessing to remediation activities. Donor plants and treatment facilities are working collaboratively together to generate future operational plans that remediate risks, maintain the effluent capability, reduce the cost of waste disposal and minimise environmental impact.

Current Status

This project is ongoing and, in the future, will investigate whether the EARP can accept other waste streams, including effluents from the HAL programme.

Delivery Partners

National Nuclear Laboratory

Contact Details

Dick Blackham and Bethann Walker technical.innovation@sellafieldsites.com

8.4 Extending SIXEP asset lifetime

The Site Ion Exchange Effluent Plant (SIXEP) treats water from fuel storage ponds and legacy retrieval operations by using sand filtration and ion exchange to remove caesium, strontium and particulates before it is discharged into the sea.

The SIXEP began operations in the 1980s with a 20-year design life for the ion exchange vessels.

However, the need for effluent treatment has now been extended to around 2060 and a risk has been identified that the plant will not last long enough due to failure of certain assets.

The replacement SIXEP Continuity Plant will not be available until 2030 so research is being undertaken to give assurance in the operational lifetime of the existing SIXEP by:

- enhancing regular inspection of components where progressive damage is observed

- reducing stress on plant items through changing the control process

When one of the ion exchange vessels is emptied and re-filled every 3 months, it is possible to carry out an internal inspection.

This has identified some damage to the internal vessel components but the rate of change of the damage is hard to quantify due to the quality of the images.

Fortunately, removal of the need to operate through a gamma gate has allowed a high-definition camera and laser scanning system to be deployed on rigid poles.

This ensures consistent positioning from one inspection to the next and provides better quality images for detailed review of the welds on the ion exchange vessels.

This new method of inspection is now in place and will be used to quantitatively measure any component movement or damage.

Changes to the control system to minimise cyclic stress on the plant have been investigated by simulating the process in a computational model. This provided a digital test bed to trial control system settings and reduce the historic flow variability.

As a result, changes have been progressively implemented to the plant control system that have demonstrated a significant reduction in the flow variation.

High-definition image of ion exchange vessel

Project

SIXEP asset management programme

Benefits

Minimising the cyclic stress on the plant will increase the SIXEP lifetime, while regular quantitative measurements of the vessels will increase confidence in the plant integrity.

This active asset management approach increases confidence that the existing SIXEP will continue to operate until the replacement plant becomes available.

Current Status

Now that the new quantitative inspection methods have been successfully deployed, data will be collected and compared at each subsequent inspection to assess and monitor the ongoing integrity of the vessels.

Delivery Partners

National Nuclear Laboratory

Contact Details

Andrew Riley technical.innovation@sellafieldsites.com

Bethann Walker, Effluent plants technical, Sellafield Ltd

Effluent plants (LAEMG) technical employee, Bethann Walker, has completed her engineering degree while working as an apprentice at Sellafield.

This five-year Degree Apprenticeship Scheme with Gen2 and University of Cumbria has enabled Bethann to study as she works, committing to a demanding schedule of day-release learning to achieve her BEng (Hons) Degree in Plant Engineering (Nuclear Plant and Process Technology) at the University of Cumbria, while contributing as a member of the Magnox Reprocessing and Effluent Plant (MR&EP) technical team.

Her final year degree project involved assessing the requirements, risks and processes involved in transferring drums from the Waste Packaging and Encapsulation Plant (WPEP) Store to the Engineered Drum Store (EDS) in order to free up much-needed space.

This required co-ordination of logistics while understanding and being mindful of radiation levels and safety requirements is critical to facilitate the start and delivery of other projects.

At the same time, Bethann has contributed towards work implementing improvements in the WPEP process which will reduce costs and make the encapsulation process more efficient.

I’m grateful to have been given this opportunity to do my degree while working at Sellafield, as I have benefitted from being able to apply my site experience to my learning and vice versa. I enjoy seeing the impact of the work I’m doing.

Hannah Paterson, Spent fuel technical manager, Sellafield Ltd

With an academic background in chemistry, spent fuel technical manager Hannah says she almost stumbled into the industry but since completing the nuclear graduates programme in 2016, she has never looked back.

During her varied career, Hannah has managed a large portfolio of R&D and test rig campaigns to support our high hazard risk reduction mission in high level waste.

She also undertook an 18-month secondment to the NDA as a national waste inventory manager before starting her current role in the spent fuel services strategy and technical team.

She describes each day as being varied, supporting project and programme teams but her main responsibility is to manage the technical programme of works for interim storage of irradiated fuel due to be received from Dounreay and setting the strategy for how the fuel will be managed.

The majority of this fuel differs in composition from current fuels stored on site as the experimental reactor fuel was exposed to wider ranging conditions in fast breeder reactors.

An RSC Chartered Chemist, Hannah remains driven by the opportunity to collaborate with other organisations and sharing ideas about the challenges of storing different fuels, focusing on safety and innovation. Hannah is also passionate about encouraging others to join the nuclear industry and is Chair of the Nuclear Institute YGN for 2021.

In the meantime, Hannah’s current priority is to finally meet her colleagues in Dounreay face to face for the first time in 18 months, a meeting which she is convinced will reap results from focused thinking in the real world, rather than the virtual.

I enjoy the unique range of challenges at Sellafield and am proud to be cleaning up our nuclear legacy for future generations.

Georgina Vickers

Technical advisor SIXEP

SIXEP technical advisor Georgina (Gina) Vickers joined Sellafield Ltd on the graduate training programme in 2019 and since then, she has seized every opportunity to come her way.

The graduate training programme, which is designed to offer experience in a variety of disciplines, has enabled Gina to gain insight into the corporate management side of the business in external affairs, as well as working in the systems engineering team of SIXEP, where great ideas translate into real changes on the plant.

Gina was keen to join the team at Sellafield after she completed an industrial placement in the Risley office, investigating methods to empty the SIXEP stores of historic waste, as part of her Chemical Engineering degree at the University of Manchester.

Her current work involves exploring how the life of the ageing SIXEP facility can be extended: aspects include understanding where the risk of failure lies, through improved inspection methods and how to fix the plant if something goes wrong, by evaluating innovative repair techniques, such as molten metal spraying.

This technique has not yet been used in the nuclear industry so the outcome of remote trials being carried out are eagerly anticipated.

Beyond the day job, in her role as STEM ambassador and school governor, Gina mentors and supports students interested in exploring a similar career pathway by providing advice and preparing them with mock interviews.

I enjoy the hands-on aspects of working on site at Sellafield. It’s great to be given responsibility when working on projects and to see things come to fruition.

9. Special Nuclear Material

The Special Nuclear Material (SNM) value stream is responsible for the safe, secure and appropriate storage of special nuclear materials, with the R&D programme focusing on:

- understanding the chemical and physical behaviour of plutonium-bearing materials to ensure long-term safe management and storage, focusing on aspects including radiolysis, evolution of sealed packages, corrosion behaviour of impurities such as chlorides and the requirements for future conditioning

- innovative approaches to the safe operation of facilities handling and storing plutonium, possibly including technologies such as robotics, automation and digital applications for alpha environments

- continued technical underpinning of POCO and decommissioning plans for alpha facilities

- techniques for the monitoring, retrieval and processing of residual product in gloveboxes, plant, equipment and facilities during POCO and decommissioning

- direct support to the special nuclear materials consolidation programme

9.1 Thorp package characterisation

The Special Nuclear Materials (SNM) package surveillance programme is needed to understand how plutonium oxide (PuO2) and its packaging ages through long-term storage.

This work can only be delivered through selective destructive testing of plutonium packages.

This plays a vital role in mitigating technical risks around the lifetime of packages within the multi-billion-pound SNM portfolio and will inform on the strategic tolerance for the delivery of the Sellafield Product and Residues Store Retreatment Plant (SRP).

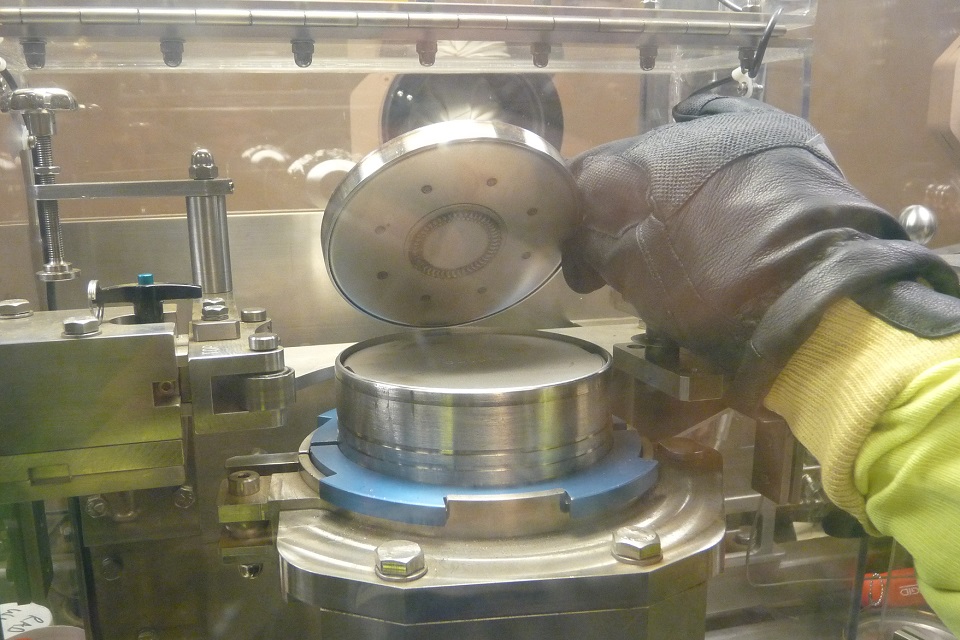

The package characterisation facility at NNL received the first welded Magnox package in 2017. Since then, over 20 Magnox welded packages have been characterised in terms of gas composition and PuO2 characteristics and detailed metallurgical characterisation of the package components has begun.

The Magnox packages ranged in age from 6 months to 43 years old but were all at sub-atmospheric pressure despite the presence of helium gas from alpha decay of PuO2.

In March 2021, the first Thorp package was delivered to the NNL facility after a project to develop a transport route from the Thorp SNM store to NNL and to implement new safety cases.

The Thorp package was more of a challenge to deliver because it is thermally hotter and presents a larger dose challenge when handling, compared to Magnox packages.

The first Thorp package was punctured in the NNL facility and the ullage gas was sampled and analysed, with no hydrogen or oxygen detected. The package contents were characterised by measuring volatile content through loss on heating, powder specific surface area, X-ray powder diffraction and thermo gravimetric analysis.

Samples were also taken for additional characterisation in the complimentary science programme.

Finally, the material was heat treated, measuring mass change in the furnace cycle, before being welded up into a new package for storage prior to transfer to a Sellafield SNM store.

The can components were size reduced, mounted, ground and polished to allow detailed metallurgical characterisation.

Now that the NNL facility can handle Thorp packages, this will allow more detailed package characterisation to be undertaken to understand the impact on package lifetime, including the rate of helium evolution and component corrosion.

Thorp package outer can

Thorp package inner can and package contents

Project

SNM package surveillance programme

Benefits

Understanding and characterising how plutonium oxide and its packaging ages through long-term storage will ensure the safe storage of the material over the package lifetime until it can be retreated and or repackaged in the SRP.

Current Status

This programme will run until at least 2028 when the SRP is commissioned. The NNL facility will continue to examine the current package types as they continue to age and capability will be expanded to receive other material and package types.

Delivery Partners

National Nuclear Laboratory

Contact Details

Jeff Hobbs, email: technical.innovation@sellafieldsites.com

9.2 Plutonium oxide evolution

Plutonium, principally in the form of plutonium oxide (PuO2) powder, is currently stored on the Sellafield site in gas-tight packages, some of which are nearly 50 years old.

Over this period, the chemistry of the PuO2 has been evolving, driven by the radioactive decay of plutonium to uranium and americium daughters and the generation of helium gas.

To inform the current and future safe storage of plutonium oxide, it is necessary to understand the effects of radioactive decay on the chemical stability of the PuO2 matrix, its ability to retain gases and alter its oxidation state.

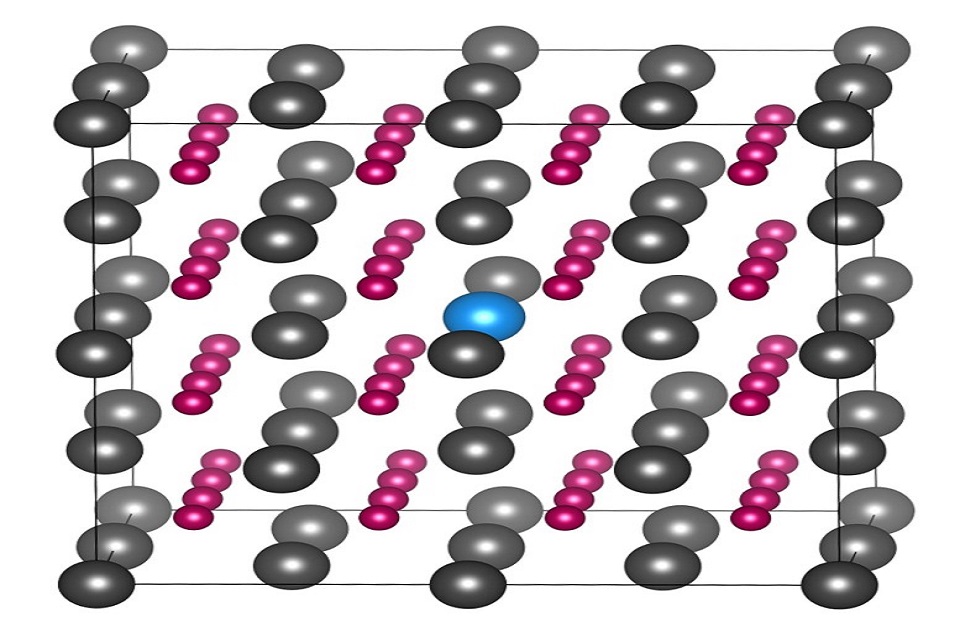

As such, we have supported a PhD programme, which is now in its second year, to model the evolution of stored plutonium oxide through Density Functional Theory (DFT) analysis.

This project is part of the TRANSCEND Consortium and is a collaboration with Lancaster University and University College London.

The chemical modelling of actinides is technically challenging. However, Lancaster University has developed a bespoke combination of DFT analysis and empirical techniques that accurately reproduces the available experimental values.

This has enabled the chemical form of the PuO2 matrix to be identified under a range of oxygen concentrations and has determined how americium ingrowth and helium can perturb it.

Graphical representation of the plutonium oxide matrix with the inclusion of an americium daughter occupying a plutonium atomic position

The results and findings have recently been published in 2 leading international journals.

- William D. Neilson, Helen Steele and Sam Murphy - Evolving Defect Chemistry of (Pu,Am)O2±x Journal of Physical Chemistry C. 2021. 2 William D. Neilson, James T. Pegg, Helen Steele and Samuel T. Murphy The defect chemistry of non-stoichiometric PuO2±x Phys. Chem. Chem. Phys., 2021, 23, 4544

Understanding any potential factors that may affect the plutonium oxidation state is essential information, in the long-term move towards its storage and will inform future disposition programmes.

Project

Evolution of stored PuO2 through DFT analysis

Benefits

This PhD research will minimise and focus future experimental work on plutonium evolution, which will reduce the risk to operators and researchers, cost and time.

Current Status

The PhD is ongoing and the next step is to study surface effects.

Delivery Partners

Lancaster University

Contact Details

Helen Steele, email: technical.innovation@sellafieldsites.com

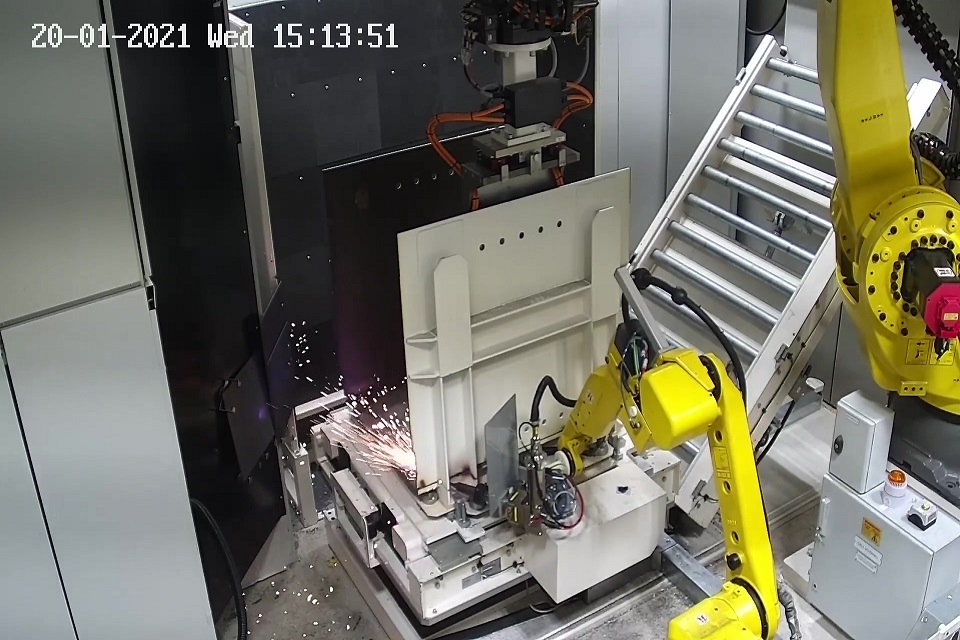

9.3 Special nuclear materials innovation programme

The SNM innovation team is tasked with providing the SNM value stream with new technology, processes and facilities to enhance the safety, accuracy and efficiency of current operations or to make new ones.

Success to date has been achieved in the following areas:

- Long-term safe management and storage

- Glovebox operations

Long-term safe management and storage

A key objective of the SNM R&D programme is the long-term integrity and safe storage of packages containing special nuclear material. An important element of this is understanding how they will evolve over time.

Innovative solutions are not only addressing can design and their performance over long timescales but are also developing technologies to enable the packages to monitor themselves and techniques to monitor for surface defects and changes to the store environment.

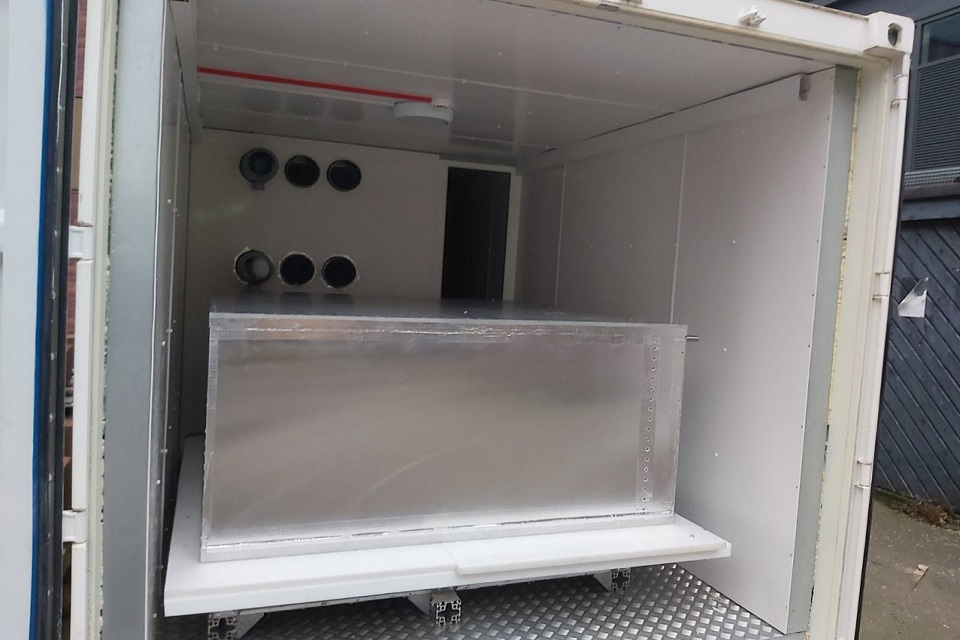

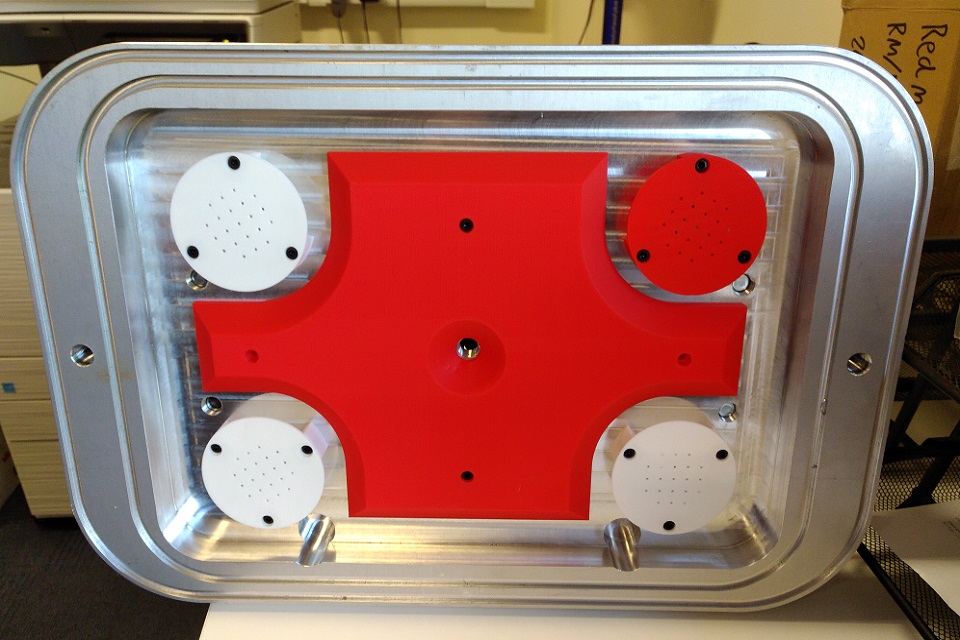

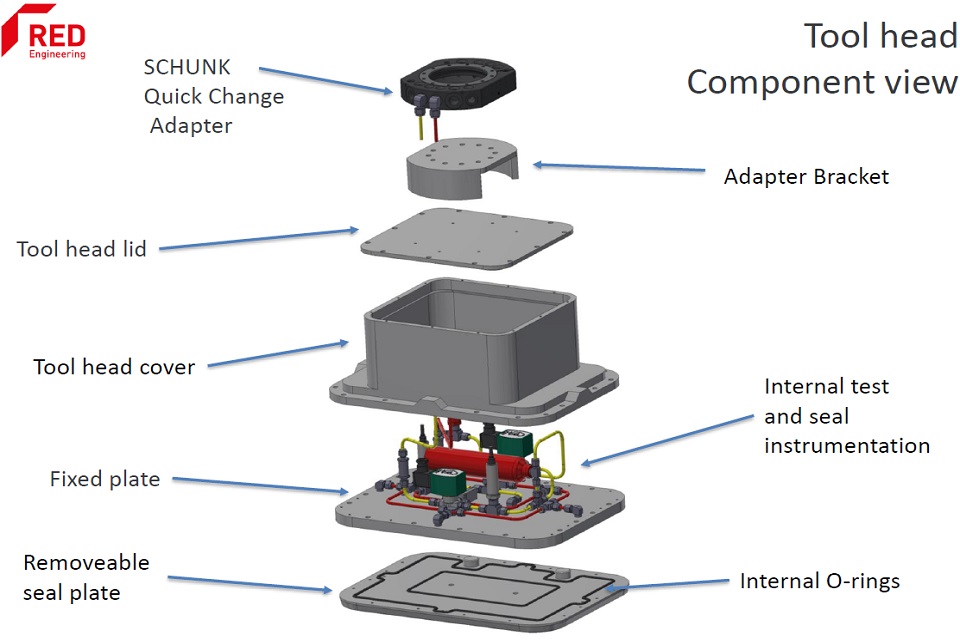

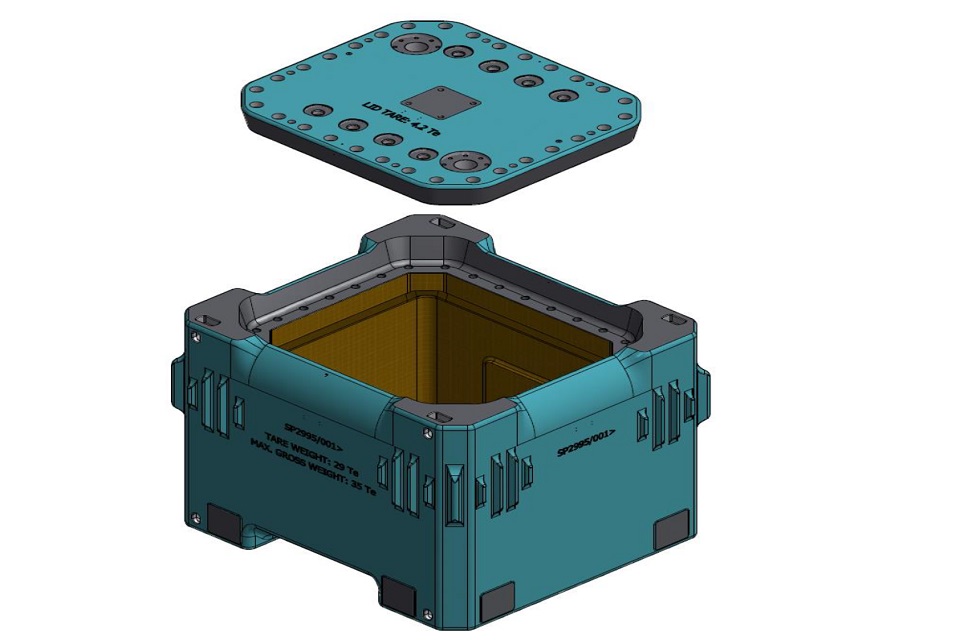

- Modular Stores Facilities – Capabilities are being investigated by RED Engineering to establish how modular storage can be incorporated into the current emergency response in case of breaches within the cell

Having pre-constructed, mobile, modular stores would significantly reduce the response time.

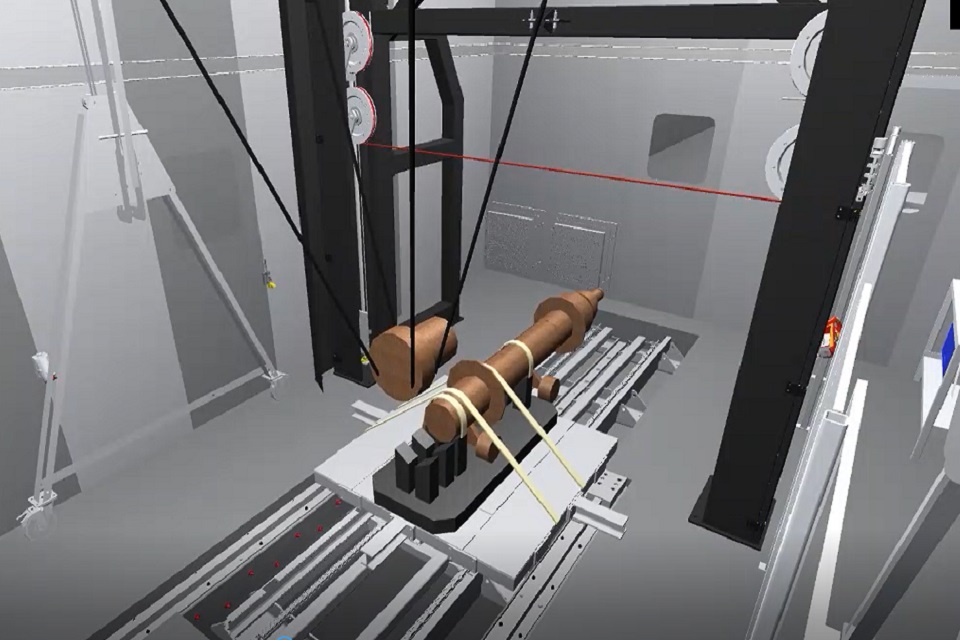

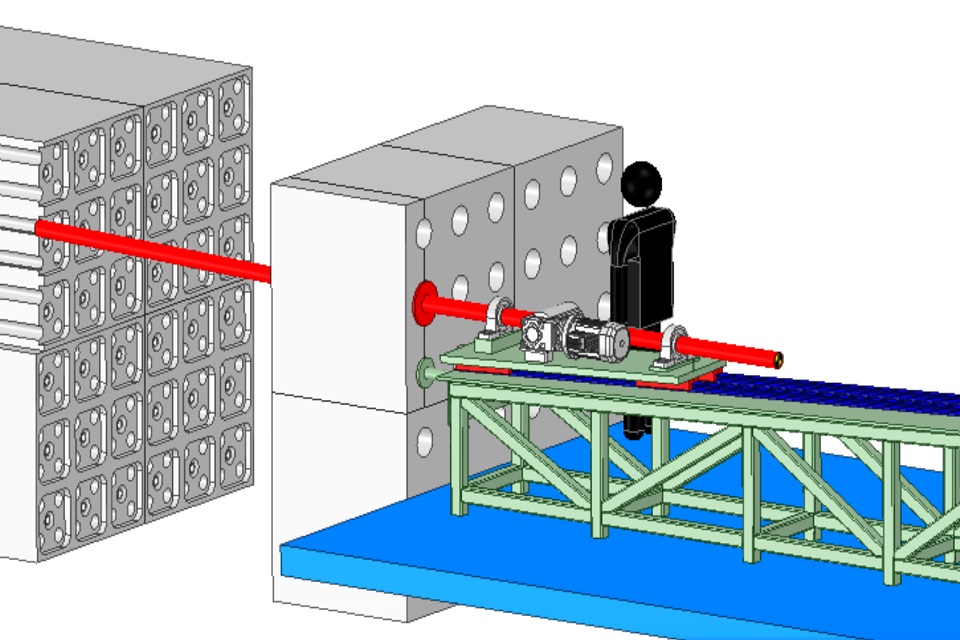

- Automated stores – Currently operated manually, the aim is to fully automate the process of retrieving, analysing and packing 600 packages per year into transport containers, as well as shuffling the packages within a channel

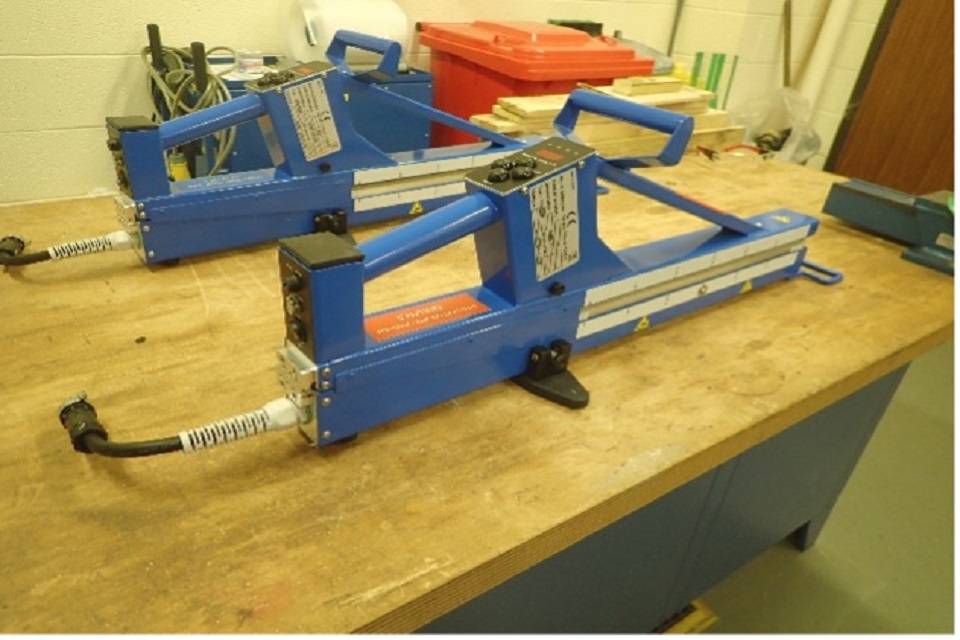

An initial concept study has been completed, demonstrating the potential benefits of a reduction in the dose risk to operators and increased productivity, allowing more time for detailed can inspections. A mock-up of a real store has been built at the NNL laboratory in Workington to test automated store systems

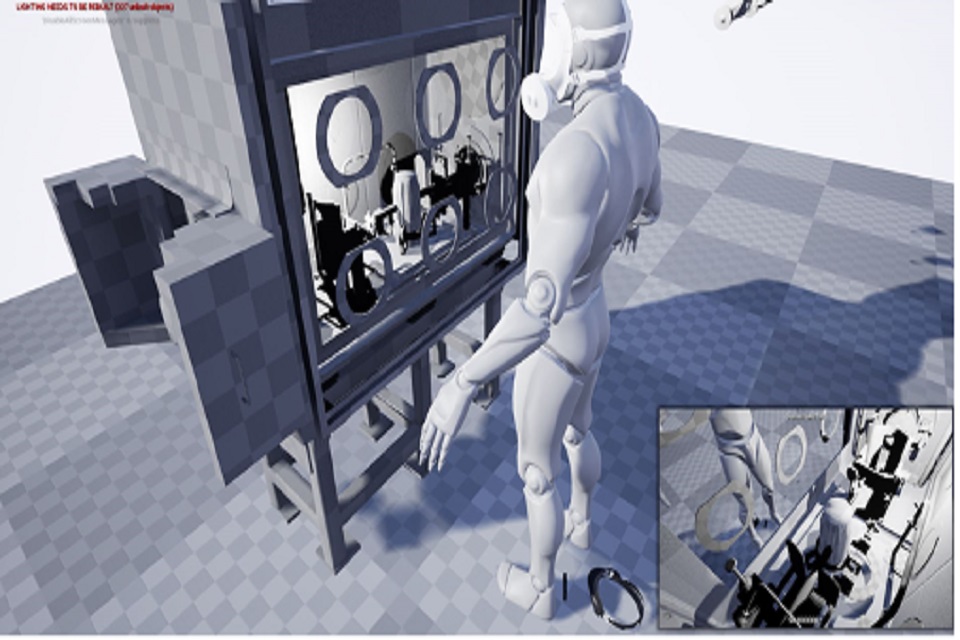

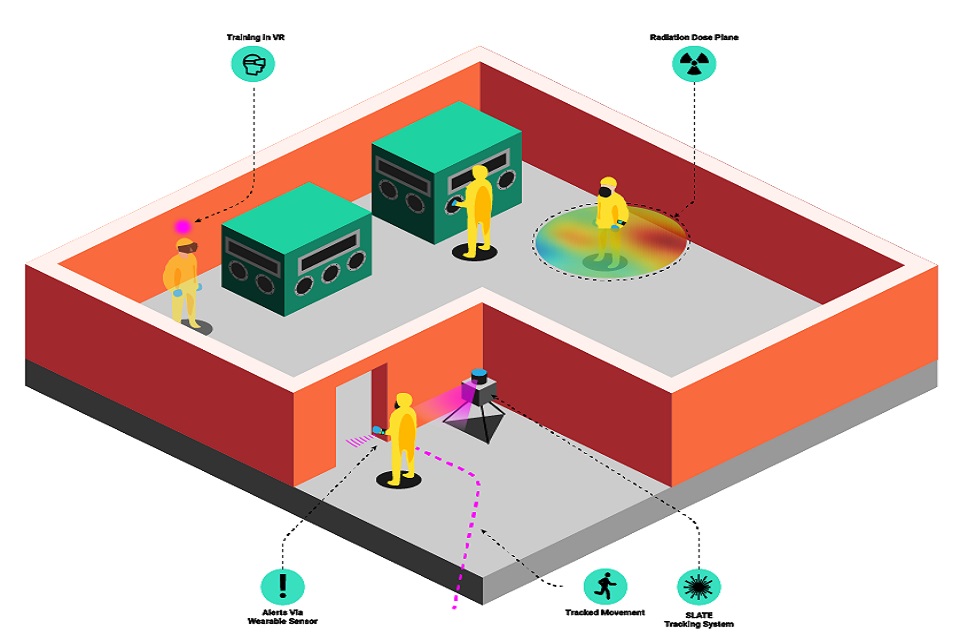

- Virtual Reality (VR) Stores Application - – Creating a virtual representation of the Sellafield Product and Residues Store (SPRS) will allow operators to become familiar with areas which would not normally be accessible in the physical environment

This will enable training to be carried out safely and, in the future, could be used to simulate ad hoc operations to test run and practice new operations. Tannahill Reay Visual Communications are currently developing the design of the VR stores application.

- High Accuracy Inspection System (HAIS) – The National Physical Laboratory (NPL) has been commissioned to develop an inspection system which will be able to generate quantitative data from visual inspections

This will enable the level of corrosion to be assessed to quantify the lifetime of SPRS to a reasonable degree of accuracy. The enhanced prototype system is currently going through CE (or UK equivalent) marking in order to allow it to be used on the plant.

Mock-up of stores layout to test automated store system

Mock-up of stores layout to test automated store system

To find out more contact Paul Mort via email technical.innovation@sellafieldsites.com

9.4 Special nuclear materials innovation programme

Glovebox operations

Gloveboxes have been used on the Sellafield site for many years for a variety of purposes such as R&D, analysis and more general operational activities.

To support the continued safe operation of gloveboxes there are a number of initiatives being progressed to improve efficiency and protect the operator:

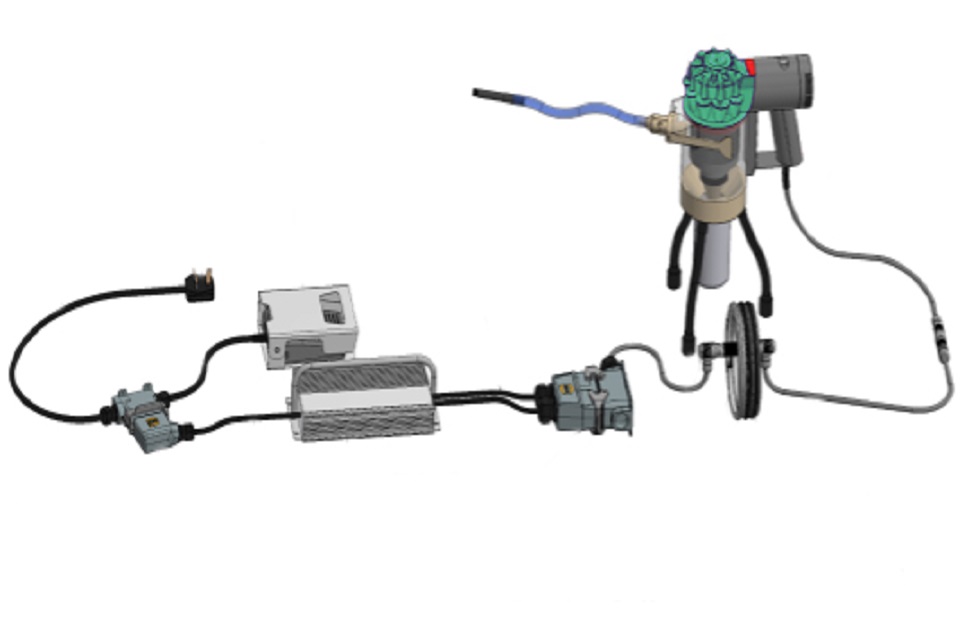

- Glovebox vacuum – The plutonium vacuum will provide a simple solution to glovebox POCO work by speeding up the process, to make it safer for the operator by reducing the time taken to perform the operation and by keeping their hands clear of any sharp hazards

A Modified Off-The-Shelf (MOTS) vacuum cleaner has been tried and tested and, from there, an initial five systems made to cope with the heightened activity of the plutonium oxide left within the glovebox

-

Heads-Up Display (HUD) – In order to overcome the limitations imposed by wearing a respirator when working on a glovebox, a new design is being tested by Tannahill Reay Visual Communications which will include an on-screen heads-up display. It will allow the operator to see any relevant instructions on screen, without having to withdraw their hands to access the paper documentation

-

3D scanners for gloveboxes – A 3D scanner has been selected which will be able to complete a 3D scan of the internals of a glovebox and produce a 3D CAD geometry. The model can then be used to support the RrOBO project and develop a glovebox database for the Sellafield site

-

ORA Welders – An initiative to secure an alternative technique to sealing the Polyvinyl chloride (PVC) used to bag- out SNM containers from gloveboxes has been developed by a French manufacturer - The ORA Company

Two ORA Welders, one calibrated for PVC and one for Polyurethane, which are cheaper, simpler to use and reduce the risk to operatives, have now been purchased and put through operator training.

In addition, a web application has been designed and built by members of SNM called the Sellafield Plutonium Application for the Retention of Knowledge (SPARK).

It provides a base knowledge for SNM new starters and has become part of the UK Alpha Resilience and Capability (ARC) programme in its capacity to retain knowledge around plutonium and storing it for future generations of operators.

Glovebox vacuum

Heads-Up Display - HUD

3D scanners for glovebox

ORA welders

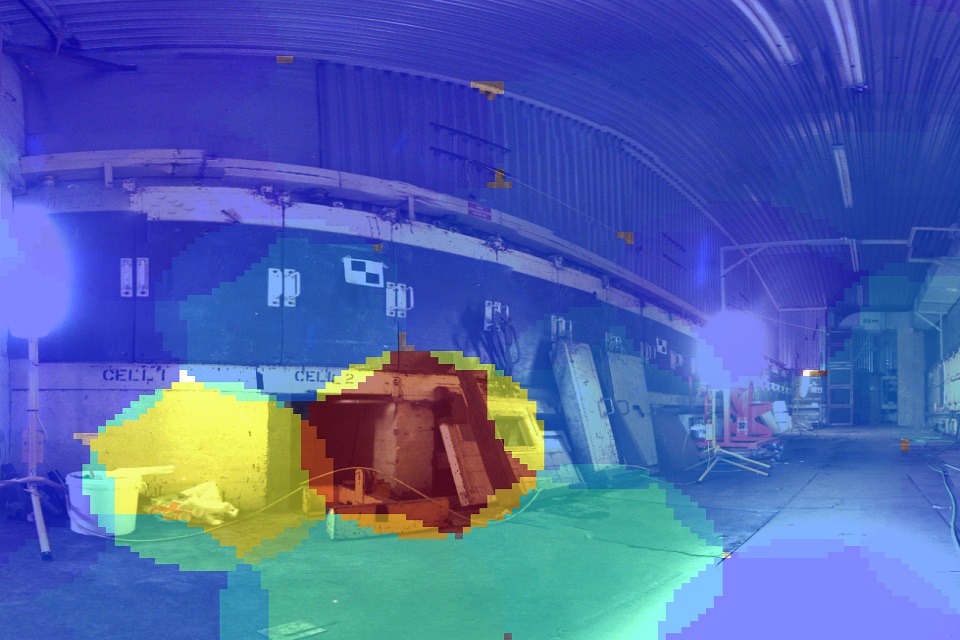

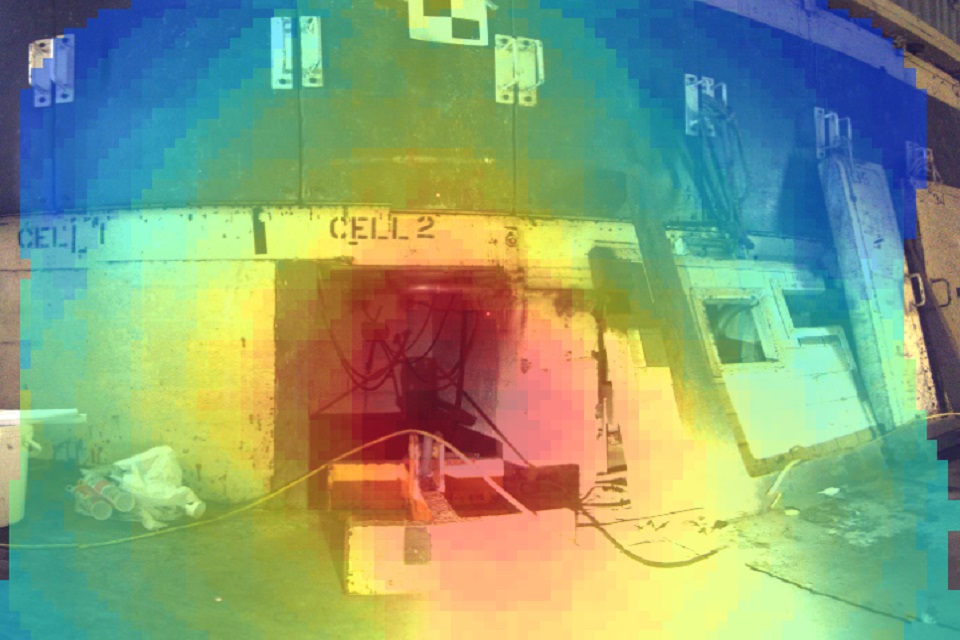

9.5 Characterisation and inspection of assets

A clear understanding of the early characterisation of the condition of assets has the potential to significantly benefit POCO and decommissioning operations.

Until now, a comprehensive assessment of assets has not been carried out. To address that gap, the SNM technical team is working closely with Operations Support to review the condition of the packages held within the stores and the store itself.

By accurately characterising a facility and its contents, risk and uncertainty can be reduced over the transfer of packages to the SRP facility. This work will allow optimised transport schemes to be developed, reducing rework and enabling better estimates of permitted safe storage times.

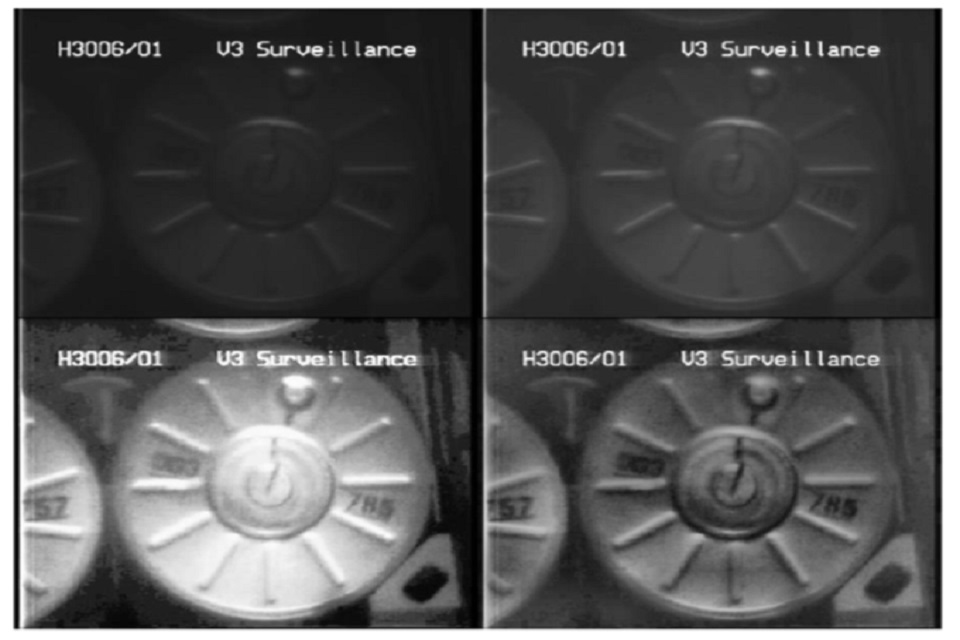

Alongside tried and tested technologies, the SNM technical team is developing new techniques to improve accessibility, quality of image, standardisation of lighting and training.

A can-confidence testing programme for both Magnox and Thorp packages was undertaken off-site to ensure that the outer cans meet their design requirements; while some outer cans were tested to destruction to understand their limits.

It is critical to have the assurance that all packages will perform safely in normal storage conditions and especially during an event.

Each outer can and package was checked prior to testing by the SNM technical team to confirm that each one was manufactured to the required standard.

They must be accurately recorded and documented to track what is required for continued safe storage, for example, with the metallurgical performance of the weld compared to the pressure-withstand capability and drop-resistance.

Currently the inspection of outer cans is carried out by reviewing package after package on screen.

A new novel machine learning approach has been investigated to automatically assess and interpret inspection videos and Cerberus Nuclear and NNL are exploring techniques to make the review job for the team swifter and less error prone.

Much progress has been made with neural networks and learning algorithms and the team is getting ready to work alongside the computer in assessing the quality of the stored packages.

Lid position checks before testing

Pole inspection of stores

Project

Special Nuclear Materials (SNM) package inspection and characterisation

Benefits

Improved characterisation and inspection of packages will ensure that the capabilities and performance of the packages are properly understood, storage risks are minimised and any issues affecting future shipments are identified quickly.

Current Status

This work is ongoing with the next step to trial the can inspection machine learning algorithm and use the results of the can-confidence testing to review the safe-to-store safety case.

Delivery Partners

Cavendish Nuclear, Cerberus Nuclear, National Nuclear Laboratory

Contact Details

Mark Greaves, email: technical.innovation@sellafieldsites.com

Jeff Hobbs - SNM programme technical manager, Sellafield Ltd

As SNM programme technical manager, Dr Jeff Hobbs is responsible for assessing the technical needs associated with the long-term storage of plutonium at Sellafield. This involves managing a small team of people, supporting their development and technically leading a wide range of projects.

This year sees the culmination of the welded package characterisation work, which Jeff has supported from the initial functional specification.

This provides a route to assess the contents of Magnox and Thorp packages with a view to characterising long-term storage behaviour. The next phase is to look at residue package characterisation.

Jeff studied Chemistry at the University of Nottingham, followed by a PhD in inorganic chemistry investigating the chemical species that corrode fast reactor fuel pins. From there, he joined the BNFL Research & Technology team in 1993 as part of the advanced reprocessing programme to improve plutonium finishing (nitrate to oxide conversion) methods.

In order to provide more hands-on support, Jeff moved to the Magnox reprocessing plant at Sellafield in 2000, working on the plutonium and uranium separation, finishing and storage areas, before specialising in plutonium storage.

A member of the Royal Society of Chemistry, Jeff’s expertise in plutonium storage enabled him to focus directly on project and programme support for the finishing and long-term storage area. In 2009, he played an active role in bringing the SPRS into operation and online, which he described as “satisfying to see transition from construction to operations.”

He is now part of the team planning the SPRS Retreatment Plant (SRP), which will repackage the plutonium material for long term storage.

It’s really satisfying to see projects through to completion, and pass knowledge on to the next generation.

Ellie Ford - Technical support, Sellafield Ltd

Ellie Ford joined the SNM technical team in 2017 as part of the Gen2 degree apprenticeship scheme and will graduate with a BEng in Plant Engineering (Nuclear Plant & Process Technology) from the University of Cumbria in December 2021.

This five-year apprenticeship scheme has enabled Ellie to continue working at Sellafield while studying for her degree, with a day-release each week for courses and tuition.

The 3-year foundation course, followed by the 2-year progression to degree, has given Ellie an extensive understanding of her field and she has been able to put this knowledge to good use to develop a prototype device for improving ex-situ inspections of packages in stores, as part of her final year project.

This device will mount a series of cameras in fixed positions around a package to provide consistent, all-round images to improve the quality of inspections and enable digital processing of images.

The prototype has been successfully trialled in the workshop and plans for future inactive and active trials are being developed.

Ellie’s focus this year has been leading the SNM-North package inspection programme, aiming to fulfil the annual targets for inspection.

There are recognised shortfalls with the current equipment and Ellie is supporting work underway to improve the inspection capability and provide better data on the packages to support ongoing substantiation.

As an active member of the Nuclear Institute (NI) Ellie also volunteers for the Cumbria branch as STEM lead, which involves arranging and supporting STEM activities in the local community.

I want to make what we are doing better and look forward to seeing my project being used to improve ex-situ inspections.

10. Retrievals

The Retrievals value stream mission is a reduction in the hazard and risk posed by nuclear waste stored in legacy ponds and silos by retrieving and transferring it to safe modern containment.

The waste is highly heterogenous and has been stored for many decades in non- ideal conditions, making it hard to characterise and retrieve.

The R&D programme is focused on:

- Characterising the waste and assessing risks in order to develop and implement waste routes

- Continued development of innovative techniques for waste retrieval

- Managing the impact of waste retrieval activities on the continued safe operation of the legacy facilities and on downstream waste conditioning and effluent treatment facilities

- Assessing treatment and finishing requirements for unconditioned waste together with Letter of Compliance (LoC) requirements

- Developing Condition Monitoring and Inspection (CM&I) capabilities to demonstrate that retrieved waste behaviour is consistent with predicted behaviour during the storage period

- Conditioning, storage and disposal solutions for metallic uranic fuel and uranium bearing material

10.1 Magnox Swarf Storage Silo skip fill optimisation

Waste stored in the Magnox Swarf Storage Silo (MSSS) facility is retrieved and packaged into MSSS 3m3 boxes for interim storage in an unconditioned form. The lidded 3m3 boxes, containing the waste, are held in an internal skip located in a concrete bund which provides multiple containment barriers.

These will be stored in either Encapsulated Product Store 3 (EPS3) or the Box Encapsulation Plant Product Store (BEPPS) on an interim basis.

This project investigates how the corrosion behaviour and thermal conductivity of residual reactive metal in sludge changes as it dries out over the storage period and how the changing thermal conductivity affects the heat dissipation from the package.

These factors feed into the safe to store case and provide assurances against potential adverse reaction during storage.

A novel experimentation technique where equilibrium vapour pressure was applied around the Corroded Magnox Sludge (CMS) and CMS+Magnox samples was used to achieve an appropriate relative humidity for the corrosion experiments to give an equilibrium sludge pore water content.

- The Magnox corrosion rate, with reducing sludge water content, was measured by hydrogen evolution quantification

- Samples were used to measure the change in CMS thermal conductivity with reducing water content

- The CMS water content/water potential (effort needed to move water within the pores) was measured to develop water retention curves and to inform the availability of water in sludge: its transport through porosity

- This resulted in an evaluation of the critical saturation factor, the point at which water ceases to be available to Magnox and corrosion (source of heat generation) stops

The associated thermal conductivity informed the rate at which heat generated from corrosion rates could be conducted away, preventing heat build- up and potential increase in reaction rate.

This demonstrated that the previous assumed CMS thermal conductivity was pessimistic and gave additional confidence in the declared margin.