Individual Vehicle Approval (IVA) for heavy trailers: help to get a pass

Updated 13 July 2017

Introduction

This guide tells you how to avoid the top 10 reasons that heavy trailers and other vehicles in the O3/4 inspection category fail the IVA inspection:

- retro reflectors

- general construction

- statutory plates and trailer identification number (TIN)

- lateral protection (side guards)

- end outline, side, stop & side marker lamps

- braking

- installation of lights

- spray suppression

- rear registration plate space

- fuel tanks and rear under run protective devices (RUPD)

This guide tells you:

- how each item is inspected

- what to check before each item is inspected

- the required standard

Full compliance with this guide doesn’t guarantee a pass. You’ll need to view the IVA Inspection manual for the full requirements and testing procedures needed to get your trailer passed.

You must apply for vehicle approval if you’ve:

- built a trailer

- rebuilt a trailer

- radically altered a trailer

- imported a trailer

You’ll be required to:

- provide suitable documentary evidence where required

- a suitable towing vehicle

DVSA will examine the trailer in all modes of operation, so you’ll need to make sure that everything operates correctly.

This guide doesn’t replace the manual. Access the IVA inspection manual for full inspection details.

Difference between IVA and MOT

IVA inspections are different from the annual MOT test.

The IVA inspection looks at the way your vehicle is constructed or adapted, while the annual MOT test looks at roadworthiness of your vehicle.

Your vehicle might pass the annual MOT test, but that doesn’t mean it will pass an IVA inspection.

1. Retro Reflectors

1.1 How retro reflectors are inspected

How DVSA inspects reflectors is straightforward, but conspicuity can be complex.

Conspicuity is the method used to make the outline of a trailer visible.

This section is divided into:

- retro reflectors

- conspicuity

Retro reflectors

A rear reflector must be the correct type and be marked with either:

- IIIA

- IIIB

Rear reflector as a separate unit.

Rear reflector as part of a lamp cluster.

As shown in the images above the reflectors can either be:

- a separate unit

- part of a lamp cluster

The reflectors must be marked with either an:

- “E”

- “e”

Not allowed: reflector obscured by locking equipment.

The image above shows a reflector obscured by locking equipment. You need to make sure reflectors are at least 50% visible at all times.

Height from ground and distance from outer edge of trailer will be measured.

DVSA will measure the height from the ground and from the outer edge of the trailer. This is shown in the image above.

DVSA will check position, appoval marks and identity symbols.

DVSA will check position, appoval marks and identity symbols.

DVSA will check:

- the position of side and front reflectors, they may be combined with side and front marker lamps

- “E” or “e” approval marks

- for IA or IB identity symbols

Conspicuity

Conspicuity doesn't go to top of trailer as when in service has a tarpaulin fitted.

Conspicuity follows the outline of the trailer.

Conspicuity must:

- outline the trailer at the rear and side

- follow the contours of the body

In the first image above the conspicuity doesn’t go right to the top of the trailer, as when in service will have a tarpaulin fitted which would obscure any tape fitted there.

In the second image the tape follows the outline of the trailer, it can’t be fitted around the ribs of the body, but must cover at least 70% of the overall length of the trailer.

Conspicuity tape must be marked with an approval mark.

Conspicuity tape must be marked with an approval mark.

Conspicuity tape must be:

- marked with an approval mark

- be white or yellow when applied to the side of a trailer

- be red or yellow when applied to the rear of the trailer

1.2 What to check before retro reflectors are inspected

This section is divided into:

- retro reflectors

- conspicuity

Retro reflectors

Retro reflectors cover:

- rear

- side

- front

All reflectors must:

- be fitted In accordance with table 1

- be “e” or “E” marked

- show relevant identity symbol IIIA or IIIB for rear, and IA or IB front and side

- be the correct colour

- be triangular in shape if on the rear of the trailer

- face to the rear if on the rear of the trailer

At least 50% of the rear reflector must be visible at all times. You must check that this is met when you open:

- doors

- hatches

- lockers

Conspicuity markings

Conspicuity markings for side and rear differ dependent upon trailer:

- weight

- size

Refer to section 21 of the IVA inspection manual for full information and to make sure that it applies to your trailer.

At least one approval mark must be visible on the conspicuity material fitted to both sides and rear of your trailer.

Rear markers aren’t required if your trailer has full conspicuity markings fitted.

1.3 The standard retro reflectors must meet

See section 21 (retro reflectors) of the IVA inspection manual for the full inspection standard.

2. General construction

2.1 How general construction is inspected

All aspects of design and construction are inspected to make sure that the trailer is of no danger to the driver, passengers or other road users.

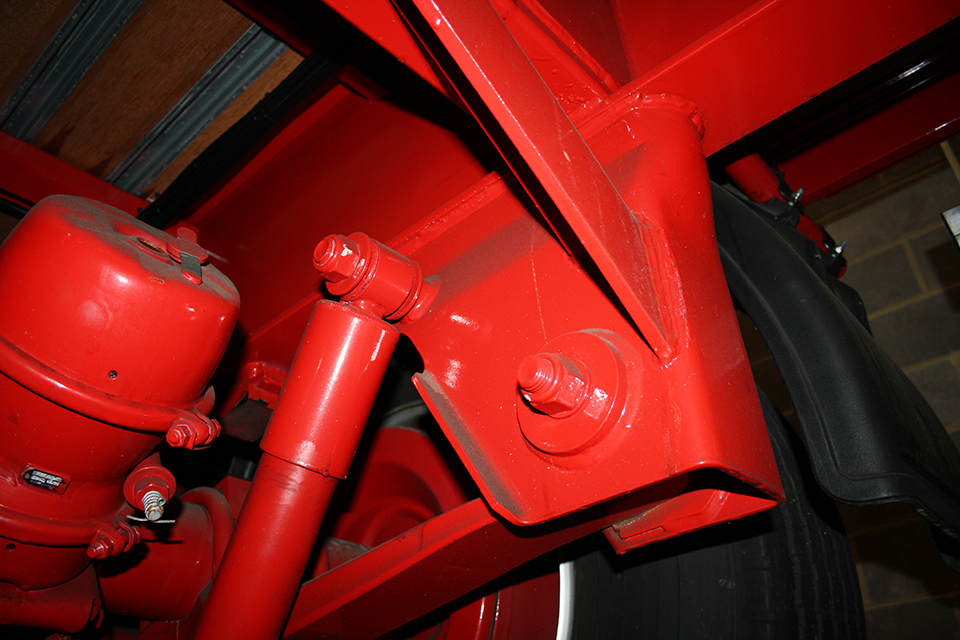

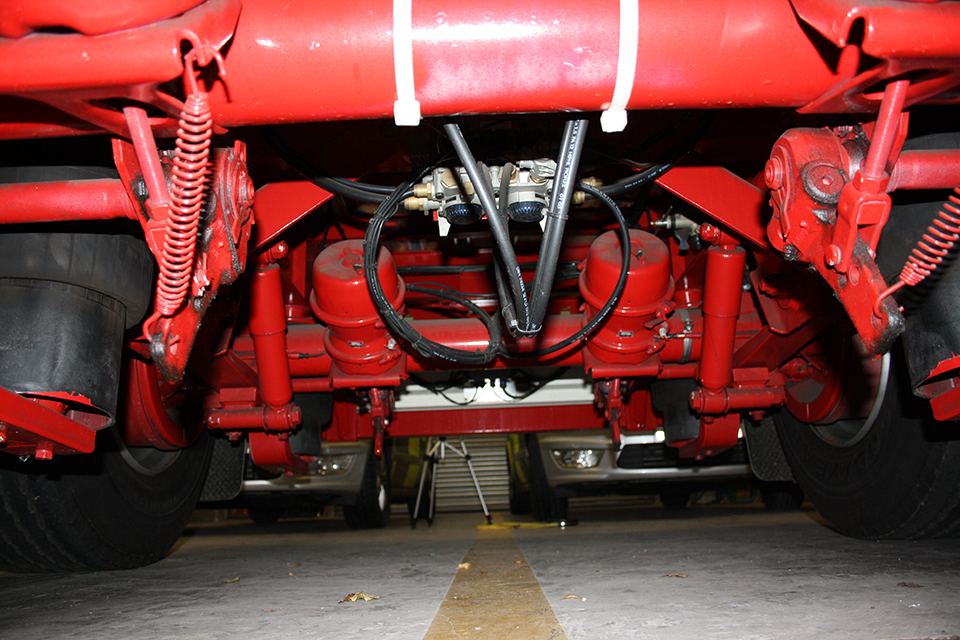

All aspects of design and constructions are inspected.

All aspects of design and constructions are inspected.

DVSA will check for:

- adequate metal used in construction

- good quality welding

- adequate size of nuts and bolts

- security of fixings

- body security

The whole trailer will be checked to make sure there is no danger to other road users.

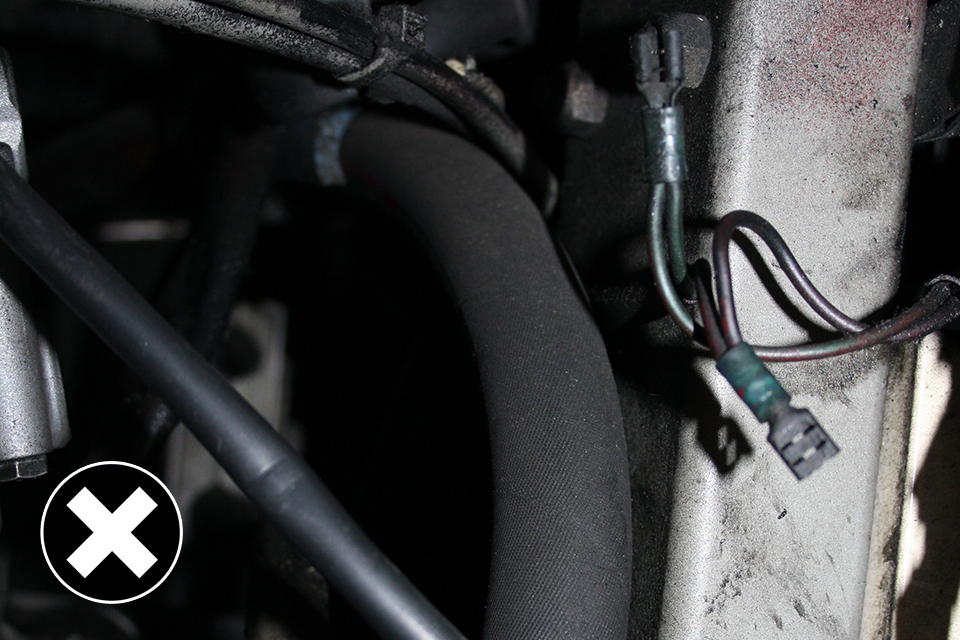

Not allowed: poor standard of build.

Not allowed: poor standard of build.

The images above show a poor standard of build. This isn’t allowed.

The common problems DVSA finds are:

- insecure wiring and piping

- loose or inadequate fittings

- poor finishing

- uninsulated wiring and terminals

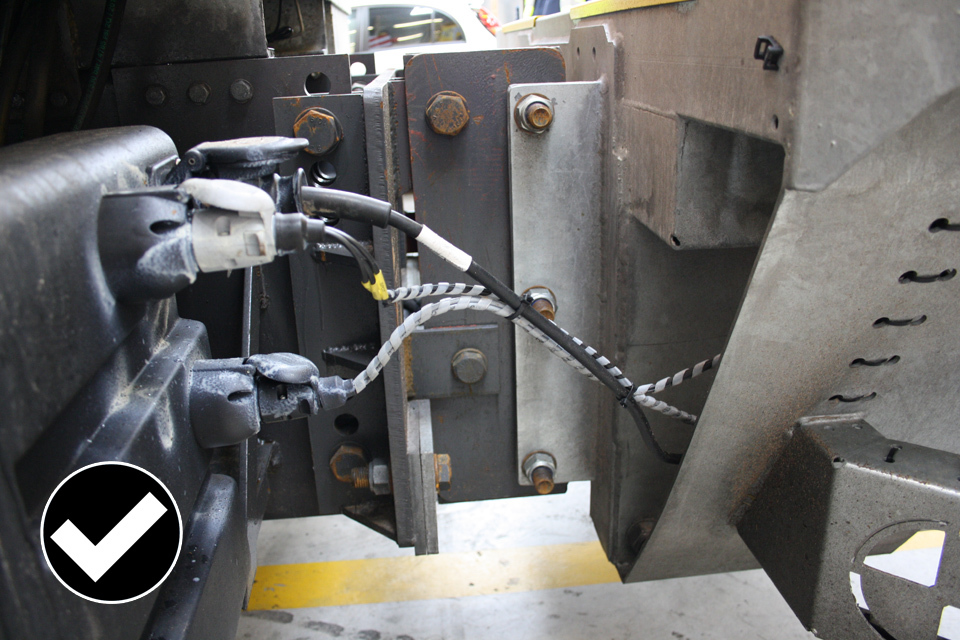

Make sure that wiring is clipped into place every 300mm and all terminals are insulated.

Wiring can be run through a chassis leg but it will need to have a grommet at either end to prevent chafing.

Bolts have been tapped through the chassis frame but may require securing with nuts and washers.

In the image above bolts have been tapped through the chassis frame. These may require securing with nuts and washers.

Allowed: good example or wires that have been clipped and fitted in a rubber grommet.

The above image is a good example of wires that are clipped in and fitted in a rubber grommet where it passes through a metal panel. This will help prevent the wires chafing or rubbing through.

2.2 What to check before general construction is inspected

DVSA will look at how the trailer is designed and constructed, and consider all aspects of the trailer in all the conditions it will be operated under. This includes:

- speed

- load

- vibrations

- acceleration

- cornering

- braking forces

2.3 The standard general construction must meet

See the IVA inspection manual for the full inspection standard.

3. Statutory Plates and Trailer Identification Number (TIN)

3.1 How statutory plates and the trailer identification number are inspected

A statutory plate must be fitted for each stage of the build of the trailer.

The trailer must have a permanently marked Trailer Identification Number (TIN).

Some of the example plates in this section are from a heavy goods vehicle, but the same principles apply to trailers.

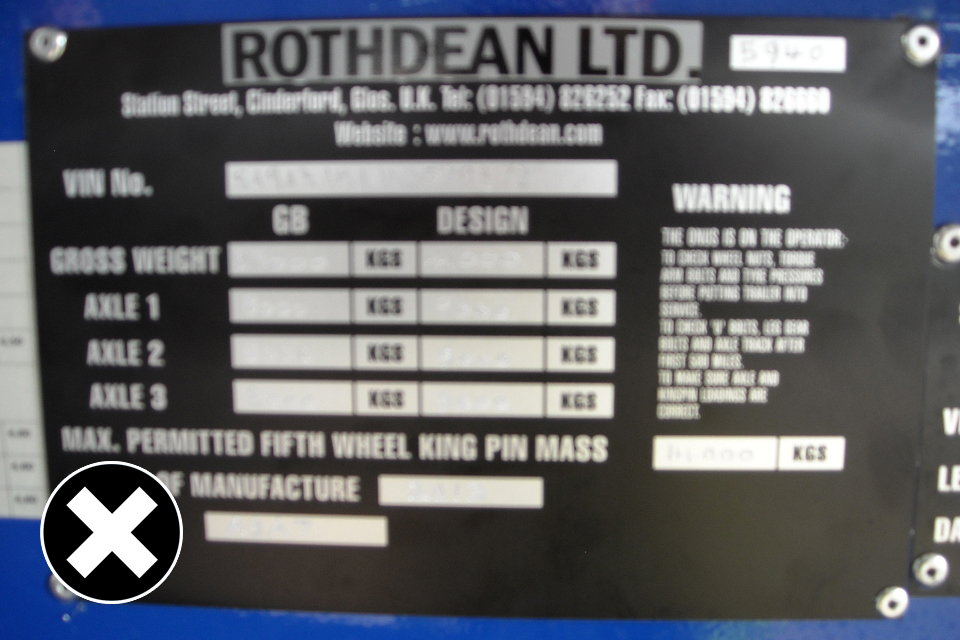

Not allowed: Information not within the approved rectangle

An example plate with other information outside the defined rectangle.

The two images above are examples of manufacturer’s plates from the same manufacturer.

The first image is an early example before approval. There is a lot of information on the plate, address, warnings etc. The required information isn’t within a clearly defined rectangle. This isn’t allowed.

In the second image the plate has other information correctly outside the defined rectangle. This is allowed.

Allowed: an example of a plate that contains other information outside the defined rectangle.

The above image is a good example of a plate that has other information outside the rectangle where only required information is allowed.

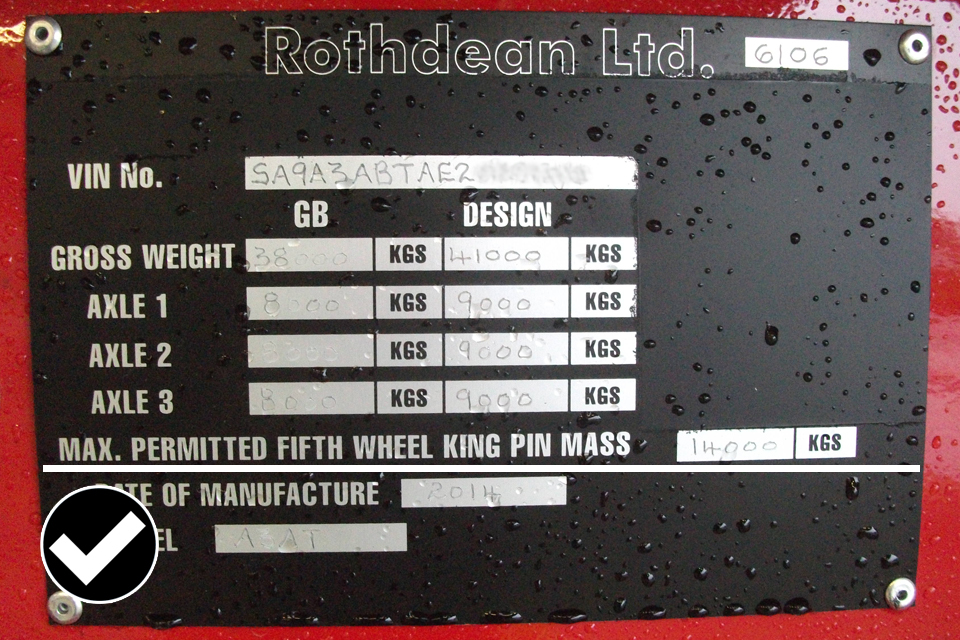

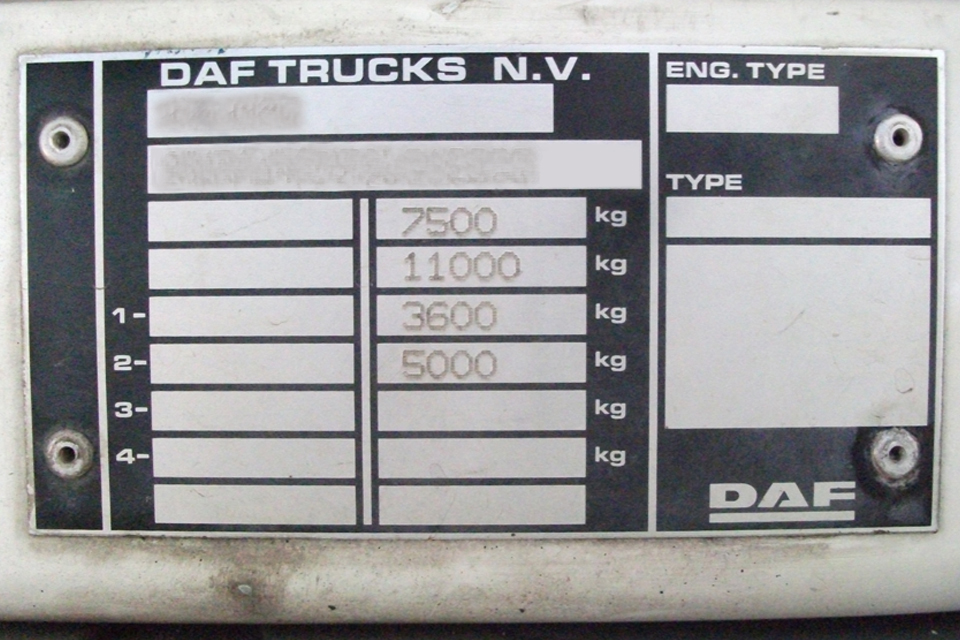

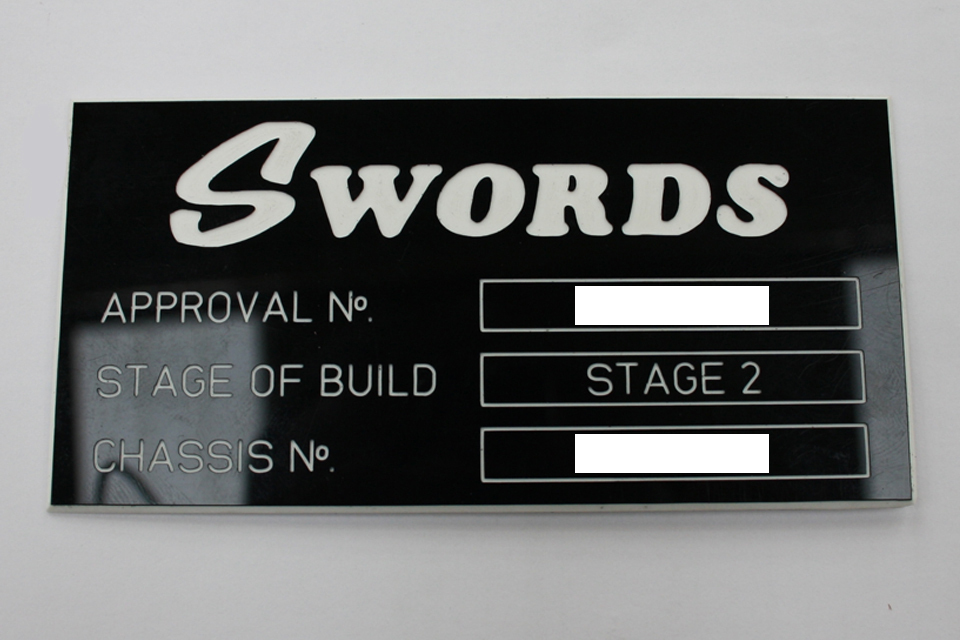

An example of a first stage plate.

The above image is of a first stage plate.

All the required information is in a clearly defined rectangle and it the correct order. There is other information on the plate but it’s outside the defined rectangle.

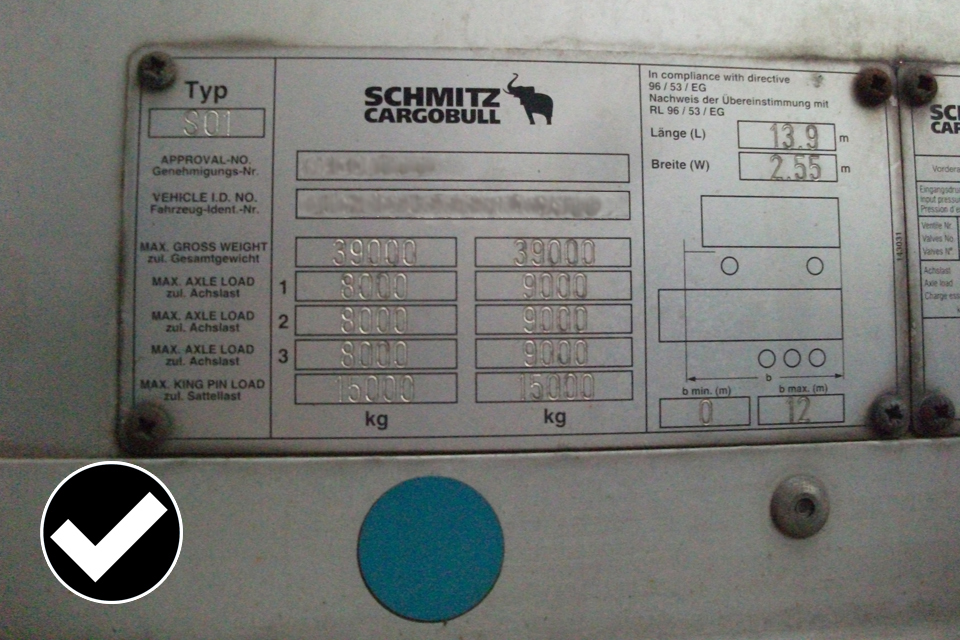

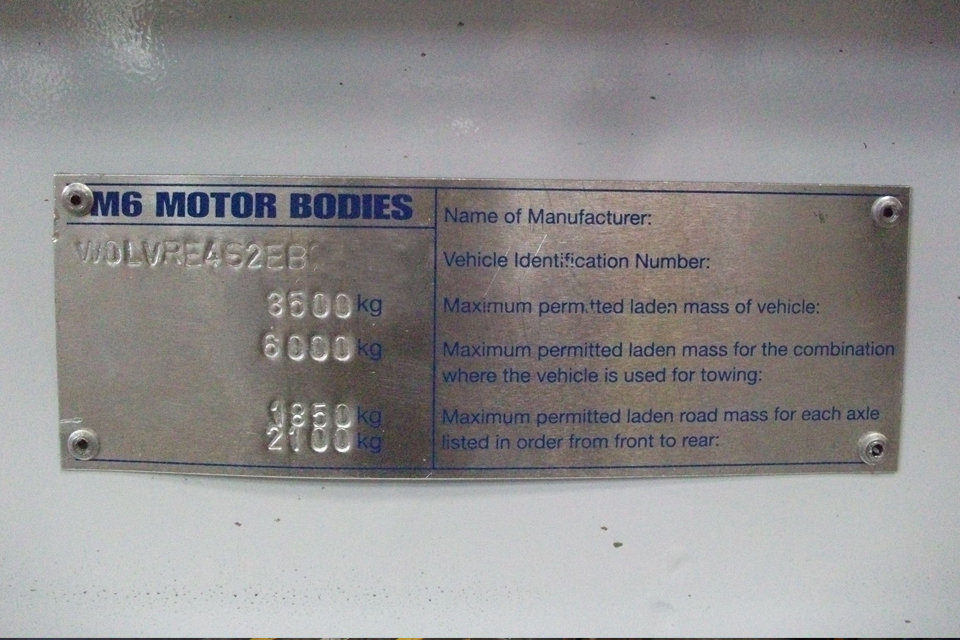

An example of a second stage plate.

The image above is of a second stage plate.

The first image shows a first stage plate where all the required information is in a clearly defined rectangle in the correct order.

The second image shows a second stage plate where all the required information has been hand stamped in the correct order in a rectangle.

There is other information on the example plates, but as it’s outside the rectangle it’s allowed. Both VIN plates are securely fixed to the vehicle.

An example of a stage one plate that lists the weights in the order that legislation requires.

The image above shows a stage one plate where the plate lists the weights in the order that the legislation requires. This means that the plate doesn’t have to define what they are and works in any language.

An example of a stage one plate where the weights haven't been altered.

The image above is an example where the stage one weights haven’t been altered, so there is no requirement to list the weights.

Not allowed: plate hasn't been seam welded to the frame/body.

A stamped in’ TIN must be:

- marked on the chassis or frame

- permanent (stamped, hammered, etched)

- on the right hand of the trailer (as you view the trailer from the rear)

In the above image the TIN is stamped into a plate that is bonded to a part of the vehicle. This isn’t allowed as the plate hasn’t been seam welded to the frame/body.

3.2 What to check before statutory plates and TIN are inspected

The plate must:

- be permanent

- be durable

- contain the required information in the correct order

The only information allowed on the plate must be within a clearly defined rectangle and in the correct order.

The order is:

- name of manufacturer

- approval number and/or build stage (if applicable)

- TIN

For trailers where weights have been changed, you’ll need to include:

- maximum permitted laden mass of trailer

- maximum laden mass for each axle in order from front to rear

- maximum permitted laden road mass for each axle, listed in order from front to rear

- for semi-trailers the maximum permitted mass on the fifth wheel kingpin

There may be other information on the plate but this must be outside of the clearly defined rectangle.

3.3 The standard statutory plates and TIN must meet

See section 18 (statutory plates) of the IVA inspection manual for the full inspection standard.

4. Lateral protection (side guards)

4.1 How lateral protection is inspected

The lateral protection inspection will check the:

- measurements

- dimensions

- fitting

- spacing

DVSA measure the height from the floor to the lowest rail.

The height from the ground to the lowest rail will be measured.

DVSA measure the height of the rail.

The height of the rail itself will be measured.

DVSA measure the gap between the rails.

The gap between the rails will be measured.

DVSA measure distance from rear of side guard to the first rear axle.

The distance from the rear of the side guard to the first rear axle will be measured.

The distance from the centre line of support legs and the kingpin will be measured.

DVSA measure the size of the vertical forward facing leg.

The size of the vertical forward facing leg will be measured.

DVSA will check external edges and corners.

DVSA will check that any external edges and corners are radiused to 2.5mm.

Not allowed: side guards have increased the overall width of the vehicle.

Not allowed: side guards have increased the overall width of the vehicle.

Side guards mustn’t increase the overall width of the trailer.

In the images above, the side guards have been added onto the side of the trailer and have increased its width by 50mm each side. This isn’t allowed.

Not allowed: facing edge isn't 100mm in depth and has a non radiused edge.

In the image above the side guard has a forward facing edge that isn’t 100mm in depth and has a non radiused edge. This isn’t allowed.

Not allowed: trailing corner/edge isn't radiused to 2.5mm.

In the image above the corner/edge isn’t radiused to 2.5mm. This isn’t allowed.

The side guard can be a solid structure.

The side guard can be a solid structure or part of the bodywork of the trailer.

The side guard can be a separate unit with rails and uprights.

The side guard can be a separate unit with rails and uprights.

4.2 What to check before lateral protection is inspected

DVSA will check and measure lateral protection for:

- dimensions

- fitting position

- security

- radius

- projections

There are different specifications for O3 & O4. The correct dimensions are listed in section 42 of the IVA inspection manual.

There are figures and drawings for gaps for stabiliser legs etc. Equipment may be incorporated into the side guard, but it must comply with the manual.

Fit the correct type for your trailer or build to the higher O4 specification.

Exemptions for lateral protection are very specific and very few trailers will meet the exception. Refer to the method of inspection in section 42 of the IVA inspection manual for more details.

DVSA will accept the design of the side of the body instead of a side guard in some cases. Car transporters are a good example.

4.3 The standard lateral protection must meet

See section 42 (lateral protection) of the IVA inspection manual for the full inspection standard.

5. End outline, side, stop & side marker lamps

5.1 How end outline, side, stop & side marker lamps are inspected

This section covers the lamps themselves and the angles of visibility.

Refer to section 20 of the IVA inspection manual for required standards.

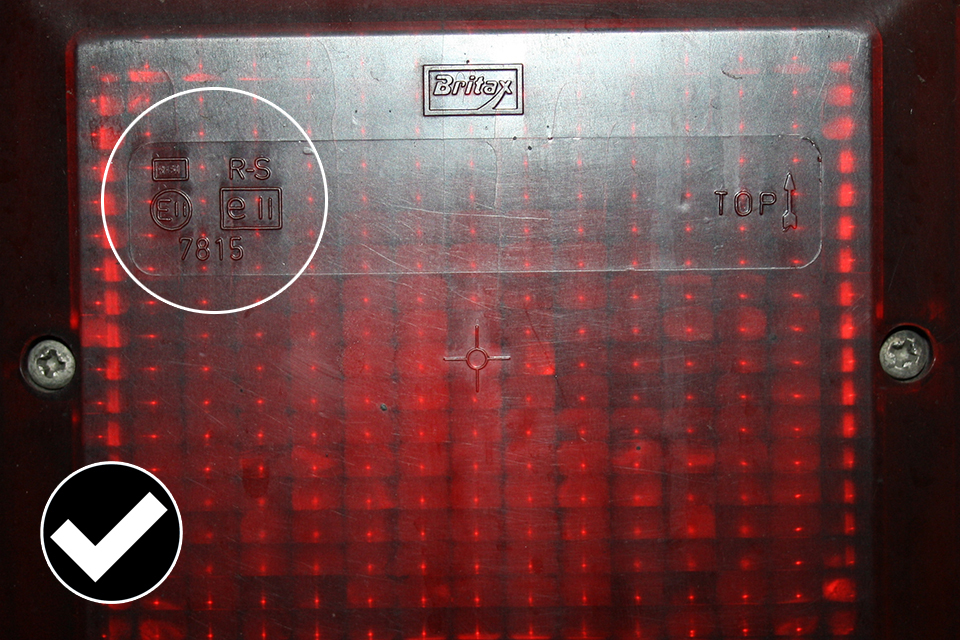

DVSA will check the approval marker and identity symbol.

DVSA will check the approval marker and identity symbol.

To make sure each lamp on the trailer is suitable, DVSA will check for an:

- “E” or “e” approval mark

- correct identity symbol

DVSA will check the height from the floor.

DVSA will check the distance from the side of the trailer.

DVSA will check side and stop lamps for:

- height from the ground

- distance in from the side of the trailer

Side markers are checked for correct colour and position.

Side marker lamps are checked for correct:

- colour

- position

An end outline marker must be fitted as high as practical.

An end outline marker must be fitted as high as is practical.

In the image above it shows that with a tipper body, the outline marker can’t be positioned any higher. This is allowed.

5.2 What to check before end outline, side, stop and side marker lamps are inspected

DVSA will check the lamps fitted to the trailer for:

- number

- operation

- position

- colour

- required symbols

- required angles of visibility of lamps

- approval mark

Wider or longer trailers may need end outline and/or side marker lamps.

There is no need to fit special brackets to accommodate end outline lamps if there is no bodywork in the required position.

5.3 The standard end outline, side, stop & side marker lamps must meet

See 22 (end outline, position(side), stop and side marker lamps) of the IVA inspection manual for the full inspection standard.

6. Braking

6.1 How braking is inspected

No physical brake test is carried out.

You’re required to provide documentary evidence.

6.2 What to check before braking is inspected

This part of the IVA inspection is purely a paperwork exercise and no physical inspection will be carried out.

DVSA will check that:

- the trailer presented has the correct brake report

- the presenter has it with them at time of inspection

Brake reports are available from:

- test laboratories

- approval agencies

There are different requirements for Special Type General Order vehicles. DVSA will accept a model report based on calculations as track testing above normal weights isn’t required.

6.3 The standards braking must meet

See section 9 of the IVA inspection manual for full inspection standard.

7. Installation of Lights

7.1 How installation of lights is inspected

The Section 20 (installation of lights) of the IVA inspection manual covers the fitting of all lights and reflectors fitted, and should be read in conjunction with sections 21-29.

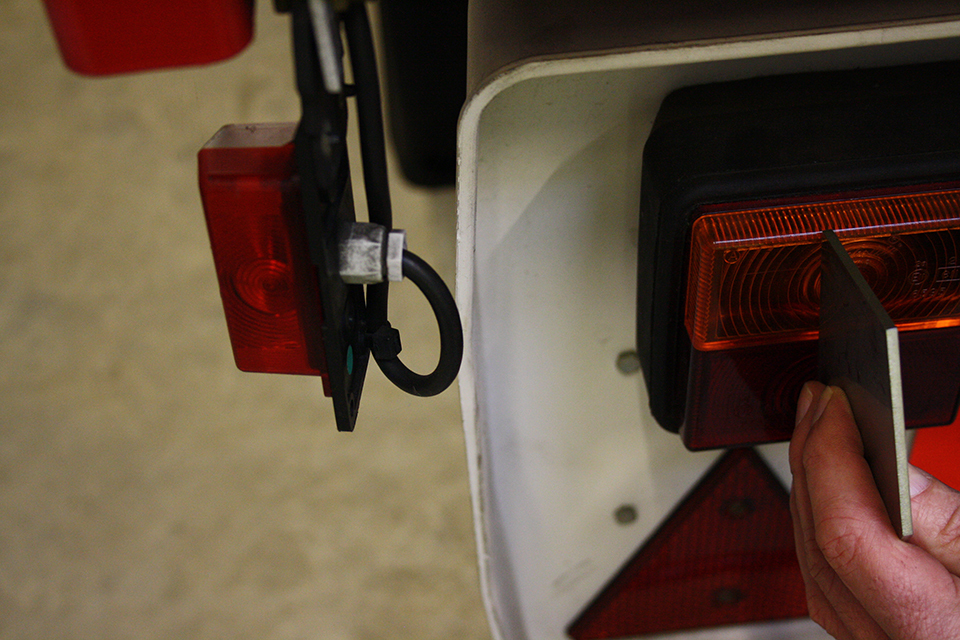

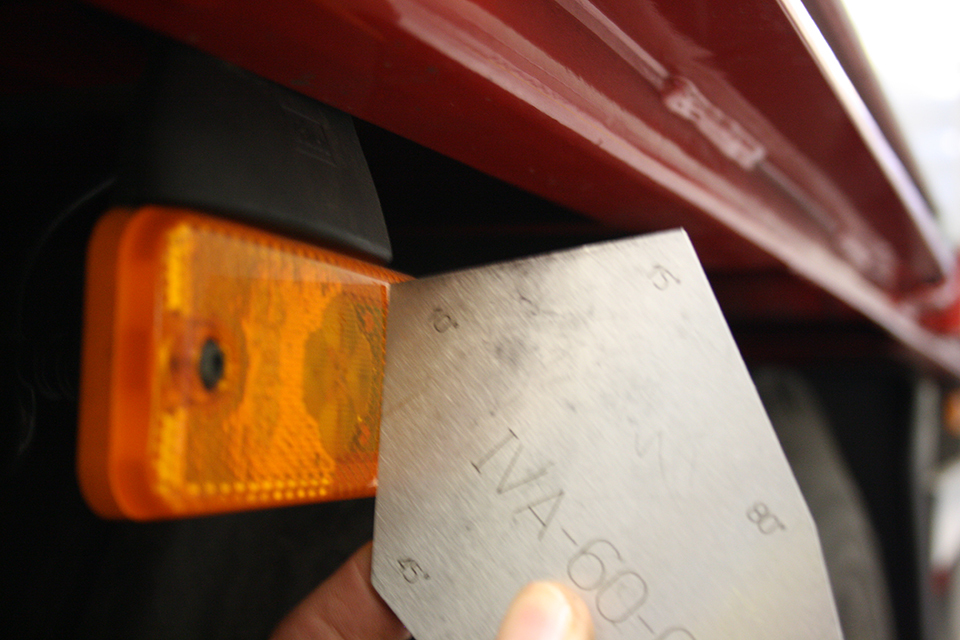

DVSA will use a gauge to check the angles of visibility.

DVSA will use a gauge to check the angles of visibility.

DVSA will use a gauge to check the angles of visibility both:

- vertically

- horizontally

This is to make sure that nothing obstructs the angles the lamps are visible from, such as:

- tail lifts

- loading ramps

- other obstructions

DVSA will use a gauge to check the angles of visibility.

DVSA will use a gauge to check the angles of visibility.

These standards also apply to:

- side marker lamps

- reflectors

Refer to the tables in the IVA inspection manual for:

- angles

- heights

- distance from the side

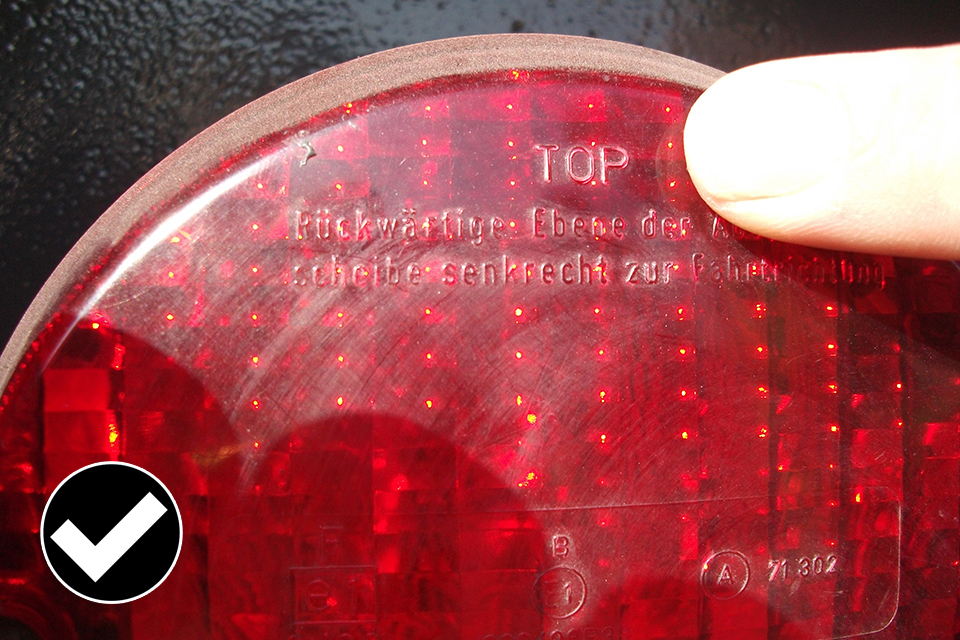

Lamps must be fitted in the correct orientation.

Lamps must be fitted in the correct orientation.

DVSA will check lamps are secure, correct postion and colour.

DVSA will check that the lamps:

- are secure

- show light of the correct colour

- are positioned correctly

7.2 What to check before installation of lamps are inspected

DVSA will check all lamps and reflectors for:

- colour

- security

- operation

- orientation

- visibility

The IVA inspection manual gives the definitions of lateral and vertical positions to be used when fitting lamps, and the figures used to define what is “one lamp”.

The inspection manual refers to semi-trailers but the requirements apply equally to drawbar trailers.

DVSA will check that all lamps and reflectors are visible when the following are fixed in an open position:

- doors

- loading ramps

- lockers

- other items

Check that when your trailer is being loaded/unloaded, on the side of the road, that the lamps and reflectors are still visible.

Lamp visibility may be increased by additional lamps or a warning triangle, but the reflectors must be 50% visible at all times.

7.3 The standard installation of lights must meet

See section 20 (installation of lights) of the IVA inspection manual for the full inspection standard.

8. Spray Suppression

8.1 How spray suppression is inspected

All road wheels must be fitted with spray suppression.

Section 43 (spray suppression) of the IVA inspection manual has diagrams and figures to help explain the requirements.

Large mudguard with spray at the rear axle.

The body forms the mudguards

Different spray suppression systems can be fitted.

The first image shows one large mudguard with spray suppression at the rear axle.

The second image shows where the body forms the mudguards.

Refer to section 43 (spray suppression) of the IVA inspection manual for the required standard measurements.

DVSA will measure the distance between the tyres.

DVSA will measure the height from the ground

As shown in the images above DVSA will check the:

- distance between the tyres to determine if separate spray suppression is required for each axle

- height from the ground

DVSA will measure the width of the spray suppression

DVSA will measure the spray suppression to make sure they cover the width of the tyre.

Rain flaps must have the whole face made from spray suppression material.

The rain flaps must have the whole face made from spray suppression material.

8.2 What to check before spray suppression is inspected

DVSA will examine spray suppression fitted for:

- dimensions

- angles

- approval numbers

- heights

- widths

Exemptions are listed in section 43 (spray suppression) of the IVA inspection manual)

Even for spray suppression exempt trailers certain required standards still apply.

To help define what system is fitted to your trailer section 43 (spray suppression) of the IVA inspection manual has definitions of:

- mudguard

- outervValance

- rain flap

- lift axle

- self tracking axle

DVSA will use a gauge/template to check compliance of mudguard and rain flaps - it’s based on the diagrams in section 43 (spray suppression) of the IVA inspection manual.

8.3 The standard spray suppression must meet

See section 43 (spray suppression) of the IVA inspection manual for full inspection standard.

9. Rear Registration Plate Space

9.1 How rear registration plate space is tested

Read this in conjunction with section 24 (rear registration lamps) of the IVA inspection manual.

Not allowed: space is to small and doesn't meet the required standard.

Not allowed: space is to small and doesn't meet the required standard.

There are two trailer size registration plate space options. These are either:

- 520 x 120mm

- 340 x 240mm

DVSA will use a template to check there is sufficient space available.

In the images above a trailer has been fitted with a plate. When DVSA uses the template to check, it’s found that the space is to small and doesn’t meet the required standard.

Number plate must be illuminated.

The number plate must be illuminated to sufficiently light the registration plate.

The number plate lamp must be marked either:

- E

- e

9.2 What to check before registration plate space is inspected

DVSA will check the registration plate space for:

- correct size

- it to be close to vertical as possible

- a suitable mounting system, when the space isn’t a part of the body of the trailer

The rear registration lamp must be:

- “e” or “E” marked

- operational

- switched on and off with the side lamps

- white in colour

- positioned to illuminate the rear registration plate space

9.3 The standard registration plate space must meet

See section 4 (rear registration plate space) of the IVA inspection manual for the full inspection standard.

10. Fuel tanks and Rear Under run Protective Devices (RUPD)

10.1 How fuel tanks and RUPD are inspected

The IVA manual section (03) is divided into:

- fuel tanks

- RUPD

You will be required to provide documentary evidence at the inspection.

Fuel tanks

Not allowed: a fuel tank cap that isn’t tethered.

The above image shows a fuel tank cap that isn’t tethered, which isn’t allowed.

A fuel cap must either be:

- attached to the vehicle

- a type where the key can only be removed when locked

- of an automatically opening/closing type

The fuel tank must be secure and positioned so it’s unlikely to be damaged in the event of front or rear impact.

The above image shows that the fuel tank must be secure and positioned so it’s unlikely to be damaged in the event of front or rear impact.

RUPD

DVSA will inspect:

- dimensions

- spacing

- measurements radius

- approval

The RUPD mustn’t be more than 550mm from the ground.

The image above shows that DVSA will measure the height that the RUPD is fitted at. It mustn’t be more than 550mm from the ground.

RUPD mustn't extend beyond the width of the rear axle.

The image above shows that the RUPD mustn’t extend beyond the width of the rear axle, where a tail lift is fitted this may extend beyond the axle width to the width of the body.

Gaps are allowed for lifts, but the limit is 25mm between working elements of the lift and fixed elements of the RUPD.

The image above shows the outer end of the RUPD must be rounded on the outside and radiused to 2.5mm.

The strength of the RUPD mountings are checked.

The image shows that gaps are allowed for lifts, but the limit is 25mm between working elements of the lift and fixed elements of the RUPD.

The outer end of the RUPD must be rounded on the outside and radiused to 2.5mm.

The section height of the RUPD and this must be at least 100mm.

The first image shows DVSA will check the section height of the RUPD and this must be at least 100mm. The device must have an approval.

The second image shows that DVSA will inspect the strength of the RUPD mountings to check they’re adequate.

10.2 What to check before fuel tanks and RUPD are inspected

Fuel tanks

The same requirements apply to ‘Age-related IVA’. Where the original cap isn’t of a tethered type, you must bring the vehicle up to the standard required in the IVA inspection manual.

Stage one builders must make sure that the tank fitted:

- has approval

- is fitted to meet the manufactures instructions

This examination only applies to the tank that supplies fuel for the propulsion of the vehicle.

For stage two builders the stage one approval will cover the tank unless it’s moved outside of the manufactures limits.

RUPD

For RUPD satisfactory evidence of compliance for either the device fitted or the design of the vehicle must be supplied, this may be a test report or approval.

DVSA will check if a separate device is fitted and make sure it’s fitted in accordance with the fitting instructions, these must be supplied along with proof of approval at time of test.

DVSA will check the dimensions of the unit and how it’s fitted. Refer to the IVA Inspection manual section 03 for the measurements and dimension. The manual will have further information that will affect the RUPD on your vehicle.

When you claim an exemption DVSA will ask you for proof that your vehicle is exempt and how it applies to your vehicle.

The RUPD are there to save lives and reduce injuries so if DVSA believes it could be fitted it will be expected that it is fitted.

10.3 The standard fuel tanks and RUPD must meet

See the IVA inspection manual for the full inspection standard.