NDA Direct Research Portfolio annual report 2022 to 2023

Published 4 January 2024

Introduction

The Nuclear Decommissioning Authority (NDA) is responsible for cleaning up the legacy from the UK’s pioneering post-war nuclear programme.

From the late 1940s onwards, the country’s smartest scientists and engineers led the world with ground-breaking nuclear discoveries. The result was a diverse range of experimental facilities and early nuclear power stations, designed initially for the UK’s defences but later to provide electricity for its citizens.

Their work spanned 17 locations across the UK and included:

- Dozens of prototype reactors

- 11 nuclear power stations

- Scores of research labs

- Fuel-manufacturing and enrichment facilities

- Spent fuel reprocessing plants

Many of the designs were unique, producing radioactive wastes and spent fuel that no-one had ever dealt with before. Structures, pipework, container vessels and land became contaminated and were mostly left for a future generation to clean up.

Many years later, NDA is dismantling this historical legacy, demolishing structures, and preparing sites for future uses. The mission will stretch for another 100-plus years and cost more than £100 billion.

Dealing with such a range of complexities and uncertainties requires fundamental science, innovative thinking, and novel engineering. Progress depends on clearly understanding the problems, finding solutions, and ensuring the cost for taxpayers remains acceptable. Research & Development (R&D) is therefore an essential part of decommissioning programme. The aim is to solve the challenging technical problems more effectively, more efficiently, more safely and, where possible, for less cost.

A total of approximately £99.8 million was spent on R&D during 2022 to 2023 by the NDA group.

The bulk of this forms part of the budget allocated to our Site Licence Companies (SLCs) and subsidiary organisations and is aimed at addressing specific on-site challenges identified during decommissioning activities. The work is carried out by SLCs, the subsidiaries and through contracts awarded to their supply chain.

Separately, NDA also retains a strategic portfolio to commission projects directly, particularly in areas with potential to have an impact across several sites, or to develop our overall strategy. This kind of research may help shape and develop our strategy, encourage early innovation, or maintain key technical skills.

About the DRP

The Direct Research Portfolio (DRP) is a key component of NDA’s R&D programme.

- Help shape and underpin NDA’s overall Strategy for the UK

- Deliver innovation across our 17 sites

- Develop vital technical expertise for the future

DRP projects are aligned against NDA’s four driving strategic themes:

- Integrated waste management

- Site decommissioning and remediation

- Spent fuel management

- Nuclear materials

DRP projects are commissioned through a series of framework contracts that run for four years using a five-step process. The current contracts, awarded from 2020-2024, involve three frameworks and cover research into the following areas:

- University interactions

- Integrated waste management, site decommissioning and remediation

- Spent fuel and nuclear materials

Twelve successful consortia are involved, six of which are led by SMEs, comprising over 60 organisations ranging from UK universities and research bodies to global corporations and small businesses.

This report outlines several of the projects and key themes funded through the DRP during the financial year 2022 to 2023, for which the total investment was £4.3 million. Some projects are ongoing from earlier contracts, but all have potential for a significant impact across the group.

Further information on NDA’s R&D programme can be found in our 5-year R&D plan.

DRP spend

£4.3 million spent during 2022 to 2023

2022 to 2023 spending breakdown

| Framework Contract | 2022 to 2023 spend |

|---|---|

| University Interactions | £3.0 million |

| Integrated Waste Management & Site Decommissioning and Remediation | £0.6 million |

| Spent Fuel & Nuclear Materials | £0.7 million |

New DRP projects started in 2022 to 2023 by NDA R&D driver

| NDA R&D driver | Number of new projects (2021 to 2022) |

|---|---|

| Delivering Innovation | 2 |

| Informing Strategy | 5 |

| Maintaining Skills | 13 |

Note: Some DRP research projects have multiple drivers

University Interactions

University Interactions Framework Contractors

| Lead Organisation | Consortia |

|---|---|

| NNL | Frazer-Nash Consulting Ltd |

| Arup and National Physical Laboratory |

New PhDs funded in 2022 to 2023

| PhD title | University | R&D Driver |

|---|---|---|

| Variable Autonomy Control Paradigm Applied to Mobile Manipulation | University of Birmingham | Maintaining Skills |

| Flexible Organic Semiconductor Radiation Detectors for Characterisation | Queen Mary University London | Maintaining Skills |

| Simulation of Nuclear Criticality Excursions in Interacting Arrays of Loosely Coupled Systems Containing Special Nuclear Material | Imperial Collage London | Maintaining Skills |

| Micromachined Multi-Sensing for Condition Monitoring of Nuclear Spent Fuel Canisters | Loughborough University | Maintaining Skills |

| In-situ Disposal of Cementitious Wastes at UK Nuclear Sites | University of Leeds | Maintaining Skills |

| Development of a Hard-Rock Disposal Concept for the UK and Ukraine | University of Bristol | Maintaining Skills |

| Developing (Bio)remediation Options for High pH Radionuclide Contaminated Land and Water | University of Manchester | Maintaining Skills |

| Enhancing Capability of ICP-MS to Enable Rapid Detection of Radioisotopes | University of Manchester | Maintaining Skills |

| Detection and Quantification of Water in Spent Fuel | Lancaster University | Maintaining Skills |

| Energy Resolved-Backscatter X-ray Imaging for Safety Inspection and Asset Assessment in Nuclear Decommissioning | Loughborough University | Maintaining Skills |

| Environmentally Strategic Decommissioning of Advanced Gas-Cooled Reactors Led by Life Cycle Assessment | University of Manchester | Maintaining Skills |

During the financial year 2021 to 2022 we:

- funded 11 new PhD’s

- awarded 7 PhD’s

- retained 71% of PhD graduates in decommissioning workforce

Case Study: Non-STEM PDRA Placements

Challenge: Over the past two decades, NDA and the wider group have sponsored a significant amount of postgraduate level research in the fields of Materials Science, Engineering and the pure sciences relating to nuclear decommissioning. This has helped to develop and maintain a strong and knowledgeable academic community within UK universities in these subject matter areas, which in turn is helping to grow future generations of subject matter experts and technical leads that can take up positions within the NDA group and our supply chain. However, many aspects of our business extend beyond these “traditional” STEM (Science, Technology, Engineering and Maths) fields, and we are keen to establish national academic communities that are knowledgeable of, and can contribute to, our wider remit. To start to address this,

Solution: NDA launched a call to all UK universities to apply for postdoctoral research funding to address several “non-STEM” challenges in the themes of Risk & Assurance and Environment & Sustainability.

Three of the proposals that we received were selected for funding:

| Project title | University |

|---|---|

| Organisational psychology and the implementation of sustainable thinking | Dept of Organisation, Work and Technology, Lancaster University |

| Cost Forecasting Framework with Expert and Analogous Data (COFFEAD) | Department of Management Science, University of Strathclyde |

| More than a Half-Life: Communities, Heritage and Decommissioning | School of Humanities, Keele University |

Benefits: The Postdoctoral Researchers undertaking these projects will be integrated with the NDA group subject matter experts to ensure that their research can draw upon real-life examples and data, and that the output and learning from the projects can be incorporated into the NDA body of knowledge. Furthermore, the experience we get from undertaking this work will help to inform the future steps we take in growing the academic non-STEM decommissioning community with a view to establishing a national capability in these fields that is comparable to the existing STEM community.

Integrated Waste Management(IWM) and Site Decommissioning and Remediation(SDR)

IMW and SDR Framework Contractors

| Lead Organisation | Consortia |

|---|---|

| DBD | AECOM, Amentum, Westinghouse (WEC), United Kingdom Atomic Energy Authority (UKAEA) and University of Sheffield including Nuclear AMRC (UoS) |

| Eden Nuclear and Environment Ltd | Cyclife EDF, Gardiner & Theobald, Golder Associates (UK) Ltd, Hydrock Consultants Ltd, Integrated Decision Management (IDM) and University of Bristol and WSP UK Ltd |

| Galson Sciences Ltd | National Nuclear Laboratory, Frazer-Nash Consulting Ltd, Amphos 21, Lucideon, Mott MacDonald Ltd, Resolve Robotics Ltd, VTT Technical Research Centre of Finland, Orano, Veolia and Universities of Bristol, Lancaster and Sheffield |

| Jacobs | Andra, CL:AIRE, British Geographical Survey, NPL, AFRY, Arup, Brenk Systemplanung, Costain, Thornton Thomasetti, Urenco, Croft, Cogentus, Decision Analysis Services, Longenecker and Associates, MCM, Imperial College London and Universities of Birmingham, Bristol and Manchester |

| NSG Environmental Ltd | Abbott Risk Consulting, KDC, Quintessa Ltd, RPS Consulting Services Ltd, SOCOTEC UK Ltd, The University of Sheffield including Nuclear AMRC (UoS) and Veolia Nuclear Solutions, Lucideon, Mirion Technologies, STERIS and The University of Manchester |

| Nuvia | TÜV UK (TÜV NORD), CIEMAT, Createc, Cognition Land and Water, Lucideon, NucAdvisor and Empresarios Agrupados |

New IWM and SDR projects started in 2022 to 2023

| Project Name | Lead Organisation | R&D Driver |

|---|---|---|

| Technical Investigations of the Near surface Disposal of HAW from sites in Scotland | Eden | Informing Strategy |

| Land Quality Management: Emerging Issues Briefing Notes | Eden | Maintaining Skills |

| Cementitious Materials for Waste Encapsulation – Mitigation for Evolving Powder Supplies | Galson Sciences | Informing Strategy |

| Development of Realtime Characterisation of Asbestos utilising non-contact methods - Phase 1 | Galson Sciences | Delivering Innovation |

Case Study: Cementitious Materials for Waste Encapsulation – Mitigation for Evolving Powder Supplies

Challenge: There is a risk that the availability of cementitious materials currently used for waste encapsulation will reduce as the cement industry transitions to achieve net‑zero carbon dioxide emission reduction targets. This could result in the NDA relying on expensive, bespoke cement powders to ensure that waste packages remain compliant with disposal specifications.

Solution: A roadmap of the different cement suppliers pathways to net-zero to enable the NDA to identify the rate at which the availability of common bulk materials will reduce. Experimental analysis of how alternative bulk materials will affect current waste encapsulation formulations and plant equipment set-up.

Benefits: Enables the NDA to transition with the cement industry avoiding expensive bespoke cement types. Helps to provide adequate time for discussing potential facility and/or formulation changes with key stakeholders.

R&D Driver:

- Informing Strategy

- Delivering Innovation

Research Organisations:

- Galson Sciences

- NNL

- University of Sheffield

- Orano

This project aligns to the NDA’s sustainability critical enabling strategy (NDA Strategy 2021) and the role of the NDA in promoting net zero greenhouse gas emissions. For the construction industry, the primary customer for the cement industry, a key method of achieving this target is for lower carbon cements to be used. As modern cement kilns are highly efficient there is little gain to be made via further production process optimisation. Instead, one of the main areas being investigated at present is bulk material substitution, replacing some of the carbon intensive cement material with a lower-carbon alternative to reduce the overall emissions.

Historically, Site License Companies (SLC’s) have used bespoke Sellafield Ltd. specification ordinary Portland cement (OPC) and blast furnace slag (BFS). These have had tightly controlled parameters that were optimised to give the properties desired for nuclear waste encapsulation grouts i.e., high fluidity, low water demand and minimal bleed. However, as of February 2023, production of Sellafield Ltd. specification OPC ceased as it was deemed no longer viable to produce by the manufacturer, showing the potential risk that can occur when using low volume (comparative to the construction industry) bespoke powders. By moving to the standard construction industry grade cement powder, continuity of supply concerns are mitigated, and a significant amount of work has been undertaken in recent years to enable Sellafield Ltd. to transition from bespoke technical specification powders to such standard construction grade powders.

Without investigation of potential bulk material substitutions, the NDA could not guarantee the waste packages produced remained compliant. Further to this, a change in the bulk cementitious material could alter how the encapsulation plant itself is operated e.g. if temperatures need to be changed to control viscosity and grout fluidity and maintained e.g. if alternative bulk powders are more abrasive.

In addition to experimental analysis of alternative bulk materials this work will gather information on future plans within the cement industry so that the NDA can remain agile to change, and aware of supply risks, building and maintaining links with cement manufacturers.

Spent Fuel(SF) and Nuclear Materials(NM)

SF and NM Framework Contractors

| Lead Organisation | Consortia |

|---|---|

| DBD | AECOM, Amentum, Westinghouse (WEC), United Kingdom Atomic Energy Authority (UKAEA) and University of Sheffield including Nuclear AMRC (UoS) |

| Eden Nuclear and Environment Ltd | Integrated Decision Management (IDM), NSG-Environmental Ltd, Nuclear-21, TÜV UK (TÜV NORD) and University of Bristol |

| Jacobs | Andra, Pacific Northwest National Laboratory, British Geographical Survey, NPL, Arup, Brenk Systemplanung, Thornton Thomasetti, Urenco, Studsvik, Croft, StrataG, GRI Ltd, Decision Analysis Services, Longenecker and Associates, Thor Energy, Loughborough Materials, Integrity Corrosion Consulting, Gary Was Consulting, Nigel Donaldson Consulting, Imperial College London and Universities of Birmingham, Bristol, Cambridge, Manchester, Oxford and Sheffield |

| NNL | Frazer-Nash Consultancy Ltd, Galson Sciences Ltd and GRI Ltd |

| Orano | EDF Energy, Cavendish Nuclear, Lucideon, Galson Sciences Ltd, University of Manchester and University of Sheffield |

New SF and NM projects started in 2022 to 2023

| Project Name | Lead Organisation | R&D Driver |

|---|---|---|

| A Review of Available Technologies to Harness Unexploited Energy from NDA Group Radioactive Inventories and Store | Orano | Informing Strategy Delivering Innovation |

| Evaluation of New Surrogate for AGR Cladding Corrosion Studies – Irradiated AGR Guide Tubes | NNL | Informing Strategy |

| Determining Key Physical Parameters of Zirconolite and Pyrochlore using Experimental and Computational Techniques | Jacobs | Informing Strategy Maintaining Skills |

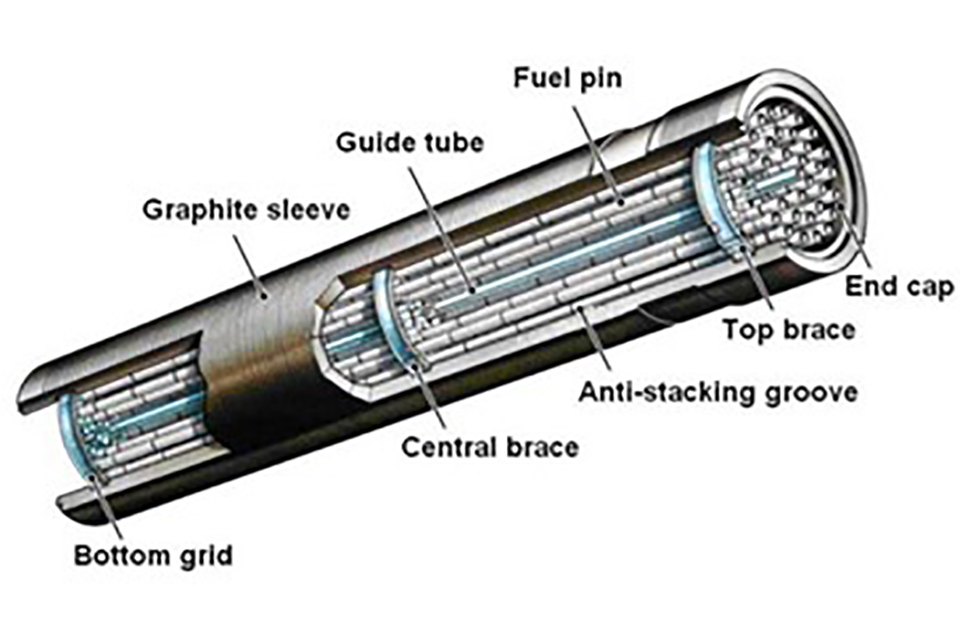

Case Study: Evaluation of New Surrogate for AGR Cladding Corrosion Studies – Irradiated AGR Guide Tubes

Challenge: The current NDA long term storage strategy for spent advanced gas-cooled-reactor (AGR) fuel requires safe and secure storage for many years prior to packaging for disposal. There are several decades’ experience of storing spent AGR fuel in the UK and there is high confidence in the pond storage approach that Sellafield Ltd (SL) currently implements. Part of the NDA group work to underpin this has been efforts to underpin the corrosion behaviour of AGR cladding during storage to determine future performance of cladding during wet storage. This work has included metallography and corrosion testing on samples of AGR cladding material taken from spent AGR fuel, due to activation during irradiation this work is typically done in hot cells which add complexity, cost and challenges accessing material. The NDA are interested in potential surrogate material which display the same sensitisation and material properties as AGR cladding material, though without the radiological risk and that could be handled in more conventional metallography facilities.

Figure 1: AGR Fuel Element, eight fuel elements stacked form a stringer

Solution: A desk-based review on AGR guide tube geometry, materials properties and manufacturing data has been conducted to a establish if irradiated guide tubes are a reliable surrogate material for AGR spent nuclear fuel (SNF) cladding.

Benefits: This work has identified potential surrogate material which could be used as an alternative to AGR cladding for measuring stress in a representative material of a lower activity than cladding. It has also identified the limitations of using guide tubes as a surrogate material, further identifying the need for continued development to identify or manufacture a surrogate which could be used for broader corrosion tests.

R&D Driver:

- Informing Strategy

Research Organisations:

- NNL

Modern guide tubes have the same material composition as the fuel pins and follow much of the same manufacturing route as the cladding tubes, differing only in the later stages of tube manufacture, and appear to have a similar extent of cold work as the fuel tube. Guide tubes do not replicate all characteristics of fuel pins, due to lower applied service stresses, minimal radiolysis effects, and lack of geometric features that affect local stress fields. These affect the degree of replication but also provide a simper system for studies. Radiation-induced segregation (RIS) calculations undertaken indicate that guide tubes from elements near the centre of the stringer can undergo substantial RIS. Calculations were also preformed to assess the viability of using guide tube material outside of NNL Windscale Laboratory active handling facility (AHF) and in other shielded facilities such as the United Kingdom Atomic Energy Authority (UKAEA) Materials Research Facility hot cells. Activity and dose calculations indicated that substantial sections of guide tube, which would be suitable for conventional mechanical testing would require some form of shielded facility. The extent of shielding would be much less than at AHF however. For unshielded facilities, specimen size would need to be reduced to a size similar to those used for electron-optical examinations, to comply with activity limits.

This report has been through an external review panel which included an NNL senior subject matter expert (SME), an SME from Frazer-Nash Consulting (FNC), SMEs from SL, and academics from the Universities of Bristol, Manchester, and Lancaster.

Although the activity of the guide tubes would still require a shielded facility and there may be some benefit to carrying out detailed equivalent dose calculations on the guide tubes for potential use so simulate potential stress profile of AGR cladding.