Sort and Segregate Nuclear Waste: specification

Published 27 July 2020

Executive Summary

This Specification has been prepared in support of the “Sort and Segregate Nuclear Waste” Competition which is being run by Innovate UK, in conjunction with the Nuclear Decommissioning Authority, Sellafield Ltd and Magnox Ltd.

This document provides background context and sets out an outline scenario, to enable applicants to understand a typical waste management challenge, which their proposal should seek to address.

The information provided should enable the development of proposals for technology development, integration and demonstration, covering a variety of tasks, including analysis and handling different materials, data capture and information management.

This document should be read in conjunction with the Competition Brief and:

- explores in more detail the wider context, aspirations, constraints and drivers for this competition in Sections 2, 3 (and Appendix A)

- provides technical background on the types and classification of nuclear waste in Sections 4 and 5

- details the specific scenario to be explored for this competition in Section 6

- outlines potential future market opportunities in Section 7

The outcome sought from this competition is for the applicants to develop an integrated, autonomous toolkit which sorts and segregates radioactive waste generated from nuclear decommissioning activities into optimised containers.

Those applying are encouraged to explain how their proposed approach will meet this desired outcome and also align with wider aspirations for how their innovation will:

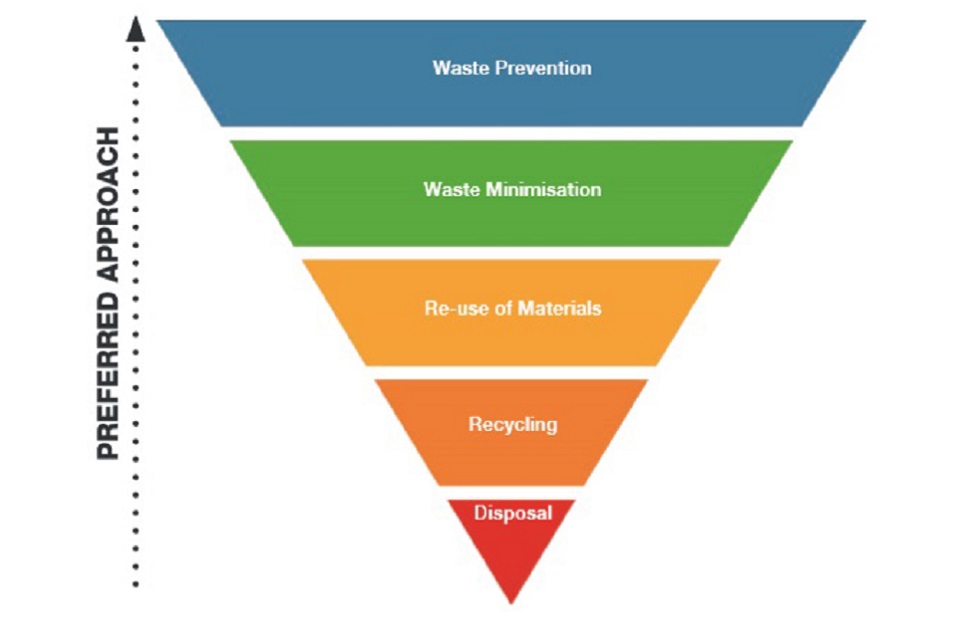

- reduce waste by prioritising recycling over its disposal

- significantly reduce sorting and segregation processes carried out by humans

- increase productivity

- be scalable and transferable.

1. Introduction

The Nuclear Decommissioning Authority’s role is to ensure that the UK’s 17 legacy nuclear sites in England, Wales and Scotland are decommissioned and cleaned up safely, securely, cost-effectively and in ways that protect people and the environment. Effective, optimised waste management is essential for the delivery of this mission and forms a significant part of the challenging and long term programme[footnote 1].

Significant quantities of legacy wastes already exist across the nuclear industry, with nearly 5 million tonnes of new waste yet to be produced from future decommissioning activities. At present these wastes are handled by operators wearing personal protective equipment (PPE), such as gloves or wearing air-fed suits to manually dismantle equipment, or by operators remotely controlling robots to cut up waste. This is labour intensive and means people must be close to the waste or use cameras to see what they are doing. Most of the current waste management processes are human-led and decisions are based on operator experience and knowledge.

Figure 1: Air-fed suit decommissioning work

Dealing with large quantities of legacy waste and planned future waste arisings is a significant driver in the decommissioning programme. In order to reduce the cost of decommissioning and provide solutions which can help to accelerate the NDA’s delivery plan, we need to find ways to move waste faster, more efficiently whilst also maintaining a robust audit trail.

There is also a continued focus on operator safety, and an aspiration to undertake routine waste management activities with less direct human involvement, by making better use of technology. This is expected to significantly improve operator safety and welfare and could also reduce the risk of human errors when identifying and classifying wastes, when working in such challenging environments.

2. Context

In January 2020 the NDA launched the Grand Challenges for Technical Innovation [footnote 2] and [footnote 3]

These set out an ambitious direction of travel to encourage innovation and stimulate new technical solutions which could change how we deliver our decommissioning mission and at less cost. This competition seeks innovative approaches which align with this wider strategic ambition.

The Grand Challenges include that by 2030:

- 50% of the waste produced from decommissioning and clean up should be recycled

- there should be a 50% reduction in decommissioning activities carried out by humans in hazardous environments.

Projects undertaken under this competition will contribute towards meeting these aims, and align with aspirations for an integrated approach to waste management activities.

The Aspiration

Safer, faster, cheaper waste management

The desired outcome from this competition

An integrated, autonomous toolkit which sorts and segregates radioactive waste generated from nuclear decommissioning activities into containers which are optimally packed.

3. Drivers and Outcomes

The main drivers for this competition are to:

- Reduce waste by prioritising recycling over its disposal by improving the use of the Waste Management Hierarchy (Section 3.1)

- Significantly reduce sorting and segregation processes carried out by humans (Section 3.2)

- productivity (Section 3.3)

- Develop solutions which are scalable and transferable (Section 3.4)

These are further explored in the sub-sections below.

3.1 Improve use of the Waste Management Hierarchy

The waste management hierarchy is not unique to the nuclear sector. It is a tool used in waste management across all sectors to drive businesses and individuals to do the right thing for the environment. It originated from the EU waste framework directive (2008) and was brought into UK Law through the Waste Regulations (2011). The hierarchy (Figure 2) sets out the 5 steps for managing waste based upon their environmental impact.

Figure 2: The waste management hierarchy

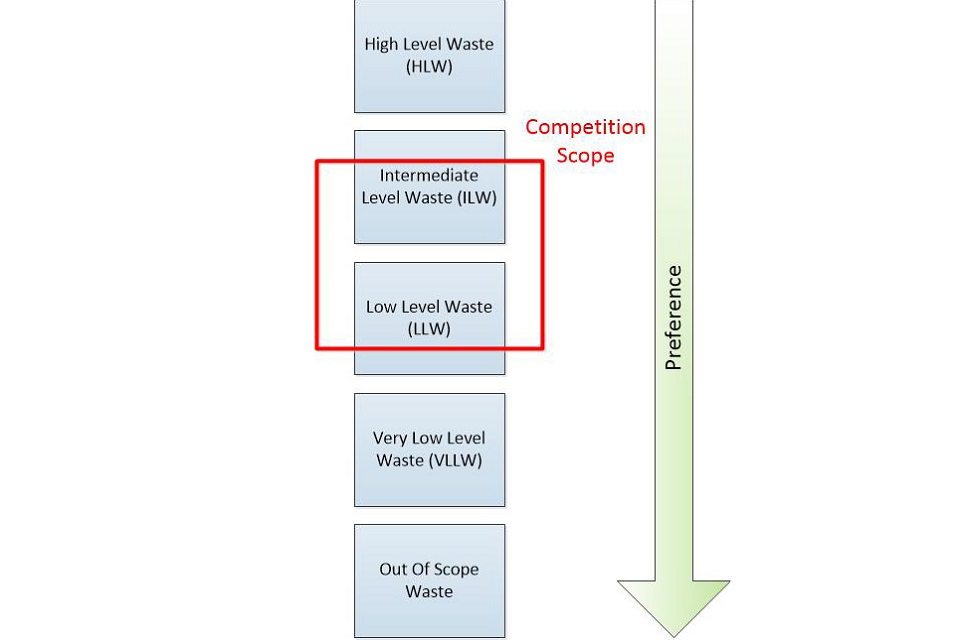

The nuclear sector produces several different types and classifications of waste (see Section 4 and 5 for more detail on these). The classifications of radioactive waste can be seen in Figure 3. In general, the more radioactive the waste is, the more expensive the lifetime costs of managing this waste are. This is, in part, due to the special requirements and facilities to receive this waste.

Figure 3: Classifications of radioactive waste

Due to the cost of disposing of the different types of waste (see Table 1) there is a driver to characterise waste accurately. As an example, if waste can be appropriately characterised as Low Level Waste (LLW), this opens up options for alternative waste management routes. There has been a successful programme diverting significant volumes of LLW from disposal at the Low Level Waste Repository (LLWR) site by working with the Nuclear Supply Chain to develop Metal Recycling and Waste Incineration routes.

In order to make the most of opportunities for waste diversion to alternative routes and increase recycling rates, the waste must be appropriately characterised and classified.

3.2 Reduce the waste sorting and segregation processes carried out by humans

Waste management in the nuclear industry involves different approaches depending on how radioactive or hazardous it is. Generally, due to the complex and unique nature of the waste items it requires a large amount of operator involvement, from decision making, through to physically moving the waste. This can involve varying amounts of protective equipment, from coveralls and gloves, through to air-fed suits (as seen in Figure 1). These operations carry an inherent risk due to the interaction with radioactive materials and more conventional risks associated with manual handling and legacy infrastructure. For example, decommissioning wastes also often require special control measures in addition to radioactivity for dust and asbestos. It is a hot, unpleasant and physically constraining working environment which significantly affects productivity.

If an autonomous system can be brought in to manage waste sorting and segregation, this would enable a significant reduction in the number of human interactions with waste and associated handling equipment. This could lower the probability of work related injuries and reduce the overall risk to human health. It would also create a much better working environment for our staff and contractors and future employees. As a secondary benefit it would also reduce the amount of secondary waste produced e.g. less use of single-use plastics and personal protective equipment required.

Another advantage associated with removing humans from processes is to reduce the possibility of errors associated with working in challenging environments. Waste management is an error intolerant process with significant consequences (financial, reputational and moral) if mistakes are made. Currently many decisions in waste management are based on the experience of trained operators with many years of experience, rather than exploiting new opportunities afforded by enhanced measurement and detection systems which capture data automatically at source.

3.3 Increase the productivity of waste management activities

There are several factors associated with the productivity of waste management activities and it is not straight forward to look at how long it takes due to the variation in waste types, levels of radioactivity and on site scenarios. There are many different examples, each with different throughputs (see below).

A key factor is when protective suits are required; there can be only 1-2 hours of productive work within an 8 hour shift due to the environment, PPE limitations, procedures required for accessing radioactive areas and monitoring operators on exit.

Recent examples of manual sorting and segregating intermediate level waste (ILW) in drums at Oldbury Site gave a typical throughput of 2-6 drums a day, with the higher figure achieved when all the waste inside a drum was of the same type and source, and the lower throughput for drums with mixed items from a variety of sources. Sorting and segregating resulted in an approximate reduction of ILW drums by 50%.

Examples of sorting and segregating radiologically contaminated material at Sellafield gave a throughput of 1 crate per fortnight and each crate having an average of 780kg of mixed waste within it.

3.4 Develop solutions which are scalable and transferable

The scope of this competition is focussed on a scenario with waste at the intermediate-low level waste (ILW-LLW) boundary. However, the future toolkit should be scalable to handle waste of different sizes and different radioactivity levels (from ‘Out of Scope’ material up to ILW – as defined in Section 5) and it should be transferable so that it could be used at different facilities and environments, i.e. ‘plug and play’ detectors could be inserted for different classifications of waste. Some examples of a number of different real life challenges are provided in Section 7 to highlight potential future opportunities. This reason for this driver is to reduce the overall /long term costs of decommissioning activities across the NDA group estate and encourage reuse, to improve value for money for the UK tax payer.

4. Types of waste created within the Nuclear Industry

There is a wide breadth of waste which is generated in the nuclear industry which needs to be managed by the Site Licenced Companies (SLCs) and their contractors. This can be split into two types; operational waste and decommissioning waste. Operational waste is not considered as part of the scope of this competition. Decommissioning waste consists mainly of building materials such as reinforced concrete, bricks, blocks and steelwork, items of plant and equipment including pipework, process vessels and ventilation systems, and soil from land remediation. Once a plant or facility using radioactive material has started up, equipment and structures can become radioactive, so decommissioning waste is certain to arise no matter how long or short its operational life.

5. The classifications of waste

In the UK, radioactive wastes are classified according to the nature and quantity of radioactivity and the heat produced. These classifications can be seen in Figure 3. The following categories are used:

High Level Waste (HLW):

Waste in which the temperature may rise significantly as a result of its radioactivity and must be considered in the design of storage or disposal facilities. HLW only exists at the Sellafield site. It is important to differentiate HLW from spent fuels and nuclear materials which are not currently classed as wastes. This waste does not form part of the scope of this competition.

Intermediate Level Waste (ILW):

Waste exceeding the upper boundaries for low level waste that does not generate enough heat to be considered in the design of storage or disposal facilities.

Low Level Waste (LLW):

Waste with a radioactive content not exceeding 4 Giga Becquerels per tonne of alpha activity, or 12 Giga Becquerels per tonne of beta/gamma activity.

Very Low Level Waste (VLLW):

A sub-category of LLW, comprising waste that can be safely disposed of alongside municipal, commercial or industrial waste, or can be disposed of at specified landfill sites, subject to limits on radioactivity content.

| Waste Level | Volume (m3) | Mass (te) | Cost/m3 |

|---|---|---|---|

| ILW | 145,000 | 150,000 | £50,000 |

| LLW | 1,450,000 | 1,800,000 | £7,500 |

| VLLW | 2,830,000 | 2,900,000 | £1,000 |

| TOTAL | 4,425,000 | 4,850,000 |

Table 1: Future volumes and mass of radioactive waste produced in the UK

‘Out of Scope’ Waste:

This waste has a radioactive content which is below the level required to legally class it as radioactive. It is ‘Out of Scope’ of the Environmental Permitting Regulations and can be disposed of through normal hazardous or non-hazardous waste routes, depending on its other properties. This waste often includes general office and canteen wastes, and construction and demolition wastes.

6. Competition Focus

As outlined in the Competition Brief, the scenario to be solved in this competition is as follows; the waste items (listed below) will start in a pile on the floor. The waste must have its radioactivity and physical characteristics assessed and then to be segregated into the correct containers with data collected to inform package records.

The containers for this scenario are limited to 500 litre cylindrical drums (1.2m high, 0.8m diameter) for ILW and pallet boxes for LLW (1.2m x 1m x 0.75m). The waste for this scenario is restricted to 1m length maximum.

The focus of this competition is limited to dealing with waste in the LLW/ILW boundary for radioactivity, this is because there are significant cost benefits associated with better sorting and segregating of waste at this boundary (see Table 1).

List of typical items (waste types):

- Steel offcuts (stainless, mild, galvanised, painted, pipework, solid pieces)

- Aluminium

- Rubble

- Graphite

- Soil

- Plastic hoses

- Asbestos

- Man Made Mineral Fibres

- Rubber (e.g. wellington boots, tyres)

- Plastics (e.g. bottles, gloves)

- Aerosols

- Batteries

- Cables

Success Factors:

- The process should require no manual intervention for the sorting, segregation and repackaging of the wastes (i.e. operators are not required to use manipulators to move, segregate and package wastes.)

- process should be more efficient than manual sorting and segregation

- The decision whether the item or part of the item is ILW or LLW can be made without human intervention.

- Radiological properties are determined and recorded with enough accuracy that the data meets the requirements for onward processing or disposal; enabling more waste to be sent for recycling or treatment.

- Most of the waste types (listed above) can be automatically identified by the toolkit.

- If there are any items which the toolkit cannot recognise or manage, these should be flagged by the system to the supervising operator.

- Surface area and volume can be measured for items

- Waste is efficiently loaded into containers to minimise the overall number of containers required.

7. Future Market Opportunities

There are significant opportunities in future where solutions developed to manage waste could be of interest to the NDA estate. These illustrative examples are provided for information only, in order to highlight where there are future opportunities in the decommissioning pipeline to potentially deploy new ideas and solutions which are currently being developed.

7.1 Sellafield Site Decommissioning Projects including reprocessing cells

There are many examples of decommissioning projects at Sellafield site which will be taking place in the next 10-50 years. At present these decommissioning projects work by removing ILW within the area and then transferring the remaining waste to the Low Level Waste Route.

In this example; large plant items such as vessels, pipes, steelwork, gloveboxes have been size reduced into sections which will fit into the waste container. They may be contaminated on one or more sides. The radioactivity per unit weight must be quantified and then the item placed in the appropriate container. It can be assumed that the waste will be placed on a waste sorting table or similar at the start of the process.

7.2 Magnox Reactor Sites: Miscellaneous Activated Components

Miscellaneous activated components (MAC) comprise of a variety of components that have been exposed to radiation during reactor operations plus other wastes that have been stored with these materials. The waste comprises of items such as core restraint clamps, buckets containing mixed metallic and organic materials (metal tubes, studding), guide tubes, hoist ropes, solenoids, tools, valves, control rods, metal fragments, absorbers, plastic bags, hemp rope and lead shielding.

The bulk of the radioactivity in the MAC waste is fixed by being bound within the material rather than being surface contamination and is dominated by short-lived isotopes (Co-60 and Fe-55) which would decay significantly over the coming decades.

The ability to remotely sort and segregate this MAC waste would provide either existing disposal routes or options for decay storage in an appropriate interim surface storage facility. By minimising operator dose, the retrieval and processing of MAC waste could enable early reactor decommissioning to be concluded and reduction in cost.

7.3 Sellafield Site Engineered Drum Stores

The Engineered Drum Stores are filled with thousands of historically packed 200 litre drums. To convert this material to a passive form, drums are assessed against a set of criteria (using legacy records and non-destructive assay) and if shown to be compliant they are super-compacted and packaged for disposal within the proposed Geological Disposal Facility. A parallel opportunity exists for the identification of drums containing activities below the LLW specific activity thresholds to be identified during the assay process and subsequently diverted to the LLW Repository.

As part of this piece of work it has been identified that there are hundreds of non-compliant drums for these routes. These drums are non-compliant for several reasons:

- Non- compliant item inside which cannot be super-compacted (e.g. Aerosol, Scaffold pole, too much re-assertible material e.g. wellington boots)

- Too high fissile content

- Unable to measure the radioactivity due to items within the drums shielding the radioactivity

Figure 6: An X-ray of a typical 200-litre drum

These non-compliant drums are required to be unpacked and non-compliant items removed or high fissile material to be spread between other drums. This work will be invasive and will require operations to be performed with Air-Fed Suits which does not meet with the desire of the Grand Challenge statements from the NDA. If the toolkit produced from this competition could be used to sort and segregate the material within these drums this would be a significant saving in terms of suit time.

7.4 Magnox Reactor Pressure Vessel Asbestos

Reactor Pressure Vessel asbestos lagging provides Magnox with a unique challenge regarding both its careful handling and removal, and the sorting and segregation to maximise waste stream efficiency. Trawsfynydd site alone has an inventory of over 410m3 of asbestos contaminated material (ACM) within the bio-shield. Untreated, this ACM could be considered a waste which does not have an available disposal route, but with a sorting and segregation process the asbestos could be removed from radioactive metal and disposed of conventionally.

7.5 Sellafield routine waste operations

At Sellafield 650m3 of waste is sent offsite down the LLW and VLLW routes on a monthly basis, for disposal or for treatment in the supply chain. The waste data is currently manually entered into a database, usually on a pallet/ bag basis (i.e. pallet of items rather than individual items). The database prompts the users for history, dose rate readings, dimensions etc. This then goes to a routing committee who assess the photos and the descriptions and decide which route it should go; the waste teams are then informed, and they arrange to collect it and place it in the appropriate container.

Figure 7: A 'Dumpy Bag' of Metal waste from Sellafield

There are inefficiencies in this process, and it is very labour intensive with many interaction points and decision points. Many decisions are based on judgements and opinions (e.g. surface area, size, material type), rather than measurement, it is error prone and due to the Waste Acceptance Criteria at the receiving sites it is an error intolerant process [footnote 4] (See Appendix A below).

The ability to automatically sort and segregate a wide variety of material with accurate assessments on its radioactivity and composition would have benefits for speeding up waste management and reduce the risk of a mis-consignment.

7.6 Magnox Reactor Sites: Reactor Graphite Waste

Across the Magnox fleet of 22 graphite core reactors there is a significant inventory of radioactive graphite. Characterisation of the graphite has been carried out throughout the operational phases of the reactors, but future disposal options are not finalised based on this knowledge.

The ability to analyse and remotely sort and segregate this waste could provide Magnox with alternative options for disposal if the waste, as currently believed, is at a categorisation boundary.

During reactor decommissioning it is expected that a percentage of the bricks, slats and tiles shall be broken or degrade in some way, leaving an inventory of fragments and powder residue. The processing of all elements, from large graphite bricks to powder residues, needs to be considered.

8. Further background reading

1. NDA Integrated Waste Strategy

3. Grand Challenges News Announcement

4. Waste Acceptance Criteria for Low Level Waste Repository

Appendix A

Key constraints from various Waste Acceptance Criteria

Once the waste has been placed in containers it is sent to a store for long term storage; to a treatment facility for further work (e.g. incineration, metal melting, shot blasting) or for disposal at a specified landfill or the Low Level Repository.

There are acceptance criteria for each of the receiving facilities. These acceptance criteria provide detail of how to send a compliant container of waste and records need to be created to accompany the waste to comply with their permits. This appendix provides information on the key acceptance criteria for the facilities and the reasons behind them.

| Constraint | Reason |

|---|---|

| Reactive metals limited to less than 10m2 per consignment to LLWR, unless painted. | To prevent excessive hydrogen generation as a result of contact with alkaline porewater within a grouted product drum/ LLWR Consignment. |

| Free Liquids- none permitted in LLW disposal or metal treatment (containers need to be drained) | Transport regulations limit, may impact smelter during metal treatment, may affect grout in LLW disposal. |

| Pressurised gas receptacles- Need to be pierced and depressurised for disposal if radiological clearance is not possible. | May cause explosion at destination facility. |

| Hazardous waste, hazardous substances and non-hazardous pollutants- require correct characterisation and declaration prior to acceptance at the destination facility | Compliance with landfill regulations. |

| Some hazardous properties may cause harm to operators at treatment facilities if not adequately identified prior to processing. | - |

| Asbestos and Man-Made Mineral Fibres in LLW Consignments: non-friable (ie, how ‘crumbly’ it is) - permitted in LLW consignments (unlimited); moderately friable - 1 tonne of asbestos-containing material permitted in a LLW consignment; highly friable - may include up to 10kg of loose asbestos (e.g cladding). Asbestos must be kept to a minimum. The container should be labelled as containing the asbestos. | Containers are not opened on receipt at the repository or Geological Disposal Facility so if the asbestos cannot be disturbed into the ground water after the repository is closed it is permitted. |

| Waste prone to decomposition by micro-organisms, for example putrescible animal and vegetable remains should be minimised. | To minimise gas generation from the unprocessed waste and final form product during interim and long term storage. |

| Small filters from glove boxes can be accepted from consignors provided they are placed in drums with other soft waste and that not more than ten filters are consigned per drum. | To comply with RWM Ltd advice on compaction of glove box filters. |

| Radiometrically dense material (e.g. lead) must be kept to a minimum. | May significantly affect radionuclide measurements in the High Resolution Gamma Spectrometry system. |

| Perspex will only be accepted if multiple sheets are interspersed with soft waste and positioned horizontally. | To minimise operational difficulties with the Supercompactor. |

| Wood will only be accepted if the drum contains less than 20% of drum height of wood (with wood cut in length no larger than the diameter of the drum). It is desirable to pack the wood flat in the drum (i.e. with the longest axis horizontal), or, failing this, at as low an angle from the horizontal as possible up to a maximum angle of 45 degrees. Wood must not be packed vertically. | To minimise operational difficulties with the Supercompactor. |

| Coiled hoses will only be accepted if the drum contains less than 20% of drum height of hoses. The hoses are to be coiled in the drum horizontally. | To minimise operational difficulties with the Supercompactor. |

| Wellington boots or heavy duty rubber gloves etc. will only be accepted if the drum contains less than 20% of drum height of such material. | To minimise operational difficulties with the Supercompactor |